Concrete is a material in demand in construction, characterized by strength and durability. However, even such a high-strength building material is subject to environmental influences. Experts have proven that concrete structures do not tolerate tensile loads well, as a result of which cracks form in monoliths. In order to neutralize the risk of destruction of structures and increase the strength characteristics of buildings, it is recommended to strengthen products using reinforcement technology.

Our company offers you services for testing the strength of concrete. In our product range you will find concrete M100 B7.5, which is perfect for use in the construction industry, and more wear-resistant concrete M450 B35, which is used for critical structures. We will quickly and inexpensively deliver your order to the construction site, because... We have our own fleet of mixers and ABN.

Why is it needed?

If you carefully studied the construction drawings, you noticed that with the correct installation of the reinforcing frame prepared for concreting, the metal rods do not come into contact with the walls of the formwork structure. It turns out that after the concrete mixture is supplied and its final maturation, a gap of a certain size remains between the metal and the formwork system. This is what is called the protective layer of reinforcement in the foundation.

The metal frame is designed to compensate for the main disadvantage of concrete material - low strength during stretching or bending. Simply put, the indicator of the strength of a structure, from which its reliability follows, is equally determined by the quality level of concreting and the compliance of the reinforcement of the structure.

Steel rods, manufactured according to GOST requirements, have the required safety margin and are designed for a long operational period. But metal can succumb to the negative effects of water and chemical compounds, resulting in corrosion. It is possible to pre-treat steel elements with special protective compounds, but such a measure significantly increases financial costs.

Reinforcing bars coated with zinc are not subject to corrosion, but they are also not able to provide an absolute guarantee that corrosion processes will not begin to develop.

In addition to the zinc layer, metal oxidation can be used. But this method is also expensive, and does not provide a complete guarantee of protection. This is explained by the fact that the protective layer does not have high strength, because its thickness does not exceed several microns. The slightest violations during transportation or welding work will easily damage the integrity of the layer. The end sections at the cutting points of metal rods are also weak in protection.

Anti-corrosion protection applied to a metal surface can be damaged by the sharp edges of crushed stone in the supplied concrete.

How dangerous is corrosion to a steel frame system? The point is not only that the metal loses its original strength - this will take a lot of time. However, the rust that forms inside the foundation will definitely lead to the appearance of void areas. Initially, they are not large in size, but gradually turn into cracks, which, under the influence of water and low temperature conditions, lead to processes of erosion, destruction and shedding of concrete surfaces. The problem is serious and it is necessary to take urgent measures to eliminate it.

The conclusion suggests itself that the reinforcement installed in the thickness of the concrete body must be qualitatively protected from any influences of a humid environment. In addition, a barrier should be provided to prevent the negative effects of chemical compounds, the sources of which are the air and soil.

The functions of such a barrier are performed by a protective mortar layer. But its purpose does not end there. Therefore, such a layer is intended for:

- ensuring the necessary positioning of the reinforcement system in concrete;

- equal redistribution of load effects on steel reinforcing bars and the main concrete monolith;

- protecting metal surfaces from water, chemical compounds, and other undesirable effects caused by weather changes;

- creating high-quality fixation of reinforcement in concrete when joining frames of adjacent reinforced concrete elements or moving to the next level;

- increasing resistance to fire;

- acting as a reliable basis for installing heat- or moisture-proof materials when finishing the basement.

A super-strong alternative to reinforced concrete has been created

Scientists have used 3D printing to create a polymer lattice structure that can act as a base for low-carbon concrete that is strong and durable.

The research was conducted at the University of California, Berkeley, and builds on previous efforts to reinforce concrete with polymer fibers.

The material emerged about half a century ago as a promising alternative to steel reinforcing bars, which have high strength but are heavy, expensive and degrade over time. On the other hand, polymer fibers are lightweight, cheap to produce, and resistant to corrosion. Current approaches involve mixing these fibers with the concrete before pouring it, but this can result in uneven distribution, meaning some parts of the structure are stronger while others are more susceptible to cracking.

The engineers behind the new research sought to address this shortcoming with a 3D printed octet polymer lattice, a structure with a unique combination of lightness and strength. By choosing it, they hoped to prevent cracks from forming. The team found success by using acrylonitrile butadiene styrene (ABS) polymers to create the lattice, and then filling the gaps with concrete that is four times stronger in compression than conventional concrete.

The researchers experimented with variations of this recipe, using different versions of the polymer lattice that ranged from 19.2% of the total concrete volume to 33.7%. Although these changes resulted in slight variations in compressive strength and peak loads, the overall mechanical properties of the concrete remained largely unchanged.

The science

Scientists have created a protein that resists radiation

“When a material is brittle, it can withstand a certain peak load before it fails,” explained study co-author Claudia Ostertag, professor of civil and environmental engineering. “In this case, we did not observe a failure. It became stronger and stronger. It’s amazing how something initially very fragile turns into something extremely malleable.”

All samples tested had high strain densities and were therefore capable of absorbing a lot of energy, while samples with a finer lattice structure were as strong as samples with thicker ones. This part is key to one of the overarching goals of the research project: using higher concentrations of alternative materials to reduce the carbon footprint of concrete production, which accounts for 8% of global CO2 emissions.

“The reaction that creates cement inherently produces CO2,” said study co-author Hayden Taylor. “But there is an alternative route to using polymers that are carbon neutral or even potentially carbon negative through the use of biopolymers, recycling and renewable energy.”

The team now plans to experiment with different lattice shapes to see if different geometries can be used for different purposes. “Looking forward, my biggest question is how to choose the best lattice structure for a given application,” said lead author Brian Salazar. “It seems to us that even more optimal geometric shapes can be found for each task.”

Factors affecting thickness

To determine this parameter, a number of conditions are taken into account. If the thickness of the concrete layer is less than the values established by regulatory documents, then the metal frame begins to corrode after some time. If you make the protection large, then the total financial costs for purchasing materials increase. All that remains is to select the best option, the norms of which can be easily found in SNiP.

The following points influence the concrete thickness parameter:

- cross section and type of metal material. The thicker the rod, the greater the parameters of concrete protection;

- mechanical force on the foundation and its nature;

- the conditions under which the foundation is expected to be used;

- type of structure or separately placed reinforced concrete element. The parameters of the layers in such cases are standardized by special documentation;

- technical operating parameters. A rod operating under heavy load is subject to significant stress, therefore, it requires full protection;

- functional load forces on steel elements. Reinforcing bars in a frame system are divided into structural, distribution and working. Each of the listed types is mounted in a common frame according to established rules.

Main Factors

It is necessary to correctly calculate the height of the protective layer. This is a very important condition for preserving all metal structures of the foundation from corrosion and other influences. If this value is calculated incorrectly, this may lead to negative consequences. For example, if it is too thin, then destructive factors may penetrate deep into the structure and the integrity of the reinforcement may be damaged.

There are many factors to consider when pouring a layer.

If, on the contrary, it is thicker than the standard indicators, then this can significantly hit your pocket. So, the height of the protective layer depends on the following nuances:

- What role do reinforcing bars perform: working, longitudinal or transverse.

- How the reinforcement is loaded: stressed or not.

- Types of supporting structure: supports, slab foundation, strip foundation, etc.

- What is the height of the reinforcing belt and what is the diametrical cross-section of the metal rods used.

- Under what conditions is it used: outdoors, indoors, in contact with soil, at what humidity level.

Protective layer thickness

Regulatory documentation regulating the specifics of construction work defines a number of conditions for the arrangement of a mortar layer for steel reinforcement in the foundation structure, ensuring:

- unified operation of metal and concrete structures with uniform redistribution of load effects;

- arrangement of joints of steel rods without disturbing the coating layer in the direction of reduction;

- possibility of fixing parts with anchors;

- reliable protection of metal surfaces from corrosion;

- resistance to elevated temperatures.

The thickness parameters of the concrete layer are determined taking into account the grade of steel rods and their cross-section, the type of elements, and the technological purpose of the reinforcing materials.

In each case, the thickness of the covering layer should not be less than one centimeter. If crushed stone of a large fraction is used, which does not allow the creation of such gap areas, it is allowed to increase the parameters to the required values.

Minimum protective layer

In systems not subject to prestressing, the least protection from the solution, taking into account the operational characteristics and the environment surrounding the product, is determined as standard:

- for closed dry rooms – 2 cm;

- in rooms with high humidity levels – 2.5 cm;

- for products used outdoors – 3 cm;

- in the soil or on its surface – 4 cm.

If the prefabricated elements were manufactured at the factory, the given parameters can be reduced to five millimeters. But in each case, it is necessary to ensure that the thickness of the concrete layer is not less than the reinforcement section.

The technical documentation, according to which reinforced concrete products are designed, establishes additional conditions:

- for structures made of heavy concrete mixtures M 250 or more, the mortar layer is allowed to be five millimeters less than the cross-section of the metal rod;

- the same condition applies to all industrial structures;

- for pre-stretched reinforcement, the maximum concrete protection can be no more than five centimeters.

The pitch of bars installed transversely should not be greater than the height of the section of monolithic concrete, and for those installed longitudinally, such a gap is not less than 0.1 of the area of the entire surface.

Taking into account the type of products, the minimum concrete layer is equal to:

- for slabs and walls up to ten centimeters thick - 1 cm, for the rest - 1.5 cm;

- for beams, lintels and slab ribs up to 25 cm - 1.5 cm, in other cases - 2 cm;

- for columns and racks - 2 cm;

- for precast reinforced concrete elements – 3 cm;

- for foundation monoliths with concrete preparation - 3.5 cm, for others - 7 cm.

All distribution elements located transversely are covered with concrete, the layer of which reaches 1 - 1.5 cm.

Control of the minimum thickness of the concrete layer for metal reinforcement is carried out non-destructively using special magnetic equipment.

Layer thickness requirements

The issue regulating the dimensional parameters of the protective layer is regulated by building codes in the document SNIP 52-01-2003. It is calculated by designers, indicating this value on working diagrams. The minimum recommended thickness of the concrete protective layer for reinforcement is affected by:

- type of fittings;

- diameter;

- function in reinforced concrete (structural or working);

- type of product (foundation, column, monolithic stairs, etc.);

- cross-sectional dimensions of the monolith and diameter of metal rods;

- environment.

Important! The minimum thickness of the protective layer of concrete for reinforcement must be at least its diameter and not less than 10 mm.

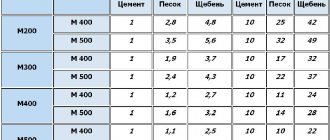

Table of the minimum thickness of the protective layer of concrete

When the structure does not have a developed design, it is recommended to fill the monolith using the values from the table:

| Options for using fittings | Minimum layer thickness, mm |

| Longitudinal reinforcement of working type, during the construction of prefabricated foundations and foundation beams | 30 |

| For working rods in foundations with concrete preparation | 35 |

| For reinforcement during foundation construction without preparation | 70 |

| Monoliths operated inside dry rooms | 20 |

| Monoliths operated inside wet rooms (without additional protection) | 25 |

| Reinforced concrete structures operated outside without protection | 30 |

| Transverse reinforcement section up to 25 mm | 15 |

| Cross rods with a cross-section of more than 25 mm | 20 |

| Concrete structures whose thickness does not exceed 100 mm | 10 |

| Non-prestressed reinforcement | not less than the diameter of the rod |

| Any prestressed reinforcement | 40 mm |

How to ensure the desired thickness when pouring

The reliability and durability of the foundation depend on the quality and correct installation of the metal frame.

If you study the recommendations, it becomes clear that the thickness of the concrete layer is included in the preliminary design calculations and drawings. All that remains is to comply with all the requirements practically.

Naturally, the bottom row of rods in the foundation trench must be raised above the ground to a certain height. Complete ignorance is demonstrated by workers who use scraps of lumber instead of supporting elements. Wood is not durable and allows moisture to pass through it. Corrosion occurs in places where such supports are installed.

It is allowed to use brick or concrete stone as supports, but this option is not an ideal solution, since it does not provide reliable tightness.

The optimal solution is special racks made of polymer materials. They are made in different sizes, you can always choose the appropriate option that matches a particular design. Their cost compared to the cost of building materials is quite acceptable. In addition, such elements have hollow structures, which, when poured, are also filled with concrete mortar.

How to maintain a minimum or maximum protective layer of concrete when pouring concrete?

There are several options with which, when pouring a concrete structure, you can clearly maintain the specified thickness of the material layer:

- Special fixators for the protective layer of concrete. These products can be purchased at building materials stores or at stores that manufacture fasteners. The cost of one retainer, depending on the purpose or design, ranges from 1.4-6 rubles per unit.

- Formwork set to the required size using elongated reinforcement belt rods.

- Concrete crackers (mortgages) with plan dimensions of 100x100 mm, a thickness equal to the thickness of the minimum or maximum protective layer of concrete for reinforcement. This option is used when the task is to protect the bottom layer of armored belt rods.

Using fasteners

With the help of plastic clamps, the installation of reinforcing bars is carried out quickly and accurately. Similar products are available in several types:

- in the form of vertical racks;

- round.

All other fixatives are derived from the main types listed above.

A vertical stand is used when installing a reinforcing mesh or a spatial type structure in a position slightly elevated above the supporting element. The height and support recess parameters may vary based on the cross-sectional dimensions of the rods and the design height of the installation.

“Stars” of rounded shapes are put on horizontal or vertical rows located at the top using special locking elements in the form of latches. The design radius does not allow the rods to approach the formwork walls, guaranteeing the required thickness of the mortar layer. The production of such locking elements is established with different diameters.

With the help of fastening devices made of plastic material, it becomes possible to achieve the following conditions:

- high-precision thickness of concrete mortar protection is achieved;

- the timing of construction activities is reduced, but the quality of preparation of the reinforced concrete structure does not decrease;

- financial expenses intended for the production of reinforced concrete structures are minimized.

The decisive factor in the use of a plastic retaining element is the characteristic features of its design and reasonable price.