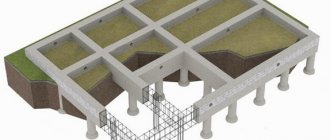

Pile grillage or strapping beam - This is an iron or reinforced concrete structure that connects all the upper parts of the foundation piles. The tops are also called pile caps. The grillage has several purposes: - the house itself is installed on its surface; — uniform distribution of the load of the house on all piles is ensured; — all the piles are tied together, which ensures a more reliable foundation. It should be noted that relatively light houses of one or two, maximum 3 floors can be installed on a pile grillage. As a rule, such houses are made of timber, logs or panels.

Depending on the materials used, there are two types of grillages: concrete and metal. Concrete grillages can withstand heavier loads. Metal grillages are quickly installed, but their service life is shorter due to corrosion of the material. At their core, concrete grillages are similar to a strip foundation, only for a strip foundation the role of formwork is played by a trench in the ground, and to create a concrete grillage it is necessary to erect wooden formwork. Also, creating a concrete pile grillage will cost more than installing a strip foundation, so materials must be calculated in advance. However, the pile grillage is not affected by heaving forces, therefore such a foundation is more stable compared to a strip foundation.

What is a grillage in construction

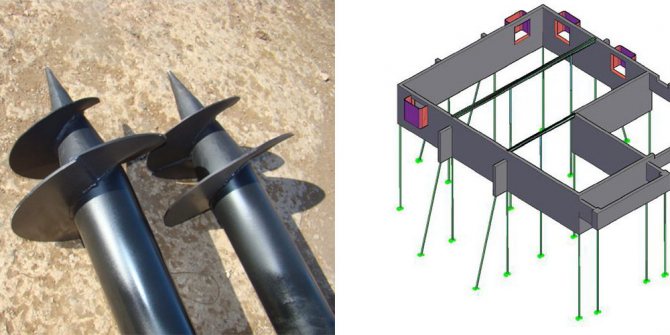

Among the various types of foundations, grillage is widely used. Grillage – what is it? This question is often asked by novice builders. Let's figure out what the grillage base of the building is. Experienced developers, when constructing houses on screw piles, combine the upper parts of the supports with horizontal beams. As a result, a single power circuit is created - a grillage, which has increased strength and rigidity. In the formed foundation, the load from the mass of the structure is carried by pile supports of the grillage structure.

The main purpose of the power harness:

- ensuring a fixed position of foundation supports;

- uniform distribution of loads transmitted by the building to the columns.

- formation of a reliable supporting surface for the construction of walls and partitions.

A grillage is a horizontally located part of a pile foundation that receives and transfers the load from the walls of a building to the piles. A

similar structure, consisting of screw or reinforced concrete piles united by a horizontal belt, is widely used in the construction of one-story buildings on various types of soils, including soils with a high concentration of clayey soils particles, sand and moisture.

The grillage base has a set of serious advantages:

- allows the construction of buildings on problematic soils;

- ensures the stability of buildings;

- does not require labor-intensive excavation activities;

- does not depend on the depth of the aquifers.

Along with its advantages, the pile-grillage foundation also has weaknesses:

- the complexity of the construction of the basement, the main dimensions and dimensions of which are related to the design of the grillage and the height of the protruding parts of the supports;

- the need to use special equipment to install the supporting elements of the foundation base into the ground.

When constructing pile foundations, in order to increase their load capacity, it is advisable to combine the protruding parts of the supports with a force belt. After all, the foundation is loaded with the weight of the roof, walls, ceiling, and household appliances. Estimates for the construction of a grillage base are always lower than for the construction of a strip foundation.

Depending on the type of foundation and the geological structure of the soil, the grillage may differ

When understanding what a grillage is in construction, study its classification. The grillage foundation is classified according to the following criteria:

- location level;

- the material used for construction;

- design features.

Let us dwell in detail on the features of each type of grillage.

Installation of a monolithic grillage

The construction of a monolithic grillage repeats the technological operations of laying supports according to the principle of columnar and pile foundations and pouring a tape encircling the heads of the pillars. However, there are some distinctive features.

The base for the pillars provided for in columnar foundations is not laid unless specified in special design solutions. Backfilling at ground level is carried out immediately after removing the formwork from pouring the columns or in two stages for low grillages: upon completion of the construction of the columns and after removing the formwork from the monolithic foundation strip.

Laying supports

Measures for marking and determining the location of pillars when installing a grillage are similar to those described in the section of another article “Marking a columnar foundation”. After completing these works, pits are developed and, if necessary, a sand or gravel bed is arranged.

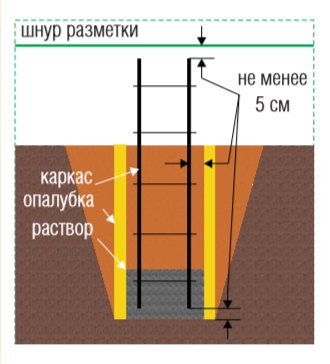

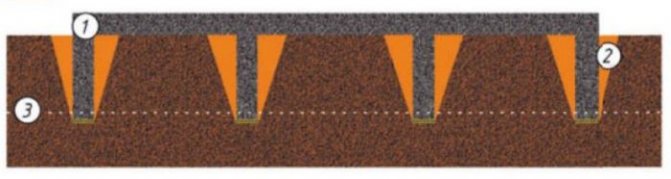

Then they reinforce (1), install formwork (2) and pour the concrete mixture into the box (3).

At this stage, after laying the first layer of mortar 20–30 cm thick, the reinforcement frame is slightly raised so that the lower end does not touch the bottom (cushion), and the upper end is at least 5 cm away from the marking cord.

Therefore, the height of the frame should be 10 cm less than the distance from the bottom (cushion) to the marking cord. After the concrete has hardened, the formwork is dismantled and backfilled.

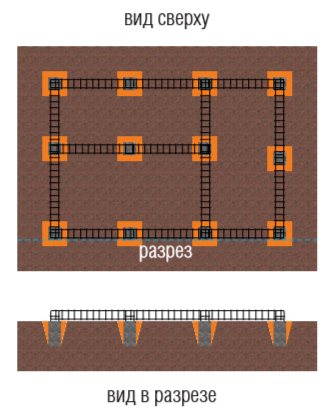

Construction of the tape part of the grillage

Before laying the strip part of the grillage, reinforced frames are installed, taking into account a distance from the bottom and walls of the formwork of at least 5 cm.

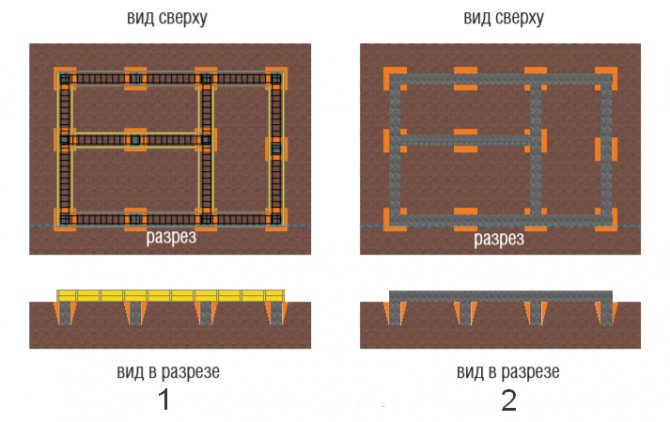

Then the formwork (1) is constructed and the concrete mixture (2) is poured.

Installation of formwork, pouring concrete, dismantling formwork and curing the concrete mixture are carried out according to the recommendations set out in the subsection “Concrete work” for strip foundations.

Types of grillage by location

When planning to build a grillage foundation for a frame house with your own hands, decide on the level of location relative to the zero mark.

The following options are possible:

- hanging foundation belt;

- towering grillage;

- shallow base.

Let's look at each variety.

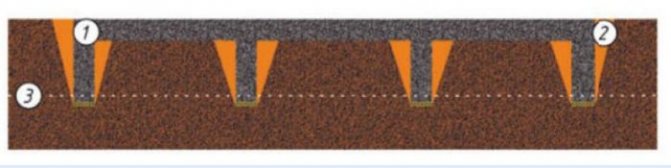

Rising above ground level

A distinctive feature of a high grillage is the location of the bottom of the tie belt above the ground surface at a distance of 10–15 cm, which allows:

- build a raised grillage base on problematic soils;

- eliminate the influence of frost heaving forces in the soil;

- avoid the development of dampness by ventilating the space under the building;

- maintain the position of the foundation supports during movements of soil layers.

There is another serious advantage of the elevated power contour - a gravel-sand cushion for the foundation of a high structure is not required, since it is located above the zero level and does not contact the soil.

Design disadvantages:

- increased level of heat losses due to the penetration of cold air masses under the building’s foundation;

- the need for enhanced thermal insulation of the floor in contact with cold air;

- increased level of costs associated with the need to install protective shields of a decorative base along the contour of the building.

If you want to build a high grillage belt, figure out how to properly make the base of the house in order to reliably protect the lower part of the building and the floor from cold air currents.

Located at zero

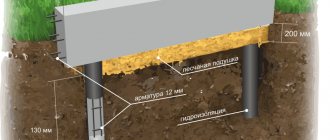

The grillage base, located at the same level with the soil, is erected quite often. The binding belt is based on a sand-crushed stone cushion with a thickness of 15–20 cm. Backfilling is carried out after the soil has been removed under the lower plane of the grillage. The main feature of the design is the damping cushion.

Refers to this type if its sole coincides with the soil level mark

She performs important tasks:

- prevents the negative impact of frost heaving of the soil;

- does not allow melt water and sediment to accumulate under the grillage base;

- seals the gap under the horizontal beam of the grillage.

To increase the strength characteristics of the structure and protect it from moisture, reinforcement and waterproofing are performed. It’s easy to make a raised grillage with your own hands. Step-by-step instructions will help you cope with the task.

Buried in the soil

The power structure connecting the upper parts of the supports is located below the zero mark. The construction technology involves the following work:

- Preparation of a pit located between the support columns.

- Leveling the base of the trench.

- Adding a gravel bed.

- Installation of panel formwork.

- Assembly and installation of reinforcement grid.

- Pouring concrete solution.

The pile heads are concreted during the process of pouring the load-bearing frame. To increase the service life of a buried grillage, it is important to reliably protect it from the influence of precipitation. Figure out how to make a blind area around the house correctly. Concrete edging along the contour of the house, made with a slope, will ensure effective removal of moisture from the grillage foundation.

The main difference between this option is the location of the tape below ground level

Types of grillage foundations

These bases are classified according to materials, location (degree of depth), and type of structure.

What is a grillage made of?

This power belt is made of various materials, and the choice depends on the properties of the local soil and the characteristics (size, number of floors, walls, etc.) of the building being constructed. To construct such a harness use:

- wood - beams, logs;

- metal - I-beam, channel;

- concrete or reinforced concrete.

In the latter case, a formwork is made for the grillage into which the solution is poured.

Wooden structure

Wood is most often chosen for the same houses and piles. A wooden grillage needs protection, so a waterproofing layer is required: for example, roofing felt or roofing felt laid in several layers. The wood is pre-treated with bio- and fire-retardant compounds. The material is fixed with bolts or brackets.

The most common option is to construct a grid of timber on a columnar/pile foundation. The disadvantage of this solution lies in the properties of wood. An eco-friendly, natural material cannot be called the most reliable and durable, so wooden grillages are often used to build gazebos, small extensions to a residential building, and canopies.

Metal grillage

Such sheathing is made from a profile - from square pipes, I-beams, channels, etc. In this case, there are no complaints about the strength or reliability of the material, so the structure turns out to be quite rigid. This type of grillage is used in the construction of one-story buildings, as a framework for pile-screw foundations of frame houses.

The elements are connected by welding. Metal grillages on piles are not used very often now, since the lattice structure is heavy, which means that the help of special equipment is necessary. This solution is simply unprofitable. Another “Achilles heel” of metal is the risk of corrosion; it is unlikely that it will be possible to avoid this process.

Monolithic belt

Power piping made of reinforced concrete is an optimal design, practically free of disadvantages. It is reliable, extremely strong and durable, capable of withstanding severe loads thanks to the reinforcing belt laid in the formwork before pouring concrete. The reinforcement is made of steel rods connected together by welding (knitting wire).

A replacement for rods is ready-made spatial reinforcement cages. Concrete structures without reinforcement are not as reliable. Therefore, their use is limited to the construction of one-story buildings, but this option is not very common due to the insufficient strength of the unreinforced grillage. The maximum number of supporting elements will help minimize the risk of cracking of the concrete frame.

Grillage location

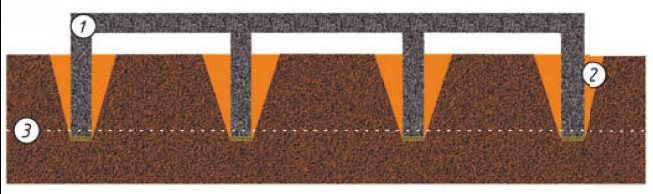

There are three options for grillage foundations: raised, recessed and high - hanging.

Non-buried

This type of construction is optimal from the point of view of foundation stability. The base of such a grillage belt is level with the ground, so the load is distributed evenly - on the frame and piles. The base is built on a bed of sand and crushed stone, the total thickness of both materials is 150-200 mm. Such a damper protects the foundation from frost heaving of the soil and from the accumulation of precipitation.

Recessed

This option involves placing the base of the tape significantly below ground level: the thickness of the cushion is 200 mm, the foundation is also buried 200 mm into the ground. In this case, a pillow must also be poured into the dug trench. This method is contraindicated for heaving soils, since their rise will provoke the squeezing of the grillage out of the soil. This may lead to the destruction of its connections with the supports.

High

The minimum distance between the ground and the hanging grillage is 100 mm. This is the best option for areas with “unquiet” soil, in those regions where humidity is high. The main advantages: no contact with the ground, ventilated space under the building. Disadvantages: the need for the most durable supports, heat loss, requiring very high-quality floor insulation. The construction of a basement is required, which means a large amount will be required that will be spent on construction.

For non-recessed and recessed structures, concrete (reinforced concrete) remains the optimal material for grillage. For hanging structures, a slight expansion of the “range” is possible: wood or a metal profile is used for their construction. But there is a limitation: with such a grillage, the construction of small buildings with only one floor is allowed.

Types of grillages

There are three types of structures that are used in the construction of various buildings. It is possible to construct a prefabricated, solid or combined grillage.

- Prefabricated metal structure. It consists of a profile assembled (welded) into a single structure. This option is usually used to create a foundation for temporary structures. The reason is a limited service life (about 20 years) due to unreliability and insufficient rigidity.

- The grillage-monolith is a solid reinforced concrete part of the foundation. It is made directly at the construction site. The most popular is the simple and economical strip type of foundation, used for low-rise buildings, but the monolith is indispensable where the soil is not stable.

- Combined option. The nodes for it are ready-made elements that can be purchased separately. They are assembled into the frame on site, then concrete is poured into the strip. This type of structure is used in industrial construction, for the construction of multi-story buildings, because such a grillage will require large investments, precision during installation, and the presence of special equipment.

For private low-rise construction, only 2 options are suitable, but one of them does not guarantee the durability of the structure. It is for this good reason that the only candidate left is a reinforced concrete grillage. It is better and easier to build a ribbon - the design is simple and not as demanding as a slab, financially.

Classification of grillage according to the type of building material used

Let's consider what material a grillage can be made from. Various building materials are used to make grillage frames:

- concrete reinforced with reinforcing mesh;

- rolled metal of various sections;

- dried and processed wood;

- branded concrete without reinforcement.

The strength characteristics of the structure must correspond to the calculation of the pile grillage. Let us dwell on the features of using various materials.

Monolithic reinforced concrete grillage

In terms of performance characteristics, reinforced concrete structures are stronger than concrete ones.

The reinforced concrete grillage, thanks to its durable reinforcement grid, has the following advantages:

- increased load capacity;

- long period of operation;

- high level of reliability;

- sufficient rigidity;

- ability to withstand increased compressive loads.

For reinforcement, steel rods connected into a common frame, as well as ready-made spatial gratings, are used.

A monolithic grillage is a one-piece structure that is poured directly on the construction site

Metal construction

A power belt made of rolled metal allows us to provide the required safety margin. The construction technology involves performing the following operations:

- Cutting blanks from channel or I-beam.

- Installation of profiled steel at the ends of columns.

- Welding individual beams into a common contour.

Apply a protective coating to improve corrosion resistance.

Wood grillage base

The strength of wood allows it to support the mass of light wooden or frame buildings. To ensure the durability of wooden beams:

- dry the material thoroughly;

- saturate the wood with antiseptics;

- waterproof the surface of the beams with roofing felt.

The service life depends on the quality of the material preparation.

Concrete grillage

The sequence of actions for arranging a grillage foundation made of concrete is similar to the construction of a reinforced concrete belt. The main difference is the concreting of the load-bearing frame without reinforcement cages. The susceptibility of concrete to tensile forces and bending moments limits the range of use of a concrete grillage.

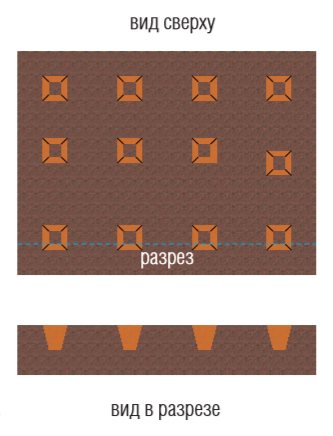

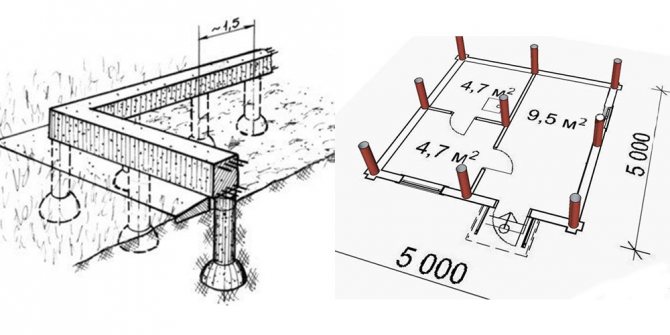

Calculation of the number of piles for the foundation

The reliability of the erected structure largely depends on the correct calculation of the number of supports and the distance between them, since they take on the main load and distribute it. When making calculations, it is necessary to take into account:

We count the number of piles

- The approximate weight of the structure, including floors, walls, ceilings and cladding.

- Payload from furniture, appliances and occupants. Most often, this parameter has a constant value: for multi-story structures - 200 kg/m2, for residential one-story buildings - 150 kg/m2.

- Load from snow cover in winter. This value is also constant; in most regions it is 180 kg/m2.

- The safety factor, which in most cases is equal to 1.1 (a factor of 1.2 is very rarely used).

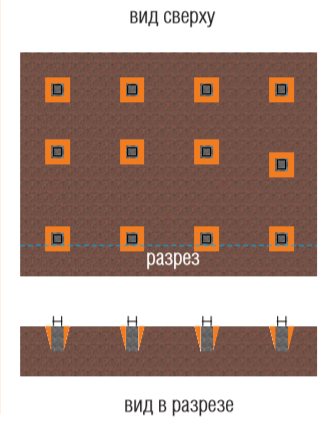

For example, you need to calculate the number of piles and the pitch between them for a building one floor high and 6*8 meters in size:

- We determine the weight of the structure; for example, we can take 29,500 kg.

- We calculate the total payload; for this, we multiply the value indicated per 1 sq.m. by the area of the house: 6*8*150=7200 kg.

- Let's find out the amount of snow load taking into account the area of the house: 6*8*180=8640 kg.

- We determine the total load on the base; to do this, we sum up the load of the structure, the payload and the snow load: 29500+7200+8640=45340 kg.

- The resulting value must be multiplied by a safety factor of 1.1: 45340*1.1=49874 kg.

- Taking into account that on average one pile can withstand a load of about 2000 kg, we determine the required number of piles. To do this, it is enough to divide the value of the total load, taking into account the safety factor, by the possible load on one pile: 49874:2000=24.937.

Counting steps between piles

When rounding this number, we find that for a one-story house with an area of 48 sq.m. 25 piles are needed. To this amount you need to add piles that will support the floor joists inside the foundation.

The step between the supports of the pile foundation is determined to be 1.2-1.5 meters.

Structural types of foundation with grillage

The classification provides for the division of grillages into types depending on the design. Possible options:

- prefabricated structure. Consists of profiles welded together. The service life is limited to two decades due to insufficient rigidity. The prefabricated version is used for temporary buildings;

- one-piece grillage. It is formed from concrete mortar reinforced with a reinforcement cage. Ensures the stability of low-rise buildings on problematic soils;

- combined version of the grillage base. Includes factory-fabricated components. They are assembled into a single load-bearing frame and concreted. The design is used in industrial construction.

The choice of the optimal option is determined by the requirements of the project.

Constructive decisions

The design can be classified according to the manufacturing method:

- prefabricated (more often used if the foundation is made of screw piles or for wooden buildings);

- monolithic (this solution is suitable if the foundation is bored or precast concrete);

- prefabricated monolithic.

Prefabricated structures include wooden and metal grillages. The monolithic version is made of concrete or reinforced concrete. In addition, the monolithic grillage is divided into:

- monolithic tape;

- monolithic slab.

Tape is the most common option. In poor geological conditions and strong soil movements, a slab grillage is designed along the edge of the foundation. It gives the structure additional rigidity, but is characterized by high cost and labor intensity.

Slab grillage.

An intermediate option between prefabricated and monolithic is the prefabricated-monolithic option. It consists of prefabricated elements that serve as formwork and are filled with concrete mixture. This solution is not widely used due to its high cost.