When building a private country house, you cannot do without a concrete base - the foundation. In order for the sand-cement mixture to obtain the required shape, formwork is used. It can be fixed or removable. In the first case, we are talking about a structure made of polystyrene foam, wood concrete or other material, which, after reinforcement and pouring of concrete, becomes part of the foundation itself. If we are talking about removable formwork, then in this case we mean a collapsible structure, which is removed immediately after the concrete has hardened.

Pros and cons of removable formwork

If we talk about the advantages of this design, then it is worth highlighting its low cost. If necessary, removable or adjustable formwork can be rented or you can independently make a more durable structure, which can then be used for another building. Some even use everything that was lying around in the barn to create such a structure.

On the other hand, permanent formwork gives strength to the entire structure. If, for example, you use extruded polystyrene foam, you can additionally obtain thermal insulation for the basement floor. But this will also require organizing a better ventilation system. It’s true that permanent formwork will cost more.

Also among the disadvantages of removable mechanisms is that they significantly extend the construction period of the foundation. In this case, you will need to wait for the concrete to fully gain strength (28 days) and only then begin finishing work. If you organize permanent formwork, then you can carry out such work immediately. But there is a peculiarity here too. Fixed mechanisms are usually not used in winter. Removable formwork allows you to use equipment for heating concrete, even in the cold season.

Therefore, when choosing a formwork system, you should focus on the allowable construction time of the building, as well as the available budget. If you decide to build a more budget-friendly structure, then you need to decide on the material for it.

Reusable laminated plywood formwork

Non-factory reusable formwork can be made from thick (from 18 mm) laminated plywood. Use timber as a frame or even do without it at all, fastening the opposite walls of the panels together with studs with nuts and washers (if the formwork is low). The material has many advantages:

• with careful use it lasts a long time; • not afraid of contact with concrete; • when properly secured, it does not deform from the pressure of the mixture; • any shape can be obtained by cutting.

The disadvantage is the same - the cost, which starts at about 1800 rubles per sheet. However, in this case, you can’t stand up for the price. For example, when pouring a floor slab or balcony platform yourself, it is difficult to obtain good geometry from below. Installation of laminated plywood supported by spacers is ideal in this case. If it is possible to pour concrete in several stages, then by calculating the maximum number of sheets required at one time, you can save a lot.

I recommend: How to properly organize a construction site for a country house

If there is a lot of concrete work to be done on the site, then laminated plywood is worth taking a closer look at: it is possible that such adjustable formwork will more than recoup its price. And if, after construction is completed, you sell it to a neighbor...

Tree

This is the most common and accessible material. As a rule, so-called type-setting boards are assembled from boards, which are fastened with bars 60 x 40 or 80 x 40 mm. The wood species can be any.

Healthy! It is recommended to use edged boards. Otherwise, after concrete is poured, it will begin to ooze through the formwork.

The boards themselves allow you to create formwork structures of any height. However, if the height of the base exceeds 1.5 meters, it is recommended to use materials with a thickness of at least 40 mm. The cross-section of the connecting bars must be at least 50 x 100 mm. Otherwise, wooden panels may not withstand the onslaught of the cement-sand mass. For a lower foundation, boards 20-30 cm thick are suitable.

As a rule, in order to create a more airtight structure, the boards are overlapped and fixed with self-tapping screws or nails, the length of which should be ¾ of the thickness of the boards and bars.

The main disadvantage of such formwork is that it is usually used only once. After this, the wooden panels are broken and dismantled.

Do-it-yourself formwork for strip foundations

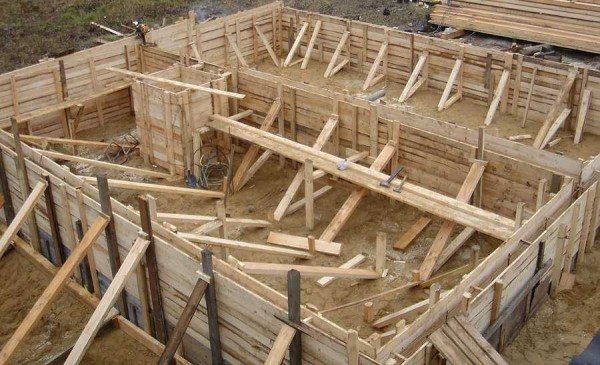

The most voluminous is the formwork for strip foundations. It follows the contours of the house and all load-bearing walls on both sides of the tape. When constructing a more or less large building with a large number of partitions, the cost of materials for foundation formwork will be very significant. Especially when laying a deep foundation.

Construction of shields and their connection

When assembling the formwork with your own hands, it is important to make the panels strong: they will need to hold the mass of concrete until hardening occurs.

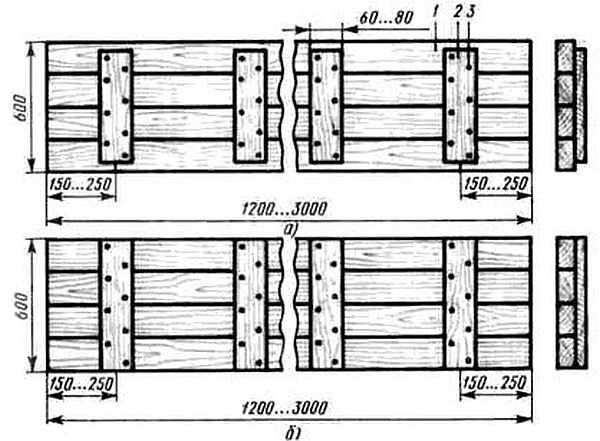

The dimensions of the formwork panels vary and depend on the geometry of the foundation. The height is slightly higher than the height of the foundation; you determine the length of each panel yourself, but usually it is from 1.2 to 3 m. It is inconvenient to work with very long structures, so the optimal length is about 2 m. The total length of the entire formwork should be such that they were placed exactly according to the markings of the foundation (do not forget to take into account the thickness of the shield).

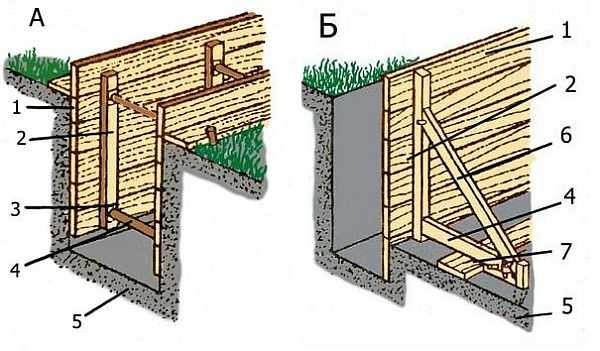

How can formwork for a strip foundation be installed: in a trench dug according to the dimensions of the strip and in a pit with braces

When making formwork from boards, cut several pieces of the same length and fasten them together using bars and nails or self-tapping screws. When using nails, hammer them in from the inside of the shield and bend them onto the block. It is easier to work with self-tapping screws: they do not need to be bent, since due to the thread they ensure a tight fit of the elements. They are screwed from the inside of the shield (the one that will face the foundation wall).

The first and last bars are attached from the edge at a distance of 15-20 cm. Between them, at a distance of 80-100 cm, additional ones are placed. To make it convenient to install the formwork panels, two or three bars (at the edges and in the middle) are made 20-30 cm longer. They are sharpened and driven into the ground during installation.

Approximate dimensions of formwork panels made from edged boards

Panels made of plywood or OSB are assembled on a frame made of bars. When assembling, it is important to strengthen the corners well. In this design they are the weakest point. They can be strengthened using metal corners.

Do-it-yourself formwork installation

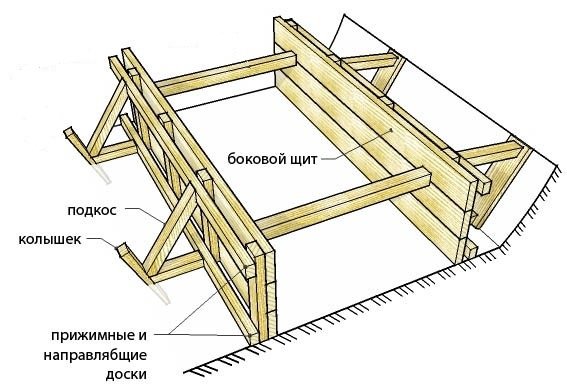

If the shields are made with several elongated bars, they need to be aligned along the cords of stretched markings. The difficulty is that you need to set it in the vertical plane at the same time. For fixation, you can use bars hammered to the mark and aligned vertically. When installing, align the plane of the shields close to these bars. They will be both support and guides.

Panels with extended cross bars are easier to install

Since the bottom of the trench or pit must be flat (it is compacted and leveled), it should be easy to position the panels horizontally. Try not to hammer them too much: it will be easier to level them later. Lower one of the corners to the level of the bedding. There should be no gaps, the solution should not leak out. Having achieved a tight fit, take a building level, place it along the shield and hammer in the second edge until the top edge is installed horizontally. You already set the next shield relative to the installed one: they should be on the same level and in the same plane.

If the shields are made without long bars, at the bottom of the pit, along the line marking the tape, a block is fixed that will serve as a stop. The shields are placed close to it, then fixed with the help of bevels and spacers.

Strengthening - braces and stops

In order to prevent the formwork from falling apart under the mass of concrete, it must be secured from the outside and from the inside.

Braces are installed outside. Supports should be placed at least every meter. Particular attention should be paid to the corners: here stops are placed on both sides. If the height of the shield is more than 2 meters, then one stop belt is not enough. In this case, at least two tiers of spacers are made: upper and lower.

Stops and braces are placed on the outside of the formwork. At high altitudes they are made in several tiers

It is also necessary to stabilize the distance between two opposing shields. To do this, use reinforcement studs with a diameter of 8-12 mm, metal gaskets and nuts of the appropriate diameter. The studs are installed in two tiers: at the top and bottom, at a distance of 15-20 cm from the edge.

The length of the pins is about 10-15 cm longer than the width of the tape. There are two options:

- Threads are cut at both ends of the reinforcement. Then each stud will require two metal sealing plates and nuts.

- On one side, the pin is bent and flattened, and a thread is cut with the arc. In this case, one nut is needed (there are still two plates).

The internal distance between the panels, equal to the design width of the tape, is fixed using sections of plastic pipes. Their internal clearance should be slightly larger than the thickness of the studs.

How to make spacer pins in formwork

The assembly proceeds as follows:

- Holes are drilled in both shields with a long drill.

- A piece of pipe is installed between them.

- The pin is threaded through.

- Metal plates are installed (they will prevent the pin from tearing the shield material).

- The nuts are tightened and tightened.

You need to work together, or better yet, three. One person installs tubes inside between the shields, and one person each to install the studs and tighten the nuts.

When removing the formwork, first unscrew the nuts and remove the studs, then dismantle the slopes and stops. The released shields are removed. They can be used further.

Plywood

This is a wood-laminated material that can be made from veneers of different types of wood. If finances allow, it is better to choose Finnish plywood; it is characterized by increased moisture resistance and strength. A cheaper option is birch veneer plywood.

Healthy! Also on sale are plywood coated with synthetic impregnations, formaldehyde glue (such products are labeled as FSF) and a protective laminated layer. These are specialized materials that are used for the construction of dismountable formwork structures that can be reused.

The optimal plywood thickness should be 10-16 mm. Such sheets are installed on a wooden (some use metal) frame made of 40 x 40 mm bars. The plywood is fixed using self-tapping screws.

Material calculation, necessary tools

When purchasing lumber for formwork, you need to remember that the boards will be located on both sides of the trench. In addition, the number of required planks also depends on the depth of the foundation and the width of the wooden product itself. After all, the boards are knocked together with beams into shields, the height of which should be slightly greater than the depth of the trench. Therefore, to determine the number of boards, it is necessary to measure the total length of the trench, multiply it by two, divide by the length of one wooden product and multiply by the ratio of the height of the trench to the width of the board. As for the bars, their spacing should be no more than 40 cm. Depending on this, the number of necessary bars is determined. So, for work you will need the following materials:

- board (humidity – no more than 22%; thickness – 25–50 mm; width – 200–300 mm);

- beams (section 40*40 mm; length equal to the depth of the trench);

- sand;

- nails, screws;

- tow;

- thin slats.

To install formwork for a strip foundation, you will need the following tools:

- wood saw, jigsaw or grinder;

- drill, hammer;

- yardstick;

- building level.

Chipboard and OSB

If plywood and boards do not seem such a durable material or we are talking about a larger-scale construction, then you should pay attention to chipboard (chipboard). As a rule, 16-22 mm panels are used for formwork structures. There are many classes of chipboard. Both low-grade panels and construction panels are suitable for formwork (more durable, but more expensive).

If we talk about the advantages of such structures, then it is worth highlighting the ease of processing. The sheets are easy to saw. But, like many others, they can only withstand one-time fastening with self-tapping screws or nails.

Another option is OSB. We are talking about oriented strand board, the thickness of which can be from 6 to 22 mm. This material is characterized by higher moisture resistance and strength. It is easy to handle. But, it is worth considering the OSB classes (out of 4 in total). The lower the class, the lower the quality of the material.

Healthy! In terms of creating a formwork structure, chipboard and OSB are no different from standard plywood.

It is worth noting that when using any untreated wooden material, you need to take into account that it absorbs moisture well, so there is a risk that the formwork will swell. Also, wood is rarely used if the formwork is planned to be re-installed.

Formwork... just formwork

Collapsible formwork from improvised means? No problem. Shields can be made from boards, ordinary plywood, and pieces of unnecessary furniture. Sew the frame from timber, attaching it with nails, install gussets and, if necessary, tighten the walls with locks from welded reinforcement. The advantage of such formwork is its low cost and complete subsequent recycling. The boards will then be used for the trestles and for the roof sheathing. After the construction of all armored belts, plywood will be useful for filling the paths.

The so-called “one-time” formwork can actually be used repeatedly several times, albeit within the same object.

Therefore, it is precisely it that is universal for DIY construction. Read about independent formwork construction in a separate article on the website. Leave your tips and comments below. Subscribe to our newsletter. Good luck to you and good luck to your family!

Metal

In this case, steel or aluminum is used. Each of these formwork materials has certain features, pros and cons. For example,:

- Aluminum has a lighter weight (no more than 30 kg per 1 m2). But in order to install steel sheets, you will need lifting equipment. Therefore, the cost of the entire structure increases.

- Aluminum structures require layer-by-layer pouring of concrete, since the material is more elastic. This significantly extends the construction period. In this regard, stronger steel, which is practically indeformable, wins.

- Aluminum is susceptible to corrosion, but steel is not.

Such prefabricated formwork structures can be rented or made independently. Metal is most often used for permanent formwork when it comes to industrial construction. If you are building a house yourself, then in this case you can use steel or aluminum profile pipes to create a reliable frame for plywood panels.

Metal formwork (factory)

Factory-made formwork made of steel sheets reinforced with a metal frame can serve faithfully for many years, having passed through dozens of construction projects. When using it, there are no problems with the geometry of the structure, its installation is a pleasure: ready-made wedge and universal locks - everything fits smoothly and without unnecessary effort. There is no risk of structural rupture when pouring concrete mixture. However, the high cost makes it impractical to purchase this wonderful item for one-time use. And it is not so necessary even for the construction of a low-rise building.

Asbestos sheets or flat slate

These materials are also used for both removable and non-removable structures. However, it must be taken into account that such sheets have good adhesion, so they are difficult to separate from the finished concrete base. In this regard, when creating removable formwork, the panels must be treated with a composition that makes it easier to dismantle structures.

If we talk about the advantages of such materials, then it is worth highlighting their low cost and ease of processing. The sheets can be easily cut directly during the formwork process. But it takes quite a long time to build. The fact is that in order to secure the spacer and thrust elements, holes for the screws will have to be made first. Since the material is highly fragile, there is a risk of damage to it.

Also today there are ready-made formwork structures made of synthetic materials on sale. They are lightweight, easy to install and can be used repeatedly. They are not cheap. Therefore, everything depends on the budget. But, one way or another, you need to take into account the characteristics that removable formwork should have.

Installation

If the depth of the foundation exceeds 0.5 meters, then when installing the formwork it is necessary to install additional struts

After completing the preparatory work and purchasing materials, we proceed to installing the formwork for the strip foundation. The procedure is as follows:

- Laying a sand cushion. Considering that the weight of the concrete structure is very large, a layer of sand must be laid on the ground to distribute it evenly. The height of the compacted and water-moistened cushion is 150 mm. On a flat and solid base, you can begin installing the formwork.

- Installation of guide boards. This procedure must be carried out strictly along the line, so stretch the fishing line along the entire length of the trench in advance. Then install the guide boards according to the markings, securing them with pegs and vertical bars on the inside. On the outside, in addition to the pegs, install additional stops. After this, check the correct installation of the guide elements using a tape measure and a building level.

- Installation of panels. We attach the boards to the beams and connect them with nails. The procedure is performed from bottom to top.

- After assembling the shields, we install spacers. As the latter, you can also use bars. As a result of installing the spacers, the panels should take their final position, that is, the formwork will take the shape of the walls of the future foundation.

Properly executed formwork for a strip foundation is the key to the strength and durability of the building

Important: To seal the resulting cracks, use tow or thin slats.

This concludes the procedure for installing formwork under a strip foundation. But there are a few more nuances that should be performed if necessary.

Nuances of work

- If the height of the formwork exceeds one and a half meters, then a window must be made at the bottom of the trench to remove industrial waste, which in this case can be very large.

- A layer of waterproofing material is laid at the last stage of formwork installation, before reinforcement.

- If a collapsible structure is intended to be reused, then an oily substance must be applied to its inner surface to minimize adhesion to concrete.

What to pay attention to

When choosing material for removable formwork, the following requirements must be taken into account:

- The structure should be easy to install and dismantle. If it sticks to hardened concrete, it will complicate the job.

- Since concrete gains strength within 28 days, care must be taken to ensure that the formwork is reliable and well secured. The structure must withstand not only the load from the cement-concrete mixture, but also the influence of moisture, wind, sun and temperature changes.

- The smoother the shields, the better. They should form a smooth surface around the entire perimeter of the foundation.

It is also worth considering the types of removable formwork designs. She may be:

- Large shield. For this, plywood or wooden sheets are used.

- Small shield. It is worth choosing more elastic materials. As a rule, small-panel structures are used in the construction of foundations of complex geometric shapes.

- Repositionable. Typically, such structures are used in the construction of very large structures.

Design characteristics

To create metal formwork, sheets 1-2 mm thick are used. Despite the high cost, the use of this material has its advantages. These include:

- foundation installation of any configuration;

- additional waterproofing;

- versatility;

- creating a completely smooth surface;

- ideal for monolithic and strip foundations (due to reinforcement welded to the formwork);

- simplicity of cladding (with a significant elevation of the base of the house above the ground);

- maximum rigidity;

- resistance to loads without deformation or bending;

- ease of installation work.

Steel formwork has the following technical characteristics:

- shield height - 0.6-3 m;

- their width is 0.25-1.2 m;

- frame turnover is up to 300 cycles, deck turnover is up to 80 cycles;

- deflection - no more than 1/400 of the span;

- concrete pressure - 75-80 kPa.

The frame of the panels is a closed circuit, for the manufacture of which 2 types of profiles are used: rectangular (for stiffeners) and edge (located along the perimeter of the panels). To create the deck, plywood is used, which is up to 2 cm thick.

Formwork for monolithic construction, area of application

Monolithic formwork is a structure in which poured concrete takes the desired shape. Available in removable and non-removable versions. Both the simplest and the most intricate structural elements are made from concrete using removable formwork:

- vertical - for walls, foundations;

- horizontal - for floors;

- creeping - for surfaces with a slope;

- rounded - for walls with any bending radius, columns.

Permanent formwork for monolithic construction is popular in private housing construction due to the minimal cost of time, labor and finances for construction, and practicality. Upon completion of the work, it remains inseparable from the concrete; the erected monolithic elements of the building are insulated and isolated from noise.