This article should begin by mentioning that the very concept of “bearing capacity of piles” is not entirely correct. In fact, the load-bearing capacity of a screw-pile foundation is determined by several factors. The main one is the characteristics of the soil, and only in second place are the geometric and design features of specific piles, which are determined by the characteristics of the soil and the load from the structure.

Thus, it makes sense to discuss the bearing capacity of piles only if it is known exactly in what soil they will be installed.

Soil load-bearing properties

Load-bearing properties are one of the most important factors in determining whether a foundation can support the load generated by the building's mass and transmitted by the foundation. When calculating this value for soils, the fluidity index and porosity coefficient are taken into account.

| Name | Flow rate, JL | Porosity coefficient, e | Design resistance R, kg/cm2 |

| Refractory clay | 0.25 < JL < 0.5 | 0,70 0,85 | 3,6 3,0 |

| Refractory loam | 0.25 < JL < 0.5 | 0,70 0,85 | 2,3 1,6 |

| Plastic sandy loam | 0<JL<0.25 | 0,60 0,70 | 2,0 1,7 |

| Soft plastic clay | 0.5 < JL < 0.75 | 0,70 0,85 1,00 | 2,4 1,9 1,5 |

| Soft plastic loam | 0.5 < JL < 0.75 | 0,70 0,85 1,00 | 1,5 1,8 0,9 |

| Sandy loam, soft plastic | 0.5 < JL < 0.75 | 0,70 0,85 | 1,1 0,8 |

| Coarse sand | 0,50 0,60 | 2,0 1,5 | |

| Medium sand | 0,50 0,60 | 1,8 1,4 | |

| Fine sand | 0,50 0,60 0,70 | 1,9 1,3 0,8 | |

| The sand is dusty, low-moisture and wet | 0,50 0,60 0,70 | 1,7 1,4 0,8 | |

| Sandy sand, saturated with water | 0,50 0,60 0,70 | 1,5 1,2 0,7 |

Due to the pressure of the layers above, the density of the soil increases as the depth increases.

| Kinds | Load-bearing capacity in kgf/cm2 at depth | |

| 1 – 1.5 m | 2 – 2.5 m | |

| Sandy loam | 1,0 – 2,0 | 2,0 – 3,0 |

| Loams | 0,9 – 2,5 | 1,0 – 3,0 |

| Hard clays | 2,0 – 4,0 | 2,5 – 6,0 |

| Plastic clays | 0,8 – 2,5 | 1,0 – 3,0 |

| Sands are gravelly and coarse | 2,6 – 3,9 | 5,0 – 6,0 |

| Medium sand | 1,9 – 3,0 | 4,0 – 5,0 |

| Sands are fine, low-moisture | 1,5 – 2,5 | 3,0 – 4,0 |

| The sands are shallow and very wet | 1,0 – 2,0 | 2,0 – 3,0 |

| Crushed and pebbly with sandy pore filling | 2,0 – 3,5 | 4,0 – 4,5 |

| Wood and gravel soils formed from crystalline rocks | 3,7 – 4,4 | 5,0 |

| Grass and gravel soils formed from sedimentary rocks | 2,0 – 2,5 | 3,5 – 4,0 |

In addition, the bearing capacity of soils can be influenced by climatic conditions in a given area.

MARCO-ECONOMY MARCO-STANDARD MARCO-PROFILE MARCO-UNIVERSAL

Bored pile foundations

occupy a special place in the work of our company.

The fact is that such a foundation in many cases turned out to be the most suitable for warm houses built using permanent small-piece formwork: MARCO , DURISOL , VELOX . The total weight of such houses, as a rule, does not exceed 100-130 tons. The bearing capacity of one bored pile with a diameter of 300 mm on medium-density sand is 1700 kg. A simple calculation shows that 70 piles are enough to build the foundation of a light house . The Our Objects section shows the most interesting foundation projects implemented by the company’s specialists.

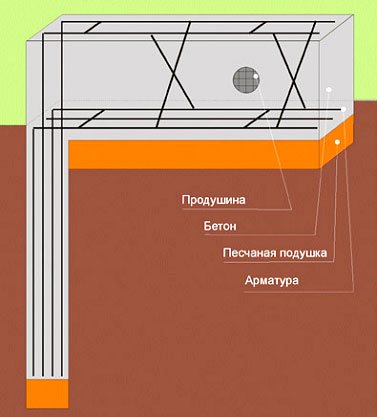

The foundation support is a bored pile. 2. Reinforcement frame of the foundation grillage. 4. Grillage 400 – 600 mm high and 300 – 500 mm wide. 5. Internal piles are designed to accept loads created by the floor, partitions, roofing and operational loads.

Piles, the base of which is located below the freezing depth, are not “squeezed out” at low temperatures. Pile foundation is cheaper

than

a strip foundation

and several times cheaper than

a monolithic foundation

. Taking this into account, our company widely uses bored pile foundations in the practice of suburban construction.

Using simple technological techniques, the diameter of the pile base can be increased to 500 mm. In this case, the bearing capacity of the pile is already 5000 kg. On such piles it is possible to build a foundation for a house made of brick or cellular concrete with a large margin. The general diagram of a bored pile foundation with a grillage is shown in the figure. This design has another name - a pile-grillage foundation.

| Do you have a question?... Ask! |

The table shows the bearing capacity of bored piles of various diameters depending on the type of soil

| LOAD-LOADING CAPACITY OF BORED PILES ON DIFFERENT SOILS | |||||||||

| Diameter of the bored pile base, mm | 100 | 150 | 200 | 250 | 300 | 400 | 500 | ||

| Base area of a bored pile, cm2 | 78,5 | 177 | 314 | 491 | 707 | 1256 | 1963 | ||

| Design soil resistance, kgf/cm2 | Load-bearing capacity of piles, kg | ||||||||

| Sands are gravelly and coarse, regardless of their humidity | Dense | 4.5 | 353 | 795 | 1413 | 2208 | 3179 | 5652 | 8831 |

| Average | 3.5 | 275 | 618 | 1099 | 1717 | 2473 | 4396 | 6869 | |

| Sands of medium coarseness, regardless of their humidity | Dense | 3.5 | 275 | 618 | 1099 | 1717 | 2473 | 4396 | 6869 |

| Average | 2.5 | 196 | 442 | 785 | 1227 | 1766 | 3140 | 4906 | |

| Sands are fine, low-moisture | Dense | 3 | 236 | 530 | 942 | 1472 | 2120 | 3768 | 5888 |

| Average | 2 | 157 | 353 | 628 | 981 | 1413 | 2512 | 3925 | |

| The sands are fine, very wet and saturated with water. | Dense | 3.5 | 275 | 618 | 1099 | 1717 | 2473 | 4396 | 6869 |

| Average | 2.5 | 196 | 442 | 785 | 1227 | 1766 | 3140 | 4906 | |

| Hard clays | Dense | 6 | 471 | 1060 | 1884 | 2944 | 4239 | 7536 | 11775 |

| Average | 3 | 236 | 530 | 942 | 1472 | 2120 | 3768 | 5888 | |

| Plastic clays | Dense | 3 | 236 | 530 | 942 | 1472 | 2120 | 3768 | 5888 |

| Average | 1 | 79 | 177 | 314 | 491 | 707 | 1256 | 1963 | |

| Coarse soils, crushed stone, pebbles, gravel | Dense | 6 | 471 | 1060 | 1884 | 2944 | 4239 | 7536 | 11775 |

| Average | 5 | 393 | 1570 | 2453 | 3533 | 6280 | 3768 | 9813 | |

Photo

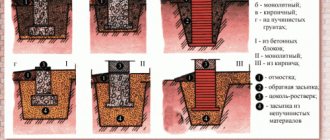

Most often we use two options for pile foundations. The first option involves the installation of a so-called hanging grillage. In this case, a gap of 70-100 mm high is left between the grillage and the ground. The gap eliminates the impact of soil on the grillage during swelling. Foundation for a house

in this case, it seems to hang above the ground.

Here, logs from the first rows of a wooden house are used as a “grillage”

Pile-grillage foundation for a frame house

Construction of a wooden house on bored piles

Pile-grillage foundation for a wooden house in the village of Pervomaisky, Moscow region

The photographs show pile foundations with a monolithic grillage for houses made of different materials. Sometimes such a foundation

for a house they call a columnar foundation with a monolithic grillage.

This definition is not entirely accurate, since not only piles, but also pillars made of brick, natural stone and even wood can be used for columnar foundations. Wooden foundations

are often found in old Russian village houses.

The photo clearly shows how the height of the piles changes in different parts of the house. This made it possible to level the foundation horizontally. Arranging grillage formwork for such a foundation is quite a difficult task for carpenters.

| Do you have a question?... Ask! |

Scheme of a recessed (lying) grillage

Recessed grillage and entrance steps on a bored foundation for a house using MARCO technology, which our company built in the Silver Horseshoe cottage village

Recessed grillage for the VELOX house in the village of Klubnichnye Polya, Moscow Region

In the second option, the grillage is buried in the ground . To eliminate the influence of soil swelling, a sand cushion

, the thickness of which is determined based on the geological features of the site, but should not be less than 100 mm.

Examples of this grillage are shown in the photographs.

Grillage

(German Rostwerk, from Rost - lattice and Work - structure, strengthening), part of a pile foundation (slab or beam) that unites the head sections of the piles and serves as a supporting structure for the erected elements of the structure.

The grillage is called high if it is located significantly above the ground or water level (for example, in the berthing structures of ports), and low when it is placed close to the surface of the ground or buried in it (for example, in the foundations of residential and industrial buildings). The materials for grillages in modern construction are mainly concrete and reinforced concrete (prefabricated or monolithic), less often - wood and metal. The name grillage arose in connection with the previously used structure, which had the form of a lattice of wooden beams on which the plank flooring was laid. Close

| Do you have a question?... Ask! |

Construction of a well for a bored pile using a TISE drill

Cardboard pipes for piles are coated with bitumen mastic

Construction of a bored foundation in the cottage village Klubnichnye Polye, Moscow Region

Free-flow asbestos-cement pipes with a diameter of 300 mm are an ideal formwork for bored piles

The process of installing bored piles is quite simple . The pile is formed directly in a pre-drilled well. As a rule, the depth of the well is 100 - 150 mm greater than the standard freezing depth of the soil in the construction area. According to the technology of execution, there are different variants of pile construction . To construct a well, hand drills of various diameters are used, for example the well-known Tise drill. In recent years, Japanese and Korean pit drills

, which significantly increased work productivity.

In the first, concrete is poured directly into pre-drilled holes. In this case, the walls of the well serve as the formwork. To eliminate leakage of cement laitance into the ground, the walls of the well must be lined with roofing felt or rigid polyethylene film. If the film is welded before use, the resulting cover is used as foundation waterproofing

.

This will prevent a decrease in the strength properties of concrete. Constructing a foundation

in this way is only possible for sufficiently strong soils.

Our company rarely uses such technology. As formwork for a bored pile, we use metal, asbestos-cement or cardboard pipes

of the appropriate diameter.

Triangular reinforcement lattice frame is an ideal option for reinforcing bored piles

Scheme of pile reinforcement with frames of various cross sections

To increase the strength of bored piles, we use reinforcement cages made of reinforcement with a diameter of 10-12 mm, which are tied into a frame in case of eccentric loads or shear forces. It is convenient for this purpose to use ready-made triangular reinforcing lattice frames , which are used in the manufacture of beams for prefabricated monolithic MARCO floors .

You can purchase such ready-made frames from our company. In addition, the reinforcement serves as a connecting link between the pile and the reinforced concrete grillage, turning the above-ground and underground parts of the foundation into a single whole. The reinforcement cage also serves as a guarantee against possible rupture of the bored pile due to frost heaving. In addition, the reinforcement serves as a connecting link between the pile and the reinforced concrete grillage, turning the above-ground and underground parts of the foundation into a single whole. The reinforcement cage also serves as a guarantee against possible rupture of the bored pile due to frost heaving.

In addition, the reinforcement serves as a connecting link between the pile and the reinforced concrete grillage, turning the above-ground and underground parts of the foundation into a single whole. The reinforcement cage also serves as a guarantee against possible rupture of the bored pile due to frost heaving.

Knitting a reinforcement cage for a grillage in the village of Klubnichnye Polye, Moscow Region

Construction of a bored foundation in the cottage village Klubnichnye Polye, Moscow Region

The pile is prepared for concreting

Manual concreting of piles for a house built in the village of Osechenki, Moscow region

Concreting piles using a mixer

Piles and grillage are prepared for simultaneous concreting

Simultaneous concreting of piles and grillage in the village of Klubnichnye Polya, Moscow Region

Using a sewer pipe to install vents in the grillage

Vents are a mandatory element of a closed base

The well is filled with concrete manually or using a concrete pump. Quite often, conditions allow simultaneous concreting of piles and grillage. This technique reduces work time. To install vents in the grillage, ordinary sewer pipes are usually used.

| Do you have a question?... Ask! |

In the second option, the smooth surface of the concrete pile is formed by using temporary metal or plastic formwork, which is removed (pulled off) from the pile 1.5 - 2 hours after filling the formwork with concrete. During this time, the concrete has time to gain sufficient strength so that the formed pile does not change its geometric dimensions during further setting of the concrete. If, during installation, the temporary formwork is leveled in the horizontal plane, the resulting pile field easily eliminates vertical differences in the surface of the area. The disadvantage of the second option is the absence of any waterproofing on the surface of the formed pile; the advantage is the possibility of creating an intermediate layer of sand between the surface of the pile and the walls of the well, which significantly reduces the possible effect of freezing soil on the side surface of the formed pile. When using formwork of different diameters or shapes, it is quite easy to form cylindrical piles with a wide base or conical piles. The foundation on cone piles under the influence of lateral soil pressure forces is not squeezed out, but pressed into the ground. Cone piles can help solve a problem that one of our website visitors once had.

| Do you have a question?... Ask! |

In the third option, metal, asbestos-cement or cardboard pipes of the required diameter are used as permanent permanent formwork for piles, which perform the function of waterproofing during the operation of the foundation. During installation, pipes can be easily leveled in the horizontal plane, eliminating vertical differences in the surface of the area. In the latter case, it is important to ensure that the depth of the base of the pile anywhere on the site is 100 - 150 mm higher than the standard soil freezing depth . The resulting pile field serves as an excellent basis for assembling the grillage formwork. In areas where the groundwater level is very high, drilled wells quickly fill with water. In this case, before filling the pile with concrete, water from the well must be removed using a pump. A more reliable result can be achieved if the base of the pipe is filled 70 - 100 mm with waterproofing concrete. Such concrete can be prepared on the basis of hydraulically stressed cement NC or by adding liquid glass to the concrete mixture. Pipes with concrete plugs at the base turn into a sealed glass, and in this case it is not necessary to remove water from the well. For the construction of the foundation in the village of Klisheva

In the Moscow region, we had to use exactly this option. A house made of aerated concrete blocks on this foundation “survived” the difficult winter of 2012 without any problems.

The use of disposable formwork for piles and columns made of special cardboard allows you to remove restrictions on the diameter of piles. This formwork appeared in Russia quite recently and has found wide application in the practice of our company. Using such formwork it is possible to construct piles with a diameter of up to 1000 mm.

| Do you have a question?... Ask! |

In all options, to ensure the strength of the piles, it is necessary to use reinforcement cages made of reinforcement with a diameter of 10, 12, and in some cases 14 mm, which are tied into the frame using clamps. The reinforcement frame of the pile serves as a connecting link between the pile and the reinforced concrete grillage, turning the above-ground and underground parts of the foundation into a single whole. The frame reinforcement prevents possible rupture of the foundation by frost heaving forces. The density of pile reinforcement (the number of reinforcing bars and the diameter of the reinforcement used) is determined by the foundation design .

For concreting wells, heavy concrete of class no lower than B15 (M200) is used.

. Concreting of each pile is carried out continuously - the time between laying individual portions of concrete should not exceed one hour. Construction on a bored 13 foundation can begin in 5 - 7 days. The foundation can be fully loaded only after the concrete has completely set, that is, no earlier than 28 days after the end of concreting.

Free-standing pile for the foundation of the entrance group

The grillage formwork has been assembled. You can start concreting

Construction of the base formwork grillage for the foundation of a wooden house in the village of Pervomaiskoye, Moscow region

Using bored piles to increase the load-bearing capacity of a monolithic foundation slab

The density of grillage reinforcement with reinforcement depends on the mass of the building and is determined by the project.

In some cases, we use bored piles to increase the bearing capacity of foundations based on monolithic slabs.

Foundation with a “hanging” grillage for a wooden house in the village of Pervomaiskoye, Moscow region.

Installation of MARCO prefabricated monolithic floor beams on a foundation with a hanging grillage in the village of Pervomaiskoye, Moscow Region

Foundation on bored piles for a log house in the village of Pervomaiskoye, Moscow region

For the installation of concrete floors on bored foundations, we recommend using MARCO prefabricated monolithic floors . The increased heat-protective characteristics of such floors sharply reduce the influence of temperature fluctuations in the soil . Even concrete floor beams MARCO-STANDARD

They are lightweight, allowing them to be delivered and installed in hard-to-reach places.

It was this feature of MARCO floors that allowed us to mount the floor on a bored foundation

located in a forest clearing.

The beams for this crossing had to be manually delivered to the site 120 meters away. I provide even more possibilities for constructing floors with MARCO-PROFILE beams

.

The weight of the beams was reduced by three times compared to concrete ones. The beams can be joined together at an angle. The new ceilings removed all restrictions on the configuration of the grillage - bay windows and curved walls of the entrance lobby consoles ceased to be a problem. MARCO-UNIVERSAL ceilings

made it possible to use standard wall blocks in the construction of ceilings.

Blocks made of aerated concrete

,

expanded clay concrete

,

polystyrene concrete

, and

warm ceramics

today can be used to construct your floors on bored foundations.

It is important to note that when pouring floors, you can use special concrete additives that prevent soil moisture from affecting the floor. In this case, the prefabricated monolithic floor acts as waterproofing for the base of the house.

| Do you have a question?... Ask! |

The table below shows the parameters and cost of a typical bored foundation, which our company recommends for houses made of light materials (timber, logs, MARCO , polystyrene concrete

,

DURISOL

).

For heavier houses (brick, cellular concrete, foam blocks), it is necessary to use foundations on piles with a diameter of 500 mm. It is difficult to give standard recommendations for such foundations. Our company’s specialists are ready to evaluate the possibility of using and calculate a bored foundation for any home. One thing is certain for us: the cost of a bored foundation is 15–20% lower than the cost of a strip foundation and 70–100% lower than a monolithic foundation .

| PARAMETERS AND COST OF A TYPICAL DRILLED FOUNDATION | ||||

| PARAMETER | Unit | Meaning | Note | |

| 1 | Well diameter | mm | 350 | |

| 2 | Well depth | mm | 1600 | |

| 3 | Outer diameter of asbestos cement pipe | mm | 300 | |

| 4 | Asbestos cement pipe internal diameter | mm | 270 | |

| 5 | Dimensions of the reinforcement frame of the pile AхB | mm | 150 x 150 | |

| 6 | Pile reinforcement diameter | mm | 10 | |

| 7 | Number of pile reinforcement bars | PC | 4 | |

| 8 | Concrete grillage height | mm | 500 | |

| 9 | Concrete grillage width | mm | 400 | |

| 10 | Dimensions of the reinforcement frame of the grillage AxB | mm | 400 x 300 | |

| 11 | Diameter of grillage top reinforcement | mm | 10 | |

| 12 | Diameter of grillage side reinforcement | mm | 10 | |

| 13 | Diameter of the lower reinforcement of the grillage | mm | 12 | |

| 14 | Recommended distance between piles | mm | 1200 — 1600 | |

| 15 | Cost of one linear meter of grillage and pile | rub. | from 6500 | Material, labor, and other expenses |

We will be grateful if you share your experience of using bored foundations. The most interesting messages will be published on the site and will allow visitors to make an informed decision.

| Do you have a question?... Ask! |

The cost of the foundation can be further reduced by eliminating the concrete grillage and replacing it with a metal profile. It is convenient to use a channel as such a metal grillage.

| Do you have a question?... Ask! |

Tips for building a bored foundation

- The foundation must be laid to a depth of 100–150 mm greater than the freezing depth of the soil in the construction area.

- The foundation can be used to compensate for natural unevenness in the soil.

- As a rule, a bored foundation allows you to preserve the landscape, since there is no need to dig pits or trenches.

- Bored pile foundations can be used in the construction of heavy houses made of bricks and blocks.

- Depending on the load on the foundation, piles are installed around the entire perimeter of the house in increments of 1.2 to 2.5 meters.

- To prevent rupture of bored piles (supports) by vertical tangential forces, a reinforcement cage is laid inside the foundation to the full height.

- When installing a grillage, it is necessary to provide ventilation holes - vents.

- For lightweight houses, a reinforced concrete grillage can be replaced with a grillage made of a metal profile.

Bored foundation construction technology

- Linking the foundation to the terrain based on the general plan of the site

- Determination of the height difference at the foundation construction site.

- Marking the foundation axes.

- Marking points for drilling wells.

- Drilling wells with a hand or motorized drill.

- Installing pipes in wells and leveling the upper sections of the pipes horizontally, filling the space between the well wall and the pipe with sand.

- Installation of reinforcement cages in pipes.

- Pouring concrete into pipes. Concrete is compacted by baying or using a vibrator.

- Arrangement of formwork for pouring concrete into a grillage connecting bored piles around the perimeter.

- Laying the grillage reinforcement frame.

- Pouring concrete into the grillage formwork.

| Do you have a question?... Ask! |

Most often, from this page site visitors go to the following pages:

Dynamics of heaving soils | Monolithic construction technology MARCO | Integrated design | Project selection | Foundations | Bored foundations | Aerated concrete ITONG | VELOX technology | DURISOL technology | SIMPROLIT technology | Aerated concrete | Building a house - mistakes, miscalculations, recommendations | Roofs | Attics | Prefabricated monolithic floor slabs |

| Do you have a question?... Ask! |

Load-bearing capacity of screw piles

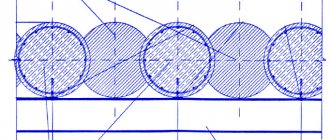

All piles can be divided into two large groups depending on the nature of the load perception:

- Narrow-bladed - the diameter of the blade exceeds the diameter of the trunk by less than 1.5 times.

- Broad-bladed (lobed) - the diameter of the blade exceeds the diameter of the trunk by 1.5 times or more.

When using narrow-bladed products, loads are perceived due to:

- precisely calculated width and pitch of the blade, as well as the number of turns - to fully take into account friction on the side surface of the barrel;

- good soil bearing capacity.

Such structures are effective in soils with a high inherent bearing capacity - permafrost

and

dense seasonally freezing soils

. However, strong friction on the side surface of the trunk requires calculations to counteract the tangential forces of frost heave.

Unlike modifications with narrow blades, wide-bladed piles cope well with design loads even when installed in soil with low bearing capacity.

Effectiveness factors:

- sufficiently large support area;

- calculation of the angle of inclination of the blades, the pitch of the blades and the distance between them for structures in which two or more blades are used;

- selection of blade characteristics depending on soil type.

In this case, the load-bearing properties of soils are of great importance at the calculation and design stage. So, for example, a bladed pile with a shaft with a diameter of 57 mm in soil with good bearing capacity can withstand a load of up to 10 tons. At the same time, a design with a 325 mm barrel in soft soil will only withstand 1 ton.

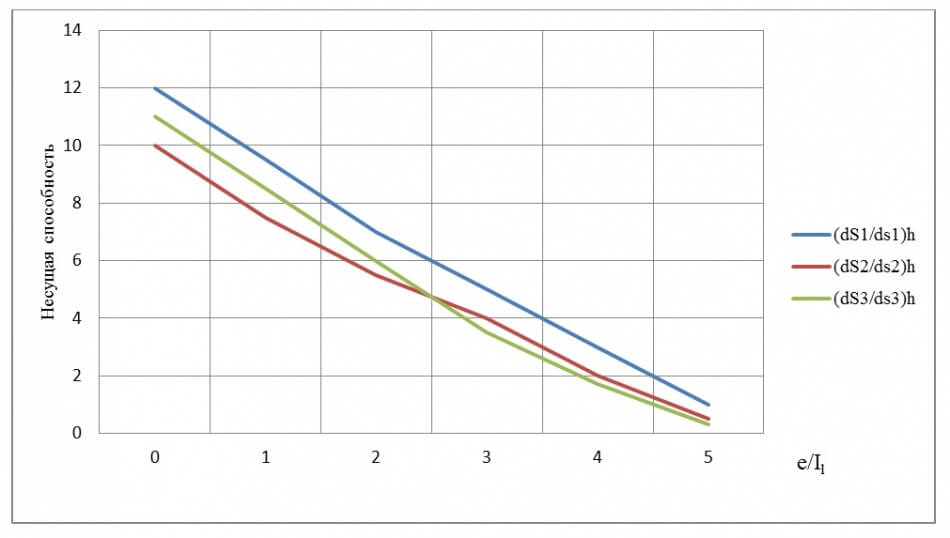

Figure 1 – Graph of the dependence of the load-bearing capacity of screw piles on soil characteristics and structural characteristics of the pile

dS1, dS2, dS3

– nominal diameter of the blade of screw piles (version 1, 2, 3).

ds1, ds2, ds3

– nominal diameter of the shaft of screw piles (version 1, 2, 3).

e/Il

– ratio of soil porosity to fluidity coefficient.

h

– immersion depth.

The figure clearly shows that the bearing capacity of the foundation is displayed in the form of a nonlinear relationship. When calculating it, it is important to take into account all significant factors.

Features and advantages of a bored foundation

In some cases, when constructing residential buildings, it is not possible to install a strip foundation. For example, due to the presence of already constructed buildings or communication nodes nearby. This problem is especially relevant in populated areas where the plot areas are small and each owner tries to place the maximum number of buildings near the house.

The use of a bored foundation on piles allows the situation to be resolved without causing harm to the foundations of existing structures. During its construction, it is possible to carry out all processes with maximum accuracy. In addition, the level of vibration vibrations during operation is minimal, which prevents a destructive effect on nearby buildings.

Advantages of using piles when constructing a foundation:

Relatively cheap construction. A monolithic or strip base, if the materials are correctly calculated, will cost much more than a bored base. Versatility of use. With the help of such a foundation, you can build a foundation on any type of soil, including areas located near water bodies. Possibility of installation to the depth of soil freezing. This solution is suitable for structures made of any materials.

For example, for houses made of brick, timber or panels. Speed of construction. Its construction takes about 5-7 days. Safety. During construction, the possibility of negatively affecting already finished buildings or harming the landscape is completely excluded.

It is worth noting that the bearing capacity of a bored foundation is not inferior to a strip or monolithic one.

Another feature of using piles is pouring directly at the construction site. The problems of constructing such a foundation include only drilling wells for filling, which are not always possible to dig with the help of technology, and all work is carried out manually.

Photos of bored piles

Calculation of a foundation made of screw piles

Before starting to calculate the bearing capacity of a pile foundation, it is necessary to conduct geological surveys

. With proper data analysis, the result will help to select the best combination of design and geometric parameters of screw piles for effective load distribution.

When designing a pile foundation with optimal characteristics for a particular building, you can use simple ready-made calculators. However, a more reliable and effective option would be for a geologist to visit the area and then prepare calculations.