The foundation is the foundation of the house, so its laying requires extreme care and compliance with certain standards. All factors must be taken into account, including weather conditions. In this article you will find information about at what air temperature the foundation can be poured so that it does not lose strength and does not change over time.

As you know, the further operation of the building depends on the foundation and how it is laid. That is why its bookmark is approached with all responsibility. It is believed that a more favorable period for concrete work is the warm season. However, building a house is labor-intensive and time-consuming; it can drag on for a long time until the first cold weather. What to do in such a situation?

Of course, according to all building codes and regulations, pouring concrete at sub-zero temperatures is undesirable. One of the reasons for this is that concrete can collapse at sub-zero temperatures, since the water that is part of the cement begins to freeze, then cracks form. In addition, under unfavorable temperature conditions, the hardening process of the concrete mixture stops. However, there is an exception - frost-resistant concrete .

We all know that our country is large, and some areas and regions are located where the air temperature is most often below zero. Then what about residents who want to build a house? Modern technologies have developed some techniques for such cases that allow them to pour concrete without disturbing the natural hardening processes.

When is winter foundation pouring necessary?

With careful adherence to all construction rules, the construction of a strong foundation is quite feasible even in severe frosts and, as a result, frozen soil. Pouring the foundation in winter is not always necessary, it all depends on the project. Most often, the decision to start construction during the cold period is related to the characteristics of the soil. There are areas where the soil crumbles in summer, and only in winter, when the ground is well frozen, can a good pit be dug. In this case, installing a foundation is an excellent solution to accomplish the task. In many regions of Russia, winter is the main season of the year, and summer practically does not exist. Therefore, there is simply no other period for the construction of the foundation. In addition, it is believed that the costs of materials and labor in winter are much lower than in the summer months, although serious savings are unlikely to be counted on. Sometimes pouring a foundation in winter is necessary when the construction process needs to be completed as quickly as possible.

Shallow-buried monolithic strip foundations

Made on heaving soils in the fall, when the concrete has time to gain the necessary strength before frost, these structures remain intact, and when heaving occurs, residual deformations do not form if measures are taken to preserve them for the winter. Shallow foundations are designed to accommodate heaving deformations. Therefore, it is possible to build wooden houses on such foundations in winter.

But even in shallow foundations made in winter, if freezing of the soil from the bottom of the trenches (pits) is allowed, cracks may form in weak concrete. When constructing such foundations on a frozen foundation, uneven precipitation will occur in the spring. At best, you will have to align the top edge of the tape. Therefore, it is not recommended to build such foundations on frozen pounds.

Types of foundations in winter

To arrange the foundation of any structure in winter, there are several types of foundations. Let's look at them in more detail:

1. The most common among developers is a strip foundation. In this case, experts advise reducing the so-called “wet” operations, for example, using ready-made concrete blocks to lay them in the pit.

2. Foundation made of concrete piles. This type of foundation is ideal for light buildings, in particular wooden houses. By following construction technology and adhering to the basic rules, you can get a durable pile foundation that is not inferior in quality to other types. Further from the article you can learn everything about pouring the foundation in winter.

How to pour a foundation using piles? First of all, you need to distinguish between their types. Concrete piles are either bored or drilled. Screw pile foundations are ideal for winter work. Suitable for any difficult soil.

Screw pile design

A screw pile structure is a hollow metal pipe with a blade welded at the end, which acts as a drill.

Photo of screw piles

The option for winter installation has a structural difference from load-bearing supports for summer use, in the form of additional reinforcement of the oblique cut of the helical blade. This reinforcement prevents damage to the pile during screwing into the frozen ground base. Thanks to the improved design solution, the soil is quickly drilled out and the pile is reliably immersed in the earthen base. The anchor structure of the pile support allows the foundation structure to be securely anchored in the ground and, during the winter heaving of frozen soil, does not allow it to be pushed upward.

Screw pile installation process:

Preparation of concrete mixture

When arranging the foundation, the question often arises: “Is it possible to pour a foundation in winter using ordinary concrete?” No you can not. For these purposes, one that contains special modifiers is suitable. Thanks to additives, concrete has time to gain the necessary qualities; it does not set prematurely. In addition, modifying additives make it much easier to pour concrete into the formwork.

When choosing modifiers, you should pay attention to frost resistance indicators and the rate of hardening of concrete. The required amount of the substance is determined according to the scale indicated on the packaging.

What happens to concrete at low temperatures?

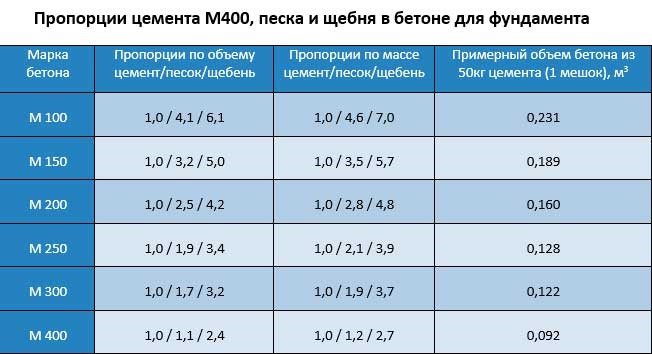

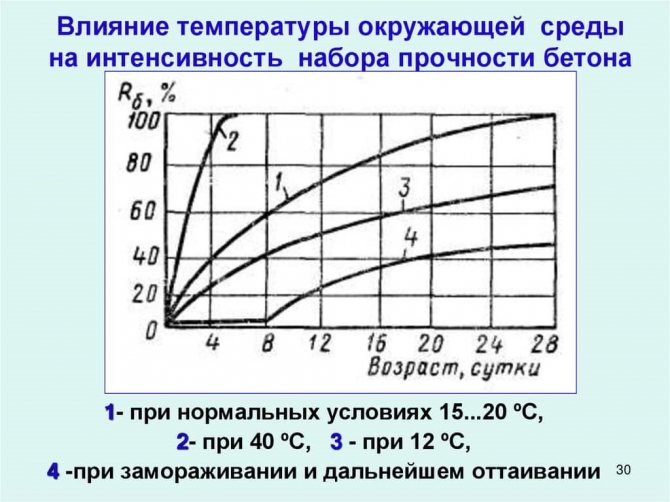

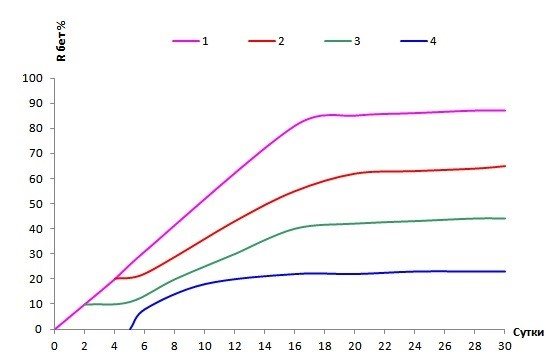

The process of concrete hardening, or, as builders and engineers also say, the development of design strength, is the result of the gradual loss of water molecules from the solution. The duration of hardening largely depends on the composition of the solution (see Table 1), but the ambient temperature influences the process even more.

Depending on the temperature, it can acquire brand strength in 14 or more days, and the colder the air - and the concrete mass - the longer it will take to gain full strength.

If the weather intervened in the hydration process and the water in the concrete mixture simply froze, then the removal of molecules from the concrete occurs only after thawing. Repeated freeze-thaw cycles have a very bad effect on the final quality of the foundation, since complete curing may not occur.

At the same time, for frozen and then thawed concrete, the strength gain is faster and more uniform, the later the mixture freezes.

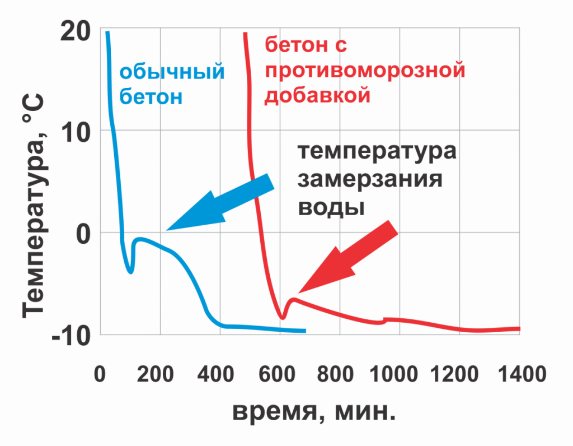

The graph shows the curves: 1. non-frozen concrete; 2. the mixture froze on the seventh day from the moment of pouring; 3. the concrete froze on the third or fourth day after pouring; 4. freezing occurred on the first day after concreting.

If we consider temperatures from +5 to -3 degrees Celsius as “winter conditions”, then it is possible to fill the foundation in winter. If we take the more typical temperature for our country at 10 degrees below zero, we will have to postpone construction work or, at a minimum, use special additives.

Antifreeze additives for concrete

When planning to pour a foundation in winter, you need to think in advance about special additives to the concrete mixture - hardening accelerators and anti-freeze additives.

Depending on the type of additive, the freezing temperature of the concrete mixture changes, decreasing.

These additives are available in powder and liquid form; the percentage in concrete depends on the ambient temperature and the composition of the additive.

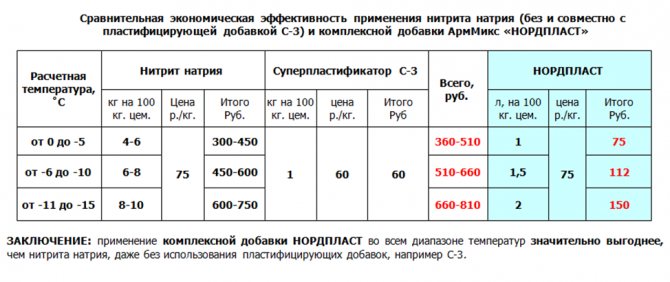

For comparison, data on three types of additives are presented.

Increasing the additive percentage above 4 usually has no effect.

How to apply modifiers?

When using modified additives, it is necessary to focus on some basic points:

— The use of frost-resistant substances allows you to reduce the amount of water consumed by 10-15% when making concrete mortar.

— The minimum temperature at which the use of modifiers is acceptable is 25 degrees below zero.

— When air humidity reaches 60%, the use of additives is prohibited.

— It is necessary to take into account factors in which individual components of modifiers interact with certain metals.

— The use of additives does not negate some additional measures when arranging the foundation during the cold period. When the air temperature is low, additives alone that affect the frost resistance of concrete are not enough. It is necessary to warm up the concrete and install additional thermal insulation to maintain a certain temperature of the finished structure.

Disadvantages of winter construction

Flaws:

- The need to use plasticizers and various special additives . All these substances will protect the concrete from freezing. It will not be possible to complete construction without them due to the water content in the solution.

- High cost of additives (increase in the cost of 1 m2 by 20 percent).

- Lack of comfort during work ; it is necessary to create partitions from the wind and buildings to warm the crew. Sometimes it is necessary to use heat guns. Concrete gains most of its strength in the first 48 hours. After this time, the guns can be removed, and then the hardening process will occur under natural conditions.

- Increased construction period (due to a strong decrease in temperature).

- Workers cannot complete a large amount of work in a day. This fact should be taken into account when planning work.

- The need for foundation waterproofing . This will help protect the building from the effects of environmental factors.

- Additional cash costs for electrical energy.

- The need to use special equipment (in the summer, workers can handle some areas).

- There is a risk of purchasing low-quality materials that suppliers have not been able to sell for a long time.

The use of additional means that make it possible to fill the foundation in winter

Another way in which the answer to the question of whether it is possible to fill a foundation in winter will be positive is to ensure that the foundation is heated. It is known that concrete gains its highest strength during the first two days. It is during this period that the foundation especially needs protection from low temperatures. To heat the base along the entire perimeter, special equipment is used - a thermal gun. With its help, the temperature required for hardening of the concrete solution is ensured and maintained. The larger the foundation, the higher the power of the device should be

You can also heat the foundation using electronic current. This method allows you to maintain the temperature required for hardening by transferring heat (from hot to cool). The concrete is heated by reinforcement rods, to which an electric current (380 V) is supplied.

Negative aspects of pouring a foundation in winter

So, the answer to the question “is it possible to pour a foundation in winter” is obvious. However, despite many positive arguments in favor of this process, there are also some negative aspects:

“Although the savings in the cost of building materials are obvious, at the same time the price of excavation work in frosty weather increases greatly. You will also incur additional costs for heating the concrete solution and structures, so in general, the savings in construction in winter are very doubtful.

— The efficiency of work in winter is much lower than in summer, since working in cold weather is much more difficult.

— The price of additives and modifying substances that affect the properties of concrete is low, but to build even a small foundation, quite a lot of them are required. And therefore the price of building materials increases significantly.

— Sometimes it is necessary to use special equipment, in particular for digging a pit.

Therefore, before thinking about whether it is possible to fill the foundation in winter, you need to calculate all the costs and consider all the pros and cons of this idea.

Technology of using frost-resistant impurities

The modern construction industry offers craftsmen various building mixtures that allow them to improve the quality characteristics of concrete

The modern construction industry offers craftsmen various building mixtures that allow them to improve the quality characteristics of concrete and at the same time reduce the drying time of the solution.

To carry out construction work on the construction of a foundation in winter, two types of impurities in liquid form are offered:

- A suspension that accelerates the drying process of the solution in the formwork, but requires constant heating of both the platform and the strip foundation.

- A mixture that promotes drying of concrete without the use of heating technologies. This construction mixture helps the concrete mixture dry and harden even at a temperature of -20 degrees Celsius.

It is important to know that the second type of building mixture does not contain water in its composition, which means that it is necessary to completely protect the poured solution from water entering it from the ground. Therefore, before pouring the solution into the formwork, it is necessary to properly waterproof the trench.

Construction of houses in winter, pros and cons

The technology for pouring mortar using admixtures is no different from the standard one. It is only important to control the moisture level of the solution at the stage of mixing and pouring it.

Tips for using concrete admixtures

Special additives to increase the frost resistance of concrete must be used very carefully

Special additives to increase the frost resistance of concrete must be used very carefully, adhering to the following recommendations:

- It is worth remembering that all chemical additives are made in liquid form, and therefore water consumption when mixing concrete should be reduced by 10-15%.

- Chemical frost-resistant suspensions for concrete can be used at temperatures not lower than -20 degrees. At the same time, it is worth taking into account the night temperature.

- Concrete with chemical additives can only be poured if the total humidity outside is no higher than 60%. Naturally, pouring such a solution in snow and rain is prohibited.

- It is also worth remembering that the chemical elements included in the additives can enter into an unpredictable reaction with the reinforcement bars. Therefore, carefully read the operating instructions.

- When using additives, in any case, it is necessary to insulate the formwork and mortar.

List of basic materials and tools for creating a foundation

To arrange and pour the foundation, the following materials and tools are required:

- shovel;

- sawdust;

- building level;

- hacksaw;

- Master OK;

- cement and concrete mortars;

- modifying additives;

- thermal insulation;

- reinforcing mesh;

- crushed stone

Trench and site heating technology

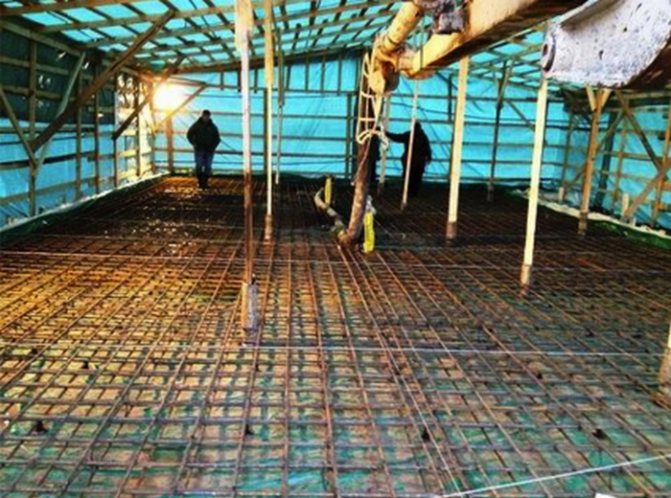

The meaning of heating technology is to build a special tent over the construction site

This technology is used only if the outside temperature drops below -5 degrees Celsius. Up to this temperature, the concrete mixture successfully hardens naturally.

Reinforcement methods for strip foundations

The meaning of heating technology is to build a special tent over the construction site as an auxiliary means. The basis of the technology is heating the walls and bottom of the trench under the concrete mixture. In addition, you can also heat the concrete solution from the inside. The heating technology looks like this:

- A temporary tent is installed above the construction site and a construction gun is mounted in it, which will pump up high temperatures to better warm up the area and soil.

- I install the formwork and reinforcing frame into the prepared trench. Moreover, here you need to do everything so that the reinforcement bars protrude above the surface of the already poured foundation.

- Concrete is poured into the formwork, and heating elements are attached to the protruding parts of the reinforcement using terminals and connected to the network.

- In this way, the entire strip foundation will be heated along the perimeter.

- After 2-3 days, the heating elements can be removed, and the finished foundation is covered with thermal insulation to maintain the temperature of the solution until it dries completely.

The main advantages of this technology are:

- Guaranteed heating of the solution by volume, which means better solidification.

- High speed of drying of the foundation, which means the possibility of carrying out construction work without stopping.

The only disadvantage of this technology is excessive energy consumption.

How to properly pour a foundation in winter?

Is it possible and is it worth doing? These questions often bother newcomers to construction. After all, it is very difficult to carry out any work in the cold; snow and frost can interfere. Expert advice will tell you how to properly fill the foundation in winter with your own hands. The rules of work are as follows:

— First of all, a trench or pit is dug, while the ground moisture that will collect at the bottom is controlled. At sub-zero temperatures, water freezes and ice forms, which must be removed, since nothing can be placed on such a base.

— Next, the concrete is mixed using the necessary modifiers and the mixture is heated to the desired temperature.

— The next step is the installation of formwork and a frame made of reinforcement. The formwork is filled with concrete mixture. The required positive temperature must be maintained for a certain period of time (to accelerate the setting process) using heating equipment. Immediately after pouring, the foundation can be insulated using roofing material or polyethylene film. You can sprinkle a layer of sawdust (20-30 cm) on top. As a result, we have a ready-made foundation in winter.

Is it possible to fill it for the winter? The answer is yes. But it is still recommended to build walls on such foundations at positive temperatures, since the concrete solution needs a certain time to acquire strength. By preparing the foundation in winter (taking into account all the rules and nuances), you can get a strong and durable structure.

Pile frame instead of strip frame

This type of foundation is used if it is not possible to fill the foundation at sub-zero temperatures in winter. The pile frame will save the situation. With this technology for constructing a foundation, the piles must be screwed into the ground to a depth of 50 cm below the freezing mark of the ground. In this case, the piles must be exclusively cast.

A pile foundation requires additional lining with a steel grillage. It is on this that the main structure of the house will subsequently be mounted. When installing such a foundation, the construction time is reduced significantly, however, working with frozen soil and screw piles requires specialized equipment, which entails considerable financial costs.