The construction of any house begins with the foundation, the main load-bearing element, the foundation of the future building. That is why a careful approach to its selection, competently performed calculations and construction work will ensure not only the durability and stability of the entire structure, but will also provide significant savings in materials, money, effort and time.

A strip foundation is perfect for those houses where you plan to build a garage and basement.

To answer questions about how to calculate the design of a building, the amount of building material, the volume of concrete and its consumption, let's start with choosing the type.

Its type is determined by the characteristics of the construction site (terrain, soil type, groundwater level, freezing depth), the load from the house, and, of course, the capabilities of the developer. So, what do we choose from?

Influence of soil on foundation depth

Ignorance of the characteristics of the soil on which it is planned to erect any building can lead to the fact that it begins to sag and collapse.

As a rule, the top layer of earth has a significant amount of organic residues, which affects its uneven subsidence and shrinkage. Consequently, such a layer of soil cannot be used as a cushion for the base.

Coarse, medium sandy and gravelly soils are best for foundations. The minimum depth for laying can be 0.5 meters. If the soil consists of fine sand or sandy loam, the groundwater level should be taken into account. Because sand, when filled with water, loses its load-bearing properties. Also, when such soil freezes, it can swell and sag unevenly.

As for clayey and sandy loam soils, they have good load-bearing properties, but when wet they begin to sag under their own weight.

In order to determine at what depth it is necessary to lay the foundation, you need to be guided by the following features.

- The number of floors of the building, the type of its construction, the weight of the walls and ceilings.

- The magnitude of the loads on the future foundation.

- The depth of the primary element in neighboring buildings (if they are present).

- Geological and hydrogeological properties of the soil on which construction is planned.

- The base of the soil under the foundation should not be heaving.

- The maximum depth of soil freezing in places where construction is planned.

Having all the information about the features described above, you can determine the most suitable depth for laying the foundation.

Materials used for the construction of strip foundations

A monolithic strip for a house is a system of beams connected to each other at corners and intersections, which lie on an elastic foundation made of underlying soil layers. Soils are capable of periodically increasing or decreasing in volume under the influence of moisture saturation, freezing and other external factors.

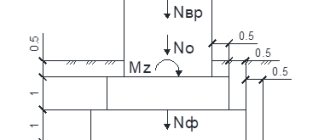

Combined with the load from the weight of the building, this causes forces acting in different directions on the foundation structure. For effective operation, the design of a monolithic strip foundation includes two components - concrete and reinforcement, each of which absorbs loads of a different nature.

The concrete used in the construction of strip foundations works exclusively in compression and is capable of withstanding an impact of several hundred kg per 1 cm² without destruction. The reinforcement absorbs loads in tensile zones of the structure and is capable of withstanding tensile forces of 400-500 N/mm2, depending on the class.

Before determining what brand of concrete is needed for a strip foundation, you should clarify what its properties and characteristics need to be taken into account when selecting the right material.

Concrete and its characteristics

The mixture used in the construction of strip foundations includes: binder - Portland cement, coarse aggregate - crushed stone, fine aggregate - sand and water. The properties of a material are determined by the percentage of all its components. The characteristics of the concrete mixture are indicated by letters and numbers in accordance with GOST 7473-2010 “Concrete mixtures. Technical conditions".

Here is a table of the consumption of all components of the concrete mixture for each strength grade, which can be used when making concrete on your own:

The main characteristic is called strength class or grade. The material class, in accordance with international standards, is designated by the letter “B” with numbers that indicate what compressive load, measured in megapascals (MPa), the material can withstand without destruction. At the same time, as was previously accepted, the strength of concrete can be characterized by a grade designated by the letter “M” with numbers that indicate what maximum pressure, measured in kg/cm², the material can withstand. In construction practice, both designations are used.

We provide a table of correspondence between material characteristics in terms of strength.

In addition to the strength grade, concrete is also characterized by such indicators as frost resistance, water resistance and workability.

Frost resistance is marked as “F” with a number indicating the number of cycles of transverse freezing and subsequent thawing that the material of this design can withstand without loss of strength. Frost resistance varies between grades F50 – F500.

Water resistance is marked as “W” with a number indicating the ability to resist water saturation. For concrete used in the construction of foundations, it varies between W2–W8. Concrete of higher waterproof grades is used for the construction of hydraulic structures.

Workability is marked as “P” with a number indicating ductility in the range P1–P5.

For example, the full designation “BST V20 P2 F100 W2” according to GOST 7473-2010 means that this is a mixture of heavy concrete with strength class B20, average ductility P2, frost resistance F100 and normal water resistance W2.

How to test concrete for strength

According to the requirements of SNiP 3.03.01-87 “Load-bearing and enclosing structures”, structures made under construction conditions from monolithic reinforced concrete can be loaded only after the material has reached 70% of its design strength. According to the standards, artificial stone gains full strength after 28 days at a positive temperature of at least 20 °C.

In real conditions, a strip foundation can gain 70% strength, sufficient to continue the construction of walls, within one to two weeks. The period for gaining the required strength depends on the air temperature during this period.

Here is a table of the time frame for concrete to gain strength.

Testing the finished monolithic structure for strength is carried out in several ways:

- testing samples in a construction laboratory. Samples of the material are placed in special molds in the form of cubes with a side size of 15x15 cm, at least three from each batch of concrete mixture delivered to the site. The cubes must gain strength under exactly the same conditions as the material poured into the structure. After the specified period, the samples are transferred to the laboratory and tested by compression under pressure;

- impact methods using a Kashkarov hammer or a Fizdel hammer. These devices, which have a working part in the form of a steel ball, strike the surface of the structure and, after measuring the diameter and depth of the dent, the strength of the concrete is determined according to a special schedule;

- percussion using a Schmidt hammer (sclerometer). A Schmidt hammer is also used to strike the surface of the structure; the strength of the concrete is determined using a graduated scale on the device;

- non-destructive methods using ultrasonic scanning, for which a special device is used that generates ultrasonic radiation, the speed of which passes through the thickness of the monolithic structure is used to determine the strength of concrete.

Armature

For reinforcement of monolithic tape, reinforcement of classes A1 (A240), A3 (A400) or A500C and high-strength wire of class BP1 are used.

Reinforcement A1 (A240) is used as transverse reinforcement (clamps) as part of spatial frames or in the manufacture of flat meshes. Reinforcement class A3 - as working rods installed along the length of the tape as part of spatial frames or perpendicular to the axis of the foundation as part of flat grids.

Instead of class A3 working rods, class A500C reinforcement can be used, which allows the use of welding in the manufacture of frames and meshes. High-strength wire of class BP1 can be used instead of structural reinforcement of class A1.

Formula for calculating the cubic area of the foundation

To calculate the cubic area of the primary element, use the volume calculation formula. For which I use the following data:

- Width.

- Height.

- Length.

These data are multiplied together to obtain the cubic area of the base. Example WxHxD = cubic area. It is also worth remembering that concrete tends to shrink when it dries, this occurs due to the evaporation of water from it, so when calculating the cubic area it is worth taking this factor into account. The percentage by which concrete shrinks depends on the brand of concrete and you can find out this data from its specification.

Why do you need the cubic capacity of the foundation?

The volume of the supporting base is important to determine for several reasons:

- First, the known volume of the foundation helps to accurately determine the volume of excavation work and the costs associated with this stage.

- Secondly, based on the volume of the foundation, it is not difficult to determine the required amount of concrete mass and building materials that will be required to prepare the solution.

- Thirdly, knowing the volume of the foundation, you can easily calculate the consumption of materials that will be required for formwork, creating a reinforcing frame and other activities.

In construction, when calculating foundation parameters, volume is taken as the basic unit, not mass, since 1 m3 of concrete mixture of different brands has different weights. To determine the cubic capacity of a complex-shaped foundation, the structure is divided into simpler shapes.

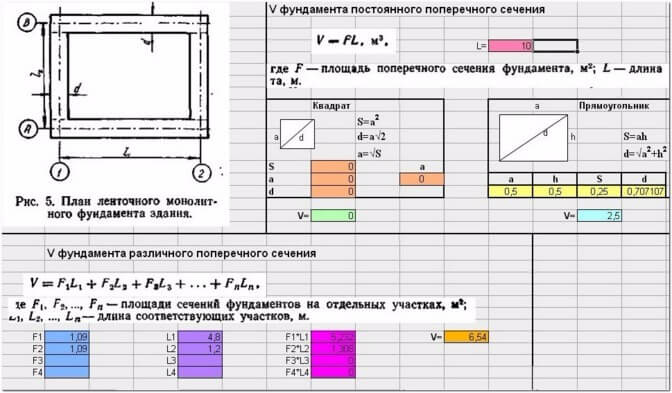

The calculation of the volume of the foundation is carried out according to a certain scheme, which depends on the type of foundation.

How to calculate

Each type of primary element has its own way of calculating the required volume of concrete. Also, to calculate it, you need to know the type of soil and its load-bearing properties. Calculation of the volume of the underlying material for each type is carried out as follows:

- Monolithic slab. To calculate the slab base, you need to know the area of the building being erected and the thickness of the poured primary element. Having these values, it is enough to multiply them together to obtain the required number of cubes of concrete. Also, if the structure of the foundation contains stiffening ribs, it is necessary to calculate the volume of each rib and add them to the total number of cubic meters of the foundation.

- Tape base. To calculate the volume of a strip primary element, it is enough to divide it into conditional walls. Then calculate their volume by multiplying their width by height and length. The results obtained must be summarized. In this way, it will be known how many cubic meters of concrete are needed to lay the strip foundation.

- Columnar base. The volume of a pile element is calculated in the following way: the volume of one pile is multiplied by their number, resulting in the required amount of concrete. The only difficulty in calculating a pile foundation is calculating the volume of one column, since their shape can be either cylindrical or pentagonal. The volume of simple cylindrical shapes is calculated as follows: the area of the circle (3.14*R^2, where R is the radius of the pile, half its diameter) of the base of the pillar is multiplied by its height.

Also, when calculating the volume of the primary basis, more complex calculations may arise. For example, when several types of foundation are used at one facility. In such cases, it is necessary to make a separate calculation for each type, and then summarize the results obtained.

Features when calculating the volume of concrete

How much concrete mixture is required to fill a given base, the result is easy to obtain. The parameters of the slab (length, width, height) are multiplied among themselves. Sometimes, the foundation may have some deviations. They can directly influence the consumption of concrete.

Return to contents

For example

To ensure the stability and hardness of the slab, stiffening ribs are made along its edges. They are placed on the lower surface of the base so that the upper part is smooth. They also require concrete. Its volume can be determined by knowing the cross-sectional area and the total length of the stiffeners. Such a slab requires a different approach. To the already known volume value it is necessary to add the product of the total length, height, width of the stiffeners. For each case, the calculation must be carried out individually.

If the ribs have the shape of a trapezoid, then the cross-sectional area of this figure is multiplied by the total length of the ribs.

Return to contents

Calculation example

Let's say it is necessary to lay a strip foundation for a one-story residential building 10 meters long and 6 meters wide on a flat area. In this case, the soil is gravel and the minimum depth of the primary element can be 0.5 meters. The width of the foundation is also planned to be 0.5 meters.

Therefore, there is all the necessary data to carry out the calculation, which consists of the following steps:

- It is necessary to find out the total length of the foundation being laid. To do this, it is necessary to sum the length and width of the building together. Example L 10mx2 = 20m and W 6mx2 = 12 m, 20m+12 m = 32 m total base length.

- Having the total length of the primary element, you can calculate the cubic area by multiplying its height by its width and length. Example 0.5m x 0.5m x 32m = 8 cubic meters.

Based on the results of the example, it follows that to lay the foundation for a house measuring approximately 10 by 6 meters (since the percentage of concrete shrinkage is unknown) 8 cubic meters of concrete are needed.

If a tiled base is used for the same house, the calculation will be as follows:

- You need to find out the total area of the foundation; to do this, multiply the length of the building by its width. Example L 10m x W 6m = 60 square meters.

- The resulting result of the total area of the foundation must be multiplied by its thickness. Example 60 m2 x T 0.5 m = 30 cubic meters.

As can be seen from the examples, the procedure for calculating the cubic area of the base does not contain anything beyond the natural, so its calculation can be carried out by any person who does not have an architectural education.

Monolithic slab base

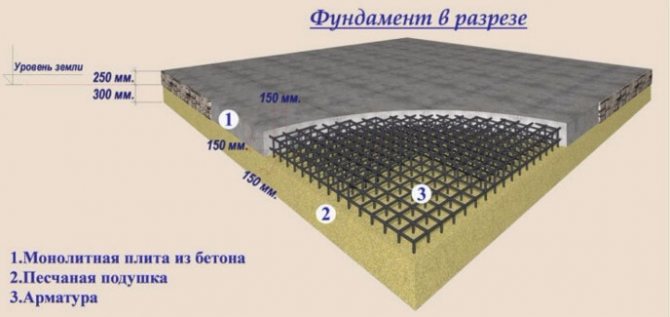

A monolithic base is a large rectangular slab immersed to a specific depth in the soil.

This means that calculating the volume of the slab will take a minimum of time, because using ready-made drawings of load-bearing walls you can calculate the length, width and thickness of the structure.

For example: the length of the foundation is 12 meters, width 7 meters, thickness 0.6 meters. As a result, the volume of the slab will be as follows: 12*7*0.6=50.4 m3.

But this volume does not entirely correspond to reality, because any monolithic slab has a reinforcing mesh. You can also calculate the total volume of all the rods and trim and subtract it from the total volume of the foundation.

But in private construction no one makes such detailed calculations, because the total volume of reinforcement is rarely more than 1 cubic meter.

Estimated cost

In order to calculate the estimated cost of laying a foundation, it is necessary to divide the work process into stages:

- Excavation. The cost of excavation work averages 150 rubles per cubic meter. That is, for a ditch 0.5 m deep and 0.5 m wide for a strip primary element for a house 10 by 6 meters, you will have to pay 1,200 rubles. Example L 10mx2 = 20m and W 6m x 2 = 12m, 20m + 12m = 32m, L 32m x W 0.5m x W 0.5 m = 8 cubic meters of land which we multiply by the cost of work 8x150 = 1200 rubles.

- Laying a sand cushion. After the pit is ready, it is necessary to make a sand cushion around the entire perimeter of the foundation 0.2 meters thick. Therefore, 32m x 0.5m x 0.2m = 3.2 cubic meters of sand. The approximate cost of sand is 600 rubles per cubic meter 600x3.2 = 1920 rubles. You also need to take into account the cost of the work, which is 100 rubles per cubic meter, which comes out to 1920+320 = 2240 rubles.

- Laying crushed stone base. Crushed stone for the foundation is also laid along its entire perimeter with a thickness of 0.2 meters. From previous calculations it is known that with such a thickness 3.2 cubic meters of crushed stone is needed. The cost of crushed stone with delivery is approximately 1,500 rubles, and the cost of laying it is 150 rubles per cubic meter. The result is 4980 rubles for work and crushed stone.

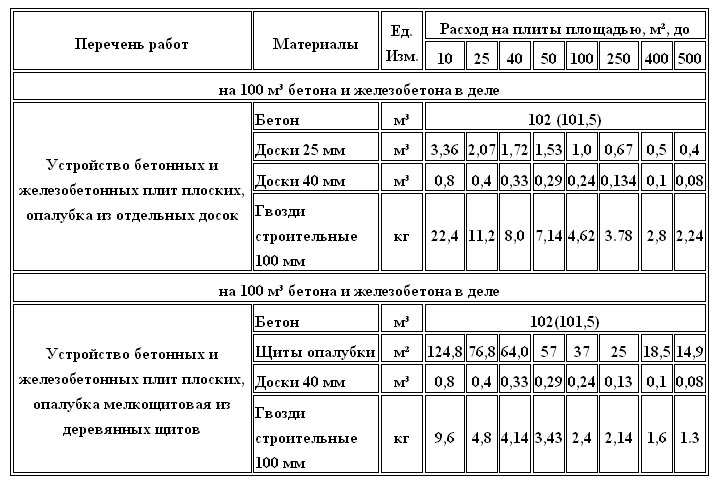

- Installation of formwork. For formwork, as a rule, they use an edged board with a thickness of at least 0.2 millimeters and a 50 x 50 mm beam for spacers. With a formwork height of 0.5 m and a board width of 30 cm and a length of 6 meters, 16 pieces will be needed. The cost of one board is approximately 200 rubles per piece, which turns out to be 3200 plus 700 rubles per beam, totaling 3900 for the formwork.

- Pouring concrete . As is known from previous calculations, 8 cubic meters are needed to fill the foundation. The cost of one cubic meter of concrete grade M 300 is 4,200 rubles. It turns out that the cost of concrete will be 33,600 rubles.

Having calculated the approximate cost of work and materials, we can summarize that 1200 + 2240 + 4980 + 3900 + 33600 = 45,920 rubles will be the estimated cost of the strip base.

Expert advice

If you are building your home and the foundation for it on your own, then in order to obtain concrete of the required grades in terms of strength, frost resistance and water resistance, you should order it from a concrete plant and deliver it to the site using a construction mixer. When producing concrete mixtures in industrial production conditions, accurate dosage of all components is guaranteed.

Each batch of material must be accompanied by a passport indicating all the characteristics. In addition, when delivering ready-mixed concrete, it is necessary to select and form samples from each batch - cubes according to the method described in the article, which, after hardening, can be tested in a construction laboratory to check the declared strength grade.

If you make the concrete mixture yourself at a construction site, then you must accurately maintain the proportions of all components indicated in the table in the article.

Determining the thickness of the slab

For these calculations you need to know:

- distance between reinforcements;

- the amount of concrete above the reinforcing mesh (lower and upper);

- reinforcement thickness.

Usually the optimal value is approximately 250 mm. They start from the fact that the distance between two reinforcement meshes is on average 70 mm. If we add the thickness of the protective layer of 50 mm on both sides, and the thickness of the steel frame, after carrying out simple calculations, we see that the thickness of the concrete slab will range from 200 to 300 mm.

The thickness of the slabs is determined based on the general loads of the structure and the characteristics of the soil. Therefore, these dimensions are optimal only for hard and uniform soil. When the dimensions of the slab are calculated, the size of the pillow is calculated.

Return to contents