Experts agree that winter is not the best time to start construction, which defies logic. After all, it is in winter, due to a decrease in demand, that building materials are much cheaper, and builders who have a lot of free time are ready to take on any job, making a big discount. So why are professionals so categorical in answering the question whether it is possible to pour a foundation in winter?

? Why do experts advise postponing work until spring? Does the quality of a concrete mass depend on the weather conditions prevailing outside the window?

Experts are ready to answer these questions, as well as tell everything related to the impact of temperature conditions on the quality of the concrete mixture. After all, over several years of active activity, we have managed to assemble a team of employees with knowledge, skills, experience, and are also ready to share them with all readers of our blog!

Taking into account time intervals when pouring concrete in parts

Before moving directly to the question of whether it is possible to fill the foundation in parts, you need to pay attention to a number of important points regarding the hardening time of concrete mixtures.

In total, there are two stages - setting and hardening of the material.

These processes have their own time intervals, which will be discussed below.

Where do legs grow from?

One famous movie character once said that smart choices come with experience, but stupid choices lead to experience. When everything is done correctly, we sometimes don’t even think about what serious troubles we avoided, but we remember our mistakes for the rest of our lives.

It all started with the construction of a small garden house. The classic strip foundation was chosen. To tell the truth, I didn’t even know about anything else at the time, and it began...

Many people then advised me to pour the foundation before winter, so that for a good quarter of a year the foundation would stand and find its place. Then, they say, not only a house, but an entire house can be built without fear.

No sooner said than done, at least I had to work hard.

First, I cleared the selected area of debris and leveled it in a horizontal plane, and therefore had to take up the shovel even before digging the trench.

Then markings. For this purpose, I hammered pegs into the ground and pulled the lacing along the lines of the future foundation.

But we had to dig a lot. Our freezing depth is more than a meter, and the tape cannot be raised shallower.

Then I put up formwork from the boards, poured out a small sand cushion,

And then I filled everything with homemade concrete grade M 350.

It’s a pity that at that time I was too green, and therefore, after listening to the assurances of my neighbors, I decided not to lay reinforcement in the foundation.

Let me remind you that all this happened in late autumn (oh, damn those advisors) and the first surprises were not long in coming. The frost hit exactly two weeks after pouring, while concrete needs at least 28 days to gain full strength. Not pleasant, right?

No, I knew that in the spring the hardening process would continue, but the result would still not be the same.

After wintering, another “gift” was waiting for me - this is the level, or rather, its complete absence (and I wasted so much time to clearly set the formwork).

“You see,” the friend continued. “And the house could have sunk!”

But the soils were reliable, and the weight of the foundation was not so significant that the difference after subsidence was up to 5 cm.

The enemy came from where they did not expect: frost heaving. I thought that if I put the foundation on non-freezing soil, I would be completely protected from it, but that was not the case.

It turns out that heaving acts on the foundation and through the side walls tangentially, however, these forces are insignificant and cannot lift the entire house, but they are quite capable of handling an unloaded belt. Therefore, the frozen soil twisted the foundation as it wanted. To top it all off, the base cracked in several places.

My “joy,” as you can guess, knew no bounds. How much cement was wasted, and how much labor... But I didn’t want to put a stone building on a defective foundation, and therefore, as soon as the soil melted, I started construction again.

I decided not to touch the old foundation, but simply pour a concrete strip along its outer perimeter. At the same time, the house increased in length and width by almost a meter, but the prospect of digging a concrete monolith out of the ground made me shudder.

Despite the fact that the foundation pit was dug in April and the formwork was installed, I only started concreting in mid-May. The lesson was learned, and therefore I did everything according to science. So, knowing at what temperature concrete sets best (which is 15-20 ° C), I took time so that the thermometer could reach this mark at night.

As for the workflow, some adjustments were also made here.

Firstly, I had to admit that saving on reinforcement is not the best idea, and even though I spent three days tying the reinforcement frame, but lazy people do it twice, and I definitely didn’t want to redo it a third time.

Secondly, I had to give up making my own concrete and buy commercial concrete. The fact is that the foundation needs to be poured not in separate sections, but as a whole and in one day, only then can you count on quality.

And most importantly, thirdly, this time I didn’t delay too much with the construction of the walls. He waited the required four weeks and began laying bricks. By autumn the box was already covered. Therefore, this winter passed without any incidents.

To tell the truth, I sold that vineyard, but the house, as far as I can see, still stands today and I don’t think the owners have ever spent money on repairing the foundation.

Setting time

To figure out whether it is possible to fill the foundation in parts, it is necessary to talk about the characteristics of the setting of the material. This process comes into effect immediately after filling the formwork with concrete mixture. Setting involves the formation of stable bonds between the components of the solution.

The process lasts on average for 3 hours, but only when the ambient temperature is above 15°C. As for the maximum setting time, in some cases it takes 24 hours or more, in particular at sub-zero air temperatures.

Is it possible to fill a strip foundation in parts? It is allowed to resort to filling the pit with a new layer after about 8 hours have passed after the start of the setting process. In this case, it is necessary to lay a layer of mortar that is not too thick. Otherwise, defects may occur in the foundation structure.

Why is it so important to pour the foundation in the fall?

It is noteworthy that the beginning of autumn creates ideal conditions for construction: the temperature outside the window does not drop below zero, the amount of precipitation is quite acceptable, and air humidity will ensure ideal setting of the mixture. But there is no point in delaying excavation and foundation work.

After all, if you do not have time to arrange the foundation before the onset of cold weather, you will have to “mothball” it, and also monitor it almost every day, which is not possible for everyone. Therefore, experts believe that the “main” work related to the construction of the foundation and the construction of walls should be completed before October-November (as before, the characteristics of the climatic zone in the region must be taken into account).

Hardening time

Until complete completion, the process lasts for a month. Only at the end of the specified period will the concrete become ready to subject its thickness to any loads. Such a slow hardening can be explained by the extremely limited access of air to the deep layers of the material. Is it possible to fill the foundation in parts at the hardening stage? Exerting pressure on a semi-liquid solution in the thickness of the foundation can lead to the appearance of cracks on its dried walls. At the same time, some defects may not be visually noticeable. However, they will definitely make themselves felt after the completion of construction work. Therefore, filling here must be done in small portions.

So, is it possible to fill the foundation in parts? This should be done only after the previous layer has properly hardened. Moreover, before performing such actions, it is necessary to dry the surface of the material and clean it with a brush with metal bristles. Only after this can you start pouring a new layer of mortar.

Foundation: main types

Before studying the technology of pouring a foundation, you should consider the main types of foundation:

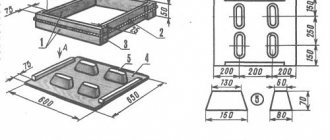

- Slab. It is a heavy monolithic concrete or reinforced concrete slab. Suitable for the construction of all types of buildings.

- Tape. High strength base. The best option for low buildings. Construction is carried out along the perimeter of the building.

- Pile. It is a cluster of pillars holding up a building. Piles are installed along its perimeter and in the corners.

Special equipment is becoming increasingly popular during construction work. Thus, a concrete mixer greatly facilitates and speeds up the process of building foundations. It is worth considering which foundation can be poured with a concrete mixer.

Horizontal and vertical filling of layers

It is worth doing the work by resorting to creating vertical or horizontal layers. When filling the formwork horizontally, the solution is poured halfway into the prepared frame. A mandatory requirement is that the height of the next layer of mortar should be above or below the reinforcement threads, but not in line with the metal elements.

Vertical pouring involves dividing the pit into sections using stable partitions. To prevent damage to the formwork walls under the weight of the mortar, with this method it is worth creating sectors that are small in area.

Is it worth pouring the solution in winter?

Laying out the foundation in winter is a complex, time-consuming, but completely doable process. However, in order for the foundation to be solid, durable and reliable, certain requirements must be met. Firstly, the work cannot be performed in parts, with a large period of time between each individual pour. It is best when the solution is laid in small segments, quickly covering with the next layer.

Also, it is necessary:

- Clear the prepared area of snow and ice;

- Cover the pit with special insulating material;

- Pre-heat the bottom between all the walls of the formwork;

- Ensure full, unobstructed access to the construction site.

It is worth noting that pouring concrete on top of frozen ground is strictly prohibited. After all, when thawing, the soil will subside, which can lead to various defects in the foundation of the finished object.

And despite the apparent savings, laying out the foundation in winter is associated with:

- Involvement of additional special equipment;

- Adding additives and plasticizers to concrete;

- Lack of wind and precipitation on the day of pouring;

- Increased requirements for insulation and waterproofing.

Therefore, the recommendations to “postpone until spring” are completely justified. But not always.

Methods for pouring the foundation in parts

Is it possible to fill the foundation in parts with reinforcement? There are several ways to do this:

- “Hot joint” - this method is relevant if the next layer of mortar is planned to be laid in less than 12 hours. In this case, after pouring the first portion of the material, its surface must be covered with roofing felt or plastic film. In this way, the concrete will be compacted, but a dense crust will not have time to form on its surface.

- “Cold seam” - this method is used when the time interval between laying the next layer is more than 12 hours. In this case, it is important to wait until the already poured mass of solution has completely hardened. If only an unstable crust has formed on its surface, the latter may not withstand the pressure during pouring, which will lead to the most unforeseen consequences during the operation of the foundation.

Preparation of concrete

Before pouring the foundation with a concrete mixer, you need to purchase a concrete solution. You can do it yourself.

Materials:

- Sand

- Crushed stone

- Cement

- Concrete mixer

- Shovel

- Bucket

- Water

Don't skimp on a concrete mixer.

A hand-mixed solution will not have sufficient strength and hardness. The sand is coarse river sand. You can use construction.

Crushed stone is fine (fraction size from 5 to 20).

Cement – class 500.

The water must be clean, without foreign impurities.

Stages of concrete production:

- Turn off the concrete mixer.

- We calculate the optimal proportions of cement for a concrete mixer.

- Pour 1 bucket of water and alternately 2 bags of cement into a concrete mixer.

- Turn on the concrete mixer.

- After 10 minutes, we begin to pour sand. In total you need to use 8 - 10 buckets. It is recommended to take short breaks every 2 buckets.

- Monitor the condition of the solution. If the consistency is too thick, add water.

- Gradually pour 8 - 10 buckets of crushed stone into the solution. After backfilling is completed, wait 15-20 minutes.

- If there is too much dust in the concrete, add water.

The resulting concrete solution can be used in construction.

Useful tips

First of all, you need to think through each stage of work in advance. It is recommended to divide the entire area of the prepared pit into sectors. In addition, it is important to timely prepare the volume of solution required to fill a particular area. Concrete should be poured evenly over the entire area of the sector. When laying the material using the “cold joint” method, it is always necessary to remove the cement film that has formed on the surface of the concrete, since it prevents the adhesion of the mortar layers. You can remove it with a metal brush or hammer.

Finally, it is worth noting that when performing work in the cold season, the surface of the frozen layer must first be cleared of ice and snow.

Self-fill

Every builder is quite capable of pouring a foundation with a concrete mixer with his own hands; he just needs to study the main stages and nuances of the work.

- First you need to do some preparatory work. This includes:

- Studying the depth of groundwater

- Calculation of soil freezing level

- Study of the composition and basic characteristics of soil

The strength and durability of the foundation being built depends on correct calculations.

- Next, you need to measure and calculate the level of load and pressure of the building on the foundation. Based on this value, it is necessary to choose the optimal type of base.

- Calculation and marking on the construction site. To do this, you need to use wooden pegs driven into the ground with ropes stretched between them.

- Removing the top layer of soil (10-15 cm).

- Construction of a trench.

- Installation of a drainage pad made of a mixture of crushed stone and sand.

- Construction of formwork from wooden panels.

- Creation of reinforcement mesh and its installation.

- Pouring the foundation.

Features of pouring using a concrete mixer

So, how to use a concrete mixer correctly? To do this, you should familiarize yourself with the main features of the work:

- Filling is done simultaneously. All corners of the formwork should be poured at the same time. It is worth remembering that the concrete solution will not spread around the perimeter of the foundation, so simultaneous pouring of all its sides is necessary. Failure to comply with this rule leads to delamination and subsequent cracking of the foundation.

- If pouring occurs only in one place of the base, then it is necessary to manually distribute the concrete over the entire surface using a shovel. This method does not guarantee a smooth surface. It is recommended to carry out an alignment procedure.

- Formwork panels must be removed 5 days after pouring concrete.

Electric foundation drying

There is another great way to dry out the foundation. When pouring it, a wire is placed in the solution. It can be copper, steel or aluminum. On one side, all ends are divided into two bundles; they will be connected to the welding machine. Light bulbs are connected to the other side, two ends to each. The lamps must be 36 V, the most important thing is that everything needs to be connected correctly. If there is an error somewhere, then nothing will work. Next, the wires are connected to the lamps in pairs and connected to the device. The first ones should light up, at first with a dim light, but as the concrete begins to dry out, they will burn brighter and brighter. This way you can perfectly monitor the progress of the entire operation and know when the foundation is ready. This method is also suitable for heating the foundation in October or other cold months.

Many builders generally prefer pouring concrete in the fall, because it does not dry out, as happens in the summer heat. The pouring method, or more precisely, the method of retaining heat in the mixture, must be chosen based on weather conditions, available equipment and materials.

How to set time intervals?

Correct determination of time intervals plays an important role in staged pouring technology. The main importance is given to the composition of the mixture, the grade of concrete and the outside temperature. The solution can be poured in layers at intervals of 2 to 8 hours; the layers should not be thick or uneven.

When the next layer is laid, the surface is covered with roofing felt or film, which does not allow the solution to dry out. When carrying out further work, the concrete scum is removed from the surface. It is important not to violate the laying intervals of layers; short periods of time lead to the formation of a hot seam. Longer intervals require complete hardening of the surface of the lower layer, otherwise a crust will be formed under which the composition does not harden, and subsequently cracks will appear on the surface of the foundation.