When constructing a monolithic foundation, it is very important to correctly position the formwork - the structure must create a rigid shape with given geometric dimensions.

The strength and reliability of the foundation support of the building directly depends on the accuracy of the alignment. This article is all about how to correctly set up the formwork for pouring foundation supports.

Which one to choose?

There are removable and permanent formwork designs. For a monolithic foundation, it is usually made of wood, plywood or metal. Fixed forms for the foundation are made from sheets of expanded polystyrene. Expanded polystyrene is not dismantled after the concrete mixture has hardened - the layer serves as additional insulation for foundation supports (this manufacturing method is most suitable for areas with cold climates).

The assembly of foundation formwork is necessary when concreting monolithic building structures - a reinforcement cage is installed in it, a concrete mixture is poured, which, when hardened, gives the foundation structures the necessary shape and rigidity. Clearly positioned formwork panels help maintain the monolithic reinforced concrete foundation in the dimensions specified by the design.

Making wooden shields

Formwork made from wooden boards must be adjusted as much as possible, achieving minimal gaps between two boards so that the concrete mixture does not flow out of the box through existing cracks. The formwork forms must be as smooth as possible and free from flaws, in which case the finishing of the foundation walls will be very easy to achieve perfection.

Wooden formwork is made in the form of an oblong panel; during installation, the elements are fastened together using metal fasteners (nails and self-tapping screws). The wood chosen is coniferous; planed edged boards with a thickness of 25 mm and a width of up to 150 mm are ideal.

The racks and frames of the form for a monolithic foundation are made of wooden blocks - these elements ensure the stability of the panels during pouring of concrete mortar.

It is very important to use lumber with high humidity for the manufacture of formwork - this is necessary so that the wood does not absorb moisture from the concrete solution, which will greatly deteriorate the quality of the hardening concrete solution.

↑ Strip foundation and its formwork

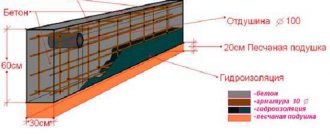

There are two types of formwork systems. One of the types is removable or collapsible structures. After the concrete becomes stronger and stronger than the critical level (about 50%), the formwork is dismantled. Thanks to the possibility of removal, it is a reusable design. The number of uses is determined by the material from which the formwork is created, on average up to 8 fills. On an industrial scale, it can withstand hundreds of uses. The photo shows a sectional view of the formwork:

The second type is formwork that cannot be removed. The use of a permanent structure implies that it will be integral with the foundation. The emergence of these structures is recent. The main resource is extruded polystyrene foam. Blocks of various shapes and structures are produced, they are combined thanks to locks and metal pins. The required formwork is created like LEGO, but in a large size.

The formwork, which is not removable and is made of polystyrene foam, serves not only to create a form, but also for hydro-, thermal and sound insulation. This pleasure costs a lot of money, but it solves many questions. And it reduces the time spent on forming the foundation.

This formwork is divided into several types. One of them is blocks made of concrete with voids inside. The blocks are presented in many different shapes: wall, corner, having a radius, etc. These blocks are based on two or three walls and lintels, supported at a certain angle by the wall. The blocks are fastened with locks and reinforced with iron rods.

↑ Requirements for formwork

A removable or non-removable structure into which concrete mortar is poured must fulfill the main condition - have increased strength. This property causes the pressure of newly poured concrete to be contained. That is why the requirements for formwork materials are so high. The panels that are assembled must be smooth inside, since they are the walls of the foundation. And waterproofing, thermal insulation and thermal waterproofing are attached to the walls. These types of insulation are attached more easily to a flat or slightly rough surface.

↑ Creating formwork that can be removed

Structures made of iron and assembled using bolts and studs are produced for pouring foundations in construction companies. But for home construction, formwork is made from moisture-resistant plywood, oriented strand board and boards. Ordinary timber will serve as spacers and stops. You can install iron formwork, however, you will have to spend money.

The higher the desired foundation, the thicker the boards used for the shield. 4 cm is the thickness of the board, which is selected for a structure height of one and a half meters.

The boards are held together with bars; their cross-section is 6-8 cm x 4 cm. Such parameters of the beam will not withstand the weight of concrete with a high or deep foundation. A beam of 5x10 cm or larger is used when the height of the base reaches a meter or more. Self-tapping screws are used to assemble the timber. Their length is ¾ of the possible thickness of the timber or board.

The idea of using plywood is not as bad as it might seem at first glance. Manufacturers of building materials produce formwork laminated plywood impregnated with synthetics. It is immune to aggressive liquid media, including concrete mortar. FSF is the name of plywood formwork; it is a brand with increased moisture resistance. FSF is obtained by gluing birch veneer (and often from coniferous trees) with compositions based on phenol-formaldehyde resins. The manufacturing process of plywood formwork is accompanied by simultaneous heat treatment under excess pressure.

The plywood sheets used to create the formwork are produced with a thickness of 1.8-2.1 cm. To construct the formwork structure, a wooden or metal frame is used, onto which the panels are strengthened.

The wood frame is made using 4×4 cm timber; for fastening, short fasteners are used - 5-5.5 cm. To work with plywood, it is easier to use self-tapping screws; it is harder to work with nails.

There is a formwork option using OSB, but it is less common. The thickness of the material is similar.

The choice of material for creating formwork remains with the developer. Buy something that won’t hit the budget so hard.

Installation Rules

During installation, it is very important to follow existing building codes and regulations - this will help to pour a strong and reliable foundation made of monolithic reinforced concrete:

- It is not allowed to install the support posts of formwork panels on dug up or fill soil; it is necessary to ensure the reliability and stability of the structure, for which, on problematic soils, it is necessary to place cuttings of boards under the support posts.

- The panels must remain in an unchanged position for quite a long time, taking into account the impact on them of the mass of concrete poured into the structure, therefore wooden formwork can be strengthened by installing braces, racks and supports.

- In subsidence and heaving soils, the mold is mounted on special foundation edges buried below the freezing point of the soil.

Installation work

It is convenient to mark the formwork on the building site using pegs and stretching a construction cord or fishing line over them. It is very important to remember that the foundation should be 10-15 cm wider than the walls. Each action should be checked with a level and a laser level - this way you can ensure the most even placement of the formwork panels.

It is possible to position the formwork correctly only by using a level, which should be used to periodically check for possible displacement of the panels during installation.

You can start installing the boards only on level ground, securing each board with scraps of reinforcement and wooden support pegs. The panels are secured from the inside with reinforcing rods - after concreting, the reinforcement will serve as an additional reinforcement element to impart vertical rigidity. Watch the video on how to install formwork without mistakes.

The lower edges of the formwork panels should rest completely on the upper surface of the ground, and adjacent elements should have the closest possible fit to each other.

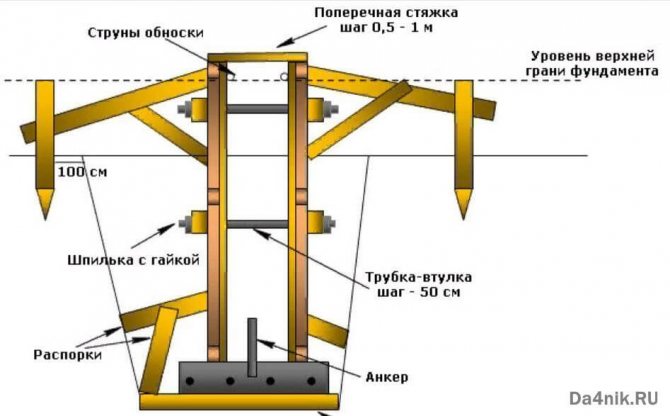

The side panels are tightened using special ties made of timber, which are strengthened on top of the formwork panels from above. Screeds are installed every 0.5 - 1.0 meter.

Purpose of the blind area

Let's figure out how to make formwork around the house if you plan to do the work yourself. First of all, it is worth clarifying the purpose of this design. In fact, it is just a strip of concrete, it is located close to the walls of the building and encircles it.

The main function of the structure is to protect the foundation. Improper manufacturing of the blind area or its complete absence can shorten the service life of the building. The blind area around the house is constructed for the following purposes:

- protection of basements from melt or rain water;

- slightly reduces the depth of soil freezing in a protected area, which has a beneficial effect on heat conservation;

- gives the building a finished look, it looks more neat and solid.

It is extremely important to make the formwork around the house correctly, so if you plan to carry out the work yourself, you need to carefully study the technology.

How to correctly level formwork panels

Usually the formwork rises 30 cm above ground level; it is very important to set the panels as level as possible so that there are no differences in height on the surface of the foundation. All formwork installation operations should be checked for level. It is very important to level the upper edge of the formwork, for which a stake is driven in the center of the building, on which the zero mark of the foundation is marked. Then, using a tubular level, marks are placed on the surface of the formwork panels or stakes. Concrete should be poured into the structure in accordance with the marked risks.

When the concrete mixture hardens and gains strength, the panels can be dismantled, usually 14-15 days after pouring the concrete.

When installing formwork for the foundation, it is better not to slack in the work, otherwise the durability of the built house will be at risk.

Requirements for concrete for pouring into formwork

Mortar for pouring formwork can be ordered from suppliers. The finished concrete solution must be at least grade M 200, M 300.

When making a solution at home, you need to adhere to the correct technology:

- if there is no need for special strength of concrete, prepare a solution from 1 part of cement grade M 400 and 3 ÷ 8 parts of gravel-sand mixture;

- high-strength concrete is a mixture of 1 part M 400 cement, 2.5 ÷ 5 parts crushed stone and 1.5 ÷ 2 parts sand.

All parts of the future solution for pouring the formwork are thoroughly mixed by hand with shovels or in a concrete mixer, and after adding water they are mixed again. As a result, the resulting concrete should not spread over the shovel, but settle on it.

Concrete mortar must be used within 4-6 hours after production.