October 17, 2020 Stroyexpert Home page » Foundation » Materials and equipment

Boards for formwork

The basis of any structure is the foundation, the quality of which determines the strength and reliability of the entire structure. Almost all types of foundations are poured using formwork; any materials can be used for its manufacture. Developers with an unlimited construction budget and professional skills use plastic, metal and other expensive materials for this purpose. A budget option is wooden formwork, which is the most affordable and easiest to manufacture.

What kind of board is needed for formwork

To obtain a high-quality foundation, which will guarantee flawless operation of the house, it is necessary to correctly select the elements of the formwork structure, including boards.

Properly constructed formwork results in a reliable foundation with precise dimensions, appropriate location and good quality of the hardened surface. All this largely depends on the quality of the boards chosen for the construction of the formwork structure:

- For work, you can use edged or unedged boards, the main condition is that the side adjacent to the concrete is perfectly smooth. For this purpose, the material is planed and ground. The smooth surface of the formwork board will allow you to obtain a flat foundation surface, which greatly simplifies further work with the foundation.

- The thickness of the boards is determined by the volume of the concrete solution being poured; with an increase in the concrete mass, the thickness of the wood material increases. It should be remembered that a board that is too thin can become deformed, which will cause the formation of a wavy surface, which will be quite difficult to correct. Boards for the entire formwork must be chosen of the same thickness in order to obtain the necessary design accuracy. If some elements do not meet certain parameters, then they should be trimmed.

- As for the length of the boards, it is best to take material whose length exceeds the depth of the trench by 2.5-3 cm.

- The width of the boards is determined by specific working conditions. However, most often they use lumber whose width is 15-20 cm. Such boards are easier to install, and their cost is slightly less, in addition, a wide board can be deformed under the influence of concrete. Narrower boards can be used as long as they meet the length and thickness standards.

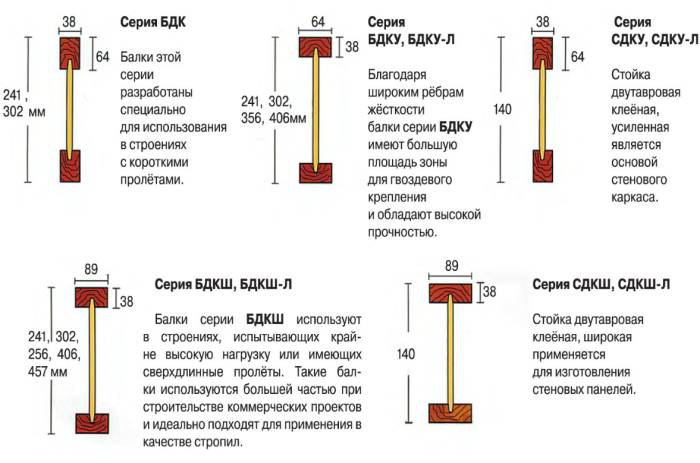

Main characteristics and types of beams for formwork

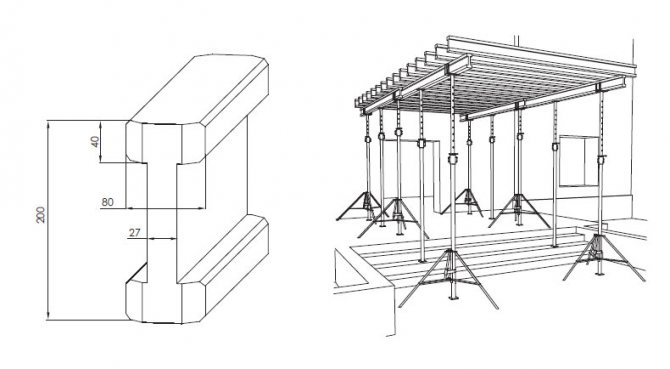

Currently, several types of beams are relevant. Among the most popular is the domestically produced beam – BDK-1. This element is made of timber, painted and treated with protective mixtures. In the standard version, the beam has the following parameters:

- length from 1.5 to 4.5 m;

- width - 8 cm;

- height – 20 cm.

Each beam has a shelf 4 cm thick and a shoulder width of up to 2.7 cm. Thanks to the design features and the material used, the finished beam structure can withstand a load exceeding 400 kN.

Beam for floor formwork BDK-1

The BDK-1 beam is made from LVL timber and coniferous wood, glued and treated with synthetic compounds that block the action of environmental factors and parasitic activity. The classic model of this type can be recognized by its characteristic yellow color and corresponding markings. According to GOST, the BDK-1 beam must have a high density (not lower than 450 kg/m3), the moisture content should not exceed 13%, and the weight should vary around 6 kg/linear m. In order for the finished system to meet all requirements, when assembling it, a maximum interval between beams should be maintained, which should not exceed 1.5 meters.

An equivalent analogue of the domestic BDK-1 is the N-20 beam, made of coniferous timber and having a plywood (FSF) core. The dimensions of the beam for formwork of this modification range from 1.8 to 4.5 meters; the formwork assembled on its basis can withstand loads of up to 500 N/linear m. A high-quality beam of this modification must meet the requirements of GOST 20850-84.

GOST 20850-84 Glued wooden structures

Beams are also distinguished by the material from which they are made; in addition to wooden – classic beams – there are beams made of aluminum and plastic. It is also possible to divide them according to operational characteristics. In this case, we can note leveling, load-bearing, forming, auxiliary beams, etc. Each variety has its own parameters, depending on size, design and material.

Material selection

Wooden formwork is a collapsible structure that, with proper care, can be used several times. However, when choosing boards, you should pay attention to the following:

Choosing board material

- The material must be resistant to cracking, so you should not opt for soft wood, including birch and other hardwoods.

- You should not use oak boards for formwork construction, since this material has high acidity, and concrete does not set well under the influence of such an environment.

- It is not rational to purchase boards made of valuable wood, since the formwork is disassembled and is very rarely used for reasonable purposes.

- For the same reason, you should not build formwork from first-class material.

Analyzing the listed factors, we can say that grade 3-4 pine boards are best suited for formwork construction.

The humidity of the material used is of great importance; in most cases this parameter should be equal to 25%. This value gives the following results:

- Dry material absorbs a very large amount of moisture from the concrete solution, which leads to a decrease in the strength of the foundation.

- A damp board absorbs cement laitance less, therefore, the material will not lose its quality characteristics and can be reused.

Features of constructing a foundation on a site with a slope

Construction on a slope is considered one of the complex processes, therefore the choice of the type of foundation and the calculations made should be approached very responsibly.

One of the features of constructing a foundation on a site of any complexity is the creation of a horizontal plane. This problem can be solved on a site with a slope if you smoothly change its height. You can achieve your goal using the following types of foundation:

- Traditional ribbon.

- Tape stepped.

- Pile.

Each type has its own construction features, as well as pros and cons.

A traditional concrete strip can be built on a site that has a slight slope. However, the mandatory presence of a horizontal bottom may cause additional costs for building materials. In this case, a stepped strip foundation comes to the rescue, which is quite suitable for construction on areas with a significant slope. If the construction site is characterized by a large slope and the presence of problematic soil, then it is best to build a house on a pile foundation.

Factors that determine the optimal thickness of lumber

When choosing the thickness of boards for formwork, many try to use thicker material, explaining this by greater reliability of the structure. However, in order to avoid overuse of building materials, it is important to know what factors affect the thickness of the formwork boards.

Formwork height and spacing between posts

As mentioned above, the main load comes from the concrete mass and the more of it, the more pressure the formwork experiences. The amount of concrete is directly proportional to the height of the base, therefore, the higher the foundation, the stronger the formwork should be. However, for greater structural strength, it is not necessary to take thick boards; it is enough to reduce the step between the vertical posts that are installed to support the formwork system.

For clarity, we can consider several examples showing the dependence of the thickness of the boards on the height of the formwork and the distance between the posts:

Formwork characteristics

- With a formwork height of 0.5-0.7 m and a pitch between posts of 0.3 m, the thickness of the board can be 19 mm. With a similar height, but a step increased to 0.7 m, a material with a thickness of 40 mm is required.

- If the base of the foundation lies at a depth of 1-1.4 meters, and the distance between the posts is 0.5-0.6 meters, then the optimal board thickness is 40 mm. Increasing the step to 1 meter at the same depth, the thickness of the board increases to 60 mm.

- A foundation with a height of 1.5-1.9 meters is poured into formwork from 50 mm boards, provided that the racks are located in increments of 0.6-0.7 meters.

Concrete load

Equally important when choosing the thickness of lumber is the dynamic load that occurs when pouring concrete mortar.

Concrete is considered a fairly dense and heavy mass, which, being inside the formwork structure, presses on the walls with a force of about 2500 kgf/m2. However, the load on the wooden formwork is not limited to this; a dynamic load is added to this value, which has the following meaning:

- The mass descending down the tray from the concrete mixer exerts a pressure of 400 kgf/m2.

- If concrete is supplied from a concrete pump, the pressure increases to 800 kgf/m2.

- A one-time supply of concrete from a concrete mixer with a volume of less than 0.8 m3 gives a load of 400 kgf/m2.

- With an increase in the specified volume, the pressure rises to 600 kgf/m2.

How to attach the film

Before concreting, the inside of the structure is lined with a durable polyethylene film for formwork, which must be secured with a stapler. Construction is best done using self-tapping screws. In this case, it can be easily disassembled, minimizing damage to the formwork boards.

Dmitrievich-50 member of FORUMHOUSE

After dismantling the formwork, I put a 30x120 mm board on the sheathing. Before this, I cleaned the surface of the boards from staples. The main thing is to disassemble everything carefully.

UKSUS70FORUMHOUSE member

My house roof is assembled from 40-gauge boards left over after pouring and dismantling the formwork. Before pouring, I covered it with film, I didn’t saw the boards sticking out in the corners, I assembled everything with self-tapping screws. After disassembling the boards were like new!

The film under the formwork will protect the boards, and they will be like new. Advice from FORUMHOUSE: the film must be secured in such a way as to prevent it from being turned out when pouring concrete into the formwork. They think in advance about which side the concrete mixture will be supplied from the concrete mixer. As it moves, it should not be poured under the overlap of pieces of film. Otherwise, the folded edge of the film may become monolithic across the foundation strip, which will reduce its strength characteristics. The film also minimizes the pouring of concrete through various cracks in the boards.

How to calculate the number of boards for formwork

To accurately determine the required amount of lumber, you can use the services of a construction company. But you can also perform calculations yourself, knowing the length and height of the formwork, as well as the approximate thickness of the material.

We calculate the number of boards for formwork

For example, the total length of the formwork is 100 meters, its height is 0.7 meters. For this height, it is recommended to take boards 0.04 meters thick. Knowing all the parameters, it is easy to calculate the required volume of lumber:

100*0.7*0.04=2.8 m3

Considering that any material should be taken with a small reserve, it is necessary to purchase 3-3.5 m3 of material.

Areas of application

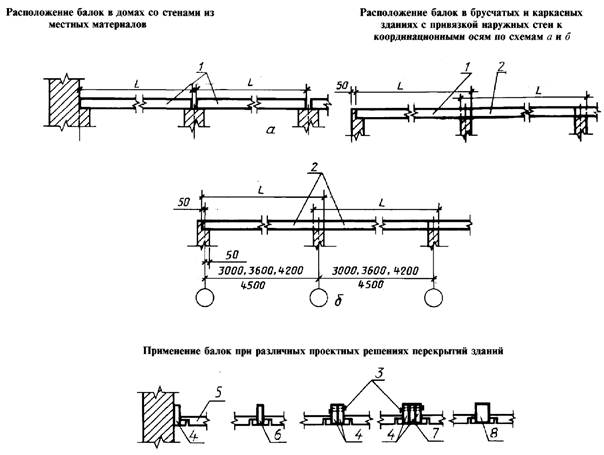

Each type of beam has a specific area of application for which its characteristics are best suited:

- a classic version of formwork with a wooden I-beam - used for pouring floors, walls, roofs, columns, etc.

- metal (steel) beams are preferable when forming structures that are designed for loads exceeding the maximum permissible for systems formed from wooden elements.

- aluminum beam - applicable for the construction of volumetric structures whose functions are leveling.

Application of Wooden I Beam

Let's find out what formwork is!

The term formwork is not related to shipbuilding, although its name may seem so. The fact is that in the old days a deck (with the emphasis on the first syllable) was a bent flooring made of strong planked logs; it was used as a support when laying vaults and ceilings made of stone blocks. The principle of operation of modern formwork remains the same - it serves for the precise formation of monolithic structures of various weights and shapes, sometimes very heavy and intricate.

Wood, metal and their combination are used as the starting material in the manufacture of formwork. Metal structures can be permanent - that is, after pouring the concrete mixture, they are walled up in the structure being built and become part of it . Wooden formwork must be disassembled after the concrete has hardened - even if it is planned to be decorated outside with the same wood .

The specialists of the site REMOSKOP.RU have prepared a special calculator for you : Formwork calculator . You can easily calculate the formwork.

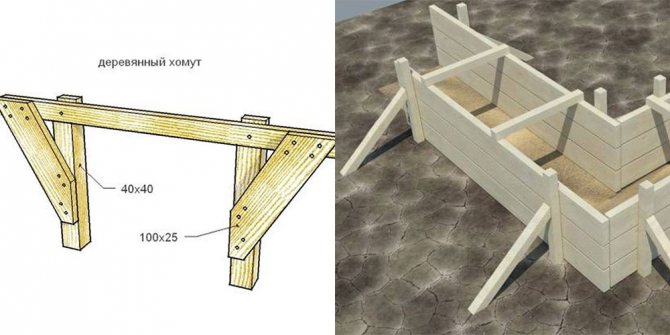

The quality of monolithic construction depends on the quality of formwork structures - the accuracy of its dimensions, position in space and even the texture of the surface of hardened concrete. Any formwork system, from homemade to industrially complex, consists of a maximum of three required parts:

- Forming elements are flat load-bearing surfaces that limit the liquid concrete mixture and shape it;

- Supporting reinforcement - this includes telescopic rods for supporting floor slabs and small supports when making a foundation for a fence made of corrugated sheets or concreting a base;

- Fastening parts - locking devices for external fastening of formwork parts to each other and internal fasteners (for example, steel wire tightening opposing boards or sheets). The internal fasteners are embedded in the concrete layer as an additional reinforcing element.

If the formwork is assembled inaccurately, subsequent correction of the monolithic structure is either incredibly labor-intensive or completely impossible in engineering terms.

The quality of installation of formwork structures, their strength and reliability is given great importance in industrial, civil and personal construction.

What does formwork consist of?

The structure includes the following elements:

- Boards made of boards;

- Struts;

- Fasteners;

- Brackets;

- Beams.

Depending on the structure in which formwork is involved in the installation, panels can be produced in one of three types of designs:

- Vertical – suitable for building walls. They have a symmetrical structure, thanks to which they can be installed in any position. Usually assembled into a long section using wedge locks;

- Corner - located in the corners of the structure, connected to vertical panels using locks. Can be reinforced with beams for greater stability;

- Universal - used for installation of any building structural element. Similar to the vertical one, but equipped with special holes for connection with other panels.