The foundation, according to its design, can be shallow or recessed. In the first case, it is located on the soil surface, and in the second, it goes down to the freezing depth. A shallow foundation combines the qualities of these two options. It has both positive and negative aspects regarding each of these types.

But the use of a small recess is sometimes the ideal solution for the construction of certain structures.

Conditions for using a shallow structure

The installation of a shallow strip concrete foundation (FMC) during the construction of a house will be advisable in the following cases:

- large depth of soil freezing;

- presence of heaving soils;

- high groundwater level.

The lowest point of the foundation structure is always located above the maximum freezing level at a depth of no more than 1500 mm. Moreover, the greater the width of the base, the greater the weight load it can bear. The small depth of the MZLF allows it to rise with the house during winter heaving of the soil, while remaining intact.

Reduced load-bearing characteristics somewhat narrow the possible range of application of the structure and allow the use of a shallow strip foundation only in the case of building houses from light building materials, which include:

- wood;

- cellular concrete blocks;

- frame-panel products;

- lightweight masonry made of hollow bricks.

The width of the sole depends on the building material.

MZLF should not be used for the construction of large houses. The depth of soil freezing under the floor of such buildings will be less than in the adjacent area. As a result, winter swelling will be uneven, which can lead to structural failure.

The use of MZLF is prohibited on clay, peat and sapropel soils.

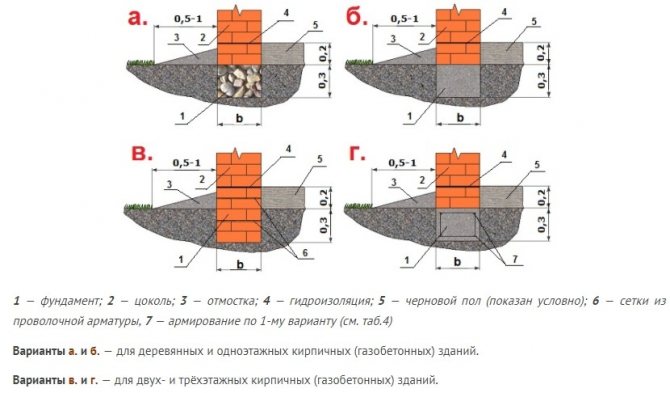

On weak and non-heaving soils.

On medium and highly heaving soils.

Insulation of the blind area

Work on insulating the blind area involves the use of the following types of materials: polystyrene foam, expanded clay, mineral wool, polyurethane foam, etc.

The depth to which the insulation material is laid and its thickness depend on the technical parameters and climate of the construction region. Modern foam building materials, even with a small size of the “insulating” layer, are much better suited for these purposes and are considered preferable to mineral wool or expanded clay.

Whatever material for thermal insulation is chosen by the owner of the house, in any case the foundation must be waterproofed, since without waterproofing, insulation becomes an absolutely useless exercise.

Foamed building materials, which actually have no negative characteristics, have many positive aspects:

- Relatively light weight.

- Low thermal conductivity.

- Increased frost resistance.

- Water-repellent properties.

- Long service life.

- Environmentally friendly material.

It should be noted that polystyrene foam does not have the positive characteristics of penoplex or, as it is also called, expanded polystyrene. Polystyrene foam absorbs moisture, thereby losing its heat resistance properties. True, this flaw is easily eliminated by installing high-quality waterproofing.

Heat flow diagram.

In addition, polystyrene foam has other disadvantages. Insufficient strength can lead to its damage as a result of ground movements. The only positive difference between polystyrene foam is its low price, but in the process of combating the mentioned negative qualities, the owner may incur much higher costs than when using high-quality insulation.

So we come to the answer to the question of how and how to insulate the foundation:

- A good material used for insulation work is polystyrene foam . Its use is possible in all parts of our country, including the northern regions.

- Another type of insulation is polyurethane foam . It is applied in a uniform layer that does not deform as a result of mechanical and other influences. The coating has no seams and is quite durable. But its application requires special equipment and handling skills. Therefore, the use of this type of insulation for a shallow strip foundation is at your discretion.

Conditions for calculating the foundation structure

In order to calculate the MZLF and determine the laying depth and width of the tape, it is necessary to take into account:

- type of soil to the depth of the calculated freezing point;

- ground water level;

- freezing depth;

- distribution of weight load on the foundation;

- height differences on the construction site;

- calculated depth, which is equal to the distance from the bottom point of the foundation to the zero level of the building.

The depth of possible soil freezing can be determined according to SNiP 23-01-99* “Construction climatology”.

If there are significant differences in height, it is structurally impossible to install an MZLF. In these cases, leveling the site or constructing a different type of foundation will be required.

The weight load acting on the foundation consists of a constant and variable component. Variables include snow and wind loads, the weight of engineering equipment, furniture, plumbing fixtures, etc. To determine the constant weight component, the height of the building, the materials used, the design of the roof and ceilings, and other design features are taken into account.

To quickly perform the calculation part, it is recommended to use the MZLF online calculator.

Risks when installing a lightweight foundation

It becomes clear that there are definitely risks when creating a lightweight foundation. For example, there may be serious problems if we use the premises for a small warehouse. As already mentioned, when the house expands, the load will definitely increase; accordingly, at one point the foundation may not be able to withstand it and will begin to deform (or even collapse).

- It is especially bad if the owners decide to add one or more floors to the house. In this situation, an emergency is almost guaranteed. If we are talking about the most ordinary extensions, then it is quite possible to get out of this situation by creating an additional foundation. However, even in this case, it is advisable to strengthen the main foundation if it is really necessary.

- If it turns out that the strength of the light foundation is not enough for the safe operation of the home, the foundation will need to be reconstructed. Accordingly, it will be necessary to spend a lot of money to carry out the full scope of construction work. And here it is no longer possible to do without specialists.

- If we have a small gazebo or a small garden or country house, then we can safely choose a lightweight foundation, since large loads on the foundation are not expected. However, consultation is still necessary. A specialist will quickly analyze even the most basic parameters of the future structure and draw some conclusions.

Design calculation

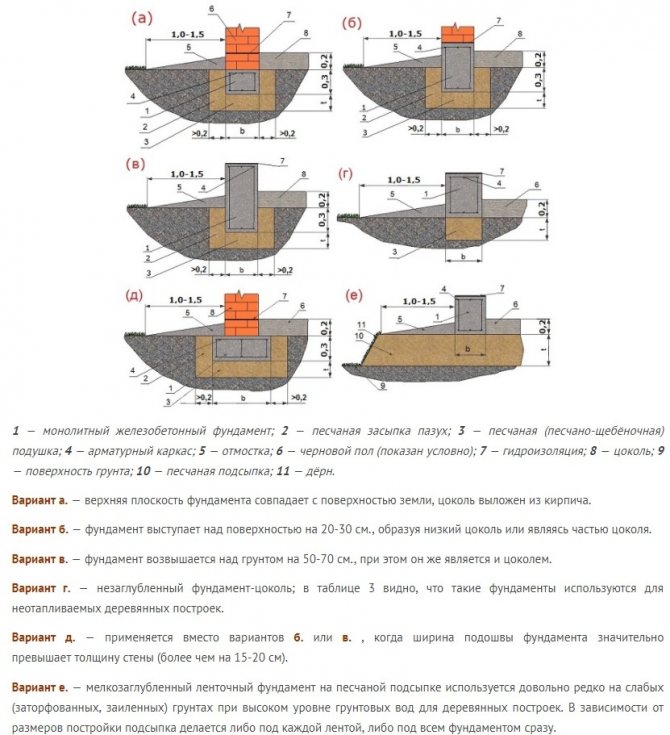

The reinforced concrete monolith of the foundation rises above the surface of the earth and rests on a cushion consisting of a layer of compacted crushed stone covered with a layer of sand.

Depending on climatic conditions, the depth of laying MZLF on heaving soils is determined by the requirements of SNiP II-B1-62 and is equal to:

- when freezing up to 1 meter - at least 500 mm;

- up to 1.5 meters – 750 mm;

- more than 1.5 meters – 1000 mm.

Therefore, builders usually make calculations for a shallow strip foundation, taking the laying depth as a value equal to the freezing depth, with a deduction of 20-25%. If this condition is met, the foundation for the house will be able to rise freely without destruction when the soil swells.

Where to start building a shallow foundation?

Scheme of a strip shallow foundation.

Required:

- cord;

- stakes;

- roulette;

- level.

Any construction begins with preparatory work. First you need to clear the required area and bring in the necessary building material. Then you need to mark the axes of the house and fix the location of the internal and external perimeter of the foundation using a cord and stakes. The foundation should not be narrower than the walls of the future building, which means that the width of its walls should be at least 30 cm, and best of all – 40 cm.

Areas with complex terrain require special attention, therefore, when marking, you should use a level and slats. It is imperative to check the correctness of the angles, which must be straight and strictly at 900. If the diagonals measured with a tape measure coincide, then the markings are made correctly, you can pull the cord.

Next you should dig a pit. To ensure the same height of the foundation, you need to use a water level. Then a layer of 10-15 cm of fine gravel or sand must be poured onto its bottom and leveled using a water level. After this, it must be moistened with water and compacted thoroughly. Next, you can either put any waterproofing film, for example polyethylene, on the sand cushion, or fill it with cement mortar. This is necessary to prevent water from seeping into the ground.

Installation of monolithic reinforced concrete MZLF

After the design calculations have been made and the project has been completed, you can begin to make a shallow strip foundation with your own hands. The work on constructing the MZLF consists of several stages, which will be described in the form of step-by-step instructions:

- preparatory;

- marking;

- earthworks;

- crushed stone-sand cushion devices;

- formwork installation;

- reinforcement;

- pouring concrete;

- base devices;

- hydraulic and thermal insulation devices;

- adding sand and building a blind area.

To complete the work you will need the following materials:

- sand and crushed stone;

- cement M400 or M500;

- steel reinforcement with a diameter of 8 and 12 mm;

- knitting wire;

- boards for formwork or ready-made panel elements;

- bitumen and bitumen primer;

- brick for leveling the base part.

When installing thermal insulation for FMZ, you can use polystyrene foam, which is secured with glue and plastic nails.

Preparatory stage

Preparatory work includes clearing and possible leveling of the construction site. In this case, uprooting of stumps and bushes should be carried out together with the roots in order to exclude the possibility of their germination in the future.

All necessary materials must be delivered to the work site and stored in such a way as to prevent damage from adverse external influences.

Marking

To perform correct and accurate markings, it is best to use a construction level and a measuring tape at least 10 meters long. Using a level, you can easily determine the required directions of rotation angles of the foundation tape. This is especially important with complex configurations.

To tension the marking cord, it is necessary to make beacons and pegs. The beacon is a U-shaped wooden structure of two stakes and a crossbar, the width of which should be greater than the width of the foundation.

Initially, the tensioned cords must run along the edge of the outer wall of the MZLF, and after completion of the excavation work, before installing the formwork, they must also be tensioned along the internal contours.

Checking the markings is carried out by measuring the diagonals inside all rectangles. They must be equal for both external load-bearing walls and partitions.

Digging a trench

The required trench depth is equal to the sum of the depth of the reinforced concrete monolith and the height of the support pad. It is determined by the calculation described above.

For central Russia, the most commonly used design is with a cushion thickness of 200 mm and a recessed part of the foundation of 300 mm. In this case, the trench depth is 500 mm.

In order to prevent soil shedding and to have access to the surface when carrying out waterproofing work, it is necessary to make small slopes of 150-250 mm. Take the width of the bottom to be 200-300 mm wider than needed for the foundation itself.

Support pad for foundation

As a cushion, you can use ready-made crushed stone-sand mixtures (SCS), which are sold on the construction market for road work.

Features of a lightweight foundation for a house

According to experts, now there is actually an increased interest in lightweight foundations, but it must be borne in mind that only houses of light weight are built on such a basis. Most often we are talking about wooden structures. It should be understood that in modern conditions wood is not used very often, so it is advisable to conduct additional consultations with specialists before choosing a lightweight foundation.

It must be borne in mind that a light foundation means a structure that is quite easy to erect, but all its features must be taken into account. Despite the fact that the house may be made of wood, equipment or furniture can be placed inside it, which will have an impressive weight and negatively affect the condition of the foundation.

If you understand that in the future you will expand your building, then it makes sense to immediately equip a strong and durable foundation, but not a light one. If in the future it is still planned to expand the space, then you will have to start with modernizing the foundation, or you will need to start construction from the very beginning. Thus, a lightweight foundation is far from the most correct solution in many modern conditions.