The best way to make the structure of your home more stable and durable is to drive reinforced concrete piles. Thanks to them, the mass of the entire house structure is distributed correctly among each other. Driven reinforced concrete piles are the most common type supplied by factories for the production process.

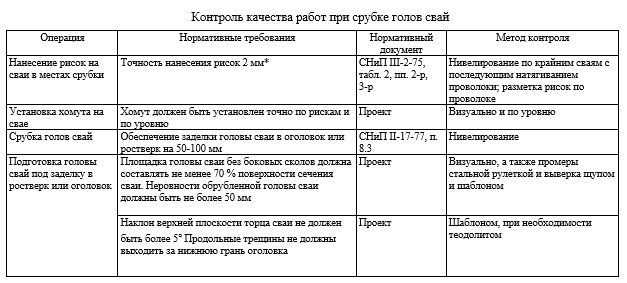

Cutting down reinforced concrete piles is necessary to adjust them to the required size, which was initially fixed in the project for building a house or structure. There are different methods, technologies and mechanisms by which part of the piles is cut down. There are different methods: from jackhammers to modern ones.

Advantages and disadvantages of processing heads with a cutting mill

Pros:

- The felling process takes a minimum of time;

- precise cutting of the pile heads without damaging the integrity of the pile.

Minuses:

- there is a risk of uneven cutting, the quality depends on the accurate calculation and selection of the cutter, i.e. the experience of the worker;

- high final cost.

Most often, preference is given to the second processing method using hydraulic attachments. The essence of the technology lies in the use of special equipment with cutting teeth. Under the influence of a hydraulic force of 1000 tons, the teeth evenly cut off the heads, eliminating damage to the reinforcement and the pile itself. From an economic point of view and taking into account the time costs, hydraulic pruning is optimal for the construction of multi-storey buildings and cottage development.

Manual cutting method

When manually cutting piles, the following tools are used:

- Jackhammer - for leveling supports made of monolithic or precast reinforced concrete.

- Hydraulic shears – for cutting off excessively protruding remnants of reinforcement. They can also be used to shorten piles made from small-diameter metal pipes and concrete caps.

- Angle grinder. It can be used both for cutting concrete supports and for cutting metal pipe piles. It all depends on the type of cutting wheel installed on it.

Compared to the mechanized method of cutting down the pile heads, the manual method is less expensive from a financial point of view. This is especially true for private developers with a limited construction budget. However, this method is very, very long, and therefore ineffective on large industrial construction sites. In the latter case, the use of manual technology for cutting down the heads of a pile foundation can significantly increase construction time.

Cutting metal supports

The least labor-intensive and easiest to perform is to shorten supports made of metal pipes. A similar design has a screw or driven foundation, intended for the construction of small buildings - private residential buildings, outbuildings, light warehouses and utility rooms. The metal support posts are cut as follows.

First of all, you need to apply markings of the same level to all piles. To do this, using measuring instruments - a hydraulic or laser level, a level - the lowest support is located. It is taken as the lowest point from which the height is measured.

Chopping concrete with a jackhammer

If the height of the support is specified in the design documentation and is tied to some external benchmark, then the markers on the remaining piles are laid exactly from this point. When marking cut points, it is not recommended to use a regular building level, setting aside marks from one mark to another. The marks should be clearly visible against the background of the metal - it is best to apply them with chalk or white paint.

Next, using a grinder with a cutting wheel designed for working with metal, an even notch 1-2 mm deep is made around the circumference of each support. It is intended to obtain a more even cut edge, without slopes in one direction or another. According to the applied risk, the pile head is cut off.

Concrete supports are cut in the same way using a grinder using special abrasive wheels. To cut metal piles, you can use cutters with an open flame - acetylene, gasoline, laser or plasma torches.

Cutting down a concrete pile

A more difficult job is cutting down the head of a concrete pile. Such piles can be poured either directly on site (bored) or at a reinforced concrete products factory (drived). In both cases, manual cutting of concrete supports is carried out using a jackhammer. The marking technology in this case is completely similar to the marking of metal supports. The only caveat is that when applying marks, one should take into account the fact that the concrete foundation supports are connected to each other by a concrete grillage.

When pouring, the grillage seems to rest on the pile heads, creating a single structure with them. In this regard, the upper parts of the concrete pile supports must be buried into the thickness of the grillage by at least several centimeters, and the protruding reinforcement of the piles must be connected to the reinforcing frame of the concrete frame. Therefore, marks should be applied slightly above the level indicated in the design documentation. It is also necessary to take into account that when cutting out a concrete fill, unexpected splits and cracking of the monolith below the designated mark are possible.

You need to cut down the concrete using alternating counter movements from bottom to top, and then from top to bottom, along the entire perimeter of the pile. The felling should be done in such a way that in a vertical section the ends of the felled part have the shape of a cone. The protruding parts of the reinforcement remaining after removing the concrete fill are cut to the required height with a grinder or hydraulic shears. Using hydraulic shears, you can also cut concrete piles.

In this case, a special round-shaped attachment is placed on the support and small pieces of concrete are carefully bitten off. In this case, the cut edge is more even than when using a jackhammer, and the likelihood of cracking of the parts of the support adjacent to the cut, leading to a weakening of its load-bearing abilities, is also reduced.

Safety precautions

When cutting a foundation support manually, you must follow the safety rules outlined in the 1982 SNiP already mentioned above. For the convenience of working with piles of considerable height, you should use scaffolding or scaffolding firmly installed on the ground. Before starting work, you should make sure that the entire structure is reliable, and only then can you begin cutting down the heads of the supports.

When working with an angle grinder or a jackhammer at height, it is prohibited to use ladders or stepladders instead of scaffolding. This is due to the fact that during work there is a high probability of falling from them and receiving injuries of varying severity.

When working with hand tools, you need to use protective clothing, gloves, goggles, and when working at height, a construction helmet. This will protect the worker from injury from flying concrete particles or metal scale. When cutting a concrete pile with an abrasive wheel, you should use a respirator or a protective cotton-gauze bandage to prevent the finest stone dust from entering the respiratory system.

It is also necessary to ensure that when working with a jackhammer or grinder on scaffolding or scaffolding, there are no unauthorized persons within a radius of 5 m. Splinters and large parts of the foundation being cut or cut down can seriously injure a person below when they fall. If a fairly massive support is being cut down, its upper cut-off part must be secured with a sling using a crane or winch. This will make it possible to avoid a heavy fragment of the support from falling on the worker doing the cutting or on the scaffolding (scaffolding).

Cost of cutting down pile heads

The final price for felling is calculated individually based on the number of piles, required time frames, standard sizes and remoteness of the work site. You can find out the cost of processing the piles of your facility by calling specialists.

We promptly carry out all types of piling work at the best prices. Quality guaranteed:

- staff of professional employees;

- modern, precise equipment;

- impeccable adherence to technology.

Call us and we will select the best felling option based on the type of piles and your budget.

How to strengthen a foundation using screw piles

To increase the strength and stability of the pile foundation, special technologies have been developed to strengthen supporting structures, which are practically used during the construction of a pile foundation with screw piles.

Typically, two methods are used to strengthen foundations made of screw supports, for which metal pipes, angles or rolled steel are used.

To strengthen the foundation belt of light buildings, you can use pipes and angles; for heavy buildings, you will need to use a durable channel.

Option to strengthen the foundation using pipes

Reinforcement of the pile foundation (with screw piles) is carried out with profiled pipes measuring 30x60 mm. The technology for performing the work involves connecting all the foundation supports in series with pipes of a certain size, including the internal pile field. This reinforcement is used when the extension of the supports above the ground is more than 0.7 m.

The pipes are welded between two pile supports on the inside of the foundation. With this position of the reinforcing belt, nothing will interfere with finishing the foundation when hanging protective panels.

When the height of the protruding pile outlets is more than 0.7 meters above the ground surface, the pipes are welded crosswise, with the middle of the pipe joint secured with a special metal plate (plate) of square section with dimensions of 200x200 mm.

Strengthening a pile-screw foundation with a corner

The technology for strengthening the base with screw piles with a metal corner is identical to the method of installing a stiffening belt made of pipes: the elements are welded to the outer and inner belt of the piles. A rigid spatial frame is formed that holds each support, preventing tilts, rolls, and warping, creating a strong strengthening of the base of the building.

Method of strengthening the foundation with a channel

Strengthening the foundation of screw piles using a channel is usually used in weak soils saturated with water (peat bogs, marshy areas). For work, a 16 or 20 channel is used; the choice of size depends on the thickness of the walls of the building. The channel is welded along the upper belt of the piles (like a head), which makes it possible to create a strong metal frame that prevents the slightest deviation of individual piles from their axis. Watch the video on how to install a channel on piles to strengthen the foundation.

The disadvantage of using a channel is the high cost of materials, however, the technical characteristics of a foundation made of screw piles, reinforced with a channel, increase significantly, increasing the strength and durability of the building itself. In fact, the belt of a welded channel with piles is equivalent to a reinforced strip foundation.

Metal belt protection

Strengthening a pile foundation with metal will undoubtedly save the structure from premature destruction and distortion, but it is necessary to remember about the protection of the metal protective system itself. A pile foundation with screw piles is operated directly in close contact with wet soil, which negatively affects the metal surface, causing rapid wear from corrosion.

When performing work to strengthen foundations, it is important to provide protection for steel pipes, channels or corners from high humidity, having previously treated them with special protective compounds.

Self-tapping mounting

The wood is secured to the posts using self-tapping bolts. The contact area is laid with roofing material oiled with drying oil. The elements are mounted to the bottom of the structure using through fastening or an anchor. The block must be securely attached and secured with a hammer. As an additional way to enhance the strength of the structure, metal corners and fastening spikes are used:

- It is advisable to use corners in corner connections of elements;

- the design detail is selected according to the exact dimensions of the pile corner section;

- The element is secured with strong self-tapping screws.

It is better not to leave untied places in the structure. Using the corners, you can process all the necessary areas. This will strengthen the entire foundation.

Reinforcement with reinforcement

The base of the building can be tied with steel reinforcement. A welding machine is used for this. The reinforcement is folded into a mesh and firmly secured by welding. This method is rarely used in construction, since after welding the steel loses its high technical strength. The reinforcement may become more flexible and cause deformations.

An alternative to welding is the manual method of steel strapping. The reinforcement is tied with strong wire and fixed with special hooks. Wire is tied around the joints and twisted tightly. Instead of wire, you can use special fasteners that do not twist.

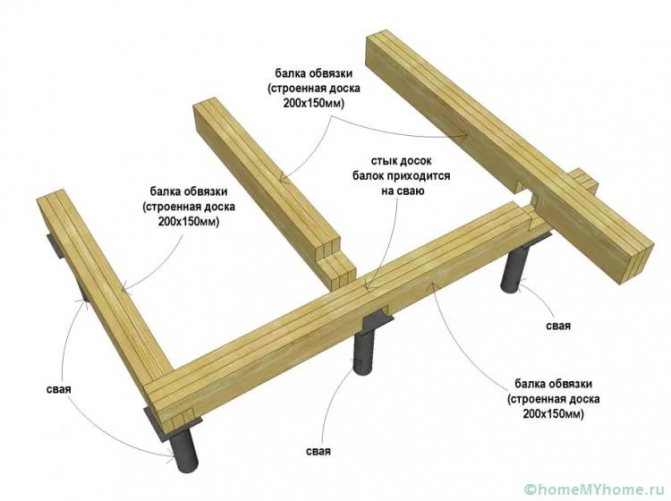

Laying timber

It is better to use larch or durable softwood for tying a pile-screw foundation. The material is placed above the ground, so moisture will actively influence it. When wet, larch acquires greater strength, so experts recommend using this particular wood in the construction of structures.

Work must begin from the corners. The flanges are laid with insulating roofing felt. It is important that the wood does not come into contact with the metal. During operation, the timber will condense and absorb moisture, so it must be isolated from the metal.

Special attention should be paid to the following points:

- the first adjacent structural elements must be joined and aligned. Their connection is checked using a square;

- the workpiece is additionally adjusted and fastened with self-tapping screws;

- During the work process, it is important to correctly calculate the geometry of the perimeter and compare its diagonals. They must be equal. After checking, you can continue installation work.

Tying a pile-screw foundation with timber is not difficult. The equal length of the beam allows you to precisely fasten all the elements together and build the entire structure end-to-end. The beam is secured with a bracket or metal plate. It is then coated with mastic to seal the material.

The pile binding made at the top and bottom is considered more reliable. To secure the screw elements as much as possible, take a 200 mm beam. At the second level, 150 mm wood is used. To install the second row, you do not need to make a special cut under the joists.

To lay the rows of timber as accurately as possible, a wedge is used. It is placed in the place of installation or washed down. Svf can be reinforced with metal elements. To tie the foundation on screw piles, you can use glued boards. This alternative to timber will cost less in construction and will save money.

Kinds

Before starting the process, the strapping technology is carefully selected. Piles can be fixed using:

- threads;

- welding;

- clamps.

It is possible to make a harness with screws attached if wooden poles were used in the construction. They should be quite dense and thick. With this technology, correctly calculate the thread. Fastening screw piles with timber is applicable in the construction of wooden, frame, block and brick houses.

Welding installation of base elements is used if the piles are metal. Tying the foundation using welding will be the best option and will allow all parts of the structure to hold firmly.

The use of clamps is a variant of strapping technology for piles made of dense wood. Clamps can be used when the thickness of the posts is small. The installation method is chosen depending on the characteristics and parameters of the piles.

Recommendations from experts

- Before starting work, you need to look at all areas and make sure that the columns are the same height. The success of the entire construction depends on this. The height of the piles must be perfectly accurate, otherwise it will be impossible to do further work well. If any pillar is higher or lower, it should be leveled. Otherwise, in the future there may be a strong distortion of the floor in the house.

- The strapping connection must be made exactly in the center of the area. It is in this place that the screws are fixed. The installation of fasteners makes the entire structure as strong as possible, so this issue should be treated with great attention. Fixing the screw in the center of the beam will prevent the wood from cracking.

- Before installing the timber, it is important to check that the length of the elements is correct. The wooden block that will be mounted horizontally should be twice as wide as the pile. Only then will the entire structure be especially strong and reliable.

- It is better not to experiment with new technological methods during the construction of the structure. Properly performed work will provide the necessary technical parameters to the entire foundation of the house. If the master does not have confidence in his own abilities, it is better to call specialists to perform a high-quality grillage.

- Compliance with all rules and recommendations of specialists will ensure high strength of the structure. In order not to redo the grillage in the future, the beam must be accurately aligned horizontally. Use impregnation compounds that will protect the material from moisture.

- Tying a pile foundation requires a complete understanding of all stages of the process. Firmly fixed structural elements will allow you to correctly distribute further load on the building, save the house from destruction and extend its service life.