Areas of use

Oriented strand board consists of several perpendicular layers of pressed wood chips with formaldehyde bonding. Multi-layering gives the material additional strength, and the processed, smooth front side is immediately prepared for finishing. The slabs can be used for internal and external cladding, roof formation, work in rooms with high humidity, as well as for installation of formwork. OSB boards are used to create strong and reliable structures.

As a rule, OSB formwork is installed to form the foundation. Despite its high strength, the material is easy to cut and otherwise process, thanks to which concrete structures of various shapes and sizes can be made from OSB.

How to make formwork for a foundation with your own hands

The choice of material depends largely on the type of structure, since it is necessary to calculate the strength of the boards, panels, metal and other elements that participate in this “interactive event”. Let's assume that a one-story house or garage is being built.

For the formwork we will need OSB sheets 12 mm thick, 10 mm is possible, but we will need to pour the concrete gradually so that the “belly” does not squeeze out anywhere.

Instead of OSB sheets, you can use old wooden doors, metal gates, iron sheets and anything that is not weaker in strength and has a smooth surface.

note

It doesn't have to be even on both sides. Even on the inside, unevenness of 2-3 centimeters is allowed - this is quite normal and will not affect the process in any way.

The main thing is that you can then easily pick this material out of the concrete, that is, without any elements that fall into the space intended for pouring concrete. Next we will need a wooden beam 50x50 mm, which we will cut.

It is desirable that it be made of hard wood, the ideal option is larch. Its cost, of course, is considerable, so if you don’t have enough money, you can buy 10 meters of pine timber.

A story about do-it-yourself formwork

In order for the formwork for the foundation to be level, it is necessary to level the sole, make sure that its angle of inclination is insignificant, and that there is a small gap between the OSB sheets and the ground, which can easily be filled with mortar. Next you need to follow the instructions.

We cut the wooden beam into 25 centimeters (depending on the width of the foundation, if it is 30 cm, then we cut it into 30 centimeters), and make sure that the cut is as even as possible. We will need about 4 such pieces per 1 linear meter of the foundation, if its height is 150 centimeters (average for a house).

We fasten the next block of OSB or any other material so that there is a minimum gap between them, and screw it with strips. So we expose everything to the very end so that there are no gaps anywhere. The thickness of the foundation will be the same everywhere, since you can control it with a wooden block. This arrangement of strip foundation formwork can significantly increase its accuracy.

External spacers

Video about installing formwork supports

Now let's move on to the most important part of our business - the external supports for the formwork. Without them, it will simply fall apart, so you need to take a little time and allocate materials for the construction of such elements. Let's look at step-by-step instructions on how to do this.

We cut the wooden beam into sizes of 60, 90 and 120 centimeters. We leave 1 edge cut at an even angle, and make the other 45 degrees.

Every meter we install 3 supports at a height of 60, 90 and 120 centimeters, respectively. We press it into the ground at a right angle and hammer the beam in a little, after which we tilt the pointed end towards the OSB sheet, to which it fits perfectly. Screw in the screw.

Important

We hammer in the vertical supports. Basically, the entire structure will rest on them. You need to take a stepladder and metal pipes, corners, squares - anything that has good load-bearing capacity and drive them 50-60 centimeters into the ground, close to the formwork. This will prevent the bottom from moving away.

Making formwork for a strip foundation in this way will maximize the safety of the structure from breakage, even when the foundation is quickly poured. But don’t rush, it’s better to do everything in several stages - the effect will be much better.

Finishing robots

It’s too early to say that you know how to make formwork for the foundation, since everything needs to be prepared for pouring concrete and only then can we talk about finishing the work. The first step is to stretch the thread - the level along which the foundation will be poured.

If you make a mistake with the level somewhere, then the entire structure will be of poor quality, since it is impossible to add 5-6 centimeters after the concrete has hardened. This violates the law of monolithicity.

It will also not be possible to install a crooked house; it will take a long and tedious time to level the first rows.

We take a level, lower it between the OSB sheets, mark the zero value line with a marker, then tighten the thread so that it passes exactly along the marks.

Now you can pour the foundation, observing the level and leveling it.

Wooden internal ties are left inside or removed when pouring the foundation (when the foundation reaches the reinforcing element, they stop for 2 hours so that the concrete settles a little, then the beam is unscrewed).

Now we have looked at how to make formwork for the foundation and strengthen it from the outside and inside. This system is suitable for a garage or a one-story house; for a cottage it would be better to use boards - they are a little stronger and easier to remove later. The only negative is that it takes a very long time to attach them.

Formwork is an enclosing structure that gives concrete products their shape. If you are going to pour a foundation, then it is these guides that will determine its configuration. Not a single serious structure can do without a foundation.

Perhaps a small shed and a summer shower can be placed on the ground. Moreover, almost all types of foundation require the preliminary installation of formwork. Do-it-yourself formwork for the foundation can be made from boards, chipboard and other materials. It can be removable or non-removable.

In this article we will look at the main types of formwork and how to make it.

The main task of this structure is to hold the concrete solution in a given shape. Therefore, it must be strong and stable: the solution has a considerable mass. To give the structure greater rigidity and stability, additional struts and bevels are often required.

In private construction, foundation formwork is almost always used. It is completely wrong to treat this stage as an auxiliary operation.

Formwork largely determines the quality and reliability of the concrete foundation of any structure and it must be installed in accordance with all the rules. Depending on the type of foundation, formwork structures also differ, but the principle of their operation is similar.

What is it used for?

Essentially, formwork is a structure that forms a cavity for pouring concrete. The solution has a fairly high fluidity, which makes it difficult to create specific, correct forms from it. The purpose of installing the formwork is to form the desired geometry of the concrete monolith.

It limits the space and holds the solution inside this volume until it hardens completely. In addition, it becomes possible to reinforce the foundation, lay waterproofing and insulation, as well as compact the concrete mass itself.

Based on the purpose of the formwork, the corresponding requirements are put forward for it:

- sufficient mechanical strength to withstand the pressures arising when pouring concrete;

- consistency of size and shape during the pouring process;

- tightness to prevent solution leakage.

Taking into account the fact that the formwork is not a structural element of the structure itself, it should be installed simply and quickly. In this case, sufficiently cheap materials should be used that do not lead to a noticeable increase in the cost of the entire foundation.

Types by design

Based on the technology of installation and further use, formworks are divided into 2 main categories.

Removable

These are formworks that are installed only during the formation of the foundation, after which they are dismantled.

They can be disposable or reusable, depending on the materials used.

In the first case, the cheapest structures are used, which after completion of the work are completely disassembled, and the material can be sent for another purpose or for recycling.

The second option involves a panel assembly, which is quickly assembled and then disassembled into individual assembly elements. It is necessary for specialized construction teams or when planning other buildings.

Fixed

Such formwork remains in place even after concrete is poured, playing the role of an additional, structural element of the foundation. They must be made of materials whose service life is commensurate with the durability of concrete. After pouring, the formwork becomes a protective element - insulation or waterproofing.

In practice, in private construction, cheap one-time (removable) formworks made by hand are most often used. Permanent structures are used for special projects and certain types of foundations.

Both types of formwork can be made from different materials.

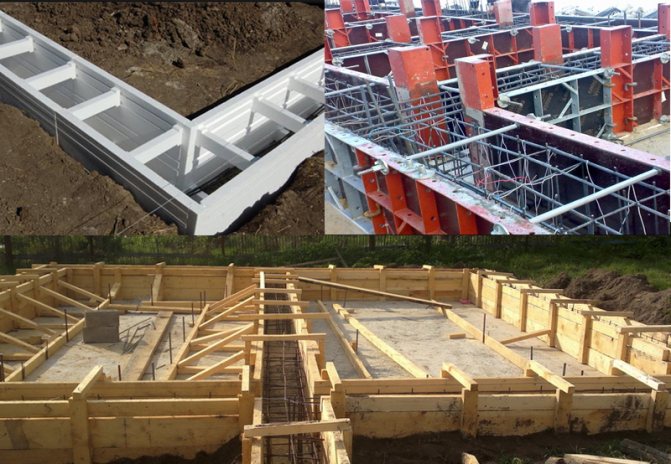

The main structure is panel. To do this, using wooden beams and boards or plywood (OSB), boards are knocked together, which are then installed in the foundation pit (trench). Wooden formwork is used in the construction of strip, columnar and slab foundations, as well as for the formation of a pile foundation grillage.

Given the low durability of wood, its use is usually limited to removable options. The main advantage of such formwork is cost-effectiveness, ease of installation, and availability of material.

The disadvantage is the need to seal the walls due to the hygroscopicity of wood, which leads to the absorption of moisture from the solution, and the presence of gaps between the boards. In addition, during installation, a system of spacers is required to give and maintain a vertical position, and difficulties arise when forming rounded bases.

Pros and cons of using OSB

The main function of formwork is to firmly hold the house structure and concrete pouring until completely dry. For this purpose, OSB panels are better suited than other materials: wooden boards or panels. Advantages of formwork for foundations made of OSB boards:

- low moisture resistance. The material does not absorb moisture and has a low swelling percentage. When laying between the panels, it is enough to leave a gap of 2-3 millimeters to provide for possible deformation;

- ease of processing. OSB is easy to saw, cut and install. Thanks to this, you can form the formwork for an OSB foundation with your own hands;

- speed of work. Due to the ease of working with panels, the construction of a house or foundation is noticeably faster;

- integrity of the material. OSB is used to create solid, dense panels through which concrete cannot leak.

In addition to the advantages, this type of formwork also has disadvantages. The material has low elasticity, so it can burst under excessive loads.

Scope of application of OSB in formwork

OSB is widely used in residential construction. This building material is used for the installation of lathing, as well as the construction of formwork systems.

Most often, slabs are used to make lathing for the foundation, as well as for fences and various outbuildings constructed using monolithic technology. The slabs are quite easy to process, so structures made from them are easy to assemble with your own hands.

Materials used

It’s not difficult to figure out how to make formwork from OSB. The main thing is to prepare the necessary materials before work:

- OSB formwork slabs 9 mm or 12 mm, pre-cut into individual elements according to the drawings;

- screws for fixing;

- glassine for filling cracks;

- reinforcement rods for attaching stakes;

- metal corners to increase the strength of the formwork;

- plastic tubes for fastening formwork panels;

- nuts and other fasteners for assembling materials;

- bars for forming stiffening elements on OSB panels.

Base insulation

Also, when building a house and making formwork, you can think in advance about how to insulate your future home. To do this, buy foam sheets of the required size and attach them to the OSB front board from the inside. To ensure that the sheets of insulation material are firmly fixed to the concrete base, pass wire loops through the foam before installing them on a collapsible structure. Thanks to this construction trick, you will be able to securely attach the foam to the foundation.

OSB boards can be used for formwork many times (at least 10), and after dismantling work, they can be used as rigid sheathing on the floor of the attic or on the roof. It turns out that with the correct organization of the work order and careful use of the material, the use of slabs will be waste-free, and you will save money.

Design features

OSB panels are a widespread multifunctional material with properties similar to chipboard. The composition contains a special glue that helps to hold together several layers of wood chips located perpendicularly. Externally, chips measuring 2*15 centimeters are located longitudinally along the main axis of the slab, forming a flat, smooth surface. OSB is highly durable due to production features: strong pressing and pressure, high temperature during processing and the use of resinous synthetic compounds.

Oriented Strand Board

OSB and OSB boards can be easily recognized from thousands by their appearance, since these types of boards have a characteristic wood structure. Oriented strand board is a type of engineered lumber that is somewhat similar to chipboard. Its production is based on the addition of adhesives and pressing layers of wood chips, which are oriented in a certain way. OSB has a rough, variegated surface, with individual shavings and chips measuring 25*150 mm, which are unevenly spaced to each other and have different appearances and thicknesses.

Application

OSB boards are often used in residential construction. Due to the unique mechanical properties of this building material, it can be used for various purposes. Most often, such slabs are needed for the manufacture of sheathing for floors, walls, roof decking and foundation formwork, as well as other reinforced concrete and concrete elements of the building. For external walls, such panels are produced with lamination on one side, which greatly helps to simplify installations and increase the energy efficiency of the fence structure. OSB is also often used in the manufacture of furniture.

Production

Before you buy OSB for foundation formwork, the material is manufactured in production. The slabs are made in the form of wide mats, as well as from layers of chips, which are differently oriented, glued and compressed with adhesives made of synthetic resins and wax (5% resin/wax and 95% wood). Typically, the resins that are used contain phenol formaldehyde, isocyanite and melamine-molded urea formaldehyde. Each of these binders is resistant to moisture. As a rule, a combination of astringents is used - isocyanite is used in the middle, while urea formaldehyde is used in the front layers. This helps to reduce the number of pressing cycles and at the same time gives a beautiful appearance to the surface of the slab.

The layers are made as follows - the wood is crushed into strips, which are then sifted and then oriented using various devices when fed to the molding line. For the outer layer, the chips are aligned along the strength axis of the slab, and the inner layers are strictly perpendicular. The number of layers placed will depend to some extent on the thickness of the panel that needs to be manufactured, but is still limited by the equipment used in production. Individual layers can also differ in thickness to give different thicknesses for the slab (usually, a 17 cm layer produces panels with a thickness of 1.7 cm). Next, the mat is placed under a thermal press so that the raw material is compressed and held together due to thermal activation and hardening of the resin that covers the wood. The individual panels should then be cut from the mats to the required size.

Please note that OSB panels for wood structures can be cut and installed as easily as real wood.

Technical properties and varieties

Adjustments during the production process may result in differences in the thickness, size of the slabs, as well as their strength and rigidity. OSB boards for do-it-yourself formwork are good because they do not have internal voids and are waterproof, although they require additional shells to obtain waterproofness and are not very suitable for external types of work. The finished product has properties somewhat similar to plywood, but is cheaper and more uniform. When testing OSB for fracture, it was revealed that the material has a high load-carrying capacity and this indicator is higher than that of milled wooden panels.

There are 4 types of OSB boards, which are defined in terms of mechanical characteristics and relative resistance to moisture:

- OSB/1 – general purpose boards for interior finishing of premises (furniture inclusive), required for use in dry conditions.

- OSB/2 - load-bearing boards that are needed for use only in dry rooms.

- OSB/3 – load-bearing type boards that can be used in conditions of high humidity.

- OSB/4 – load-bearing type boards (for heavy loads), which can be used in conditions of high humidity.

Although OSB does not have a continuous grain like natural wood, it does have an axis along which the resisting force is greatest.

It is interesting that it is the strength characteristics of the slabs that make their use as a material for the manufacture of foundation formwork expedient, and the ease of processing makes it possible to carry out the work with one’s own hands, without the involvement of specialists.

Formation of formwork

You must first dig a trench under the base and fill the bottom with sand, leaving space for communications. Formwork is formed as follows:

- cutting OSB sheets to the required width and length;

- forming a frame for panels from wooden blocks or profile pipes;

- fastening OSB with self-tapping screws to the frame, as well as strengthening the panels with bars in increments of forty centimeters;

- installation of shields on both sides of the trench and their connection with metal spacer pins. At the attachment points it is necessary to make holes with a diameter of 16 millimeters. Fasteners are made with nuts and washers;

- Before inserting the studs, they must be passed through identical plastic tubes so that the same width is maintained along the entire perimeter of the formwork. Instead of tubes, you can use 4 nuts on both sides;

- to strengthen the corners of the structure in corner areas, it is necessary to drive into the ground bars secured with steel corners;

- outside the structure, in increments of 1 meter, bars are installed at an angle so that the formwork can withstand the weight of the concrete mixture;

- After installation is completed, you need to check the evenness of the panel edges with a laser level or string.

To reduce the pressure on the structure when pouring concrete, you can take breaks, pouring the mixture in layers. This way the concrete base will set gradually. Forming formwork from OSB panels will help not only save time during construction and money on materials, but also provide additional insulation of the base. The panels make it possible to lay thermal insulation sheets between them and the concrete.

Which formwork is better - plywood, OSB or edged boards

7 Sales department of plywood, OSB, hardboard

No construction can be completed without the use of reinforced concrete; even a completely wooden building must stand on a reliable stone foundation.

Moreover, when constructing a private low-rise building, owners usually prefer to cast structures on site rather than order ready-made reinforced concrete products.

A do-it-yourself concrete structure is always cheaper and is guaranteed to have the required configuration. But in order for the monolith to turn out to be of high quality and a clear shape, special attention should be paid to the construction of the formwork.

plywood formwork FC

bent plywood formwork

It is most advisable here to use coniferous (or aspen) edged boards, 25-50 mm thick, plywood sheets or OSB-3 boards. Each of these materials, with the right approach, can be reused for subsequent concrete pours.

They are often used when performing various kinds of rough work, for example, hemming and rough flooring, creating roof decking/lathing, etc.

That is, in fact, if you plan your actions correctly and make some efforts, then we get formwork made from lumber or wood-containing slabs for free. Let's take a closer look at why plywood is so popular in formwork.

- Excellent form-building and load-bearing abilities. Plywood allows you to get smooth, clear concrete surfaces. A smaller number of gaps (they are only at the junctions of the panels) reduces the likelihood of laitance leakage. Plywood glued together from several layers of veneer has good elasticity and strength, so less materials are used to strengthen the panels, and there is less risk of destruction or deformation of the formwork. When creating narrow and shallow foundations (for example, for a fence from a blockhouse), it is generally not necessary to reinforce the plywood sheet with bars.

- Versatility. We have the opportunity to choose the thickness of the material in gradations of about a millimeter. Depending on the tasks set, you can buy plywood of various grades, brands, sizes, which determines the turnover of the boards, their strength qualities, and cost. As a plus, you can write down resistance to moisture (both inside and outside), to aggressive chemistry of the solution, and to temperature changes. Formwork is made from plywood for: foundations (column, strip, grillage), monolithic floors, swimming pool bowls, lintels over openings, cast walls, columns, monolithic belts, flights of stairs, porches, etc.

- Convenience and speed of installation. The plywood sheet is easy to cut straight and curved, drills without problems, and holds fasteners well. Since plywood is a large-format product (the standard size can be considered 1220X2440, 1525X1525, 1500X3000 mm), it will be easier to create a shield than, say, from an edged board. It is especially convenient to work with plywood slabs when it is necessary to make formwork of a complex configuration; a striking example is pouring flights of stairs, when the edge of the panel forms the shape of the steps.

- Ability to create curved shapes. If we want to pour a porch with round risers, an oval pool or a concrete arch, then plywood is perfect. For these purposes, they take sheets of relatively small thickness, and after bending them (How to bend a plywood sheet is a separate article), they assemble the formwork.

The only disadvantage of using plywood as formwork is its cost, which, however, is not so important if you need to pour several foundations, or if the subsequent use of sheets in other structures is envisaged.

When comparing the initial costs of purchasing FK plywood with OSB boards, it becomes clear that there is not much difference.

But the edged board turns out to be much cheaper than all competitors, although some amount will be spent on purchasing additional lumber and fasteners to create a reliable board from piece elements.

Important

Let's try to count. Conventionally, to fill the strip foundation of a 10X10 cottage (the total height of the foundation is 1.5 meters, there is one load-bearing wall inside the house), we need to collect 150 square meters of panels. In this case, excluding crossbars, spacers and jibs, our costs will be approximately:

Material Unit of measurement Quantity Cost (RUB) Total (RUB)

| OSB-3 18 mm 1250Х2500 mm | m2 | 150 | 368 | 55 200 |

| Plywood FSF 4/4 18 mm, 1220Х2440 mm | m2 | 150 | 570 | 85 500 |

| Plywood FC 4/4 18 mm 1525Х1525 mm | Sheet | 68 | 830 | 56 440 |

| Plywood FOF 18 mm 1500Х3000 mm | Sheet | 34 | 4700 | 159 800 |

| Coniferous edged boards, 2nd grade 25Х150Х3000 | PC. m2 | 333 150 | 55 122,2 | 18 333 18 330 |

You can learn in detail how to make formwork from grade 2 edged boards in the article of the same name.

First of all, you need to take into account the turnover of plywood - this is the main classification indicator for products for this purpose. Turnover characterizes the possible number of cycles of using the same shields under similar conditions without losing their performance qualities.

In addition to operating conditions (types and intensity of loads, ambient temperature, protection methods, general production culture), it will depend on the type/brand of material used. The greatest number of concrete casting cycles will be provided by laminated plywood of the FOF brand, specially designed for concrete casting (up to 50 cycles or more with proper maintenance).

FOF plywood – laminated – ideal option

Formwork made of FSF plywood - moisture resistant

Moisture-resistant FSF plywood lasts less (can be used up to 5-7 times). The FC slab will be the least reversible (up to 2-3 times), since it is not able to fully resist high humidity.

Grade 2 edged boards with an initial moisture content of about 22-25 percent are considered the least practical when used in a formwork system. But even such a shield, after treatment with lubricant or waste oil, can be used to fill 8-10 monoliths.

For a better and smooth surface and to minimize mortar leaks at the joints of the boards, we recommend using glassine attached to the boards with a regular hand-held construction stapler.

The turnover rate of plywood of the same brand can vary greatly depending on its quality and other technical features.

Thus, Chinese poplar plywood products live in formwork approximately two to three times less than domestic ones, including due to reduced strength and wear resistance. A sanded slab will last longer than an unsanded one.

Advice

Coniferous veneer is more durable than birch veneer. When protecting plywood or board panels with oils, drying oil or plastic film, the turnover rate increases.

Based on the tasks set, we have the right to choose the brand of plywood that will provide us with the required number of turnover cycles. Obviously, for a one-time pour, it makes sense to buy FSF or FK plywood, or give preference to grade 1 or 2 edged boards.

By the way, it is precisely for the assembly of formwork panels with low turnover that you can easily use plywood of a lower grade - 4/4.

But, if you plan to use the formwork for 30-40 cycles, then it will be much more profitable to immediately spend money on durable laminated FOF products than to buy FSF brand plywood 7-8 times and assemble new panels the same number of times.

We will not talk now about how to prepare and lay concrete or how to knit reinforcement. Let's focus on working with shields. The methods for assembling and installing plywood formwork are the same as when using edged boards, but there are some nuances.

- 1. Cut the sheets. It is best to cut sheets with a circular saw. It is more convenient to make a curved cut with a jigsaw.

- 2. Protection of the working plane of the slab. Impregnating and lubricating the veneer of a non-laminated slab will provide a smooth concrete surface, facilitate removal of formwork, and increase the durability of the products. If it is necessary to obtain greater turnover, use diesel fuel, mining oil, and lubricating oil. But there are also specialized lubricants for “active type” formwork, which cost more but consume less. You can also use drying oil to protect the plywood or line the inside of the formwork with polyethylene.

- 3. Protection of the ends of the slab. FOF laminated plywood has painted edges, and this helps to increase its service life in aggressive conditions. Therefore, it is also recommended to paint FC or FSF plywood along the edges; for this, it is best to use “paint for the ends of lumber,” for example, KRASULA® for the ends from the North company.

- 4. The assembly of the shield in most cases is carried out with the arrangement of a rigid spatial frame on the rear side. Usually, along the perimeter of the slab, a profile pipe or structural lumber is placed - a block with a cross-section from 50x50 to 50x100. Several stiffening ribs are also placed along the entire plane.

- 5. The placement of shields is carried out according to level and plumb. The direction is controlled by the casting cords. The panels can be located entirely in the pit, or the system can be built only on the surface.

- 6. Paired panels must be parallel to each other; for these purposes, remote wooden spacers, stakes (hammered into the ground), and diagonal struts are used. The struts should be located at least every 1000 mm. When creating pool formwork, spacers are often placed between opposing walls of the formwork system.

- 7. Shields should not be crushed by the mass of poured and vibrated concrete. To do this, at the bottom and top of the formwork, tie rods made of threaded rods with a plastic sleeve are used, which help to easily remove hardware during formwork removal (cut plumbing pipes can be used). Often, wire is used to tie the formwork.

- 8. To prevent mutual displacement of adjacent panels and eliminate the possibility of cement laitance leaking through the joint, the panels are either bolted through the frame beams or connected with an overlay made of boards (or plywood scraps).

- 9. It is advisable to place plywood formwork panels flush with the calculated upper level of the foundation. If there is such a possibility, then it is better to orient the shield so that the factory uncut edge of the plywood goes up.

- 10. All fasteners that are used when assembling panels into a single system must be accessible for removal at the time of formwork removal, which occurs on average after 3-8 days. To do this, screwing in self-tapping screws and hammering nails is performed exclusively on the outside of the formwork panel.

Website about the dacha

Formwork for the foundation is an integral part of the construction of such a building, which requires the mandatory construction of that very foundation. The formwork for the foundation is used as a strong frame, into which concrete is subsequently poured. Sometimes a structure is erected only for the frame, but often today the formwork is part of the foundation, so it is erected with a preliminary decision to leave it forever. This type of work requires mandatory compliance with long-term use for the selected material. First things first.

Conclusion

And so, let's sum it up! To choose the material from which the structure will be framed. You need to decide on its dimensions and calculate the approximate weight of your structure. To understand what kind of foundation you need to make. Depending on the monumentality of your structure, you need to choose a material so that it can withstand the load.

Also, if you are engaged in construction, then you should think about creating a removable structure for yourself, this will help you save time and money. Also on this page, you can share your experience in construction or our readers about what you can’t do and how best to do it.

It's time to remove the frame

In terms of density and safety, an important factor is the question of when the formwork can be removed from the foundation. If the structure is collapsible, you need to wait for the concrete to completely harden - this may take 1-1.5 months.

Making a strip foundation using a structure is not so difficult, but painstaking. The main thing is to study exactly the advantages and disadvantages of the listed methods of formwork for a foundation with your own hands (removable and non-removable). Knowing how to install formwork, you can choose a more suitable material for the job and, if possible, save on construction costs.

Assembly of formwork blocks from OSB and their connection into a single structure

The technology for making a formwork block with your own hands is quite simple. It requires the worker only basic skills in working with woodworking tools. The sequence of work is as follows:

- Sheets of calculated sizes are cut from standard slabs.

- Two sheets are placed on top of each other and holes are drilled in them for the tie rods.

- Wooden blocks are screwed to the OSB boards from the outer sides with self-tapping screws along the perimeter along the sheets and across the sheets to create additional stiffeners.

- Two prepared slabs are connected using pins, which are passed between the slabs through corresponding sections of plastic tubes.

- Corner blocks will be different from regular ones because the front sheets will be longer than the inside sheets.

After the blocks are lowered into the ditches for the strip foundation, they are connected in series into a single structure.

Particular attention should be paid to the reliability of the connections of OSB boards at the corners of the structure with iron corners.

In these places, during pouring, the greatest pressure is usually created with the concrete mixture on the formwork structure.

Pouring concrete into the tape

Then the entire structure is attached to the ground by driving reinforcement pegs into the ground so that the formwork does not play from side to side when pouring the rubble concrete mortar. Finally, cracks that may form at the joints of OSB boards are sealed using plywood and glassine. It is enough to attach glassine and plywood to the formwork structure using self-tapping screws.

It is advisable to pour concrete evenly around the perimeter in large portions, so the initial pressure on the formwork will be large until the solution “sets.” In order to avoid destruction of the structure during pouring the foundation, it is necessary to place washers of sufficient size under the nuts on the studs that connect the opposite OSB boards.

If the foundation of the house has a high base, then when constructing formwork with OSB above the ground level, it is necessary to create additional stiffeners with your own hands. Slopes from wooden beams, additionally strengthening plastic OSB slabs every 0.5 - 0.7 meters, will help to avoid deformation of the correct geometry of the foundation during its pouring.

The invariable advantage of collapsible structures made from OSB boards is that their material can be reused and reused.

When purchasing OSB boards to create foundation formwork, you need to know that this material is produced in thicknesses from 9 to 38 mm in four types:

- OSB board 12 mm thick

for use in low humidity environments (OSB-1);

- for use in dry rooms (OSB-2);

- for creating structures used in environments with high humidity (OSB-3);

- to create load-bearing structures that are used for a long time in environments with high humidity (OSB-4).

In practice, people who build houses with their own hands usually choose OSB-3 slabs with a thickness of 12-16 mm for the construction of formwork for pouring a strip foundation up to 30 cm wide. This material is used quite rarely for pouring more massive foundations of houses.