Order a turnkey 8×8 pile foundation for RUB 62,400 49,600.

Get a quote

The houses, which have an area of 8x8, are spacious enough for a family of several people to live in them. A variety of materials can be used for their construction, and the correct selection of the foundation plays an important role.

Screw piles for an 8 by 8 house are an ideal option, because the foundation of them can be installed on almost any type of soil, including complex ones. With all this, the price of a foundation on 8x8 screw piles is significantly lower than traditional analogues.

Is it any wonder that it is very popular among both private developers and construction companies?

What factors influence the price of a foundation?

Construction should begin with design documentation for calculations. It is carried out immediately after analyzing the specific construction conditions. Based on this data from the documentation, correct calculations should be made.

Contact specialists to create design documentation - this, of course, costs money, but it will allow you to use the optimal amount of materials for the project. To put it simply, you don’t have to take insurance and make the tape 10 cm wider than what the structure requires.

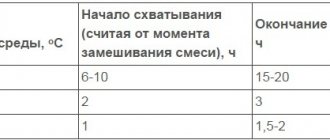

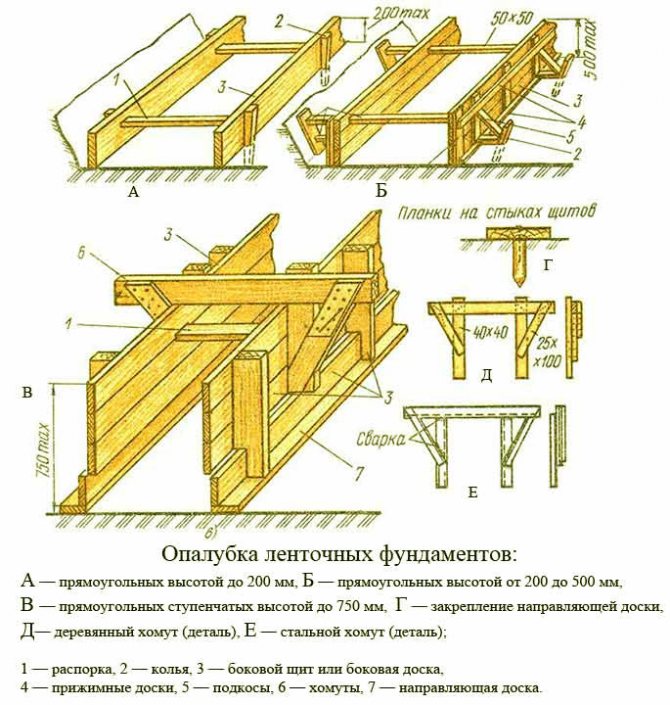

Strip foundation on the diagram

Now let's look at the work that takes place before the actual completion of the construction of the strip foundation. The list of required activities in hierarchy is as follows:

- Decide on the size of the house and order a project.

- Obtain a construction permit from the relevant authorities.

- Prepare the building area, remove existing debris, clear the ground cover of all objects, and mark the site.

- Prepare trenches for pouring concrete mixture.

- Fill the trenches under the foundation with a special “cushion” - a layer of compacted sand and crushed stone.

- Create an armored belt or reinforcement belt.

- Install the formwork required for pouring concrete.

- Buy or prepare concrete of the required grade in accordance with the construction conditions at this site and pour it.

- At the final stage of foundation construction, after the reinforced concrete mixture has hardened, it is necessary to remove the formwork and install waterproofing materials.

As a result of the work, it is very important to plan in advance the location of all communications, since at least one will be located in the foundation.

Formwork with pre-installed pipes

After drawing up a work plan, you can start making calculations.

Departments

Accounting

The accounting department has all the necessary information about the receipt of payments from Clients for services provided by GlavFundament (sale of screw piles, construction of foundations on screw piles, express geology, design of foundations on screw piles, civil and industrial facilities). Each Client has the opportunity to promptly receive information about the receipt of his payment to the organization’s account. The department's tasks also include issuing invoices and documents closing the reporting period.

Vasiliev Denis Alexandrovich

Corporate department

The Corporate Department is responsible for fulfilling contractual obligations to Partners for the supply of screw piles to the GlavFundament company (quantity, nomenclature, assortment, timing and other terms of delivery). The department provides assistance in working with other departments and separate divisions of the company, providing the Partner with marketing, technical and logistics support, and promptly compiles financial estimates and other documents.

Head of Corporate Department

Kopev Evgeniy Sergeevich

Human Resources Department

The HR department of the GlavFundament company occupies a responsible position in the development of the organization's plans in terms of providing it with labor resources, carrying out selection, admission, official employment, adaptation, accounting and dismissal of employees.

The tasks of the department include carrying out work on the formation and preparation of a reserve of personnel for appointment to appropriate positions, advising senior management and heads of departments on personnel policy issues in the development of projects, the production of screw piles, and construction. The department evaluates the performance of each employee of the organization.

Head of HR Department

Dubovik Elvira Gizetdinovna

R&D department

The Research and Development Department (R&D) is engaged in research into the nature of the joint work of screw piles with soil, development and implementation of innovations in the field of pile foundation construction.

The department’s specialists create technological solutions that make it possible to reduce work time and reduce costs without compromising quality.

The department’s tasks also include organizing scientific cooperation with departments of construction universities dealing with foundation engineering problems, providing consulting and information assistance to employees of the company’s structural divisions.

Head of R&D Department

Glazachev Anton Olegovich

Sales department

The sales department is the link between the company and the Client, carrying out the interaction process from the first contact to the end of the contractual relationship.

The department provides consultation, preliminary calculation of the cost of screw piles purchased by the Client, technical support, and conclusion of contracts.

Head of Regional Sales Department

Akatiev Sergey Nikolaevich

Advertising and PR Department

The advertising department is a structural unit tasked with determining the direction, planning and organizing advertising campaigns, as well as developing advertising and information materials.

The advertising department of the GlavFundament company carries out work on advertising its products (screw piles) and services provided (installation of foundations on screw piles, design and redesign of foundations and buildings/structures), and is working on concluding agreements for advertising products and/or services with third-party organizations.

In addition, advertising department specialists promptly notify Clients about various promotions and advertising campaigns, plan participation in exhibitions, and enter into agreements with organizing committees of fairs and construction forums.

Sergin Roman Petrovich

Purchase department

The purchasing department makes decisions regarding the purchase of raw materials required for the production of screw piles, being responsible for concluding product supply contracts and selecting suppliers.

Department employees provide information on the purchase of materials necessary for construction, advise on price categories, and also quickly calculate the cost and delivery time of screw piles to a particular region to organize the delivery of cargo to any point in Russia or the CIS countries.

Calculation of materials needed for the construction of a strip foundation

For example, in a project to build a house with dimensions of 8 by 8 meters. To build the base of this structure, you will need a reinforced concrete structure, which consists of concrete. As a result, we will need to calculate the amount of concrete required for the strip foundation.

To simplify our calculations, let's calculate the total amount of cement mortar for the construction of the outer box (internal partitions are not included in the calculation).

Base diagram

Formwork ready for pouring

They usually start by determining the parameters of the foundation structure:

- Perimeter. It is necessary to determine the length of the future structure: add 4 walls of 8 meters each and get a value of 32 m.

- Width. It directly depends on the load on the base of the future frame of the house and can be determined by specialists. For calculation, you can take a value of 40 cm.

- Heights. Experts determine this parameter taking into account the depth of soil freezing and its other characteristics. For example, it will be buried 1.5 meters, and the elevation above the ground will be 0.5 m. The resulting height is 2 meters.

Next, we calculate the calculation of concrete consumption. To do this, you need to find out how much it will take per 1 m: the height is multiplied by the width (2 x 0.4) and you get 0.8 cubic meters. The box will take (32 x 0.8) 25.6 cubic meters. To determine the partitions, it is enough to carry out a calculation using a similar principle. The average cost of concrete for 2020 is about 3,000 rubles. It turns out that just the support for the box will cost 76,800 rubles.

When choosing a concrete mixture, its brand is of great importance. To build a base 8 by 8 m, you can safely use the M300. If necessary, you can increase its frost resistance and strength characteristics. For example, order a solution with special additives – plasticizers – from the manufacturer. They can improve the properties of cement mortar.

Foundation cost 8 8

You can find out the cost of the foundation only by studying the future pile field: the height difference, the length of the aircraft depends on this, the screw-in depth (based on the results of trial tests), the choice of pile diameter, and other conditions. At the preliminary stage, you can compare the cost of a foundation of 8 8 or other sizes with similar projects already completed in your area, but this will only be a preliminary price, it may be higher or lower than finished projects. For any structure, an individual calculation of the number of screw piles is required. Our specialists are ready to calculate and select the necessary piles for your project. To do this, just call 8-495-127-05-63 or leave a request using the feedback form.

We count additional materials

The cost of concrete is not the only factor in determining the cost of a strip foundation for a house. To build a strong and reliable structure, you will also need other materials:

- Fittings. Typically, rods of at least 14 mm in size are used. To build a conventional reinforcement belt for a strip base, you will need 4 rods. The cost of 1 m is within 40 rubles = 160 rubles per linear meter. As a result, 32 x 160 = 5120 rubles.

- Formwork. The cost of its creation will not exceed 1000-2000 rubles. It all depends on the cost of materials in a particular region.

- Waterproofing. Since it is not always used, we do not use it in the calculation. But additional costs should be taken into account if necessary.

- Pillow. For a trench with a width of 0.4, if the cushion is 15 cm (0.15 m), the crushed stone consumption will be 1.92 per base for the box. The average price for granite crushed stone is 1,400 rubles. As a result, you need to spend 2688 rubles.

You also need to take into account the cost of removing equipment (if it will be used to dig a trench) and sand.

Choice of foundation. Its varieties

The main purpose of using a foundation is to support the weight of the building and prevent it from sagging or collapsing. Depending on the level and type of support on the ground, there are three types:

- Shallow strip foundation. Experts recommend using it specifically for the construction of a house made of timber. This is due to its practicality and ease of manufacture. Pouring such a foundation occurs using a mixer, or with your own hands. You need to use only high-quality concrete grades, such as M300 and higher. When making your own foundation, it is important to properly prepare the mixture. The proportions of cement, crushed stone and sand should be 1:2:2.

- Monolithic slab. Such a foundation is located under the area of the entire house in the form of a reinforced concrete slab or a structure consisting of reinforced concrete beams. It is used most often on heterogeneous soils that can move. Its installation will lead to high costs. It can be used as a foundation for a small log house, where a reinforced concrete slab is used as a subfloor.

- Pile foundation. This structure consists of several piles, which are covered on top with a reinforced concrete slab. This type of base is universal and economical, but is much less common than all others. This is due to the fact that for its construction you need to use special equipment. These piles will be indispensable in areas where the upper part of the soil is mobile. You can see what this foundation looks like in the video.

- Other types. In addition to the above options, today you can find both rubble and brick foundations. A rubble foundation is constructed from rubble stone and cement mortar. This construction is labor-intensive and complex, but the result will be a durable and strong foundation. A concrete foundation can also be found as a structure for a log house. In another way it is called “poured”, and it contains concrete in its pure form.

Selecting the right base will require some testing. It is definitely worth examining the composition and characteristics of the soil. It is worth considering how much the soil will freeze in winter. Thanks to such studies, it will be possible to understand what indicator of stability the soil has.

In addition, it is worth finding out at what depth the groundwater is located. During the construction of the foundation, it is necessary to ensure that the level of these waters is located significantly lower than the level of soil freezing. Also, when choosing a base, you should definitely take into account the area of the building.

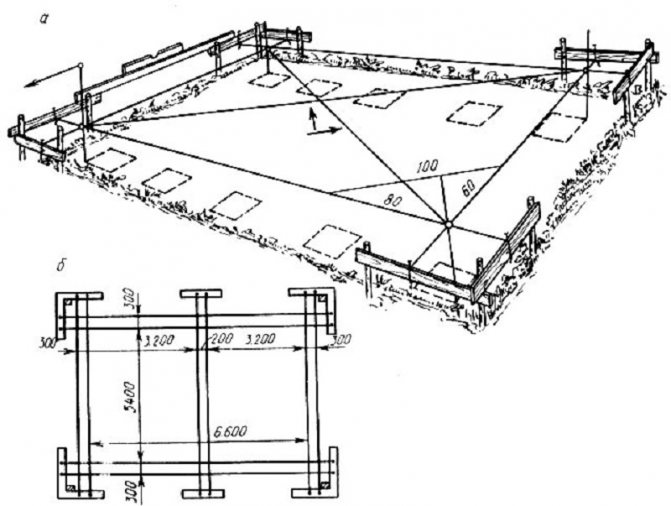

Marking for the foundation on the site

Scheme of correct marking of the foundation on the site

The first step in creating a foundation with your own hands is to correctly mark it on the site. To do this, you will definitely need a project for the construction of a house made of laminated veneer lumber, simple or profiled. Without diagrams and drawings of the location of the house, it will not be possible to correctly mark the territory. It is necessary to prepare the area for marking. The entire construction site must be level.

The first step is to determine the starting point. It should be located in the location of the facade of the future house. You need to drive a peg into this place. Then you need to measure the length along the facade, and drive the peg into the end point again. The third point is in the opposite corner of the second peg, and the fourth point is in the opposite corner of the first peg. Drive stakes into the third and fourth points as well. The end result should be a rectangle.

The next step is to accurately measure the diagonals. To do this, you need to measure the distance between corners 1 and 4, 2 and 3. The resulting indicator should be the same. If this is not the case, then using a large protractor you need to start aligning the corners. It is required to achieve ideal diagonals. When this step is done, you need to mark the location of the partitions. There can be no problem with this. The main walls are marked, now following the house design, you need to measure the required distance from them.

This work done is considered the initial marking. After its completion, you can begin the second phase of work. Why is this necessary? When the time comes to dig a pit, the previously driven pegs will get in the way, because they are located on the foundation line. To prevent this from happening, you need to prepare a cast-off. It should be positioned behind the dig line to define and show the inside base line. How professionals do this process can be seen in the video.

The cast-off must be located behind the foundation line, after which a cord or thick thread must be pulled between its elements. The cast-offs should be installed so that the cord is located on the top line of the foundation at the same level. This completes the marking process; you need to start digging trenches.

Proper digging of a foundation pit

One of the very first preparatory stages associated with laying the foundation is digging a pit. Initially, for this it is necessary to remove a layer of plant soil. The depth of this layer, which must be removed, is 20 cm. After it, another layer begins, which will also need to be removed.

If special devices are used to dig a pit, then you do not need to dig it completely. It is important to leave 10-15 cm more soil than is required to remove it manually. Thanks to this, the continental soil will be preserved, which will be in contact with the foundation.

The pits may be different. For example, narrow trenches are perfect for a strip foundation; wide trenches should be used if the house has a basement or basement. It is worth noting that when digging a wide pit, all walls must be reinforced with special slopes. They should be installed at an angle of 30°.

To select the type of pit required for a particular house, you need to invite a geotechnician. If the soil is loose, it is worth digging wide trenches and, conversely, if the soil is very dense, then narrow pits should be dug. The size of the narrow pit corresponds to the width of the base. To make all digging work easier, you need to make the walls with a slight slope.

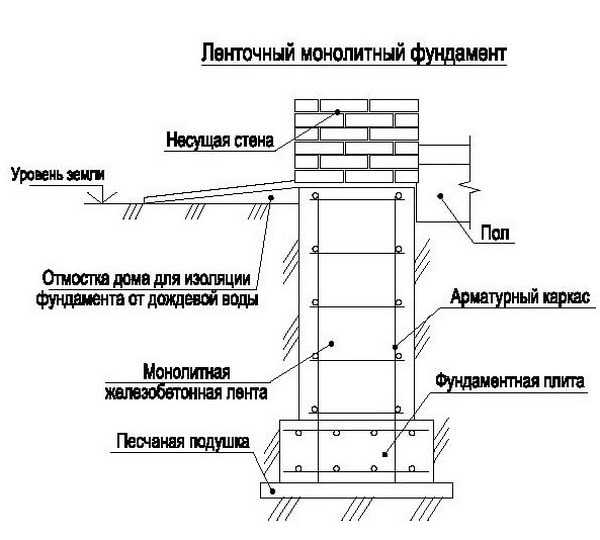

Sand cushion for the foundation

Sand cushion is a layer of sand located under the base of the foundation. The purpose of its use is to create a level and strong platform for laying the foundation. The main advantages of its use are the provision of optimal load on the foundation and high-quality protection against destruction of the foundation by groundwater.

A sand cushion can serve as a substitute for soil. If in the dug pit there is a layer of earth in poor condition that cannot be used for construction work, then it can be removed. Sand is placed instead.

Great care should be taken when choosing. Firstly, the grains of sand should be of medium size, neither large nor small. Secondly, the thickness of the sand cushion under the base must be at least 25 cm. After laying the sand in the pit, it must be leveled. The result should be a perfectly even, smooth layer of sand, without excess in some places. After this, the pillow is compacted. This is necessary so that the sand is not so unstable.

During compaction, the sand must be constantly moistened with water. This should be monitored especially carefully during the hot summer season. Thanks to humidity, the sand will become denser and more convenient to work with.

Installation of formwork. Choosing edged boards

In the process of creating a foundation for a house made of 8x8 timber, one of the main places is occupied by the installation of formwork. The final quality of the foundation will depend on the correct execution of this step. First, you need to decide on the material that will be used to make the formwork. The most popular edged board for this is 25x100.

Edged boards are used most often as a material for making formwork. This is due to the exact dimensions of the product, thanks to which it is possible to reduce finishing work. Because of this, there is a reduction in the overall cost of building a foundation.

An important matter is the choice of wood for the production of formwork. In this case, it is worth taking into account the magnitude of the load that is expected to be exerted on the foundation. Hardwood is very popular. They are strong and reliable, making it possible to perform the majority of types of formwork. Other nuances of choosing wood can be viewed in the video.

After choosing the material, you should start making the formwork yourself. It should be slightly higher than the height of concrete pouring. First you need to knock down the shields. The length of each of them should be 25 mm longer than the length at which it will be installed. All panels are fastened in the shape of the letter “L”, so this precaution will save material and ensure reliable fastening.

When assembling boards for a house made of timber with your own hands, it is best to use simple nails rather than self-tapping screws. After driving the nail into the board, you can bend it. This will increase the strength of the entire structure. When using self-tapping screws, they can jump out from the pressure of the concrete solution.

After assembling and fastening all the panels, it is necessary to install jumpers to the top of the formwork. To do this, you need to install wooden spacers that will strengthen the walls of the formwork. Thanks to this, it will not fall apart, and the concrete will not leak out. This completes the installation of the formwork. If after this there is an edged board left, it is better not to part with it. It will be useful for installing a subfloor.

To calculate the cost of formwork, you need to divide the sum of the lengths of all sides of the trench by 6. You get the standard length of one board. Afterwards, the height of the formwork must be divided by 0.15 (the width of the board). Round both results obtained and multiply by each other. The total will be the number of boards required for assembly.

In 1 cubic meter – 43 boards with a section of 25x100. Therefore, the resulting result when multiplied must be divided by 43. You will get a number indicating how many cubic meters. required. Approximate cost of cubic meters boards - from 8,500 rubles, but for formwork you can take boards of 2 grades, from 6,000.

So how much does it cost to pour a strip foundation?

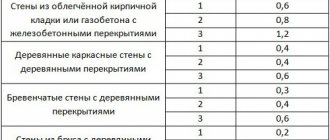

Let's sum up everything we've counted. Consumption of concrete 76,800, reinforcement 5120, cushions 2688, formwork 1500 = 86,108 only for the external walls of the base and without taking into account rods for vertical reinforcement, hiring labor, costs of transporting materials and other minor points. To get an idea of the amount, you can use the following table:

| Base perimeter | Price of materials | Price for work | Turnkey order |

| 9 by 9 | 150 000 | 110 000 | 250 000 |

| 8 by 8 | 140 000 | 105 000 | 240 000 |

| 6 by 10 | 130 000 | 100 000 | 225 000 |

| 6 by 8 | 100 000 | 70 000 | 165 000 |

| 6 by 6 | 85 000 | 60 000 | 140 000 |

The table shows approximate data

Of course, for the construction of a strip foundation for a house, in each individual region, prices for building materials will vary greatly. You can save on labor, for example, dig a trench yourself with your own hands, or ask your friends to help. Let’s add that it is recommended to buy concrete and materials for the pillow from one manufacturer - this way you can count on a discount

4.2 / 5 ( 4 voices)

Advantages

- Reliability. The high-strength base is designed for the construction of heavy, long-term structures made of brick, cellular concrete, etc.

- Effective. The strip foundation ensures high stability of the structure on clay and sandy soils, as well as loams, which are most often found in St. Petersburg and the Leningrad region.

- Durability. The service life of foundations of this type exceeds 50–70 years at an affordable cost.

- Efficiency. Preparatory activities and actual installation take only a few days.

Typical calculations

For a 6 by 4 house with a different type of foundation, the calculation scheme will be the same. The main rule is to calculate the length and number of rods and the volume of solution required for pouring. In this case, the 5*15 foundation will most likely be deeper.

If the sides are 11, 12 or more meters long, pay close attention to the calculation of the reinforcement threads, which depend on the depth of the base.

Lightweight small-sided buildings measuring 5 by 6 meters; 6 by 7; 8 by 9 or 7 by 9 meters do not require deep pouring and are sometimes performed without formwork. For more information about foundation construction, watch this video:

If you have a project on hand, you can order a calculation of the cost of work and materials from a professional estimator. The specialist will take into account all the necessary types of work and indicate the required amount of materials. In this case, it will be possible to calculate the need for financing in stages, and understand what work can be done independently, while saving money.

We build a slab foundation for a house, make an accurate calculation

- Calculation of load characteristics;

The soil under the slab foundation is heaving. To determine this, you will need data on the number of floors, area and materials used to make the house. And also operational data. That is, to what extent the house will be loaded. There are 2 existing formulas, but they can be used either by people who understand mathematics well or by specialists from construction companies. But the resulting calculations are too long and contain a lot of unnecessary stuff. In order to find out the approximate amount of materials needed and the costs for them, you can simply calculate basic data.

- Determination of strength;

This base itself is very strong and its thickness is usually 0.3-0.5 m. Of course, the area will be under the entire territory of the house; strength calculations are needed only to determine the optimal value. To determine strength, it is worth weighing the approximate amount of building materials from which the house will be built. Next, use addition and multiplication to obtain the approximate weight of the house. Divide the resulting weight by the size of the slab. The resulting number is the optimal thickness of this slab.

- Example of calculations.

For example, from all the building materials used, the approximate weight of the house was 77 tons. The territory of the house is 7m*11m. Then the optimal slab thickness is 77 tons/77 m2, which will be 1 m.

The size remains 77 m. Then you need 77 cubic meters of concrete. To do this, you need to take sand and cement in a ratio of 1:2. For example, if there is 20 kg of sand, then 40 kg of cement per 1 cubic meter.

Then the entire territory will require 1540 kg of sand and 3080 kg of cement.

Tape concrete support

Much more common is a strip foundation for a house. Its construction will reduce the overall construction cost of a 9x9 m building. You should first calculate the minimum area and depth of the concrete support. The main factors that determine the parameters of the foundation are soil characteristics, groundwater level, and freezing depth.

Preparatory work

The construction process proceeds in stages:

- The space under the foundation is cleared of debris and leveled.

- Hammered pegs and a rope stretched between them will help you make markings for a 9x9 m structure.

Attention! The correctness of the outlines is checked by diagonal lines, which must be the same.

- Along the intended boundaries, trenches are dug for the future foundation. Their width exceeds the thickness of the house wall and ranges from 50 to 70 cm. If you do all the work manually, the recesses for the formwork will be more even. Hiring an excavator reduces labor costs, but does not guarantee high quality. Subsequently, it will be necessary to adjust the outline of the foundation for a 9x9 m house using formwork. The depth varies depending on the characteristics of the soil, the average value is 0.50-1.0 m.

- At the bottom it is recommended to make a drainage layer of broken brick or crushed stone, which is filled with sand, watered and thoroughly compacted.

After these procedures, they move on to the next stage.

Formation of formwork

Despite the variety of methods for arranging formwork, the most popular is still the option of a removable structure made of wood material. An edged planed board with the following parameters will help you make high-quality formwork for building a 9x9 m house:

- Humidity levels are within 22%. The use of dry lumber should be excluded: in the absence of waterproofing, it will absorb moisture from the concrete solution, causing a decrease in the strength of the foundation.

- The thickness of the boards is from 25 to 30 mm.

- The width varies between 100-150 mm.

Smooth boards contribute to the formation of a smooth foundation that does not require additional finishing work. Accordingly, this will reduce the cost estimate when building a 9x9 m house based on a frame. In addition to the deck, for arranging scaffolding and fasteners you will need to purchase timber with a cross-section of 50x50 mm and nails or screws.

The structure must be made 0.4 m above the level of the trench; in the future, this will form the base of the building 9x9 m. When assembling the formwork, the maximum permissible size of the gaps between the boards is 3 mm. Large gaps will cause concrete mortar to leak out and worsen the performance of the foundation; smaller gaps will disappear as a result of swelling of the boards.

After completing the installation of the formwork, experts recommend waterproofing it. This measure will prevent premature evaporation of moisture from concrete and a decrease in the strength of the supporting structure for a 9x9 m house.

Reinforced frame

The metal frame is an integral attribute of the concrete support for the structure, its function is to ensure the strength of the foundation and the 9x9 m house as a whole. It is preferable to make it from ribbed reinforcement with a diameter of 10-12 mm, forming cells 20-30 cm in size using knitting wire.

Comment! It is better to avoid the use of welding, as it reduces the reliability of the frame at the joints.

Pouring the mixture

Before starting work, it is necessary to calculate the need for concrete solution. A lack of mixture and subsequent topping up will negatively affect the characteristics of the foundation and worsen the performance properties of a 9x9 m house. The excess will quickly become unusable and entail irrational expenses. To prepare the solution you will need:

- cement grade not lower than M250;

- washed sand of medium or coarse fraction;

- medium sized crushed stone.

It is more convenient to mix using a concrete mixer. The use of a vibrator helps to distribute the solution evenly between the reinforcement frame and remove air bubbles that reduce the strength of the foundation. In the absence of a useful tool, a bayonet shovel will replace it.

The final touch is to provide conditions for uniform drying of the foundation. If this is not done, the supporting structure will not meet the declared strength parameters and may cause deformation of the 9x9 m house. Therefore, before the next stage of construction of the 9x9 m building begins, it is advisable to take a break of 30-40 days, depending on weather conditions.

Advice! In case of hot weather, the foundation is periodically moistened to prevent cracking; in case of precipitation, it is covered with polyethylene.