Types, methods and technology of piles are used to create foundations that can stand correctly on unstable and loose soils.

You can correctly make a foundation on driven piles using several methods, and one of the most popular is the method of vibrating them.

Vibration driving of piles

This article will discuss the features of the technology of vibration driving of piles, methods of driving piles, SNIP, according to which the technology for carrying out all work is correctly regulated, as well as the inspection report of piles, which is their regulatory documentation necessary to begin any pile-driving work. Upon completion of the work, a corresponding act is also drawn up.

You will also learn about such a device for driving piles as a vibrating hammer (hydraulic hammer) of reinforced concrete piles, and become familiar with their types, operating principles, as well as the features of this machine.

Answers to frequently asked questions

How quickly can you get started?

Usually it is 2-4 days. But if the equipment is busy, the time can take up to 6-10 days.

What technology are your vibratory hammers based on?

Our vibratory loaders are based on a Hitachi excavator, as well as on a crane.

The equipment is selected depending on the project and complexity.

We prepare the final proposal after inspecting the construction site, studying the design documentation, and consulting with you as the customer. Based on this, we make an accurate estimate and after its approval, we do not offer any additional work.

We are ready to immerse piles and pipes using the vibration method. We have highly productive equipment and qualified personnel.

This page provides information about vibratory hammers used for the installation of reinforced concrete piles. We will consider the purpose of this equipment, its varieties and technological stages of the process of vibrating pile driving.

Our company provides services for the installation of reinforced concrete piles and pipes using the vibration immersion method. To carry out the work, we use modern copra equipment and qualified personnel, which allows us to carry out any projects efficiently and quickly.

Vibration pressing of supports

This method of driving piles combines indentation, impact and vibration techniques. The pile being driven is immediately affected by three forces. The work is carried out using an installation consisting of an electric generator, a winch with two drums and a guide boom equipped with a vibrating hammer. The design also contains blocks through which a rope is connected to the vibratory loader from the winch to perform pressing.

|

|

|

|

Purpose of vibratory hammers

In construction practice, vibration equipment is used for the installation of reinforced concrete piles and rolled metal. Compared to impact driving technology, vibration driving of piles has the following advantages:

- High productivity in non-cohesive soils (sandy and sandy loam);

- Low level of destructive dynamic loads transmitted during vibration loading to the foundations of nearby structures;

- Minimum noise level during operation, which allows you to work in city conditions without violating standards.

This method also has disadvantages, including:

- Low productivity in dense and highly hard soils;

- Negative effects on the soil (decompaction), which limits the possibility of using the technology in unstable soil.

Rice. 1.1 : Vibratory driving of piles into frozen soil

Vibration immersion technology is used for the following purposes:

- For the installation of reinforced concrete piles - arrangement of pile foundations, bridge supports, power lines, hydraulic structures;

- For installation of pipes when fencing pits, strengthening slopes, tunnels and embankments, creating hermetically sealed tanks in the ground.

Expert advice! In practice, vibratory drivers are most often used for driving sheet piles, since this class of equipment works most effectively with flat structures with thin walls. Using vibratory driving, it is rational to install Larsen sheet piles (trough-shaped), Z-type sheet piles, flat profiles and sheet piles (hollow steel pipes).

Vibration driving itself occurs as a result of the transmission to the submersible structure of low-frequency vibrations that the vibrating driver produces during operation. These vibrations are transmitted along the walls of the pile to the soil layer in contact with them and cause its decompaction.

Decompaction leads to a significant reduction in the counter resistance of the soil as a result of a decrease in the forces of its friction with the walls of the immersed structure, which is lowered into the ground due to the weight of the vibratory loader acting on it and its own mass.

Rice. 1.2 : Vibration driving of a metal pile

Expert advice! Vibratory driving technologies, when working in dense soils (clayey, loam), in most cases are preceded by leader drilling, after which the pile structures are driven into pre-drilled wells.

Indentation method

Driving piles by pressing requires a special installation and a powerful crane. The reinforced concrete support is placed in the clamping mechanism, after which it is partially buried to a distance corresponding to the length of the hydraulic jack rod. Then the pile is released, the jack piston is raised, and the element is clamped again. Then the pressing is repeated again. The cycle is repeated several times until the support stops.

The technology of immersion by pressing involves several stages of removing a pile installed all the way and its subsequent deepening. Each time the support will fall lower, but the last mark at which you can stop will be its design position.

The indentation method is used most often in areas with dense layers of soil, although it can be used in any conditions, even without geological research.

This method of foundation construction has many advantages. Among them:

- speed of construction of the underground part;

- possibility of installing fewer supports;

- high reliability of the design;

- elimination of soil looseness.

But quite often the shortcomings turn out to be more significant. First of all, this:

- large dimensions of the equipment - an area of at least 500 m2 is required for placement;

- high cost of work;

- the difficulty of moving the installation from site to site.

Classification of vibratory hammers

Vibratory pile drivers are a broad class of pile driver equipment, classified according to several factors.

Classification by operating principle

According to this parameter, the equipment is divided into:

- Vibratory hammers;

- Vibratory hammers.

The differences between these units are that the vibrating hammer, in addition to low-amplitude vibrations, transmits a shock load to the mounted structure. In the lower part of the vibratory hammer body there is a striker, on which the vibrator strikes during operation (impact frequency - up to 480 per minute).

Rice. 1.3 : Hydraulic vibrating hammer

Expert advice! Compared to classic vibratory hammers, vibratory hammers have greater efficiency - their use allows you to drive sheet piles and reinforced concrete piles into denser soil layers (to greater depths) without leader drilling.

Classification according to the nature of vibrations

According to the nature of the vibrations transmitted to the pile, vibratory hammers are distinguished:

- Longitudinal action;

- Longitudinal-rotational action.

Unlike longitudinal loaders, in longitudinal-rotary units the unbalances (uncentered shafts, the rotation of which produces vibrations), rotate in two planes.

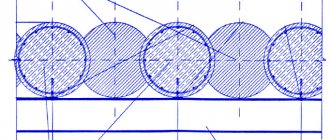

Classification by operating frequency

According to the operating frequency range, vibratory hammers are classified into:

- Low frequency - 300 -700 counts/min;

- Mid-frequency - 700-1500 counts/min;

- High frequency - 1500-2500 counts/min.

Low-frequency units are used when there is a high soil resistance of the submerged structure, which is typical for the installation of piles with a large cross-section, high-frequency units are used for the installation of flat rolled metal.

Rice. 1.4 : Installation of reinforced concrete piles with a low-frequency vibratory hammer

Expert advice! Most modern vibratory hammers are multifunctional; they operate in a wide range of frequencies - from 300 to 2300, which allows you to choose the optimal driving mode for the installation of any structures.

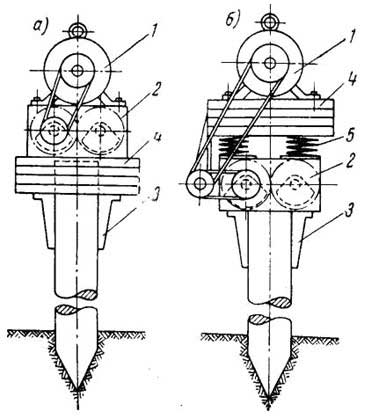

Classification by design features

Depending on the design features, vibratory hammers are divided into:

- Simple (hard);

- Sprung.

Rigid vibratory loaders consist of three main units - a housing in which the weights and gears are located, mounted on the surface of the electric motor housing and a cap, due to which the unit is connected to the pile. In sprung units, the electric drive is fixed on the surface of the platform connected to the body by means of springs.

Rice. 1.5 : a) hard; b) sprung vibratory driver

The presence of springs can significantly reduce vibration vibrations transmitted to the electric motor and, thereby, increase the service life of the drive. Due to their greater durability, sprung units have almost completely replaced rigid vibratory hammers from use.

No. 3. Vibro-impact method

As the name suggests, this method involves a combination of vibration and shock loading. The pile is simultaneously affected by both vibrations and impacts, which allows it to quickly and relatively easily enter the soil. This method is used on dense soils , where another method will be ineffective.

The installation, which carries out vibroimpact driving, has two frames: on one there is an electric generating impact apparatus, on the second there is a boom with a vibratory driver. The vibrator is connected to the pile using a head, then the pile is positioned and the mechanism is started. , piles up to 6 m long can be driven

Driving piles with vibratory hammers

Due to the limited productivity of vibratory hammers when working in dense (clayey and loamy soils), the installation of piles and pipes is often accompanied by soil erosion. The implementation of this method is recommended when immersing elements to a depth of over 8 meters.

When working in frozen and highly hard soils, in which the efficiency of erosion is reduced, the method of leader drilling is practiced - developing wells for subsequent vibratory driving of piles.

Figure 1.6 : Lead drilling for installation of piles using a vibratory hammer

Direct vibration immersion is preceded by a set of preparatory work, which includes:

- Relocation to the site of pile driver equipment;

- Delivery of loaded structures, their distribution to consumable warehouses;

- Marking a pile field or fence.

Rice. 1.7 : Vibratory driving of piles

The vibration immersion method is implemented in the following sequence:

- The pile driver is placed at the pile installation point;

- The pile located in the consumable warehouse is pulled to the installation site by the winch mechanism of the pile driver;

- Auxiliary personnel fix the slinging cables on the pile, the structure is lifted into the air and installed in the driving position;

- The head of the vibratory driver is connected to the pile;

- After securing the pile, the vibratory driver is turned on, transmitting high-frequency vibrations to the submerged structure, under the influence of which it is lowered into the soil.

Expert advice! During the installation process, the operator of the pile driver monitors the vertical depth of the pile using sensors located inside the cabin. If it deviates from the required trajectory, the structure is leveled using guy ropes using winches.

Rice. 1.8 : Vibration immersion of sheet piles

More detailed information about the technology of installing piles using a vibratory driver and the services of our company in this area is presented at the link: Vibratory driving of piles.

We offer vibration immersion

PILE

Length up to 12 m. Section 350x350 mm. The price is indicated for 1 linear meter with a volume of 1000 mp. from 450 rub. Order

PIPES

Diameter 350 mm. The price is indicated for 1 linear meter with a volume of 1000 mp. from 450 rub. Order

Vibratory hammer rental in Moscow

IC "Bogatyr" provides rental services for vibratory hammers. Our company is ready to provide productive pile drivers to individuals and construction companies in Moscow.

Vibratory pile drivers and pile drivers on which they are installed are accompanied by qualified specialists who, following your recommendations, carry out piling work of any complexity in a high-quality manner.

By ordering vibratory hammers for rent you receive:

- Minimum prices in the capital;

- Confidence that vibratory loaders will carry out all the work, and the object will be commissioned within a strictly specified time frame;

- There are no unforeseen situations associated with breakdowns of rented vibrating equipment - all our equipment undergoes regular technical inspections and is in excellent operating condition;

- Full compliance of the piling technology with the requirements of SNiP.

To order a vibratory loader for rent, contact representatives of our company by phone, or fill out the “Send a request” form and expect a call from our manager within 60 minutes.

Technique used

When using the vibration method of driving piles, specialized equipment is used - vibratory drivers and lifting mechanisms. As the latter, a crane, an excavator with appropriate characteristics, or a pile driver are used.

The main purpose of a vibratory driver is to immerse and extract various pile elements on clay and sandy soils. The principle of its operation is based on such a property of two-phase liquids as thixotropy. As a result, there is a sharp decrease in immersion resistance when vibration is imparted to the pile element.

Application for work Leave a request

Signing the contract

Relocation of equipment

Vibration driving of piles

Delivery of the object