We build a foundation from foam blocks for a bathhouse

Foundation for a bathhouse made of foam blocks

The foundation for a bathhouse made of foam blocks must be made especially thoroughly. After all, it should not be driven; this material may not withstand changes. Today we will look at what kind of foundation is needed for a bathhouse made of foam blocks. A video will also be presented in this article and you will be able to see everything clearly.

Some features of the foam block

Foam concrete products have become widespread in individual low-rise construction. They are used in the construction of cottages, garages or bathhouses. However, it should be noted that the material is least suitable for constructing a foundation. Insufficient plasticity of foam blocks when exposed to frost heaving forces negatively affects the strength of the underground structure. The porous structure facilitates the absorption of large amounts of moisture from the soil, leading to rapid layer-by-layer destruction of lightweight concrete.

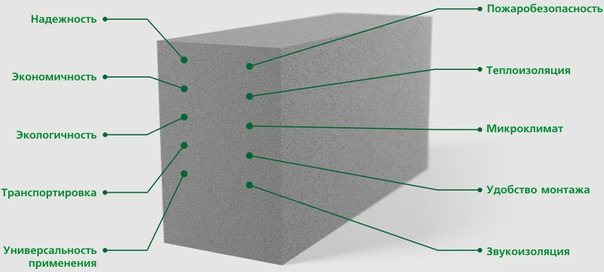

Meanwhile, the construction of bathhouse walls from foam blocks is today one of the best solutions when choosing materials for such a building. The determining factors in this case are:

- excellent thermal insulation;

- small weight;

- affordable price;

- environmental friendliness;

- fire resistance;

- durability.

The cellular structure of the foam block, filled with a mixture of inert gases and ambient air, provides it with a low thermal conductivity coefficient, comparable to similar indicators for wood of various species. When using it, there is no need for additional insulation. In addition, porosity allows the material to “breathe,” which ensures the timely removal of moisture from a steamed room and the creation of a special microclimate.

The relative lightness of foam blocks makes working with them comfortable, and their rather impressive dimensions, unlike bricks, make it possible to quickly build a building with your own hands. But when choosing an artificial stone, you should not forget about the high level of water absorption of the material, so for a bath you should purchase foam blocks of maximum density. Otherwise, a structure associated with high humidity and steam formation will not last long.

Choosing the type of foundation

The construction of any building is not complete without the construction of a strong and high-quality foundation. If construction work on buildings is carried out without creating a solid foundation, the risk of rapid destruction of the building increases. The construction of a bathhouse also requires the construction of a solid foundation. This article discusses the issue of creating a foundation for a bathhouse.

When choosing a foundation for a bathhouse made of foam blocks, you must be guided by certain factors:

- Take into account the characteristics of the soil at the site of the proposed construction;

- Selected materials for the construction of bath walls.

In order to understand what type of foundation should be built, it is necessary to examine the soil. To do this, you need to dig a small hole and look at the composition of the soil. The type of future foundation depends on the characteristics of the soil. And the money spent on its construction depends on the chosen foundation.

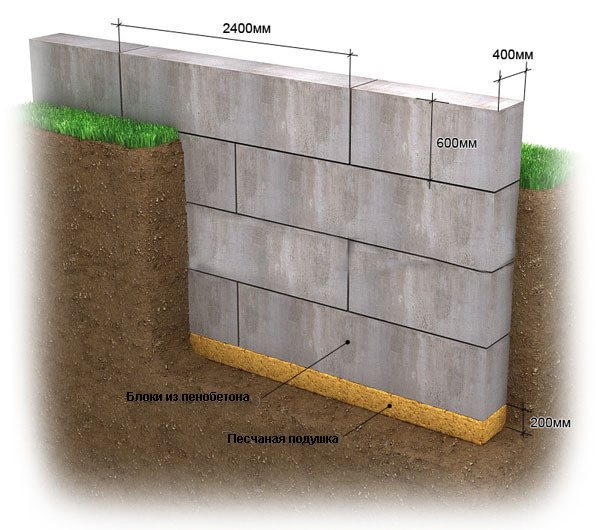

- If there is a huge amount of garden, swamp or forest soil in the ground, then it is necessary to create a strip type of foundation. A sand cushion will serve as the foundation.

- If the soil consists of clay rock, coarse sand and gravel, then a strip or columnar version is suitable for creating the base of the bathhouse. It is with this composition that the earth is considered the most convenient option for construction work.

- For soil containing fine sand, quartz or rock, any type of foundation will do.

One of the most important factors when choosing the type of foundation will be the material from which the walls are planned to be built.

- With a strip foundation, you can build walls using brick or concrete blocks, logs, beams.

- For the columnar version, only walls built using wooden materials are suitable.

Attention: The choice of foundation depends on the soil, the proximity of groundwater and the weight of the structure. These three factors will be the main ones. Be sure to take into account the distance from the foundation to the roof of a foam block bathhouse

Soil requirements

Before choosing a construction site, we look at the soil.

Here we take into account the following:

- Particularly important characteristics that the soil must have are: uniform distribution of moisture, the soil should not swell or sag.

- The best option would be soil with a dense and uniform composition.

- If the ground freezes strongly during the cold season, it is necessary that the bottom of the foundation be a couple of tens of centimeters below the level to which the soil freezes. Thanks to this, you don’t have to worry that the walls may crack over time.

- To prevent the earth from swelling around the foundation, it is necessary to fill the perimeter of the foundation with sand.

Choosing the location of the bathhouse foundation

Before starting construction work to create a foundation, it is necessary to prepare the site:

- You need to find an area that has a slight slope. The slope does not allow standing water to form; all fallen water will flow down the slope, which will ensure constantly dry soil under the foundation of the bathhouse.

- To begin with, the top layer of soil is removed from the site. When marking the future foundation, it should be taken into account that its width should exceed the width of the walls. To plan the foundation, you can use a construction tape, a special cord, a building level, or pegs made of wood or metal.

- Pegs are used to mark the internal contour of the room. To do this, you need to create one of the corners of the bathhouse and install a triangle in it. Along the sides of the triangle, the longitudinal and transverse walls of the building are marked.

- Next, to mark the foundation, a cast-off, constructed using various boards and columns, is installed. This structure should be located a few meters from the peg. All boards must be attached to a height of about 1.5 meters above the ground.

What should be the depth of the foundation for a bathhouse?

Are you planning to build a comfortable steam room near a country house? In this case, you will have to figure out how deep the foundation for the bathhouse should be.

Bathhouse foundation

It must be said that this parameter is determined by many criteria, but, first of all:

- structural features of the bathhouse;

- type of foundation being built;

- characteristics of the soil in a given area (type of soil, its homogeneity, presence of groundwater, etc.);

- budget allocated for construction.

Choosing a suitable foundation

The photo shows the formwork for pouring a strip foundation

So, let's try to figure out which base for a bath is better, and at what distance it should be located from the surface.

The foundation is the foundation of a building, the main function of which is to bear the load of the construction site.

In addition, a properly made foundation with your own hands can protect the building from the negative effects of groundwater and excess humidity.

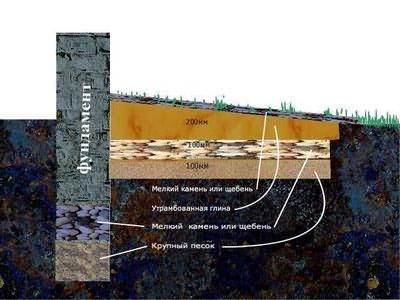

Schematic representation of the base for a bathhouse

Therefore, before starting the construction of the foundation, it is necessary to analyze the condition of the soil and determine its type. Only after this can the appropriate foundation depth for the bathhouse be calculated.

Features of the soil at the construction site

When assessing the strength and stability of the soil, it is necessary to consider methods for strengthening it. Again, it will be necessary to take into account the likelihood of subsidence and the possibility of landslides depending on the proximity of groundwater.

Important: Bathhouse construction statistics indicate that such facilities are not recommended to be built in areas where the soil layers are located on a slope and on silty soil, peat and fine-grained sand. All of the above types of soil are unstable and mobile.

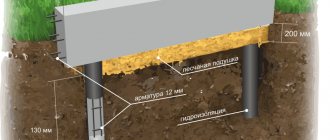

Sand cushion at the bottom of the trench

If construction is planned on a problem area, a cushion of fine crushed stone or coarse sand with a layer thickness of 20 cm is made under the base. Thus, when building a bathhouse on problem soil, another 20-25 cm must be added to the depth of the base for the construction of the cushion.

Important: The distance of the foundation from the surface depends on how deep the ground freezes. If construction is carried out on clay soil, the base should be placed approximately 25 cm lower than it is usually built on ordinary soil. The fact is that clay soil is characterized by swelling when the upper layers freeze.

When erecting buildings on land with a high sand content, the degree of soil freezing is not a fundamental factor. But it should be remembered that the depth of the base in this case, regardless of the chosen modification, must be at least half a meter.

If we are talking about a foundation for a strip-type bathhouse, then its depth under load-bearing walls should be more than half a meter, and under internal walls - at least 40 cm.

Features of the building materials used

The degree of foundation deepening is largely determined by the type of building materials used to construct the object. For example, it is no secret that a building made of foam blocks will weigh an order of magnitude less than a house with the same dimensions, but built using brick.

Consequently, for a brick building, in order to prevent subsidence, a more massive foundation is needed than for a bathhouse made of foam blocks or lumber.

Lightweight construction from foam blocks

According to statistics, for the construction of a bathhouse from piece building materials (blocks, bricks, etc.), it is advisable to use a strip base. If the construction is carried out using logs or beams, a columnar foundation for a bathhouse, made by yourself, is suitable.

Log bathhouse on a columnar foundation

To summarize the above, we note that the optimal type of foundation for small baths are strip and column structures, which provide not only the strength and durability of the building, but also the effectiveness of insulating the floor in the bath and the convenience of arranging utilities (drain for water drainage).

Dependence of depth on freezing level

Now, regarding the depth of the base. As follows from the above, the most important criterion for determining the depth parameters is the intensity of soil freezing.

As a result, it can be assumed that a well-planned foundation laid below the freezing level will not be subject to frost heaving of the soil.

Consequences of frost heaving

On the other hand, do the parameters for laying the foundation of a bathhouse depend on how much the ground freezes or is this parameter not so important? For example, if the type of soil is not heaving, the base will practically not be exposed to the forces of frost heaving.

Consequently, the construction of a deep foundation in this case can lead to an increase in the cost of the structure.

An integrated approach to determining the depth of the bathhouse base

In fact, determining the depth of the foundation requires an integrated approach.

That is, when calculating the depth parameters, you need to take into account:

- soil type;

- groundwater level;

- the approximate mass of the construction project and, as a result, the load on the soil;

- climatic features of the region;

- degree of freezing of the ground.

By comparing all these factors, you can most accurately determine how deep the foundation should be in order for the bathhouse you built to last for many years.

The type of soil and its ability to change volume in a wet state when the temperature drops or rises especially strongly influences the depth of placement.

Based on the degree of volume change, soils are divided into three main categories:

- Heaving - loams, silty sandy loams, fine sands;

- Slightly heaving - coarse and medium sands, gravel rocks, coarse clastic rocks;

- Non-heaving - semi-rocky and rocky rocks.

The groundwater level is also of considerable importance when designing small-sized construction projects, which are bathhouses.

For example, if the groundwater level is high and the soil on the site is characterized as heaving, the price of building a bathhouse will be so high that it is advisable to find a site with denser and more stable soil.

As a rule, it is not easy to determine the groundwater level on your own, but such information can be obtained from regional or district cadastral authorities, as well as from specialized organizations engaged in geological surveys.

Returning to the parameters of freezing depth, we note that they largely depend on the climatic zone in which a particular area is located.

As an example, we provide data in millimeters for a number of settlements:

- Odessa – 700;

- Kyiv – 900;

- Minsk – 1000;

- St. Petersburg – 1200;

- Moscow – 1400;

- Novosibirsk – 2200.

From the above example it is clear that the closer to the north, the deeper the ground freezes and, therefore, the more massive the foundation on which the bathhouse will be built should be.

Suitable laying depth

Instructions for laying the foundation

The degree of deep freezing and the level of groundwater are not particularly important criteria if the construction of the foundation is carried out on rocky and semi-rocky rocks. Thus, construction on such a plot of land is the most profitable, since the depth of the foundation, regardless of the climate, is less than half a meter.

The length of laying the foundation on soil consisting of medium, coarse or gravelly sand is more than 0.5 meters, regardless of the freezing depth and groundwater level.

On heaving soil, three options for laying the foundation are possible:

- the foundation is buried only half a meter if the groundwater level is 2 meters higher than the calculated depth of soil freezing;

- the laying depth should be 0.7 meters or more if the groundwater level is less than 2 meters higher than the freezing depth of the soil;

- the laying depth must exceed the soil freezing depth if the groundwater level is less than the calculated soil freezing depth.

Conclusion

A well-designed and properly constructed foundation is a guarantee of the durability and functionality of the bathhouse. In order to achieve optimal results, it is important to maintain the laying depth in accordance with the above parameters.

You will find more useful information that will make it easier to build a bathhouse by watching the video in this article.

9ban.ru>

Construction of the foundation of the future bathhouse

It is quite possible to make the foundation for a bathhouse with your own hands. But it should be said that for some types it will be necessary to hire equipment, otherwise the work will take a long time. The final price will also depend on the choice of type. So calculate everything thoroughly.

Attention: When choosing any type of foundation, you should immediately take into account that it must be wider than the structure itself. It is necessary.

Strip foundation type

You can build the foundation yourself. If you have some information in the field of construction and certain skills, then there will be no special problems with this work. It is very easy to build a strip foundation.

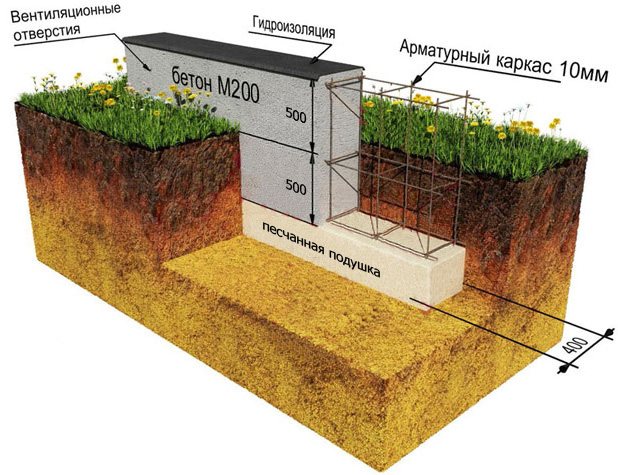

Strip foundation diagram

- The components needed to create a foundation are: water, cement mixture, fine-grained sand and crushed stone. In order for the concrete mixture to be of good quality, certain rules must be followed when mixing all components.

- If you mix the components in the correct ratio, the future building will be strong and durable.

- To prepare the cement mixture, large containers are used. When making a concrete mixture, the first step is to mix sand and cement, then add crushed stone to the resulting mass and mix again. After this, water is added and the mixture is stirred until a homogeneous structure is obtained.

There are various options for constructing a strip foundation:

- Sand and crushed stone are poured into the finished trench. All layers are carefully compacted and filled with water. After this, everything is filled with the prepared cement solution. The next step will be the construction of the base, which is insulated from moisture using roofing felt.

- The second option assumes that first a layer of sand is poured into the trench, and then gravel. After this, brickwork is laid in one layer. Then they build wooden formwork and fill everything with concrete. As soon as the mixture has hardened, the formwork is dismantled.

- If there is dense soil on the site, then you can create a foundation without digging a trench. A formwork is created, into which crushed stone and sand are placed and filled with concrete mortar.

- As soon as the mixture has dried (it takes about 3 hours for the mixture to dry), it is covered with materials that can allow water to pass through.

- The material you can use is sawdust, wood shavings, or burlap. The covered material is soaked generously with water and wrapped in plastic wrap. After a couple of weeks, you can remove the formwork and use the finished foundation.

Attention: For foam blocks it is necessary to reinforce the foundation. The structure must stand rigidly.

Columnar foundation type

Foundations for column-type buildings are ideal in areas where the soil is not dense. The structure of a columnar foundation is very simple.

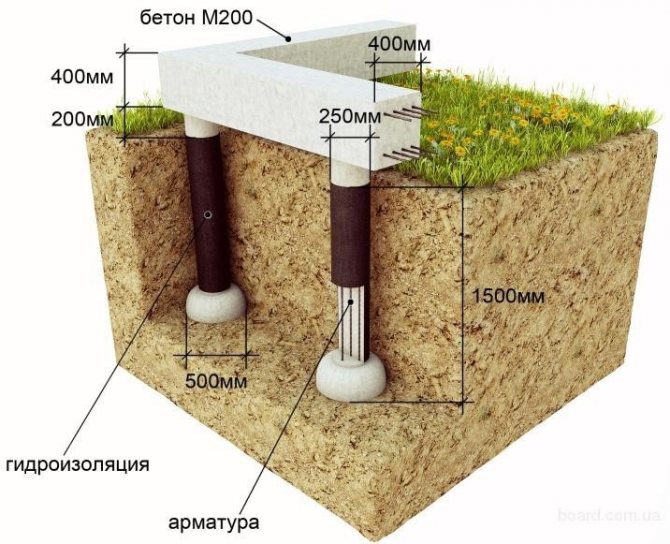

Columnar foundation diagram

- In the corners of the future building and in places where there is a heavy load, columns are placed a few meters from the previous column. Columns can be made of various materials, it can be: metal, wood, stone or brick.

- If wooden beams are used in a columnar foundation, then before installation they must be treated with antiseptic agents, then thoroughly dried and treated with tar. This will protect the tree from the onset of rotting processes.

- The easiest option for creating a foundation is to use asbestos-cement pipes. They are buried in the soil, and the cavity is filled with concrete mortar. It is recommended to bury the pipes in the ground to a depth of about 1.5 meters.

Slab as a foundation

As we wrote at the beginning of the article, the choice of foundation will depend on the quality of the soil at the site of the proposed construction. If the soil at the site where the bathhouse is built is weak, then a solid slab would be an excellent foundation option.

Holes in the foundation for sewerage

Often, when installing a sewer system, the owner of a bathhouse is faced with one main problem - how to route the pipes through the foundation. There are few ways:

- Drill holes in the foundation for the sewer pipes and run them through them.

- Direct laying of sewerage under the foundation.

It seems that it is easiest to arrange holes for pipes at the initial stage of constructing the foundation, but as practice has shown, this option is not always feasible. This is often due to the fact that the planned size of the holes ultimately does not correspond to the specified parameters.

There may be several reasons for this:

- the quality of materials used for the construction of the foundation;

- loose soil or its shrinkage;

- changes in the project during installation work;

- errors in the design or construction of the foundation itself.

Therefore, most experts still recommend drilling holes in a ready-made foundation. But here too many difficulties arise. Strong concrete is not easy to drill. In addition, such work should be carried out with the utmost caution, since any crack that appears in the foundation during the work will render it unusable.

Holes in the foundation for sewerage are made using tools such as a hammer drill, an impact drill, a diamond-coated drill and a hammer. It should immediately be noted that this process is quite labor-intensive. When carrying out work, the tool may rest not only on stones, but also on reinforcement.

What parameters need to be taken into account when choosing a foundation for a block house?

This relatively new material has many advantages over its analogues:

- ease;

- hygroscopicity;

- high sound and heat insulation properties;

- environmental friendliness;

- non-flammability.

The foundation for a house made of foam blocks is built with your own hands according to the same principles as the foundations for any other buildings. When choosing the type of foundation you need to pay attention to the following parameters:

- Soil characteristics. These include freezing depth, soil composition, and groundwater level.

- Estimated load. This includes the weight of the building itself, including its underground part, the weight of furniture, communications, and residents. When calculating the load, an adjustment must be made for the additional load from precipitation - rain and snow. It is at this point that the advantage of expanded clay concrete blocks, which have much less weight than conventional brick, will be visible. Consequently, a block house requires a less capital foundation.

- The cost of the material, as well as the timing of laying and standing of one or another type of foundation.

Influence of soil parameters on choice

Let us note right away that you should not try to save money on the construction of the base. This saving can create a lot of problems in the future. An improperly laid foundation can cause walls and floors to break, the house to slope, and dampness and mold to grow inside the building.

Scheme of laying a foundation made of foam blocks

Ordering a 3D model of the soil on which construction will be carried out is quite an expensive undertaking, and not everyone can afford to turn to specialists. If your neighbors built not long ago and conducted a soil study, you are in luck. You can use their calculations. It is unlikely that the data will differ much within small areas. If this is not possible, we will try to do everything ourselves.

To do this, you need to drill a well (preferably several) up to 2.5 meters deep, not forgetting to take soil samples every 20-30 cm. This way you can understand what type of soil you will have to deal with and what the depth of the groundwater is.

If the soil is not heaving, then the soil freezes shallowly. Provided that groundwater flows at a level of at least 2 meters, you can opt for a shallow foundation. It is the least financially expensive and easier to build with your own hands.

For close groundwater and heaving soils, it is better to use more permanent types of foundations.

Types of technologies

Having decided on the characteristics of the soil and the weight of the building made of expanded clay concrete blocks, you can begin to select the type of foundation.

Bases are divided into two main types:

Shallow ones are easier to do with your own hands. They do not require a large amount of excavation work. In addition, this type is the least expensive in terms of material.

Tape base

The strip foundation is shallow. The easiest way to install it with your own hands is under a building made of expanded clay concrete blocks. This type of foundation is best used in conditions of stable soils and deep groundwater, as well as for buildings of relatively light weight. Such a foundation will perfectly support a bathhouse made of blocks, a garage or a one-story house made of expanded clay concrete blocks.

To build a strip base, you need:

- Dig a trench according to the plan for the future construction. The foundation must be laid to a depth exceeding the freezing depth of the soil.

- Install the formwork according to the plan. You can use a non-removable polystyrene foam structure, which, moreover, will serve as additional thermal insulation.

- Reinforce the space with metal or fiberglass reinforcement.

- Let's start pouring the concrete foundation with our own hands.

Pile foundation

Quite a popular type of foundation for buildings made of expanded clay concrete blocks. This design does not require large material costs, and it is also easy to do it yourself. This type is best used as a foundation for a bathhouse made of blocks, a garage or other buildings that do not include a basement or ground floor.

Piles are installed at the corners of the building and under the load-bearing points of the building made of expanded clay concrete blocks. There are two options for laying a pile foundation with your own hands: the pillars can be poured from reinforced concrete, as is the case with a strip foundation, or screwed in in the form of ready-made screw piles.

The piles are screwed into the ground to a depth exceeding the soil freezing level by 0.2-0.3 meters. The number of piles is calculated based on the weight of the future structure. One pile can withstand a load of 2.5 to 4 tons.

This type of foundation is considered the fastest and cheapest to construct. In addition, it perfectly performs its functions in unstable soil conditions.

Types of foundations

Foundations are divided into several main types:

- Tape.

- Columnar.

- Slab.

- Pile-screw.

Each type of foundation has its own characteristics, strengths and weaknesses. Since we are talking about a foundation for a bathhouse made of foam blocks, no overly powerful foundation is required, and the choice of material for construction will not be difficult; any type will do.

Types at a Glance

- Strip - a base consisting of a continuous concrete strip along the entire perimeter of the building and internal load-bearing walls. The most common type of foundation, tested on thousands of buildings. It has a high load-bearing capacity and quite high material consumption.

- Columnar consists of a system of pillars or piles located at the key points of the future building - in the corners, at the junction or intersection of load-bearing walls and piers. Most often, such a foundation is buried in the ground to a depth of 0.5 - 1 m below the freezing depth of the soil. When building a bathhouse, you can get by with simpler methods - use pillars from individual blocks on a sand bed, without burial. About the serious mistake of such foundations, watch the video below.

- Screw piles . Such a foundation is most beneficial in areas with complex terrain, with slopes or folds. Screw piles are screwed into the ground until the hard layers are formed; the top is cut or extended until a single plane is formed, on which a grillage supporting the walls is mounted. They make it possible to avoid leveling the terrain of the site, which requires equipment and is not always possible.

- Slab . This is a monolithic concrete slab laid under the entire building. Such a foundation is also called “floating”, since the slab is not buried in the ground and moves along with the building during any soil movements, for example, seasonal ones when snow melts, etc. Used on soft soils, capable of bearing significant loads. The high material consumption, and, as a consequence, the high price of such a foundation, is compensated by the fact that the foundation itself is the floor of the basement.

Useful video

The video below shows how a foundation made of screw piles will help to erect a structure at relatively low (compared to concrete) costs on terrain, slopes and even over water:

The following video shows a serious mistake made when constructing columnar foundations:

Do-it-yourself bathhouse made of foam blocks

As you know, the classic Russian bathhouse has been built of wood since ancient times. However, current construction technologies include the use of other materials during the construction of baths. From an economic point of view, the most profitable option would be a bathhouse made of foam blocks. It will cost the owner several times less than a wooden structure.

Several decades ago, regulatory documents provided for the use of only waterproof and bioresistant materials for the construction of baths. No voids or air gaps. Today’s version of the bathhouse, with some additional insulating modifications, can be built from foam blocks, gas and foam concrete.

What are foam blocks?

Foam blocks are an artificial building material. It is made from ordinary cement-sand mortar and a special foaming additive. The latter can be in the form of ready-made foam. Or in the form of active substances that begin to foam when the solution is stirred.

The foam is unevenly distributed in the structure of the blocks. Therefore, the finished mixture turns out to be heterogeneous. And promotes the accumulation of moisture in the blocks. Therefore, when building a bathhouse with your own hands, you should also carry out additional hydro- and vapor barrier work.

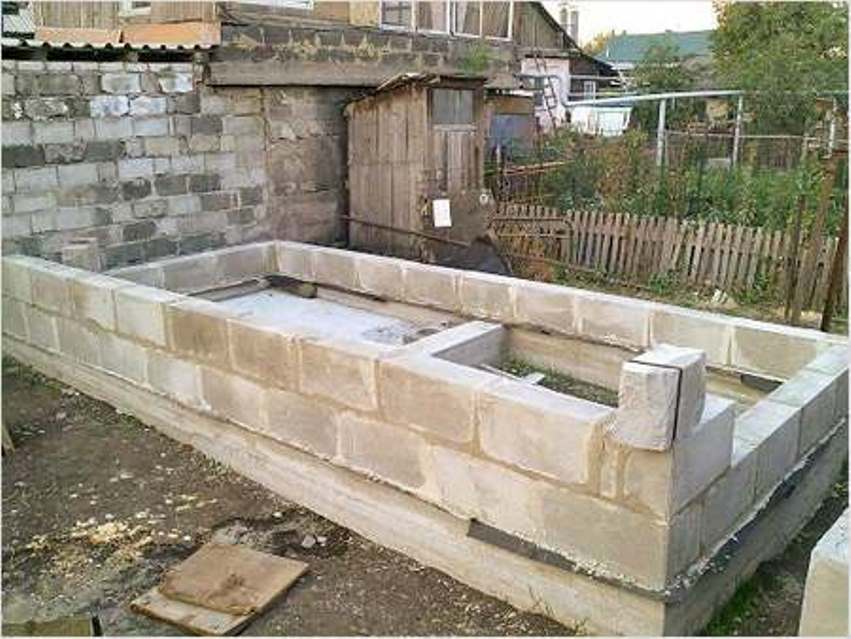

Work on arranging the foundation is carried out in the following order.

Choosing a location and digging a trench

Immediately before starting to build a bathhouse, you need to choose a suitable place for it. The ideal solution would be to choose a flat area with dense soil.

Using pre-made markings, a rectangular trench is dug under the foundation. The depth is about 40-60 cm. And the width is about 30 cm. It is important that the dimensions of the trench completely coincide with the dimensions of the future bathhouse. The pins should be driven vertically into the corners of the dug rectangle. And then the pins are driven in along the entire perimeter of the trench. Intermediate pins are installed at a distance of about 1-1.5 meters from each other. Next, a cord or rope is pulled over the installed pins. The horizontalness of the cord is checked with a level.

The nuances of installing formwork

The frame of the bathhouse is prepared from reinforcement 1.2 cm thick. To tie the frame horizontally, thinner reinforcement or wire is used. Formwork may not be installed in a trench if:

- The soil is quite dense.

- The walls of the trench are almost perfectly smooth

Concrete is poured directly into the trench. In this case, the formwork is installed only for the above-ground part of the foundation.

For formwork panels, boards or plywood 2.5 cm thick are used.

Pouring the foundation

To fill the foundation, grade 200 concrete is used. The total height of the foundation should be about 70 cm. Depending on the size of the future bathhouse, the foundation will require approximately 5-7 cubic meters of concrete.

When the concrete hardens, you should wait a couple of weeks. And only then can you start creating a sewer system. The diameter of the sewer receiver should be about 10 cm.

Then the entire area is covered with a layer of crushed stone. To increase the thermal insulation of a building, you can pour a thin layer of expanded clay on top of the crushed stone. After this, a grid is laid over the entire area of the building. Then markings are made along the foundation. It determines the upper level of the screed. After this, concrete is poured.

It is important that the screed is no thinner than 15 cm. To increase the moisture-proof properties of concrete, special additives can be added to it. Before laying the blocks on the foundation, you need to lay a waterproofing layer. For this, ordinary roofing felt or specialized material can be used.

Bathhouse made of foam blocks: erection of walls

When carrying out calculations, you should carefully select the blocks themselves. For example, the best option would be M25 blocks. With a density of D700 and dimensions of 10×30×60 cm.

Foam blocks are laid on edge. If possible, the seams between blocks are made as thin as possible. In order to prevent heat loss through them. The first row of blocks is laid on a cement-sand mortar. Using the solution, all irregularities are eliminated. After laying, this row is checked with a level. And, if necessary, adjusted with a rubber hammer.

The second row is laid with a half-block shift in relation to the first row. As a rule, subsequent rows of foam blocks are not laid using conventional cement-sand mortar. And on a special glue for foam concrete. A wooden or metal beam should be installed above the doorway. The next row of blocks is laid on top of it.

Construction of a bathhouse roof

After completing the laying of the walls, you should wait a couple of days. After this, you can begin laying horizontal beams and rafters under the future roof. The simplest roof option is a gable roof with a ridge in the middle.

The rafters should rest against the tie rods and fit together at the ridge. It is possible to join rafters into half a tree. Or a simple slotted tenon. The length of the rafters depends on the width of the room and the angle of the slopes. For humid climates with a lot of precipitation, it is better to choose a slope angle of more than 50-60 degrees. However, this will require more materials. The roof overhang over the walls should be approximately 50 cm.

Subtleties of laying rafters

To increase the strength of the roof, the rafters should be tied together using metal staples. Depending on the total length of the roof, the pitch between the rafters is selected. The approximate distance between them is usually 1-1.3 meters.

It is very important to choose the right material for the rafters. Because they bear the entire burden. The wood should be only first-class, with a minimum of knots. The calculation of the rafter pitch is carried out so that the rafters are located at a considerable distance from the chimney. Their distance should be at least 40 cm.

Laying the sheathing

The sheathing of the future roof is laid on the rafters. As a rule, boards are chosen for it. And their thickness depends entirely on the type of roofing material. Do not use boards with a large number of knots. Because under heavy load they can break. Unplaned boards are laid with the convex side down. As a result of this, accidentally leaked moisture can simply roll down them.

Depending on the material used for the roof, the sheathing is done in a continuous layer or in a continuous layer. For slate it should be done in one layer, and for roofing felt – in two layers. If tiles are chosen as the roofing material, then the sheathing is made from 50x50 mm beams. In this case, the last block must be laid 2-3 cm higher than the rest.

Roofing

After completing the work on the sheathing, the roof is laid over it. Sometimes roofing material spreads under the roof. It is covered with small pebbles and filled with bitumen. Then a rough ceiling is mounted from a 25 mm board. Foam plastic is laid on top of it. From the attic, the foam layer is covered with the same boards. They play the role of a subfloor in the attic.

Foundation for a 4x6 bath:

The 4x6 strip foundation begins with markings. To get started you need:

1. Drive stakes in the corners according to size. Next to them at a distance we drive in 2 more stakes from each corner.

2. Pull the lace along the far pegs, measure and set the diagonal. We make sure that there is an angle, the dimensions of how to measure it were shown above 3x4x5 meters.

By the way, for sizes it is better to take a white thread, because you won’t see black thread at all.

3. Next, you need to know the width of the tape of the future foundation; for us it is 25 cm.

4. Then, next to the hammered stakes (where the thread is stretched), we retreat a distance of 25 cm and drive another stake from each corner for the inside of the thread.

5. We dig a trench 40 cm deep. As soon as you dig it, you need to make a pillow with sand (layer 20 cm), pour it well with water and compact it.

6. We assemble and set up the formwork, as described above.

7. We put reinforcement into the formwork and pour concrete.

I hope everything was clear, if anything is unclear, you can ask in the comments.

Bathhouse made of foam blocks: interior work

Although the bathhouse is being built from foam blocks, all internal partitions in it are made of brick. As for choosing a stove, any option is suitable for a bathhouse. You can purchase a ready-made factory-made oven. Or make it yourself. Regardless of the option chosen, a foundation must be made for the stove.

Installation of internal and entrance doors is carried out in the usual way. Doors can also be purchased ready-made. Or do it yourself. However, the most important thing in building a bathhouse from such material is heat and vapor barrier.

Before installing the insulation, a protective primer is applied to the foam blocks. And then plastering is done using tile adhesive. After this, you can begin laying the insulation. Cotton wool or polystyrene foam can be used as insulation. Foil with a vapor barrier base is laid on top of the insulation.

Then the cladding is carried out using wooden lining or OSB panels. The material should first be treated with an antiseptic. An air cushion must be left between the lining and the foil.

The last construction operation is flooring. Metal sheets should be placed on the walls around the installed stove and at the chimney outlet. Asbestos is always laid underneath them.

Optimal base options for a bath

Considering that foam block is one of the lightest building materials, it makes no sense to build a foundation with a large margin of safety, so let’s consider foundations that will be effective both from a structural point of view and from a financial point of view:

- Columnar with grillage,

- Shallow tape,

- On screw piles.

The choice of a specific type depends on the characteristics of the soil, terrain, and groundwater level. For example, in swampy areas it is better to use screw piles or simply piles, “tape” or pillars are unprofitable and not always possible - it is necessary to make a deep trench, which is simply unrealistic to do when the groundwater level is high.

Advice from professionals

- Before starting work, especially when it will be carried out in a structure that has been in operation for several years, be sure to make sure that there are no hidden water pipes or wiring in the foundation structure.

- While drilling, do not forget to cool the drill and tool. Check it for chips, dents or scratches.

Regarding the size of the holes, the following requirements must be met:

- The diameter of the finished hole must be at least 50 mm larger than the diameter of the sewer pipe, or more.

- To reduce the load resulting from pressure from water pressure. It is advisable to mount the transition unit at the junction of the vertical and horizontal pipes.

- Considering that over time the bathhouse may shrink. It is advisable to place sewer pipes in metal sleeves provided in such cases. The space between the walls of the sleeve and the pipe is filled with heat-insulating materials.

Sewage through the foundation, installed correctly, will be the key to comfortable use of the bathhouse.

Columnar foundation with grillage

One of the cheapest options for constructing foundations for the construction of light buildings and structures, such as foam block baths.

Suitable for non-heaving dense soil types. The big advantage of this base is the minimal excavation work (digging a trench) and the ease of the device as a whole. The columnar foundation can be made from stone, rubble brick, or monolithic reinforced concrete pillars.

The task of any foundation is to evenly distribute the load transmitted from the building to the soil. This function is performed by pillars; their number is calculated depending on the project, but the distance cannot be less than 2 meters from each other. It is important to make the correct calculation of the number of pillars; too many will lead to overspending on the construction of the base, and less will lead to uncontrolled deformations, which is especially dangerous when building from foam blocks and will certainly lead to cracks or, even worse, destruction of the foam block masonry.

To make the correct calculation, it is necessary to determine what kind of soil we have, and also calculate the total weight of the bathhouse. You need to take everything into account: possible furniture, stove, foundation with grillage, walls, roof, possible snow load.

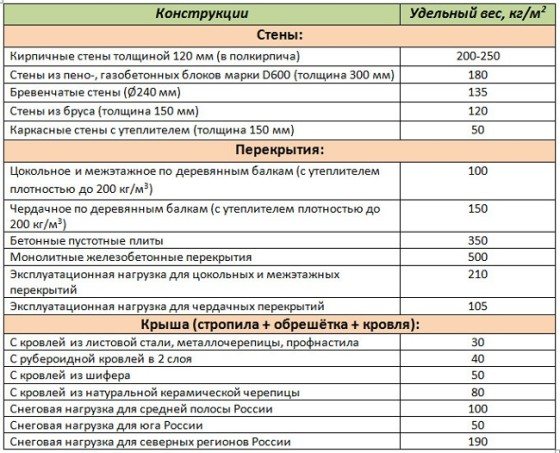

The table shows approximate specific gravities for calculation

Table for calculating the specific gravity of a house

To determine what kind of soil, it is best to conduct a geological survey. It is clear that such a project will be quite expensive for a private developer. If the construction budget is limited, you can use a pit to determine what kind of soil. To do this, at around 0.5-0.6 meters from the planned depth of the foundation, we take soil and make a small ball out of it.

Next, we try to roll a small ball out of the soil:

- if you can’t roll a ball, we have a sandy layer,

- if it rolls, but when squeezed it breaks up - sandy loam,

- if, when pressed, the ball retains its shape and there is no cracking along the edges, it is clay,

- if cracks appear, we have loam in front of us.

Now we need data on the calculated resistance of the load-bearing soil:

Table for determining the design soil resistance

We determine the minimum total area of the foundation; to do this, we multiply the weight of the entire house by the safety factor (usually a value from 1.3 to 1.5) and divide by the calculated soil resistance.

To determine the number of pillars, we first determine the area of one pillar, then divide the minimum total area of the foundation by the area of one pillar. We get the required number of pillars.

- We begin constructing a foundation for a bathhouse made of foam blocks with markings. Using cords of wooden pegs, we mark the perimeter of the future bathhouse and check the diagonals (they must be equal to each other).

- Marks the locations of the pillars. These are the corners of the house, the intersection of load-bearing and internal walls. The remaining number of pillars is distributed evenly around the entire perimeter; for symmetry, you can add several pillars

- An important rule: Pillars can be added as needed; making the quantity less than the calculated amount is strictly forbidden.

- After applying the markings, we dig holes using a drill or other device below the freezing level.

- Depending on the material chosen for construction, the pillars are erected or poured.

- After the foundation hardens, a reinforcement frame is made around the entire perimeter.

Shallow strip foundation

Schematic diagram of a shallow strip foundation

Soil analysis and foundation calculations are carried out by analogy with a columnar foundation, only instead of the number of columns, the width of the foundation base is calculated.

A shallow foundation for the construction of a bathhouse made of foam blocks can use different materials, as well as their combinations

- We carry out marking and excavation work to dig a trench. A geotextile backing is laid.

- We fill the pillow in several layers; it can be sandy or sand-crushed stone. The pillow must be compacted well; for this, a hand tool or a special platform vibrator is used.

- We install the formwork, check the geometry, and lay the reinforcement. If the foundation is up to the level of the plinth, communication pipes are laid

- Concrete is being delivered and poured.

- To prevent air pockets from remaining in the concrete, the mixture is compacted using a vibrator.

- When the concrete has hardened, remove the formwork

- We backfill and compact in layers.

- We immediately make an insulated blind area.

- After 28 days (this is how long it takes for concrete to gain strength), you can continue building a bathhouse from foam blocks.

What are the options for sauna drains?

- Sewer system. It is made of large-section metal or plastic pipes, and the wastewater is directed under the foundation to a septic tank or filter.

- Flat drain. This design is used with gray drains, is installed directly under the washing compartment and provides an inclined sealed second floor, which must initially be made when installing a screw pile foundation. To prevent the drains from freezing in winter due to the difference in ambient, soil and room temperatures, insulation is done with foam plastic or other material on the inner surface of the second floor.

Foundation on screw piles

Screw piles for a foam block bath

It is used very rarely for construction from foam blocks. Foam block is a fragile material and if you do not calculate it correctly or make inaccuracies when installing piles, there will be big troubles.

But the simplicity of constructing such a foundation and the ability to use it on unstable soils sometimes makes it almost the only option. The difficulty arises in the construction of a grillage connecting the piles to each other.

- Before starting construction, you need to calculate the number of piles, this is done as when building a columnar foundation.

- Next, you need to make markings, check the geometry, and mark where the piles will be located.

- Next, using a wrench, the piles are screwed into the ground to a depth of 0.5 meters below freezing.

- Using a water level, the piles are trimmed to one level.

- Connecting grillage devices are being produced.

To make the right choice of foundation for building a bathhouse from foam blocks, you need to start from the soil that is on your site, then determine its calculated definition, calculate the cost of this or that type of foundation. Having this data, analyze which design will be the most optimal in your region.