Using a drill for a pile foundation is an inexpensive but very convenient way to create a poured foundation with an expansion at the bottom. This device allows you to save time and effort on digging a pit or driving piles. In addition, small trenches for sliding gates are sometimes dug using a drill. The drilling rig allows you to make smooth, non-crumbling walls, which is very difficult to achieve when digging with a regular shovel.

How the TISE foundation drill works

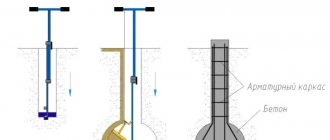

The TISE drill, which facilitates the work, consists of the following elements:

- a working handle designed to transmit torque through a metal rod to the working element. Structurally, the handle is a steel pipe of square, rectangular cross-section, or a solid metal profile. Rubberized handles are installed on two opposite sides of the rotation mechanism at a distance of 50–55 cm;

- steel rod consisting of two sections. The sliding parts, each 1.1 m long, are locked using a clamp. The base part of the rod provides the ability to accelerate work at shallow depths due to the reduced weight of the device. If it is necessary to extract soil at a depth of up to 1.8 m, an extension element is used. The components of the rod are interchangeable; a hand handle can be attached to each of them;

- soil accumulator with a radius of 12.5 cm, forming a well of the appropriate size. The soil receiver is made in the form of a metal cylinder equipped with loosening cutters, special plates and a guide rod. The design features of the soil storage tank ensure free penetration of loosened soil inside the cylinder and do not allow the auger mechanism to deviate from the vertical position;

- folding knife, hinged at the bottom of the tool. The device is designed to form a spherical expansion in the lower part of the well, increasing the area of the supporting surface of the future column to a diameter of 0.5–0.6 m. When immersed in the ground, the folding blade rotates due to its own mass. The hinged cutting edge is lifted manually using a metal cable, the end of which is fixed to the working handle.

How does the TISE foundation drill work?

The speed of drilling operations and the ease of use of the TISE hand drill depend on the weight of the device and the quality of manufacture.

Advantages and disadvantages

Creating a foundation using a foundation drill is an advantageous way that allows you to save a lot of time on the construction of a pile, columnar or strip-column foundation. Despite the attractiveness of the idea of quickly laying a foundation, you need to decide whether it is worth spending money on a drill, or perhaps the construction of such a foundation is not suitable for the given soil.

A hand drill is a rather expensive thing, and before buying it, you need to understand what advantages and disadvantages it gives its owner. In large cities, you can rent drills with a fee per hour, day, or meters drilled.

Advantages:

- Simplicity, the main thing you need to know for proper use is to turn clockwise and remove the soil in time.

- Reducing the time spent on erecting a columnar foundation.

- Safe for the environment, only gravity and manual labor are used to rotate the device.

- The reliability and extremely simple structure of the mechanism mean you don’t have to worry about expensive repairs; only with frequent use you need to sharpen the cutting parts.

Flaws:

- The price varies from 3 to 5 thousand rubles.

- Difficult to use on rocky soils, the receiver can only pick up stones up to 5cm in diameter.

- It is difficult to use on dry, compacted soils; additional preparation may be required by first pouring water into the holes. In particularly difficult places it is not possible to use a manual mechanism.

TISE drill for piles - advantages and disadvantages of the equipment

The TISE foundation drill, which facilitates the formation of cavities in the soil for pile supports, is widely used in private construction. The tool has a number of advantages:

- reliable and proven design. A high-quality TISE hand drill can be used for a long time without needing repair;

- ease of use. To perform operations for forming wells and extracting soil, you do not need to undergo training;

- environmental friendliness. When operating the tool, there is no negative impact on construction personnel, and the structure of the excavated soil is preserved;

- versatility. A foundation drill can be used to form cavities for various purposes, and can also be used in both summer and winter.

The design features of the tool make it possible to use it for preparing supports for piles on soils of varying complexity.

The use of a homemade TISE drill allows:

- build a pile foundation for a private house in a limited time with minimal labor intensity;

- build reinforced concrete supports with increased load capacity;

- eliminate the need to use heavy drilling equipment on a vehicle;

- carry out measures to extract soil under the foundation columns on your own;

- significantly reduce the amount of costs associated with the implementation of measures to form cavities.

Why do you need a drill for the TISE foundation?

The homemade TISE drill does not require connection to the electrical network or water supply lines, which ensures the possibility of its autonomous use. Among the disadvantages, it should be noted the need to periodically renew the sharpness of the cutting edge on the working cylinder. Thanks to its many advantages, the homemade TISE drill has become widespread in individual construction.

What is chise - f

When building a house with your own hands, it is often not possible to hire special construction equipment to dig foundation pits or trenches. Drill tise f is a fairly simple way to prepare voids for a pile foundation. You can work with it alone; due to the special shape of the cutting parts, clearing a place for one pile takes 1–2 hours.

The drill was invented in the 90s, when the private construction sector began to grow rapidly. Due to the use of the chise foundation drill, the costs of constructing a columnar and pile foundation are reduced by up to 4 times.

Components:

- the handle allows you to rotate the drill alone or with two people;

- rod, main and extension, allowing you to adjust the drilling depth, reaching up to 2.2 m;

- the soil accumulator allows you to collect quickly loosened soil;

- folding plow, this drill provides the ability to make an additional void to create piles with thickening.

- you can create a sand or gravel cushion wider than the pile, which will give the structure stability.

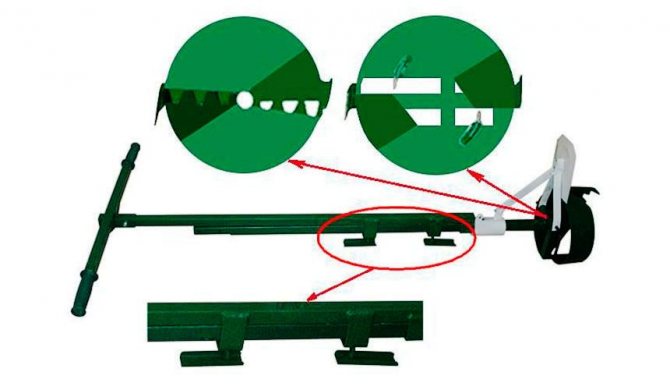

What kind of soil receivers are included with the foundation drill?

The construction of buildings on columnar foundations is carried out both on heavy soils containing mineral inclusions and on light soils with a high concentration of sand fraction. To ensure the possibility of drilling channels for piles on various soils, the tool is equipped with various types of soil receivers. There are certain differences in the design of the soil accumulator:

- To perform work in clay soil and soils with an increased content of small stones, the working tool is equipped with four soil-collecting elements located vertically at the same distance from each other. Small rocky inclusions up to 50 mm in size penetrate into the gap between the fangs along with the soil. When drilling soils with a high content of clay particles, clay adhesion is eliminated;

- for forming wells in loose soils, the working head is equipped with two cutting elements with a serrated edge. The design and location of the horizontal cutters prevent spillage of soil when removed from the cavity of the drilling device. The sawtooth-type working edge ensures the selection of small rocky fractions and effectively loosens the soil.

Manufacturers of hand tools, in accordance with the wishes of the customer, can equip the TISE auger with a soil intake of the required design.

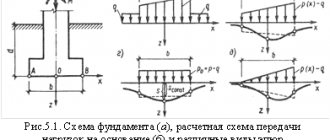

Limitations in the use of TISE bored piles

Along with its advantages, TISE also has limitations in use:

- other types of piles (bored, screw, driven) rest on the first dense layer on top. For TISE, this condition is not necessary; it is enough to immerse the piles below the frost line. Because of this, in terms of reliability, piles using TISE technology are inferior to other piles;

- Due to the increased grillage, the house is ventilated from below. To avoid heat loss, TISE is often made with a brick, stone or wooden fence, with insulation, and also with a blind area. All this increases the cost of the structure;

- TISE cannot be installed on swampy soil, as well as unstable soil, which is characterized by horizontal and vertical movements. In these cases, the most reliable foundation is a floating slab (it is also the most expensive);

- as in the case of other pile and columnar foundations, it is impossible to create a full-fledged basement with TISE. For this purpose, a recessed strip foundation is optimal;

- a disadvantage characteristic of all reinforced concrete structures is the duration of construction, since at each stage you have to wait for the concrete to harden.

TISE hand drill - performance characteristics

Industrially produced manual drilling devices and home-made tools have common characteristics and differ only in the design of the soil receiver.

Operating parameters of the device:

- maximum soil healing depth – 0.18 m;

- the size of the working body in diameter is 0.25 m;

- working handle length – 0.55 m;

- folded length – 0.125 m;

- size when extended – 0.225 m;

- diameter of the formed expansion – 0.4–0.6 m;

- weight of the tool assembled with the storage device is 10–12 kg.

The characteristics of the hand tool make it possible to effectively use it on light and clay soils, as well as soils with a high concentration of mineral impurities.

Well production

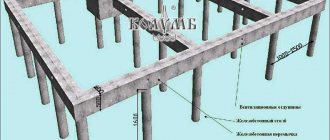

The basic method for producing a pile foundation is as follows:

- Drilling holes

- Installation of reinforcement surface in a well

- Pouring concrete with mortar

The simple technology of foundation manufacturing, ease of execution and low financial costs make this type of foundation the most common.

The main part of the work in foundation construction is drilling a well. This part is also the most costly, because... To implement it, you need to use a specialized tool - a drill.

How to make a TISE drill with your own hands

To independently manufacture hand tools intended for drilling cavities, you must perform the following work:

- decide on the type of soil receiver;

- develop drawings or sketches;

- prepare the necessary tools and materials.

Having completed the preparatory activities, you can begin manufacturing the device. Let us dwell on these points in detail.

TISE drill drawings

When planning to make a TISE drill with your own hands, drawings must be prepared in advance.

The following options are possible:

- acquisition of ready-made drawings or sketches, according to which the drilling device has already been manufactured;

- independent sketching from a full-scale sample, the performance of which was tested during the formation of wells.

You can also use standard drawings with your own dimensions on them. When choosing this option, remember that increasing the diameter of the working part will cause a significant increase in the forces on the handle.

Drill device

What is needed to make a TISE drill

To perform the work yourself, you will need the following equipment and tools::

- electric welding machine;

- drill with drills;

- grinder with a circle for metal;

- brush for painting.

For manufacturing you need to prepare the following materials :

- a piece of steel pipe with a diameter of 25–30 cm, corresponding to the size of the pile;

- used or new blade from a circular saw;

- pipe or metal profile for making a handle;

- pieces of metal 2–3 mm thick;

- profile pipe 4x4 cm or pipe with a diameter of 3.2 cm;

- paint for anti-corrosion protection of metal surfaces.

The design allows the use of materials of other assortments, selected according to the requirements of the drawings.

Homemade TISE drill - assembly technology

After preparing the materials and tools, start making the TISE drill.

Global modernization of the TISE drill

When performing work, follow the sequence of operations:

- Cut the workpieces, the dimensions of which correspond to the requirements of the drawing.

- Make working edges using a cut saw blade.

- Assemble the rod with the locking clamp.

- Weld the cutting edges at the bottom of the rod at an angle of 15–20 degrees.

- Assemble the soil accumulator by fixing the tubular workpiece above the knives.

- Fix the vertical knives on the outer part of the soil receiver by welding.

- Tie the hinge mechanism hinges over the soil pick-up cylinder.

- Hinge the working blades with the loops and attach the steel cable.

- Weld a cross member to the top of the extension to act as a handle.

- Make sure that the extension rod and hinge mechanism move freely.

- Check the quality of welded joints, clean them and remove burrs.

- Remove rust and coat the metal surface with an anti-corrosion compound.

After assembly is completed, the functionality of the tool must be checked. Properly installed cutting edges should effectively fill the soil container with soil.

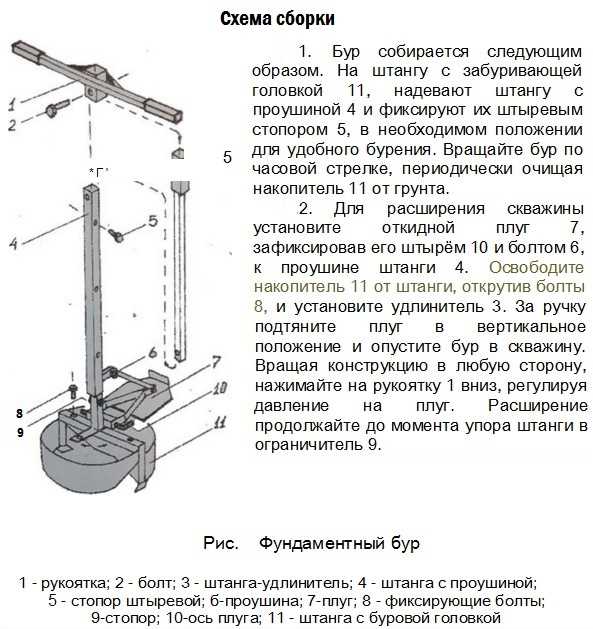

Drill assembly diagram

Advantages of TISE technology

- The foundation on TISE bored piles is made with an increased grillage: the upper part of the piles goes into pillars on which the lower frame of the house rests. Thus, the house is raised above the ground, separated from the ground by a ventilated gap;

- TISE is suitable for houses made of different materials, from stone to frame, and at the same time practically does not shrink;

- It is not difficult to install a house on a slope on a TISE foundation: the height difference is compensated by the different heights of the pillars above the soil level. You can create two-level platforms with a large number of levels;

- You can install the TISE base yourself. When ordering from a specialized company, the cost of TISE bored piles is lower than that of other types of foundations;

- high load-bearing capacity – up to 12 tons per support;

- environmental cleanliness.

We have been installing bored piles for over 10 years

For any questions call: 8 800 707-72-09

We will help you choose the most suitable and economical option for manufacturing a bored foundation.

How does a foundation drill work?

The drilling technology is quite simple and does not require special training.

When performing activities to form wells, perform work according to the following algorithm:

- Mark the pile field and remove the turf in the drilling areas.

- Assemble a TISE hand drill and equip it with the necessary storage device.

- Dig small pits 15–20 cm deep in the drilling area.

- Place the tool at the drilling point, ensuring its vertical position.

- Rotate the homemade TISE drill, applying force to the handle in a clockwise direction.

- Monitor the filling of the soil receptacle and periodically remove soil from it.

- Extend the length of the rod if necessary and clamp its components with a clamp.

- Continue plunging into the soil and form a depression at the bottom of the cavity.

- Pull the cord, lift the paddle and remove the tool from the hole.

Drilling wells for TISE piles

When working on light soils, one pit can be formed in half an hour. The duration of drilling on heavy soils is 2–2.5 times longer.

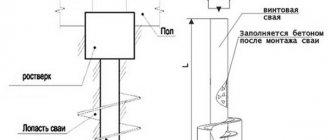

Pile foundation

The use of a pile foundation allows the construction of buildings and structures in places not suitable for construction. This could be the surface of the water, swampy areas, or land areas subject to seasonal flooding.

When constructing this type of foundation, piles are used that are driven into the ground. The building, in turn, is built on stilts. The technology of its construction is quite easy to use. Therefore, this type of foundation is quite popular when building on low-quality land plots. A pile drill is used to install and install holes.

TISE drill - reviews and practical recommendations

Private developers and professionals who have used the TISE industrial and homemade drill in their work speak positively about this tool and note the following qualities of the device::

- Ease of use;

- compactness;

- durability.

Experts recommend adhering to the following recommendations when using the device:

- do not apply increased force in the handle, since the tool easily sinks into the soil under its own weight;

- avoid lateral loads, which could result in significant deformation of the assembly rod;

- control the verticality of a homemade TISE drill when immersed in the ground.

The tool will make the job easier and will not cause problems if used correctly.

We install bored piles using TISE technology in Moscow and the Moscow region

Buy Larsen sheet piling Turnkey bored foundation Retaining wall made of bored piles Calculation of bored piles

The TISE foundation was developed by designer R.N. Yakovlev. as an environmentally friendly basis for low-rise buildings. The base - bored piles using TISE technology - are made with widening in the area of the base, which makes the foundation stable on different soils, including clayey soils prone to frost heaving.

Arctic Hydro Stroy installs bored piles using TISE technology in Moscow and the Moscow region.

We offer turnkey projects or carry out individual work at the customer's discretion.

Tool capabilities

The drill is successfully used in foundation construction. Its successful use is determined by the following factors:

- Construction of foundations for various objects on any land plots

- Work to strengthen and replace the foundation

- Recommended for work where resources must be saved. You can work without using electricity and without involving additional human resources

- Low cost of work

- Speed of execution

- Minimum period of work on a land plot

To correctly select a construction drill, you should calculate the necessary parameters of the wells, study the main characteristics of the foundation and analyze the load of the building on its foundation.

Electric drill

If it is necessary to construct wells of large diameters, an electric drill is used. The dimensions of drills for pile foundations of this type are quite large and allow making holes with a diameter of more than 50 centimeters.

Device. The mechanism has the following design:

- Electrical engine

- Special handles are attached to it on both sides

- Rotating clamping mechanism

Operating principle: when the device is plugged into the network, the engine starts running. It is held with special handles. The motor supplies work to the screw rotation device. The device does the necessary work.

Often, an electric drill comes with a set of additional accessories that make the work easier.

Currently, there is a wide variety of equipment models. They belong to different price categories, have different characteristics and methods of operation. Manufacturers of foundation drills recommend purchasing equipment after making accurate calculations of the building layout, establishing the dimensions and type of foundation.

Also, the main selection criterion is the power of the device. Energy consumption, operating time, its quality and the need to make additional efforts depend on it. The best performing power tools are ways to get the job done in no time. So, to drill a well with a depth of 100 centimeters, it will take only 10 minutes of operation of the device. It is also worth considering the diameter of the future hole. The larger it is, the more the operating time increases. In any case, it will be much lower than the operating time of a hand tool.

When choosing equipment, you should give preference to models with a self-sharpening function. All cutting elements must have a high degree of sharpness. Only electric drills with such parameters are able to cope with uneven ground, stones, tree roots, etc. The low parameters of the devices contribute to their rapid breakdown when working in difficult areas of the ground.

The price category of electric drills varies from 5 to 10 thousand rubles. Thus, you can purchase a device with a basic configuration and low power efficiency. The most expensive models are equipped with various additional functions. They allow you to complete the work in the shortest possible time, because... have increased power parameters.

Using a drill

To find out which drill is used for a pile foundation, it is necessary to study and calculate the basic parameters of the building. Based on these characteristics, it is worth choosing a tool.

- So, for holes with a diameter of up to 30 centimeters, you can use hand tools. It allows you to make holes about 5-6 meters deep. The drill design allows you to use a minimum of effort when working. The main load falls on its blades, so working with the tool is quite easy.

- When constructing holes whose diameter exceeds half a meter, it is recommended to use an electric tool. It can produce wells reaching depths of 4 meters.

- To carry out work at the bottom of the well, its expansion and improvement, a drill-blade is used.