Monolithic glass-type foundations

Uniform distribution of loads in the frame structures of buildings and structures on the underlying soils is necessary for the stability of the entire structure, therefore it is important to correctly calculate and install the foundation for the columns, which ensures long-term operation of the walls and ceilings. Columns are often used as loaded elements in the construction of not only industrial but also residential buildings and are installed with the same stringent requirements for reliability and permissible deviations from the design calculations, regardless of the method of their production and installation.

Significant foundation requirements

In standard construction, frame buildings are erected only for industrial purposes. With the development of the segment of individual buildings consisting of several floors of a large area, load-bearing supports in the form of columns have become in demand both in the houses themselves and in adjacent structures (balconies, fences, canopies, garages for several cars).

Often the frame structure of external walls and floor support is made in the form of pillars made of reinforced monolith with the gap between them filled with light aerated concrete blocks. Uneven settlement of concrete pillars will lead to cracking of the wall material. Therefore, it is necessary to responsibly approach the correct construction of the foundation under the load-bearing elements, which are made in the form of pillars.

The main document for such construction will be the “Guidelines for the design of foundations on natural foundations for columns of buildings and structures of industrial enterprises.”

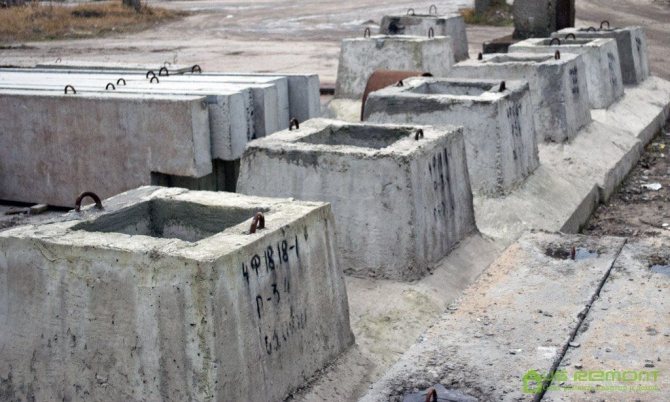

Ready-made reinforced concrete products

When designing the supporting part of a structure, standard factory-produced elements with already known characteristics and mounting loops for quick installation can be taken into account.

The base for the column is selected based on the results of studies of the mechanical and dynamic characteristics of the underlying soils. The variety of options for the general design of foundations for columns is determined by the design features, area and shape of the future structure.

Where is it used?

- Bridge structures (across reservoirs, rivers, as pedestrian crossings);

- Underground garages, parking lots, other social facilities;

- Engine rooms – for example, heating plant, power plant, boiler room;

- Warehouses in the agricultural sector, industrial enterprises with lightweight products.

- Single-level sports and shopping complexes with a lightweight structure.

Frequent customers of columnar bases are government services, municipalities, and social organizations. They are demanding to comply with requirements regarding the type of structure, functional component, and material.

For construction, reinforced concrete and pure concrete are used (less commonly, due to reduced strength). The structural component at the drawing stage is certified by specialists.

Initial conditions

The dimensions of the sole for the standing support are chosen so that the load on the plane of contact with the ground does not exceed its load-bearing capacity. Typical indicators for shrinkage of each individual loaded element in the foundation did not exceed the permissible values specified in the standards.

The column can stand on a separate foundation or be located in a group for which there is a single base (strip or slab type).

Group of columns on a single base

Releases of reinforcement for future columns in a monolithic concrete slab.

When calculating a columnar foundation for a column, the area of the base of 1 column is taken as the starting value. The required number of such supports must be taken with a margin of at least 50% in strength for each element being installed.

The materials for the manufacture of single foundations are:

- reinforced concrete products;

- rubble stone;

- brick;

- poured concrete.

Rigid types of foundations include structures made of monolithic branded concrete and made of brickwork.

Columns installed on a prepared foundation differ in the type of material they are made of: metal, reinforced concrete products. Each variety has its own method of attachment at the lowest point. Column supports for them are manufactured in the factory (standard type) or directly at the construction site at the installation site (design calculation).

The monolithic self-fabrication method has the advantage that it is universal, regardless of whether the steel or reinforced concrete product will be mounted on top of the base.

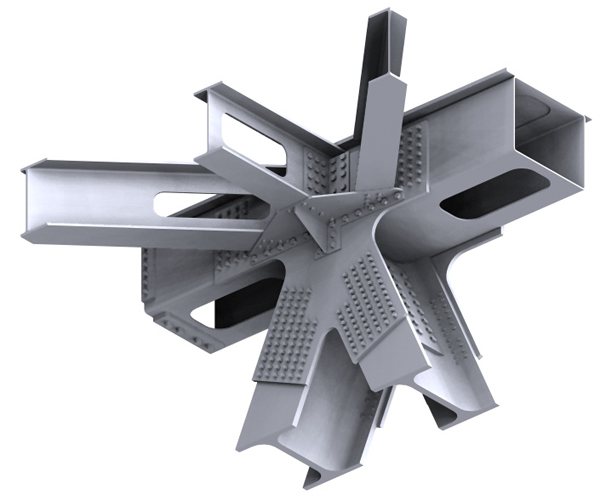

Connecting metal structures with bolts

Bolted connections can be made with bolts of varying accuracy depending on the purpose of the connection and the loads it can bear. Fasteners of normal and high accuracy are mainly used. For connections that are subject to shear loads, normal and rough precision bolts must not be used.

Holes for bolts are drilled or pressed so that the diameter of the hole exceeds the outer diameter of the bolt by 2-3 mm. This simplifies assembly, but makes them less resistant to deformation. For this reason, bolts classified as coarse and normal in accuracy class are used only when one element directly rests on another. Examples include connections on support tables, strips and flanges.

Connections that use high-precision bolts are an alternative to rivet connections in hard-to-reach areas. For such connections, the diameter of the holes is larger than the diameter of the bolt by up to 0.3 mm. If this requirement is met, the bolts sit in the holes very tightly and withstand shear loads well.

High strength bolts are the most effective fasteners. They combine high load-bearing capacity with significant resistance to deformation. Such bolts can be used instead of rivets in almost all connections. The nuts for such bolts are tightened using ratchet wrenches, which allows you to control the tightening force.

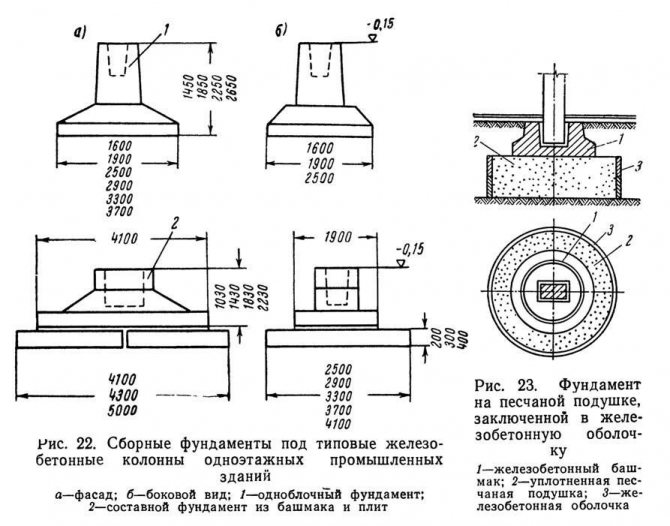

Soles for reinforced concrete

Load-bearing structures made of columns are installed on free-standing glass-type foundations, so as not to pour a large volume of concrete into strips or slabs. They will accept and distribute the load from the structure at the most critical points. Standard products for standard construction of industrial facilities are made in factories in a form ready for assembly. They consist of a sole that widens towards the bottom under the column and a column inserted into the glass.

Such prefabricated elements must comply with GOST 24476-80.

An example of a finished foundation (with various dimensions) for a column is shown in the drawing:

Increasing the area of contact with the ground due to the expanding support heel leads to the following results:

- the bearing capacity of the column increases;

- the load on the ground from the total weight of the foundation structure is reduced due to the difference in the cross-section of the base and vertical pillars - their Ø is calculated according to their ability to support the building, but does not depend on the area of support.

In multi-story construction, it is permissible to choose this type of support if the soils underlying the building are non-heaving, calm and not prone to subsidence. Glasses can stand on strong, motionless rocks with a deep groundwater level.

The connection of individual columns and their foundations into a single rigid strip-type structure is performed by 2 main types of connections:

- Reinforced concrete products are connected by inserting beams into the base of the column, followed by filling with cement mortar.

- The steel elements are fastened with anchor bolts, which are poured into the foundation block under the holes in the heel of the column and provide a strong, stationary fixation.

If standard factory products do not meet the technical characteristics laid down in the design of the structure, then, after carrying out engineering and geological surveys, it is allowed to manufacture a glass foundation for load-bearing columns on site based on calculations for the specific conditions of the construction site.

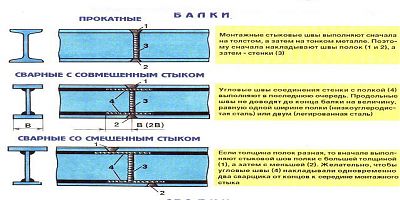

Connecting metal structures by welding

Most of the installation connections are made by welding, a smaller part by bolts, and rivets are used even less often. This affects the cost of installing metal structures - welded joints are the cheapest. Connecting with rivets is the most labor-intensive, however, in some cases it is necessary to use only it. An example would be the building of a forging and press shop, in which bolts or welding cannot be used to create a load-bearing metal structure—the constant vibration created by the forging equipment will inevitably destroy these connections.

Welding is used when a rigid connection of structures is required, with a tight fit of the element and a water- and gas-tight seam. This is the only way to connect sheet structures in the casings of blast furnaces and thermal furnaces, tanks, dust collectors and gas holders. Among supporting structures, welded joints are used for the joints of columns with crane beams and trusses. Elements of steel structures can be welded with reinforced concrete elements. In such cases, the profiles are welded to the embedded parts.

To obtain a high-quality seam, the parts to be welded are pressed tightly against each other. Basically, rough mounting bolts are used for this. In some cases, additional metal joining plates are used to create a connection.

Columns whose height exceeds 18 m are divided into shipping elements for transportation, the dimensions of which depend on the means used for transportation. For installation, parts of the columns are assembled into a single whole. Column joints during the construction of one-story industrial buildings are usually made in the part above the crane, above the crane beams. The milled ends of the main and crane parts of the columns are joined and welded along the contour of the joint. To increase the rigidity of the connection, butt sheet overlays are used.

To install crane beams, they are supported on the corresponding column slabs and connected first with bolts and then welded. Additional fastening of the beam is carried out to the crane part of the column using brake structures. They are also initially bolted and welded with an extended seam. The connection of trusses with columns is carried out in a similar way.

When installing buildings made of metal structures, the quality of the welds performed is of great importance. They are checked by external inspection, which can determine deviations from geometric dimensions, cuts, lack of penetration or large pores. The surface of the weld should be smooth or have small flakes, and the deposited material should be of the same density. The permissible sizes of deviations and defects are specified in regulatory documents.

Pouring the foundation on site

To pour the foundation at the installation site of the column, an individual calculation is performed to determine the area of the base, the weight and height of the glass.

It is necessary to correctly manufacture the reinforcement frame using a reinforced design so that the created structure has a high degree of strength. The anchor bolts are laid in accordance with GOST 24379.1-80, deviations are allowed within ±0.02 cm from the design.

How the reinforcement of a column support under a free-standing metal support should be done is assessed in this video:

It is necessary to make a foundation for a metal column in accordance with the following standard requirements:

- use grade concrete not lower than M 200;

- maximum water resistance not higher than 5% (correspond to B2);

- a protective layer of concrete on reinforcing bars of at least 3 cm (the presence of visible sections of the steel frame is prohibited);

- cracks in a frozen monolith cannot exceed 0.1 mm.

A reliable formwork is installed under the foundation being constructed, which will withstand the loads when pouring the liquid mass and maintain the specified geometry of the product; the output of the steel rods is rigidly fixed.

The foundation for a column, poured on site, undergoes a detailed calculation of all parameters in a specialized design organization or using a computer program that determines the required geometric dimensions of each part and the required reinforcement of the base and column.

During the concreting process, it is necessary to lay down special geodetic levels (benchmarks) and elevation marks. They will be required both to control the installation of other building structures, and for geodetic studies during operation to identify foundation settlement.

Installation of crane beams

These beams are installed after installing a pair of columns. During lifting, the beam is held in place by two guy wires. To receive it at height, installers are located on scaffolds, platforms and assembly ladders. The workers’ task is to keep the beam from touching the previously installed structural elements and give it the desired position. To control the descent of the beam, there are risks on the console. To eliminate vertical deviation, steel pads are used, placed under the beam. Anchor bolts are used to temporarily secure the beam.

installation of crane beams

If crane beams are installed on columns with milled soles, the foundation of which is concreted to the design value, or columns on planed metal slabs, then it is enough to check the position of the beams along the main axis.

Column installation

Reinforced concrete pillars of square or round cross-section are placed on milled shoes, which are placed at the required level by surveyors on the concrete solution.

The same care is taken when placing anchor bolts under metal columns. The part of the rod protruding above the concrete is marked in advance and fixed in a special jig to maintain the horizontal and vertical dimensions.

In some types of factory poles, anchors are not laid, but a well is left in the upper part for independent installation on site.

In each case, any column must be placed on a geometrically verified, rigid base in accordance with the developed design documentation. In each individual case, it is necessary to involve a specialist for a new structure in order to optimize the amount of work, financial costs and avoid irreparable mistakes.

Our services

accepts applications for the following types of work: pile driving, leader drilling for piles, sheet piling. See more details about our services in the website menu. To submit a request for work, fill out the form:

"]" data-sheets-userformat=",,NULL,NULL,NULL,NULL,NULL,NULL,NULL,0,NULL,,NULL,11]" style="font-size: 110%; font-family: arial, sans, sans-serif;">

Foundation for a bathhouse: their types and comparison

carries out immersion of piles during the construction of foundations for various buildings: residential, industrial, economic, therefore, according to...

More details

Foundation for a country house

The construction of a foundation even for a small country house has a large number of features. They take into account soil types, groundwater levels, climatic conditions in the region...

More details

Foundation for an extension to a house

Construction specializes in the construction of foundations of varying complexity and type in Moscow and the region. If you decide to expand your living space...

More details

TISE foundation

In this article we will talk about TISE pile-strip foundations. You will learn in what cases it is rational to use such grounds, what advantages and disadvantages they have.

Reinforced concrete foundation

On this page we will look at the main types of reinforced concrete foundations, the technology of their construction and determine whether it is rational to build them yourself.