After a long, harsh winter, the active construction season begins. Unfortunately, construction is not an undertaking whose duration can be planned down to the day and hour. You need to wait a certain amount of time between performing some jobs, and besides, something unexpected can always happen. An important point is how long it takes for the foundation to dry and how quickly you can begin further work after it is completed.

Features of strip foundation

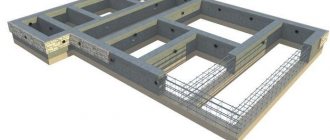

Laying the foundation is a very labor-intensive stage of construction work. The strip foundation is laid under each outer wall of the building in the form of a continuous strip, as well as under load-bearing interior walls and is a high or not very high half-wall, depending on the depth of the laying. The strip version is the most popular among other types of foundation. Depending on the method of construction and the materials used, the strip foundation can be prefabricated or monolithic:

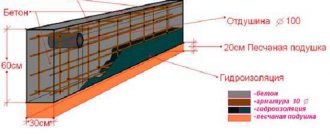

- A monolithic foundation is erected directly on the building construction site, and there are two types depending on the expected weight of the structure - shallow and buried. Shallowly buried strip monolithic foundation is used in the construction of lightweight buildings on clay soils. A buried monolithic foundation is constructed in the case of the construction of heavy structures and buildings that include a basement floor, an underground garage or other basements on unstable soils.

- A prefabricated strip foundation is made up of blocks based on reinforced concrete, which are manufactured at the factory, transported by special equipment to the construction site and installed in trenches at the construction site using a crane. In terms of strength, a prefabricated foundation of this type is inferior to a monolithic one.

What conditions affect the hardening time?

The duration of hardening is influenced by the following conditions and factors:

- Ambient temperature conditions;

- Air humidity level;

- Presence or absence of precipitation;

- Type and structure of soil cover;

- Features of the relief characteristics of the area and the level of groundwater;

- The quality and types of materials from which the foundation is made;

- Construction technology;

- Type of formwork;

- A type of foundation waterproofing.

However, even if all these conditions are used during construction, it is not always possible to obtain an ideal foundation. Therefore, it is necessary to take into account the most unfavorable conditions of the area, and based on them, calculate the duration of settling.

It is also important that when the temperature level drops below +5, the foundation has already been made. Otherwise, it will have to be insulated, covered, and insulating the base is a difficult task, which requires additional costs.

The foundation has been built. Are we building walls?

Most likely, those who have taken on the construction of a house know or have heard that immediately after laying the foundation, you should pause before continuing construction. But not everyone understands why it is necessary to defend a strip foundation.

According to building regulations, any type of foundation must be settled before the construction of a building continues on its basis (with the exception of a pile-screw foundation). This is necessary so that the concrete dries completely, so that the structure does not sag in the future or crack, for example, in a wall. In a word, it was not deformed.

Why can this happen? The reasons for various types of defects are very diverse:

- incorrect trench depth for laying the foundation;

- low quality of the prepared concrete mixture;

- high humidity of the soil where the foundation was laid;

- season of the year and air temperature when laying the foundation and other reasons.

Basic methods

The traditional construction method suggests leaving the foundation for a year, or even a year and a half. They say that it is during this time that concrete gains suitable strength (although it takes several decades to gain its full strength), and the structure itself goes through the entire cycle of “tests” by soil movements, as well as temperature changes and frosts (the forces of frost heaving).

Many argue that it is possible to build a cottage almost a week after pouring the foundation: supposedly by this time the concrete has gained strength sufficient to support the walls. However, they forget that after winter the foundation may settle unevenly, which means that not only it, but also the walls will crack, and all the work will have to start all over again.

There is a lot of information on this issue from builders who consider it sufficient to lay the foundation for a period of three to six months, but only under the condition of “good soils” and not swampy or heaving ones. That is, before laying the foundation, you need to do all possible geological surveys so as not to take unnecessary risks. And then it is better to lay the foundation before winter, since it is during the winter months that concrete has to withstand the most severe loads in the form of snow, frost and soil expansion. In the spring, the foundation is leveled, reinforced if necessary, and, in principle, walls can be built. But if there is an opportunity not to rush, it is better to wait a year. This approach cannot be called erroneous; rather, it is more progmatic, but it blurs the deadlines.

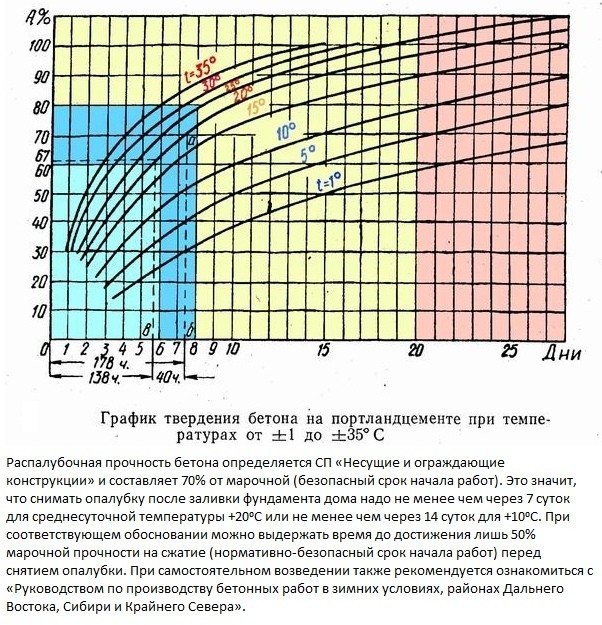

The Optima-Sinergidom company is guided by standard indicators; we affirm that with proper implementation and verification of all stages of preparing the foundation base, installing drainage for drying the soil, using high-quality materials, it is possible to begin loading the foundation with the first rows of wall masonry within a time period at which the strength of concrete reaches not less than 50-70% (usually 1-2 weeks in the warm season in St. Petersburg). The table below shows the conditions under which it is better to do this without consequences for the reliability of the design.

| -3 | +5 | +10 | +20 | +30 | |||

| Strength of concrete, % of brand | |||||||

| M200-M300 | 1 | 3 | 5 | 9 | 12 | 23 | 35 |

| 2 | 6 | 12 | 19 | 25 | 40 | 55 | |

| 3 | 8 | 18 | 27 | 37 | 50 | 65 | |

| 5 | 12 | 28 | 38 | 50 | 65 | 80 | |

| 7 | 15 | 35 | 48 | 58 | 75 | 90 | |

| 14 | 20 | 50 | 62 | 72 | 90 | 100 | |

| 28 | 25 | 65 | 77 | 85 | 100 | ||

– standard-safe strength

| – safe concrete strength |

| – full strength of concrete |

Duration of concrete strength gain for foundations in different weather conditions

Optimal conditions for concrete to gain strength are created at a temperature of +20°C. Under such conditions, the process is very active in the first 7 days. During this time, concrete gains about 50-70% strength. With these parameters, it is already possible to continue construction further. The design strength, which is taken as 100% during design, under such conditions is gained in 28-30 days; in fact, this is the brand strength that concrete must correspond to during laboratory testing of a batch sample.

Seeing with your own eyes the houses being built by SYNERGIDOM is the best opportunity to understand the advantages of the Passive House technologies used not only in words!

Decided: the foundation needs to settle

So, it was decided to defend the erected foundation in order to avoid troubles with possible subsequent deformation of the building. But again the question of timing arises, the construction season in Russia is short. So how long does a strip foundation need to stand?

And here we find many opinions, very diverse, sometimes contradictory. Let's figure it out.

- It is traditionally believed that the constructed foundation must stand for at least a year in order for the concrete to acquire the necessary strength. Although it is known that the process of strengthening concrete lasts decades.

- There is an opinion that it is quite acceptable to continue construction a week after the construction of the foundation, and that this time is enough for the concrete to completely harden. However, I would like to warn supporters of this concept in construction, since in our difficult climate it is impossible not to take into account seasonal fluctuations in the soil, which can lead to subsidence of the structure after winter and multiple cracks, both on the foundation itself and on the walls. Of course, with this development of events, work in the spring will have to start from the zero cycle.

- Some builders also have the opinion that on “good soil” 3-5 months are enough for the foundation structure to settle. It seems that in order to avoid risk, it still makes sense to do preliminary geological research.

- Other construction experts suggest laying the foundation on the eve of winter, which, according to their assumptions, will provide the concrete with a full test of its strength with the help of frost, snowfall and seasonal soil movement. This may not be a bad idea, but then in the spring the foundation should be reinforced and then the walls should be erected.

There are many opinions, but only you can decide for yourself which one is optimal and preferable in your case.

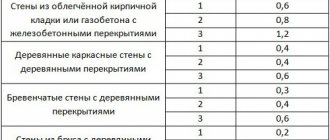

Dependence of waiting time on the type of base

There is an opinion that the new foundation should stand for a winter or a year - there was no confirmation of the information. The main mistake of distorted information is misunderstanding: the period is waited between the construction of the house and the start of finishing work. This is done in case of uneven shrinkage of the base with the formation of cracks.

The only parameter on which the waiting time depends is the type of foundation.

Is it possible to leave the foundation for the winter:

Columnar support

Pillars for the foundation can be driven in (ready-made) or poured - a solution is poured into the roofing felt formwork. But the pillars are sunk flush with the soil surface, and a grillage is poured on top.

A part of the reinforcement, pipes, are left from the supports, which become part of the upper connecting belt - a tape with a reinforcing structure inside.

The finished structure has a low total mass, reducing pressure on the soil. Thanks to the design, there will be parts of the base that are not loaded with the mass of the main building.

The soil under the base remains mobile, leading to deformation. The building cannot be left to settle; construction can begin immediately after the fill has completely dried.

Tape fill

There are two types of strip foundations: shallow and recessed.

The small version is used for light frame-type buildings made of wood beams or other lightweight materials. Often these are structures for technical purposes, such as a shed for equipment or an outdoor toilet. The lower edge of the structure is located above the groundwater flow level.

Approximately the same degree of pressure is exerted on the structure as on the grillage of a columnar building. If you need to wait before building a house, then definitely not from autumn to spring. Heaving of the soil from the cold, an increase in the amount of groundwater, and seasonal changes in the soil increase the risk of deformation of the fill.

Tape form

When the house is planned to be heavy, it is completely buried by 1.5-2.5 m; more accurate data depends on the depth of soil freezing. The base of the base must be below the line of soil moisture flow.

The pressure is distributed very deeply, evenly, and there are no points of unloading. The foundation shrinks under the influence of its own mass; by the time it dries completely, the process is completely completed. You can start working.

Concrete slab

Monolithic pouring is a good option for the foundation for a heavy, multi-story building. The high support load is distributed evenly, ensuring minimal specific pressure on the soil. A properly formed bulk sole eliminates even small movements during the shrinkage period.

Some general tips

To determine how long a strip foundation should last in your particular case, it is useful to familiarize yourself with some recommendations that will help you better navigate this issue. Already at the stage of preparatory work and laying the foundation of the future building, regulatory recommendations should be strictly followed. For example, before pouring, make sure that the sand cushion is thoroughly compacted, and the construction work itself is carried out in several stages, this will improve the quality of the foundation and reduce the likelihood of its deformation.

If a building of 2-3 floors is being erected, then according to the standard, the time for complete hardening of concrete is 46 days. To be completely sure, when carrying out work in the autumn-winter period or due to the not entirely satisfactory quality of the concrete or cement brand, the curing time can be extended to 60 days.

When the first floor is erected, work is suspended for 7-10 days, allowing the foundation to adapt to the load. If cracks suddenly appear, the situation at this stage is much easier to correct, preventing its consequences, than after the work is completely completed.

You can often see how the foundation is laid in the fall, guided by the idea that after the end of winter frosts, melting of snow and meltwater, it will be established exactly how well it was laid. Of course, this is reasonable. But there are also some objections here: firstly, this technique requires a significant time period; secondly, autumn bad weather and spring snow melting can excessively saturate the strip foundation with water, and this is undesirable.

Therefore, when using this construction technique in the fall, a drainage trench for rain and melt water is dug along the foundation in a circle, both from the outside and from the inside. Moreover, you need to dig at some distance from the base of the foundation in order to protect not only it, but also the adjacent soil. This will prevent soil movement under the foundation and its deformation.

Strengthening with concrete

The concrete mixture dries and receives the necessary and sufficient strength values during the process of passing through two successive interconnected stages:

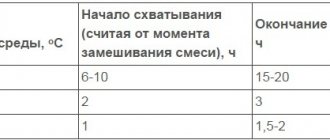

- Setting stage. Preliminary setting of the concrete mortar laid in the formwork in the summer at an ambient temperature of about 20 o C occurs within 24 hours. During cold seasonal periods, it is necessary to use available heating means and use heat-insulating structures. It should be taken into account that setting processes begin to occur within the first two hours from the moment the concrete mixture is mixed with water. That is why the operations of mixing the mixture and laying concrete in the formwork should be as close as possible to each other in time intervals.

- Hardening of concrete. Concrete gains strength through the process of hydration - the formation of molecular bonds between water particles and the substances that make up the mixture. Hydration occurs within a narrow range of temperature and humidity, which must be ensured by concrete care measures. The importance of careful control of the course of the physical and chemical process in the mass of a reinforced concrete structure is explained by the complete dependence of the quality of the structure.

| Concrete grade | Standing time (days) | Strength of concrete (% of the standardized value) depending on the average daily temperature (о C) of the concrete mass | |||||

| -3 | +5 | +10 | +20 | +30 | |||

| M–200, M–300 | 1 | 3 | 5 | 9 | 12 | 23 | 35 |

| 2 | 6 | 12 | 19 | 25 | 40 | 55* | |

| 3 | 8 | 18 | 27 | 37 | 50 | 65 | |

| 5 | 12 | 28 | 38 | 50 | 65 | 80 | |

| 7 | 15 | 35 | 48 | 58 | 75 | 90 | |

| 14 | 20 | 50 | 62 | 72 | 90 | 100 | |

| 28 | 25 | 65 | 77 | 85 | 100 | – | |

Errors during construction

The most important myth regarding the strengthening of the foundation and the transition to the next stage of work is that the foundation must be allowed to stand (overwinter) before building a house on it. This statement is not supported by any regulatory documents and is not practiced by professional builders. This action does not bring any benefit, on the contrary, it is harmful.

The negative consequences of allowing the foundation to “stand” include:

- increased time spent on building a house;

- the uselessness of the measure for high-quality compaction of the base (according to technology);

- the risk of cracks occurring during construction on clay, loam, sandy loam, fine and silty sand when work is stopped in winter due to the forces of frost heaving, because an unloaded foundation will be easily pushed out by frozen soil.

Among professionals there is such a definition as “preservation” of the foundation

It is important to understand that this is not a necessary, but a forced measure, which is resorted to when the future owner, for his own reasons, cannot continue construction. But there is no such concept that supports for a house should “stand”

If there is a need for conservation, it is recommended that you read additional information on this issue, since there are several nuances here.

To ensure the strength and reliability of the foundation, it is important to allow it to gain sufficient strength (dry). Determining the time is not difficult using the information in the article

This will not take much time, but will save nerves, time and money in the future.

Good publicity

How to properly allow a structure to harden

As already mentioned, a concrete surface from viscous becomes more or less hard in about one week - and it is during this period that it acquires more than half of its strength properties, but this is far from the limit and should not be stopped there. That is, after just a seven-day wait, you cannot test the concrete with your finger and, having convinced yourself of its hardness, happily begin building floors, walls and ceilings.

It is important to remember that concrete cannot simply be left alone - otherwise it will dry out greatly and may crack: throughout the entire drying period, no matter how paradoxical it may be, it needs to be slightly moistened. Do not water with water from a watering can, like a flower bed - namely, moisten it a little - and this is all done throughout the entire period, how long does it take to dry the foundation for a bathhouse or for a country house

Such a strange at first glance event is being carried out, if only to ensure that the concrete does not dry out and crack, and that the chemical reactions at the moment the foundation sets proceed correctly and evenly. In the end, potassium hydrosilicates are formed precisely from the mineral compounds of cement mortar and water, or more precisely, from their interaction and fusion into one single substance.

It is important to note that the direct process of increasing strength characteristics can last several years - but this no longer affects construction (if we are not talking about massive dams and bridges), but only provides an additional guarantee of quality. If the foundation can withstand the load now and distribute it correctly, then everything will only get better - it already inspires some hope for the future

There is a more or less average period, after the completion of which construction usually begins: this is due to the same fairly tight deadlines for the construction of a building so that the construction of a dacha does not take decades. Concrete, which dries and hardens under natural conditions without additional influence from the outside or inside and without any catalysts, requires an average of a month to completely react with water and enter a state where it can already be subjected to various loads

Maintenance of concrete structures

The main goals of surface care after pouring the foundation:

- reduction of plastic shrinkage;

- increase in strength;

- preventing drying out;

- neutralization of the influence of temperature changes;

- increase in service life;

- preventing the influence of chemical and mechanical forces.

To understand how much concrete needs to be watered, you need to know about the existing rules. Methods of care after pouring the foundation are influenced by:

- type of cement;

- type of construction;

- climatic conditions, etc.

The maintenance period is affected by the hardening speed of the cement in the mixture:

- structures made of cement, which hardens gradually, need to be wetted for 4 weeks;

- structures based on Portland cement - from 2 to 3 weeks;

- on quick-hardening cement - 8 days.

In hot and dry weather, longer maintenance is required. To slow the evaporation of moisture and to protect against overheating after pouring, it is recommended to cover the foundation with moistened sawdust, matting, and roofing felt.

In hot weather or strong winds, it is recommended to start irrigating the surface 2-3 hours after finishing work. Not everyone understands how to water correctly.

If you use a jet with strong pressure to moisturize, the plane that has not had time to harden may become deformed. It is recommended to use a sprayer to create an imitation of rain over the surface.

Watering should be carried out throughout the day so that the structure is constantly wet

You can understand how often you need to irrigate a surface by paying attention to the temperature and humidity of the air.

It matters how much time should pass between waterings. In extreme heat, breaks between moisturizing should not be more than 2 hours, in other cases - every 3 hours during the day, and up to 3 times at night. The appearance of hissing during irrigation indicates an insufficient amount of water.

Requirements for water for irrigation:

- must be clean flowing;

- it should not contain impurities that can have an aggressive effect on the surface;

- groundwater located close to the surface cannot be used;

- recommended pH level = 7 (permissible deviation - 1);

- must not contain pesticides or organic deposits;

- There should not be a large amount of calcium, magnesium, sodium.

On the foundation, which is in the formwork, moisture is retained longer, so irrigation is allowed less often. After removing the formwork, it is necessary to begin watering, paying more attention to the edges of the structure, since they are more susceptible to the influence of wind and temperature, so moisture loss occurs faster.

Sometimes, to preserve moisture, the surface is covered with a polyethylene film. During the evaporation process, water droplets end up on the inside of the film, and some of the moisture returns to the foundation. This technique allows you to reduce the number of waterings, but is not able to replace them completely.

Kinds

There are many types of formwork. For heavy structures, strip foundations are used. This is a structure that looks like a wall dug into the ground.

For light structures without basements, columnar structures are used. Support pillars are installed at the corners of the structure and at the intersection of wall partitions.

Slabs are also used, but this is a less durable base. Due to the influence of external factors, the slab loses its qualities over time and collapses.

Another type is pile formwork. This is a very expensive structure and is used for the construction of large buildings.

Consequences of premature removal of formwork

To understand the full extent of the process, you need to know its scale, as well as calculate how much concrete is needed. To lay a strip foundation, you need to use a mushy concrete solution. After penetration into the formwork, the hydration and hardening procedure begins. This is called the settling period.

If the formwork base structure is dismantled before the cement sets, there is a high probability of the structure collapsing, cracks appearing, and crumbling. A weakened structure will not be able to withstand not only external weight, but also its own. This is especially dangerous if there is an underground part of a permanent structure, basements, or other premises.

There is no answer to how long the foundation should stand after pouring, since the numbers are different in each situation. The average is 29 – 30 days. There are often exceptions in the form of 17 - 23 days; in difficult circumstances or weather conditions, the period is extended. Most experts defend the point of view that it should dry for one calendar month.

Factors affecting drying speed:

- Minimum and maximum ambient temperature;

- humidity indicator;

- frequency and amount of precipitation;

- seasonality of the time of year;

- soil quality;

- general relief of the horizon;

- dimensions;

- base type;

- concrete strength according to design data;

- high-quality composition of materials for the building;

- height of groundwater;

- type of construction technology;

- magnitude, loads that correspond to the calculation.

Sometimes it happens that the foundation settles for several months. For example, they poured it in the fall, left it for the winter, and only in the spring did they begin the construction of load-bearing walls. This is done in order to promptly identify defects and cracks in the structure after the soil base has thawed. In this case, the entire monolithic frame must be tightly covered and moisture cannot penetrate. How much insulation is needed is decided individually in each case.

When calculating the timing, most often, the worst conditions for a given region are taken. So the called reserve will play into our hands later.

What happens during shrinkage

After concrete is poured, several parallel processes occur. The strength of concrete increases and after 12-18 months reaches values close to maximum. The mass of the slab compacts the soil, squeezing particles of clay, sand and other substances. Along with the seasons, soil characteristics such as moisture and mobility also change.

The slab pushes the earth until it reaches the point where the influence of other factors becomes too insignificant. It is impossible to determine how long these processes take. Therefore, the time that the foundation should stand is determined on the basis of geodetic research.

In regions where winter temperatures drop below minus 10 degrees Celsius, the pit depth should be below the freezing depth. Therefore, the finished base must stand longer, because the temperature at such a depth never drops below 0.3 and does not rise above 5 degrees Celsius.

At this distance from the surface, the influence of rainwater runoff is too small, so the shrinkage process occurs under the influence of groundwater. When determining how long the foundation should sag, be sure to take into account the depth of freezing. Otherwise, there is a high probability of damage to the foundation and the walls of the house located on it.

How to determine that shrinkage has ended

All processes associated with soil compaction occur so slowly that it is impossible to visually determine their completion. Therefore, the end of shrinkage is determined on the basis of calculations in which all factors are taken into account.

If there is an error in one of the values used for such calculations, then there is a high probability that the entire process will not proceed correctly.

There are known cases when a team of builders erected a house, but incorrectly determined the characteristics and properties of the soil.

This increases the installation time of the house, but greatly reduces the likelihood of improper shrinkage of the base and sagging of the walls.