In the field of individual construction, when using a pile foundation, a monolithic reinforced concrete grillage is the most popular option, since even with significant dimensions it can always be made on your own.

The materials used for this can be delivered to the construction site by ordinary freight or even passenger transport without the use of special platforms or cranes.

However, the installation of a monolithic grillage is more complex than a prefabricated grillage, and the main difficulty lies in the correct reinforcement of the pile grillage.

What is a grillage?

For those who do not know construction terminology, we inform you that the grillage is an important part of the pile foundation, connecting the pile heads into a single power circuit.

There are different types of grillages used in pile foundations:

- tape type, representing a monolithic concrete tape. It is located along the perimeter of the supports, successively located under the load-bearing main walls;

- slab structure, in the form of a monolithic slab, the dimensions of which correspond to the contour of the base of the building and cover all supports.

The grillage is a ribbon structure connecting free-standing piles to each other

Depending on the characteristics of the grillage foundation, it can be manufactured in the following versions:

- Whole version.

Manufacturing is carried out by pouring concrete mortar into pre-prepared formwork. The formation of a monolithic base occurs after the concrete mixture has hardened. - Composite form.

The base is a prefabricated surface made of industrially produced reinforced concrete products, connected during installation with supporting columns, as well as with each other.

Regardless of the design features, the grillage forms a supporting surface intended for the construction of the walls of the building. The tying of columns located in the ground ensures high rigidity of the spatial system and resistance to the effects of existing forces.

Reinforcement of a pile-grillage base allows you to strengthen the monolithic base with steel rods, which contribute to the integrity of the structure and increase durability.

Installation of a monolithic grillage

To make a monolithic grillage foundation, you will need to perform several stages of work.

- Installation of formwork.

- Grillage reinforcement.

- Concreting.

- Stripping.

- Waterproofing tape.

Installation of formwork

The grillage foundation is made suspended or buried in the ground. The design of the formwork directly depends on its shape.

Regardless of the design, the side walls of the formwork must be assembled at a strictly vertical level, and the angles must be 90°, unless the design provides for a different design.

When making a tape in the ground, you can use soil instead of formwork as a support for the future foundation. Above ground level, formwork is usually assembled from boards or plywood. It is knocked together or pulled together in such a way that the concrete does not squeeze out the boards and does not spread during the process of laying it. That part of the foundation that protrudes above the ground will be protected by such a structure.

If a hanging version of the grillage is chosen, then it is necessary to provide a high-quality foundation in the formwork. It needs to be calculated based on the load it must withstand. The load is determined by the mass of concrete and reinforcement. It is also necessary to take into account the mechanical effects on the structure from vibration of concrete during the pouring process.

The side walls of the formwork must be firmly assembled. For this, transverse ties, spacers, tubes with studs and other materials can be used that will ensure the reliability of the structure.

Poor quality formwork can lead to failure of the concrete laying process. This is unacceptable in construction, but often occurs due to negligence in this part of the work.

Grillage reinforcement

Reinforcing the grillage of a pile or columnar foundation is one of the most critical stages in constructing the foundation for a building.

Periodic metal reinforcement is used as the main material for reinforcing foundations. Recently, it has begun to be replaced with composite fiberglass. It is worth noting that fiberglass reinforcement is not suitable for hanging structures. It is good where there is support on the ground.

Reinforcement is welded into beams

The reinforcement is tied or welded in some cases into frames, so-called beams. There are several types of beams. The type of reinforcement, and therefore the type of beams, is determined at the design stage.

During self-construction, when there is no project and there is no opportunity to contact specialists, there is an option to use an online reinforcement calculator. It is advisable to find several such online programs on the Internet and make calculations in each in order to compare the data and determine the error in the calculations. Having calculated the reinforcement based on the entered foundation parameters, you can begin work.

The reinforcement of a monolithic grillage in its most common form consists of straight longitudinal and transverse rods, which are connected to each other by binding wire or welding. In order to properly connect the structure, clamps and U-shaped products are made from reinforcement. They are connecting elements in the nodes of the reinforcement frame.

To find out how reinforcement frames and their assemblies are correctly manufactured, you need to familiarize yourself with the manual for the design of concrete and reinforced concrete structures made of heavy concrete (without prestressing).

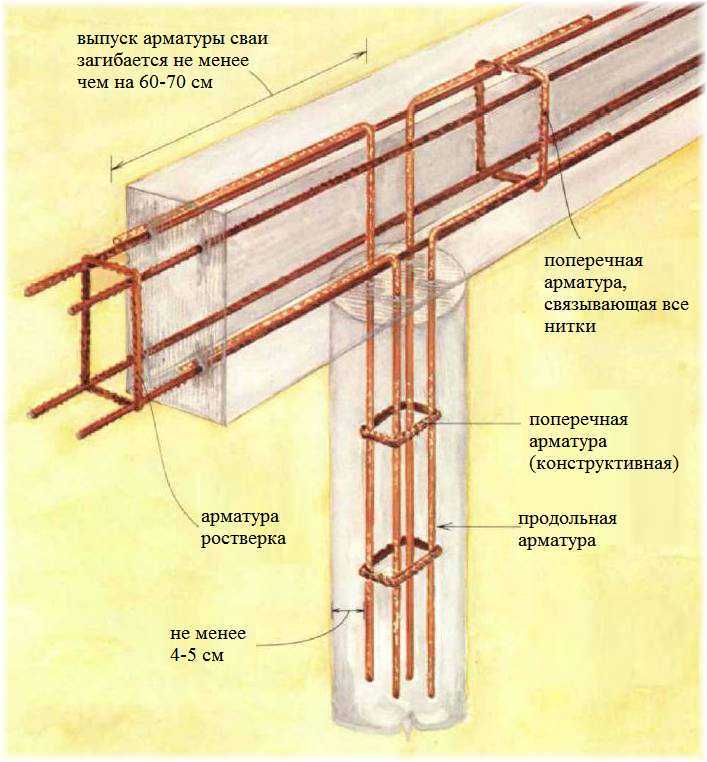

Reinforcement of pile-grillage foundations is impossible without connecting the pile reinforcement to the grillage frame. When constructing a pile field at the reinforcement stage, vertical rods are made with allowances in height. When installing the reinforcement frame of a strip foundation, the rods released from the piles are bent at the required horizontal level and connected to the main frame. Thus, the integrity of the structure is achieved. For all the details on pouring a pile-grillage foundation, see this video:

You cannot heat metal reinforcement in order to bend it. For bending it is necessary to use special devices or a pipe bending machine.

Concreting tape

The grillage foundation is poured with concrete at the same time without interruption in the work until it is completely completed. It is strictly forbidden to make breaks along the length of the foundation. The only permitted action is a gap in the height of the grillage. After pouring a 150-200 mm layer over the entire volume of the tape, a break in work is taken.

Before continuing construction work, it is necessary to wait until the concrete reaches the minimum permissible strength. Then you need to clean off the top layer, the so-called concrete milk, and only after that continue concreting the tape.

It is important to carry out the work so that there are no pores in the concrete mass. It is required that the concrete fills the entire space in the formwork. There should not be a single air pocket left inside the grillage.

Stripping

You can neglect this process once and carry it out ahead of time in order to incur losses that will significantly affect the construction budget.

If the formwork is removed prematurely, the foundation may crack, which will leave virtually no options other than dismantling it. In this case, a new foundation will be required, and accordingly construction costs will increase significantly.

Concrete gains strength depending on its grade and ambient temperature. The ideal temperature is 20°C; in such conditions, concrete grades M200-300 will gain 100% strength in 28 days.

Data on concrete strength gain are presented in the table.

| Percentage of concrete strength depending on temperature | |||||||

| Concrete grade | Hardening time, days | -3°C | 0°C | +5°С | +10°С | +20°С | +30°С |

| 1 | 3 | 5 | 9 | 12 | 23 | 35 | |

| 2 | 6 | 12 | 19 | 25 | 40 | 55 | |

| M200-300 on Portland cement M-400 and M-500 | 3 | 8 | 18 | 27 | 37 | 50 | 65 |

| 5 | 12 | 28 | 38 | 50 | 65 | 80 | |

| 7 | 15 | 35 | 48 | 58 | 75 | 90 | |

| 14 | 20 | 50 | 62 | 72 | 90 | 100 | |

| 28 | 25 | 65 | 77 | 85 | 100 | — |

The table shows that at low temperatures it is advisable to use concrete with additives to quickly gain strength. This slightly increases its cost, but will also significantly speed up the construction process.

It is allowed to remove the formwork when the concrete has reached at least 50% strength.

Waterproofing tape

With a hanging grillage, you can use coating waterproofing. In the recessed version, it is possible to lay roll waterproofing in the ground before pouring concrete and, after stripping the upper part, completely cover the foundation with it. For more information about waterproofing a grillage structure, watch this video:

It is important to protect the base from moisture. If the foundation absorbs water, then in winter at subzero temperatures, microcracks will form in it during the expansion of freezing water. This must be avoided.

Design features

To form a strip foundation located on piles, grillages are made at different heights relative to the zero level. Depending on the location of the contour relative to the ground level, the following types are distinguished:

- high, the lower mark of which exceeds the ground level by 10 cm or more. Constructed for light buildings located on any type of soil. On problem soils, its device is especially important. The structure needs serious strengthening with reinforcement, which is due to the presence of cavities under the concrete monolith located above the ground surface;

It is in the case of installing a monolithic pile grillage, which is used in the construction of houses made of heavy materials, that it is necessary to reinforce the strapping

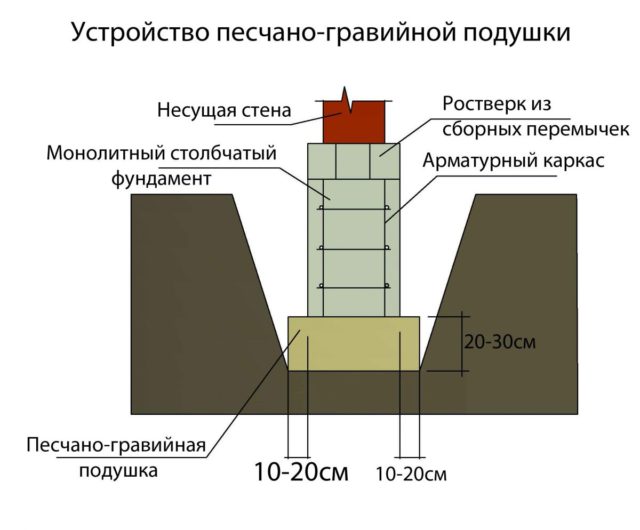

- ground version, made on a gravel-sand backfill without penetration into the soil. Its peculiarity is the absence of free space between the concrete monolith and the ground. Installation is carried out on non-problematic soils. When the soil is exposed to frost heaving, cracks may form and the hardened concrete mass may separate from the supporting columns;

- shallow type, formed by burying the lower part into the soil on a previously prepared sand and gravel backfill. The design of such a foundation resembles a strip foundation, the base of which rests on piles. The formation of a buried foundation is associated with significant costs and is used for the construction of massive buildings located on soils characterized by low bearing capacity.

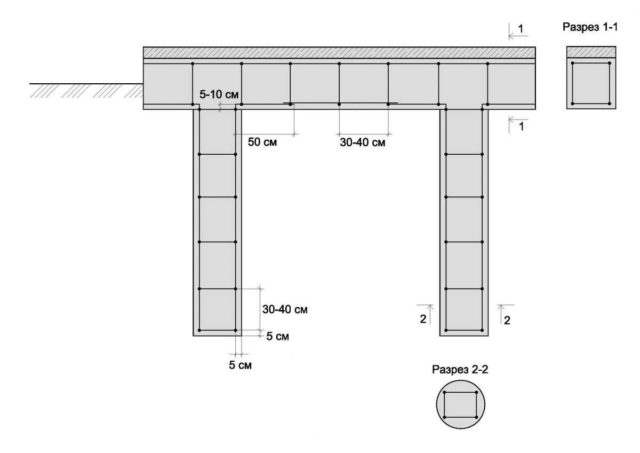

Pile-type foundations are formed mainly for light buildings. That is why the construction of a grillage foundation is quite common, the base of which is a hanging ribbon of concrete reinforced with steel reinforcement. With a base height of up to 40 cm, its width depends on the type and size of the material used to build the walls, and is 30-40 cm.

Application of pile foundation

Pile foundations are widely used in industrial, civil and country construction.

The prerequisites for the construction of this type of structure are:

- Weak soils at the construction site, namely:

- clay, loam;

- quicksand;

- peat and silty soils;

- places with high groundwater levels;

- wetlands, flooded areas;

- soils with a large freezing depth, more than 2 m.

- Desire to save money - if, when calculating a strip foundation, its width turns out to be more than 1.5 m, a pile foundation can be used to reduce material consumption.

- Construction sites with uneven surfaces and slopes.

On the feasibility of reinforcement

The need to strengthen the foundation of a building with steel reinforcement is related to the characteristics of concrete. The material has increased resistance to compressive forces, but is susceptible to bending moments and tension, which cause disruption of the integrity and deformation of the base.

Note that foundations that use two types of piles are subject to reinforcement: driven and bored.

Reinforcement of a pile-grillage structure allows you to prevent the likelihood of destruction, increase the stability and service life of the building being constructed. The reinforcement frame located inside the concrete mass absorbs tensile loads and bending forces, ensuring the stability of the constructed foundation.

Regardless of the design of the piles used, located inside the soil, the supporting columns are also reinforced with reinforcement. The steel rods located in the piles are connected into a common structure with the reinforcing frame of the supporting surface.

Reinforcement of the pile foundation grillage allows:

- Prevent destruction of the monolithic massif as a result of soil reaction.

- Significantly increase the strength of the base, which absorbs the load from the mass of the structure.

- Prevent shrinkage of the structure caused by low strength characteristics of the base.

Strengthening the grillage foundation allows you to avoid negative phenomena.

Advantages of slab foundations

A monolithic slab with a grillage, as a supporting structure for the base of a building, has increased strength characteristics, is reliable and is highly resistant to possible ground vibrations. The foundation slab is erected in a short time; even non-specialists with minimal knowledge of construction can handle this work.

The resistance of the monolithic slab to humidity allows you to equip a building with a basement protected from flooding and destruction from the effects of groundwater.

All materials for the construction of a monolithic foundation slab can be purchased within walking distance.

Specifics of reinforcement

Reinforcement of the pile foundation grillage is carried out by a pre-fabricated volumetric frame, consisting of two tiers of rods, combined into a single structure using steel lintels.

Reinforcement of the strip grillage is carried out using a spatial reinforcement frame consisting of two longitudinal reinforcement belts

For the longitudinal chords of the frame, corrugated rods are used, produced by the hot-rolled method, which corresponds to class A3 reinforcement. Depending on the load perceived by the base, the diameter of the rods is 12-16 mm.

The combination of connecting elements located in the vertical and horizontal planes into a common power circuit can be carried out:

- separate steel corrugated rods of rectilinear shape, the diameter of which corresponds to the range of longitudinal reinforcement;

- steel clamps of rectangular configuration, made of smooth rods of class A2 with a cross-section of up to 10 mm. Despite the increased complexity of manufacturing and installation, rectangular jumpers ensure the reliability and durability of the reinforcement structure.

When strengthening a strip foundation placed on piles, adhere to the following recommendations:

- Use at least 4 rods located in the upper and lower tier of the strip contour frame, ensuring an interval between elements of 10-15 cm.

- Maintain a distance of 15-25 cm when installing jumpers in the longitudinal belt.

- Ensure the pitch of the vertically located frame jumpers is 30-40 cm.

The amplification of the grillage begins after all the previous stages of arranging the pile foundation have been completed - installation of piles, their trimming and arrangement of formwork

- Fix the metal frame structure, ensuring a distance of at least 5 cm to the concrete surface being formed.

The need for a protective layer between the metal frame structure and the concrete surface of the grillage is determined by the following factors:

- the need for proper distribution of the current forces by the metal structure of the frame;

- the susceptibility of reinforcing bars to corrosion processes arising from moisture penetrating into the concrete.

Maintaining a fixed distance from the reinforcement to the formwork while providing a protective layer is achieved by using stands made of plastic.

Strip foundation on a recessed slab

In projects with an underground floor, the height of the strip part of the slab foundation reaches 2 - 2.5 meters. This complicates concreting in one go due to large volumes of mixture. Therefore, step-by-step filling technology is often used. Vertical lintels are prohibited from being mounted in corners, and reinforcement must not be cut to install panels. Therefore, panels with cuts are used, into which rods are passed, and the remaining cracks are filled with polyurethane foam.

When concreting in stages, the next section can be poured after the previous section has gained 50% of its strength. The joint area is cleaned with a metal brush, steam, or a grinder. All film from the surface of hardened concrete must be completely removed.

Due to large volumes of concreting, formwork requires a lot of lumber and plywood. When treating the inner surface of the boards with polyethylene film after stripping, these materials can be used in the future (partitions, subfloors, roofing, rafter system).

At this height of the tape, two reinforcement belts are no longer enough; more belts are added every 50-70 cm in the middle part. At the same time, the size of the clamps increases; additional elements may be required to ensure a stable geometry (gaskets on the sides for a protective layer).

Calculation method

To determine the need for reinforcement that allows for the reinforcement of the pile foundation grillage, it is necessary to first develop a drawing. The documentation contains the following information:

- Design dimensions.

- Number of reinforcement belts.

- Reinforcement profile.

- Diameter of the rods used.

- Distance between jumpers.

Scheme of correct reinforcement of grillage corners and junctions

Knowing the overall dimensions of the grillage foundation, it is easy to calculate the length of the steel reinforcement bars in the upper and lower chords, as well as the dimensions of the lintels.

Having summed up the obtained values, we obtain the total length of each standard size of the reinforcement used. Knowing the footage and weight of one linear meter of a certain rod, it is not difficult to determine the need for reinforcing bars, expressed in kilograms.

If you do not plan to connect the elements using electric welding, you will need knitting wire. Having a drawing that shows information about the number of connection points, you can calculate the required amount of binding wire. Considering that about 30 centimeters are needed to securely fix two perpendicularly located rods, the total need for wire is determined by multiplying the number of connections by the length of the material.

Carrying out the calculations is not difficult. The main thing is to first develop a reinforcement drawing.

CALCULATION OF REINFORCEMENT OF A SLAB FOUNDATION

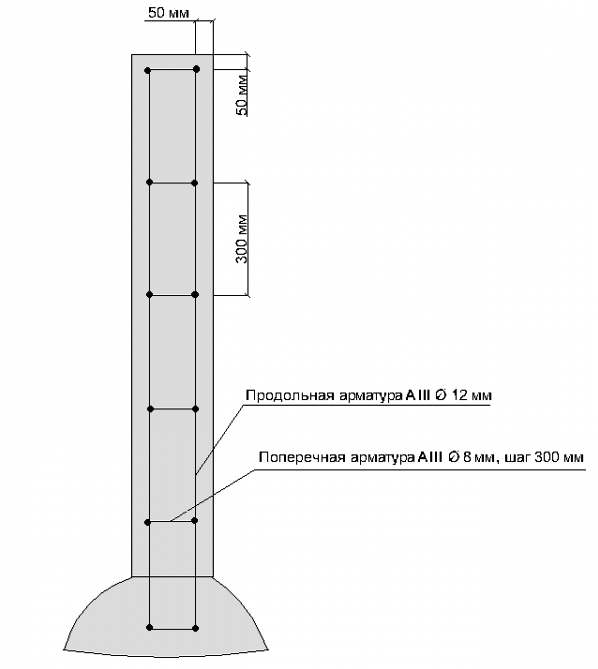

Foundation pile diagram.

To calculate the amount of reinforcement, you need to be guided by the type and shape of the foundation. They can be determined based on the load on the foundation and the bearing capacity of the soil. As an example, you can calculate the reinforcement for a house whose size is 6x10 m and has 2 internal walls.

Rods that have a ribbed surface will be used. Class A3 fittings meet these requirements. The thickness of the reinforcement was taken to be 10 mm in diameter. You need to remember the fact that the thicker the rods, the stronger the foundation will be. The thickness of the reinforcing rod must be selected taking into account the weight of the house and the type of soil on which it is located. If the soil on which the future structure will be located is quite dense and its bearing capacity is high, then the deformation of the foundation will be less. When building a panel, frame or light wooden house, where there will be soil with good bearing capacity, it will be possible to use rods with a diameter of 10 mm. If a slab foundation and soil with weak bearing capacity are used, then in this case it is necessary to use reinforcement with a diameter of 14-16 mm. The mesh pitch of the reinforcement frame is 20 cm (0.2 m). The quantity calculation will look like this:

((10/0.2)+1) = 51 pcs. rods 10 m each.

((6/0.2)+1) = 31 pcs. rods 6 m each.

51 + 31 = 82 pcs. rods

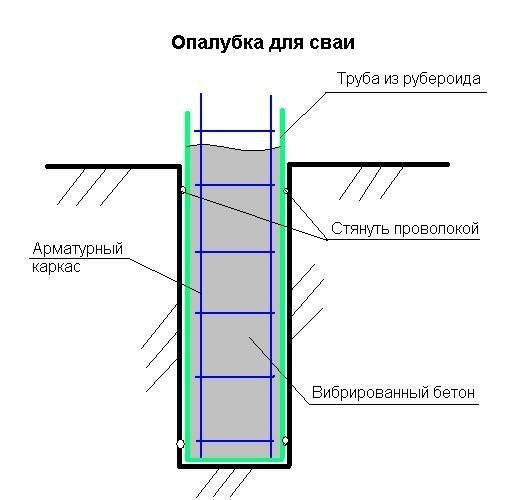

Formwork diagram for piles.

Since the foundation is slab, it uses 2 reinforced belts: lower and upper. It needs to double the number of rods. It turns out 164 rods, of which 102 pcs. 10 m long and 62 pcs. 6 m long. The result is:

102 * 10 = 1020 m.

62 * 6 = 372 mm.

1020 + 372 = 1392 m.

The lower grid of rods must be connected to each other. Connections are made at the intersection of the transverse and longitudinal rods. The number of connections is calculated:

51 * 31 = 1581 connections.

If a slab is used, 200 mm thick. And the distance of the slab surface to the frame is 50 mm, then 200 – 50 – 50 = 100 mm or 0.1 m.

1581 * 0.1 = 158, m.

158.1 + 1392 = 1550.1 m - the required number of rods for a slab foundation.

The knitting wire is calculated:

51 * 31 * 2 = 3162 connections.

You need to connect with double folded tie wire. The length of a piece of wire is 15 cm. Multiplied by 2, the result is 30 cm. The number of ties at the joints is multiplied by the number of connections and the result is 6324 pieces.

6324 * 0.3 = 1897.2 m of wire.

Grillage reinforcement technology

If the reinforced piles have been installed and the formwork has been installed, then you can begin to form the reinforcement frame. Please note that the frame is fixed to the reinforcement protruding from the concrete piles to the height of the formwork. Fastening steel rods can be done by welding, as well as using binding wire.

The algorithm for performing the work is as follows:

- fix horizontally located longitudinal rods at a distance of 5 cm from the bottom of the formwork;

- place and secure the perpendicularly located rods of the lower chord;

- install rectangular clamps or vertically located rods for fastening the bars of the upper tier;

- secure the longitudinal rods of the upper chord;

- Perform angular reinforcement of the grillage by installing curved rods in the corners of the structure.

Reliably strengthen the corners with reinforcement, since in these places the frame absorbs significant forces.