An original way to build a strong and reliable foundation for any type of building on heaving soils is a do-it-yourself foundation made from tires.

This technology has become popular due to its low financial costs and its simplicity.

The foundation made from car tires has its own design and operational features.

The use of old car tires to build the foundation is a unique development of Mikhail Semykin, who first implemented it during the construction of a 3-story private house with an area of 260 sq.m.

Advantages and disadvantages of the foundation

Each material used to build a foundation has its own advantages and disadvantages.

Advantages

The key advantage of a design made from car tires is its affordable cost: used tires can be purchased at any service station, auto repair shop, or from fellow motorists.

In addition, such a base has the following advantages:

- high load-bearing capacity - the finished structure can withstand a load of several tons;

- reliability and strength - support from truck tires prevents subsidence, deformation and overturning of the structure when the ground is moving;

- high waterproofing properties - the base provides reliable protection of the structure from the negative effects of groundwater and high humidity;

- depreciation during sudden changes in temperature conditions;

- seismic resistance to ground vibrations, which prevents the formation of cracks and splits in the finished structure;

- simplicity and accessibility of arranging the foundation yourself, without involving expensive specialists;

- light weight of the material and ease of transportation;

- long service life.

Flaws

The disadvantages of the material include the susceptibility of rubber to the negative effects of ultraviolet radiation and elevated temperatures.

When heated, car tires can release toxic substances and a synthetic odor.

The only measure to eliminate this deficiency is to reliably isolate tires from the negative impact of environmental factors. For example, painting with heat-resistant paint or covering with corrugated board around the entire perimeter of the base.

Wheel instead of foundation block

And so, a used car tire, when used as a basis for the creative construction of a foundation, has a number of undeniable positive qualities:

- Automotive rubber is quite durable, especially for frames from famous Western manufacturers, which use multi-layer reinforcement with steel and polymer threads; a sufficient percentage of the rubber composition is natural and synthetic rubber, known for its resistance to deformation and wear resistance;

- Such material can be purchased for free. Due to the fact that many tire shops are faced with the problem of recycling used tires, your costs may be limited only to transporting the wheels to the construction site;

- Rubber has excellent waterproofing properties, is resistant to damage by microorganisms and fungi, and is able to retain its shape and basic qualities for a long time;

- Easily transported, stored and mounted;

- It tolerates seasonal temperature fluctuations and soil displacements and movements in the adjacent area.

The main disadvantages include the following:

- The flammability of the rubber composition, which can initiate a relatively high fire hazard for the object;

- Tendency to destruction of the surface layer under the influence of sunlight, primarily the ultraviolet part of their spectrum;

- The appearance of an unpleasant specific odor, especially in the hot season, when the rubber surface is heated.

Scope of use of the foundation

Tire foundations are successfully used for the construction of buildings on heaving soils and in seismically active zones. The foundation is provided for the construction of:

- private frame houses. Tires are installed in several rows in a pre-prepared pit;

- outbuildings - garages, sheds, gazebos. A columnar base made of tires is installed at the outer corners of buildings;

- baths and saunas. For wooden baths, a foundation made of car tires does not require additional backfill;

- fencing. Tires are installed in one row along the entire perimeter of the site.

The most popular is the foundation made of tires for bathhouses and houses.

One tire, two tires – it’s a house!

Regular readers of our site know well that a used car tire is a universal building material. From them a foundation , lay a drainage system, and even carve sculptures . However, the scope of application of tires is far from exhausted. A resident of the Colombian city of Bogota, Alexandra Posada, proposes to build entire houses and even cottage settlements from “used” tires.

Despite skepticism from professional builders, the woman said that tires are an almost ideal building material for the poor.

Alexandra Posada: – Used tires cost nothing, are practically eternal and are ubiquitous. Why not a building material for people who need to build housing in the shortest possible time?

To dispel all doubts, Alexandra rolled up her sleeves and, with the support of two assistants, built a round house with a diameter of 10 meters in 2 weeks. The technology captivates with its simplicity. First, the construction site is cleared of fertile soil, then the soil is compacted, covered with sand, and tires are laid on the prepared base.

Because the house actually has no foundation; Alexandra advises putting tires from trucks or buses under the foundation. If you plan to build a large house, then it is better to use tractor tires.

Alexandra ’s recipe for properly “cooking” a tire :

– The tires are filled with earth, then the next one is laid on the first row. With each subsequent row, the diameter of the tires decreases. The tires are fastened to each other with reinforcing bars. For greater reliability, several rows of tires can be filled with concrete. It turns out to be an army belt.

The roof is also assembled from tires. It has the shape of an arch. An interesting point is that glass bottles are inserted into the roof to save energy. On sunny days, sunlight is refracted and enters the room.

What a solar pipeline is is explained in detail here .

The researcher says that such houses are durable, well soundproofed and environmentally friendly. To do this, all walls, joints, cracks in the house, inside and outside, are thickly coated with a solution of clay and sand. It turns out to be a kind of mud hut.

Clay insulates rubber well from atmospheric influences and does not allow the sun's rays to heat the tires. Those who have already lived in a house made of rubber “bricks” say that there is no smell or any harmful fumes in the premises.

Having seen the result, a whole line of people lined up to get a similar house to Alexandra. The researcher says her future plans include upgrading the technology by experimenting with different tire fillers. Such houses have limited architectural possibilities. But for a number of countries, such an approach is a real solution, both in the construction of prefabricated houses and in the disposal of millions of used tires.

How to build a house from bags of earth is described here . This topic contains information about the construction of reed houses. And here you can learn how to make a lamp from a plastic bottle that does not consume electricity.

Types of tire foundations

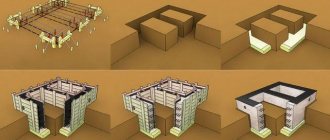

Due to their high load-bearing capacity, foundations made from car tires are recommended for the construction of lightweight objects. Based on the installation method, there are two types of base:

- columnar. It is represented by separate support pillars, which can consist of 4-5 tires. Concrete mortar or soil is used as filler;

- slab. To construct the slab, the building material is installed in two rows and reinforced with a special reinforced belt made of metal rods.

Important! It is recommended to use large-diameter tires for the foundation of a house, which have increased strength and wear resistance. In addition, all elements must be the same size and brand, this will ensure the construction of a reliable and durable structure.

Application area

Today, such foundations are used when building houses from lightweight materials up to two floors high , for example, frame or other structures for utility purposes. It is better to take tires from heavy-duty vehicles because they are stronger, more durable and dampen vibrations better.

Return to content

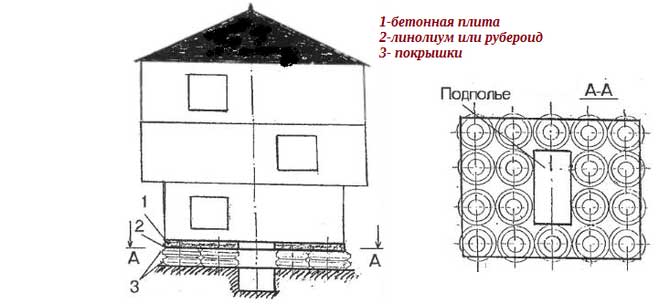

Arrangement of a slab foundation

The slab foundation is a durable slab built from old tires. Construction work is carried out in the following order:

- Clearing the construction site of debris and trees, dismantling old structures.

- Removing the top layer of soil to a depth of 15 cm.

- High-quality laying of tires in a double layer to increase the strength of the base for the future structure.

- Filling the resulting voids inside and between individual elements with fractional material - fine gravel or broken bricks. The interior space of each tire is only 85% filled.

- Laying roofing felt or linoleum as a waterproofing layer.

- Installation of removable panel formwork around the entire perimeter of the base. In this case, the height of the finished formwork must be at least 10 cm.

- Installation of reinforcing bars on the waterproofing layer to increase the strength of the finished structure.

- Pouring with a concrete mixture made from cement, fine sand and water.

- Dismantling the removable formwork after the concrete has completely dried.

Attention! Sand cannot be used as a void filler in tires. This is fraught with excessive shrinkage of the base and deformation of the finished structure.

Manufacturing

Before you start making the foundation, you need to prepare consumables and tools:

- shovel and bayonet shovel;

- linoleum or roofing felt;

- sand, crushed stone;

- pipes, boards for tamping;

- building level;

- tires;

- reinforcement of different sections;

- slats, bars.

This type of base is only suitable for wooden buildings. Wood has high elasticity and does not collapse from small vibrations. This cannot be said about buildings made of bricks and blocks.

Shovels (Photo: Instagram / cordondubna)

Arrangement of a slab base

Stages:

- Prepare the construction site. Mark its outer boundaries, remove debris, trees, and bushes.

- Remove the fertile layer. To do this, you need to remove 25 cm of soil.

- Lay out a layer of waterproofing, which will be done by roofing felt.

- Lay out the tires without any gaps.

- Check the evenness of the layer with a large building level. It is important that there are no protruding tires.

- The voids inside the tires should be filled with fine gravel and broken bricks between them.

- If the soil is waterlogged, make a high slab of two rows of tires.

- Lay out 2 layers of roofing material.

- Build formwork from boards around the future slab. It is important that its height is 20% greater than that of the finished slab base.

- Tie a metal mesh that will reinforce the screed. Secure it over the roofing felt.

- Mix the concrete solution and pour it into the formwork.

It is important to pour the concrete solution at once so that the base does not lose strength and is more uniform. This type of foundation is more solid and expensive, but it is suitable for different types of soil and the construction of massive buildings.

Tires (Photo: Instagram / vse_o_bane)

Making a columnar foundation

Stages of arrangement:

- Choose a place for the bathhouse.

- Determine the dimensions of the base, mark it using pegs with a stretched thread.

- Outside the internal boundaries, remove garbage, cut down trees, uproot stumps.

- Remove top layer of soil.

- Place tires on top of the pegs so that the peg itself is their center.

- Align the tires horizontally. To level the height, you can use a building or water level.

- Leave 100–120 cm of free space between individual posts.

- Mark locations for each individual post based on the corner points of the base.

- Dig pits for posts 2 tires deep.

- Pour a 20 cm thick layer of sand and small crushed stone onto the bottom and compact it.

- Make central pegs from the reinforcement for each of the pillars.

- Place a layer of waterproofing on top of the compacted pillow. For this it is better to use roofing material.

- Place the tire inside so that the metal rod is in the center.

- Fill the inner space of the tires with broken bricks.

- Mix the concrete solution and fill the tires.

After the concrete has hardened, a layer of roofing material is placed on top of the tires, and the first piping crown of the building is attached to it.

Pouring a tire with concrete (Photo: Instagram / borodatyidrug)