The plinth gives strength and stability to the structure, therefore, when constructing a building, a plinth must be made. It takes on the bulk of the load. It is mainly made of red brick, since a large load falls on its walls, and such material has significant weight. You also need to pay special attention to brick calculations when building a plinth; you need to think about its weight and quantity.

It should be borne in mind that materials with different markings from different manufacturers often do not match, which negatively affects the reliability and strength of the structure. Also, bricks from different batches differ in color, which can affect the exterior.

Create a brick plinth for your home

Information on the purpose of the calculator

The online brick calculator is designed to calculate the amount of building and facing bricks for a house and basement, as well as related parameters and materials, such as the amount of masonry mortar, masonry mesh and flexible connections.

Also, the calculations can take into account the dimensions of gables, window and door openings of the required number and size. Since ancient times, brick has been the most popular, widespread and familiar building material for the construction of long-term and reliable structures. This situation persists for a number of reasons, despite the emergence of new, modern and cheaper building materials. There are several most common types of bricks for any construction needs:

- Adobe - made of clay and various fillers

- Ceramic - (most common) made from baked clay

- Silicate - made of sand and lime

- Hyper-pressed - from lime and cement

- Clinker - made from special baked clay

- Fireproof - (fireclay) made from fireclay

Ceramic brick

(clay) are divided according to purpose into façade, ordinary and clinker. Ordinary brick (backfill) may not have an ideal geometry and in most cases is used for laying rough walls of houses, plinths, garages, which are subsequently plastered, painted and protected with facing materials and coatings. Its color has various shades of red.

About facing

(facade) are used for the construction of walls without any additional finishing in the future. There are also various special types of facade bricks that can withstand high mechanical loads and adverse atmospheric influences, and are usually used for paving paths, building all kinds of retaining fences, stairs, and walls.

K linker

It has an ideal smooth surface, various shades of red and black colors and is highly dense.

With silicate

is a light-colored lime-silicon artificial stone. Sand-lime brick differs from ceramic brick in that it is not fired during the manufacturing process. It is quite hygroscopic, and accordingly is not used for the construction of objects that will be operated in humid environments, such as the basement and basements.

Also, sand-lime brick is not used in the construction of furnaces, pipes, chimneys and foundations, since it withstands external destructive loads quite poorly.

Oh fireproof

is divided into several types and is used for the construction of structures exposed to high temperatures, such as stoves, fireplaces, chimneys and smelters. The most common is fireclay brick, it has a yellowish tint, made from special fireclay (chamotte) and, unlike ordinary clay brick, can easily withstand high temperatures (up to 1400 degrees), as well as numerous heating and cooling cycles without loss of strength.

Irpichy can be solid (volume of voids no more than 25%), hollow and porous-hollow. It is believed that depressions and voids in the material not only reduce weight, but also significantly increase the overall strength of the masonry by increasing the contact area between the brick and the mortar.

When calculating the amount of brick needed for work, they usually use a rule called format, in which the dimensions of the brick itself are increased by 10 mm (this is the standard joint thickness), that is, it turns out: 260x130x75 mm.

Below is a complete list of calculations performed with a brief description of each item. If you haven't found the answer to your question, you can contact us via feedback.

How to calculate permanent loads

The loads imposed by insulating materials, engineering systems, building structures, plumbing, furniture, and people are considered permanent. It is important to calculate their impact. The stress from the walls has a direct impact on the foundation of the building itself. To calculate this indicator, you need to determine the total area of the walls and multiply it by the weight of the wall (with a thickness of 15 cm).

Also, the calculation of loads reveals the mass of basement and attic slabs. Their S is multiplied by the weight of reinforced concrete. You can calculate the payload from the internal maintenance of the house if you multiply the entire area of the building by the maximum load parameter of 180 kg per square meter. meter.

Number of bricks per plinth - exact calculation and table

To give the structure stability and strength, a plinth must be made above the foundation at the construction stage. In the future, it will take on most of the load of the future structure (pressure from floors, walls, roofs, etc.). As a rule, the base is made of brick. The walls of the basement experience serious loads, so it is customary to use solid red brick for its construction.

Markings that can be used are M200 and higher strength factors. Such a brick has more weight than its traditional counterparts, but in this case it is justified. It is also important to correctly calculate the bricks for the plinth so that you definitely have enough material and do not have to overpay.

It is better to take time in advance to correctly calculate the number and weight of bricks.

It is important to remember that the performance characteristics of a product with similar markings, but from different factories, often do not match, and this negatively affects the strength and reliability of the entire building and the base in particular. In addition, material from different batches differs slightly in color, which can spoil the entire exterior of the structure.

It is recommended to immediately purchase a sufficient amount of brick of the chosen brand and production of a certain company.

We calculate the specific pressure on the ground

The purpose of the calculation is to determine the ratio of the specific pressure on the soil under the base of the foundation from the weight of the house - R t/m 2 and the calculated soil resistance - R t/m 2. The calculated soil resistance characterizes its ability to absorb the load from a building without settlement. The value of P is determined by calculation, and R is regulated by DBN V.2.1.-10-2009.

The main requirement for reliable operation of the foundation is compliance with the conditions under which the value of P must be less than the value of R.

We determine the specific pressure on the soil under the base of the foundation R t/m 2.

To do this, divide the total weight of the house with loads of 238.0 tons by the area of the base of the foundation 21.4 m2, we get P = 11.12 t/m2.

According to Table E.2 DBN, we find that R for fine sands is 20.0 t/m2. When determining R, since geological studies of the soil have not been carried out, we select the minimum indicator of this value from the table (indicators of porosity, humidity and water saturation of the soil).

As we see, R is greater than P, which corresponds to the main condition for reliable operation of the foundation.

To create a safety margin for the foundation that covers inaccuracies in the selection of initial data, it is necessary that the value of R be 15-20% greater than P. For us, with a 20% margin, it is enough to fulfill the condition - the value of P should be no more than 16.0 t /m 2 (control value).

Calculation method based on plinth area

In accordance with GOST, the dimensions of red brick are as follows: 250x120x65 mm. All its sides have their own name: spoon, bed and poke, respectively. The amount of material is calculated using several methods. The initial data in the first method is the area of the plinth along with the area of one of the sides of the brick. To make calculations, you need to know for certain the overall dimensions of the object.

As an example, let's take a house whose base area is 5x4 square meters. m. Of course, the size of the house can be any, but we give examples of the most convenient ones to calculate, so that you don’t get too confused in the calculations.

The standard height of the plinth is 1 meter. The length of the walls of the building is 18 m (5+5+4+4 m). You can calculate the amount of building material in meters, which will be more convenient.

The simplest masonry is made so that its thickness is a multiple of half the length of the brick. The width of a standard brick is 0.12 m, which fully corresponds to the width of such masonry.

When laying a masonry of one brick, its thickness will be 0.25 m, and if one and a half - 0.38 m, etc.

Main types of masonry.

The easiest way to calculate the base brick that will be required is this:

- First of all, we calculate the initial amount of material for one square meter of area, provided that the masonry is half a brick (even if we make another masonry).

- The outer surface is a spoon with an area of 0.01625 square meters. m (0.25x0.065 sq. m).

- When one square meter is divided by the area of the spoon side, the so-called base number is obtained. This is the amount of material required to lay out 1 square meter. m of base with a wall thickness of half a brick. The formula looks like this: 1/0.01625 = 61.53 pcs.

- We calculated the amount of material without taking into account mortar joints, the thickness of which is usually 0.005–0.01 m. Taking into account brick joints, 10–15% less may be required. However, it is worth remembering such a thing as material damage during delivery. It can reach up to 5–7%.

Based on the above, if the area of the basement base is 18 sq. m (18x1 sq. m), when multiplying the resulting base base by this value, the quantity required for work is obtained - 1107.54 pcs. (1108 after rounding up). This amount of building material will have a very large weight, so it will be very difficult to deliver it yourself.

By the way, the same amount of material for the basement extension is obtained by dividing the area of the entire surface of the base by the previously obtained area of the spoon, namely 18/0.01625 sq. m.

If necessary, masonry of one brick or wider can be used. Accordingly, the wall thickness will be 0.25 m or more. Despite this, we consider the basic value only for half-brick masonry. Simply then (when laying in one) we multiply this value by two, when laying one and a half - by three, in two - by four. In other words, how many times the half fits in the thickness of the masonry, this is the multiplier of the base number.

Consumption of building materials and their weight(s):

- concrete grade M 150 for strip reinforced concrete monolithic foundation

.

The volume of the foundation (preliminary) is determined by calculation: width 0.4 m x height 1.0 m x length 53.5 m = 21.4 m 3. The specific gravity of reinforced concrete is 2500 kg/m 3 or 2.5 t/m 3 (according to SNiP II-3-79). We calculate the weight of the foundation: volume 21.4 m 3 x 2500 kg/m 3 = 53500 kg or 53.5 tons

(preliminary data); - solid single ceramic brick M 125 (GOST 530-2007) for external walls, 2 bricks thick

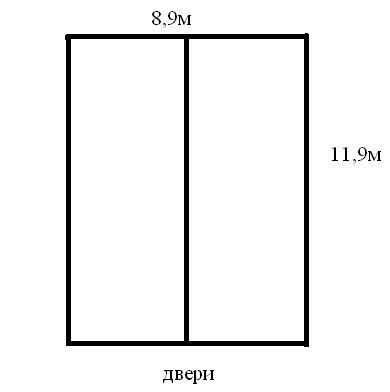

. The length of the perimeter of the walls will be 11.9 + 11.9 + 8.9 + 8.9 = 41.6 m. The height of the walls will be 2.6 m. Excluding windows and doors, the volume of the walls will be 41.6 x 2.6 x 0 .5 = 44.7 m3. For 1 m 3 of a solid wall, 394 pieces of single brick and 0.240 m 3 mortar are needed. The total required bricks are 44.7 x 394 = 17612 pieces. With a weight of 1 brick of 3.4 kg, the weight of the external walls will be 17612 x 3.4 = 59880 kg. Or 59.9 tons.

For 1 m 3 of masonry, 0.240 m 3 of cement mortar is required. The specific gravity of the cement-sand mortar is 1.8 t/m 3 (according to SNiP II-3-79). External walls will require 44.7 x 0.240 = 10.7 m 3 of solution. In total, the weight of the mortar on the external walls will be 10.7 x 1.8 = 19.3 tons.

The total weight of the external walls will be 59.9 + 19.3 = 79.2 tons

;

- ceramic solid single brick M 125 (GOST 530-2007) for the plinth, 2 bricks thick, 1 row high

.

With a foundation perimeter of 41.6 m, the volume of the base will be 41.6 x 0.5 x 0.130 = 2.7 m 3. For 1 m 3 of a solid wall, 394 pieces of brick and 0.240 m 3 of mortar are needed. The weight of the base will be: for bricks - 2.7 x 394 = 1064 pcs. If 1 brick weighs 3.4 kg, it will be 3617 kg or 3.6 tons. Cement-sand mortar per 2.7 m 3 of masonry requires 0.65 m 3. This will be 0.65 x 1.8 = 1.17 t of solution. Total weight of the base 3.6 + 1.17 = 4.77 t

;

- single ceramic hollow brick M 100 (GOST 530 - 95) for interior walls

.

The total length of the internal walls is 39.2 m. With continuous brick laying in the floor, minus the volume of internal doors, we obtain the volume of internal walls 39.2 x 0.120 x 2.6 = 12.2 m 3. For 1 m 3 of a solid wall, 420 bricks and 0.189 m 3 of cement-sand mortar are needed. Subtracting the volume of internal doors, the required number of bricks will be 3800 pieces and cement-sand mortar 1.7 m 3. Determine the weight of the internal partitions. The weight of the brickwork is 3800 x 2.5 kg (weight of 1 brick) = 9500 kg, or 9.5 tons. The weight of the mortar is 1.7 x 1.8 = 3.06 tons. The total weight will be 9.5 + 3.06 = 12, 56 t

;

- metal

_

Steel on metal doors: 1 - 2.0 m high, 0.8 m wide with a metal frame; 2 - double height 2.0 m, width 1.6 m with a metal box. According to the manufacturer's certificate, their total weight is 290 kg or 0.29 t

; - timber (softwood)

for the construction of: internal wooden doors, cashing;

window frames made of timber; floors made of timber and floorboards; roof rafters made of timber, boards, slabs; roof gable made of boards. The measurements of all the components of these structures (according to the completed sketches) amounted to a total volume of 19.5 m 3. The specific gravity of coniferous wood is 500 kg/m 3 (according to SNiP II-3-79). We determine the weight of all the timber used - 19.5 x 500 = 9750 kg or 9.75 tons

; - floor slabs made of aerated concrete

.

For ceiling and basement floors. It is planned to use PP 60.2.5-4.5 slabs (GOST 19570-74). The specific gravity of the slabs is 0.63 t/m3. The total floor area is 8.9 x 11.9 = 106.0 m2 x 2 = 211.8 m2. With a standard floor thickness of 0.22 m, the volume is 211.8 x 0.22 = 46.6 m 3. The total weight of the floors will be 46.6 x 0.63 = 29.36 tons; - ceramic tiles (GOST 1808-71) for roof covering

.

Weight 1 m2 - 46.5 kg. The total weight of the tiles is 175.8 x 46.5 kg = 8174 kg or 8.2 tons

; - floor insulation

.

It is necessary to insulate a floor with an area of 8.9 x 11.9 = 106 m2. To insulate the floor, we will use mineral wool mats with a specific weight of 35 kg/m 3 and a thickness of 0.1 m. In this case, the weight of the insulation will be 0.371 t

; - insulation for external walls

.

The perimeter of the walls is 41.6 m, height 2.6 m. The total area of insulation of the walls is 41.6 x 2.6 = 108.16 m 2. For wall insulation, we use EPPS with a thickness of 0.1 m and a density of 35 kg/m 3. Insulation weight 108.16 x 0.1 x 35 = 0.379 t

; - roof insulation

.

We will insulate the roof along the attic floor with mineral wool or EPS with a thickness of 0.2 m and a density of 35 kg/m3. The insulation area is 106 m2. Insulation weight 106 x 0.2 x 35 = 0.742 t

; - waterproofing for foundation and roof

.

For the foundation we use “Aquaizol SBS” (TU 30510965-001), in two layers. The specific gravity of the material is 2.5 kg/m2. The length of the foundation is 30 m. When laying Aquaizol in one layer 0.5 m wide, we need 53.5 x 0.4 = 21.4 m 2 of material, and with two layers 21.4 x 2 = 42.8 m 2 . The weight of the waterproofing will be 42.8 x 2.5 = 107 kg or 0.1 t. For the roof, we will use a waterproofing membrane with a density of 940 kg/m3. For a roof area of 175.8 m2, the weight of the membrane is 175.8 x 940 x 0.0006 = 99.15 kg or 0.099 t. The total weight of the waterproofing will be 0.199 t

; - glazing

_

10 windows. Glass thickness 4 mm. Total weight - 980 kg or 0.98 t

; - plaster

, thin-layer, cement-sand mixture for the facade and internal partitions -

0.62 t

.

Calculation method using volume

To calculate the required amount of material, you can use a volume measure.

V (basement) = (5+5+4+4) m x 1 m x 0.12 m = 2.16 cubic meters, V (brick) = 0.25x0.12x0.065 = 0.00195 cubic meters. Everything seems very simple, and it really is.

When dividing the volume of the base by the volume of the brick, we get the required amount of material: 2.16/0.00195=1108 pieces after rounding up. Therefore, for the entire base we will need 1108 bricks, excluding mortar joints and breakage. As a result, we see that after two calculations there is no difference between the two obtained values!

Using the method of counting quantities using volume is also relevant and no less accurate in terms of the final value. True, sometimes it is difficult to compare the sizes of the base and individual bricks.

Description of the house

One-story brick house. The composition of the premises is shown in the drawing. Net area - 84.1 m2. Living area - 72.6 m2. Roof area - 175.8 m2. Overall dimensions of the house: 8.9 x 11.9 x 5.55 m.

General view of the house

House foundation diagram 8.9 m x 11.9 m.

The construction of the house is supposed to be on fine sandy soil. Objective data: freezing depth up to 1.4 m; the distance from the planning mark to the groundwater level during the period of soil freezing exceeds the calculated freezing depth by more than 2 m. Construction site - Moscow region.

Taking into account objective data, we assume a foundation depth of 1 m and a width of 0.4 m (preliminary data). The length of the foundation according to the accepted scheme is 53.5 m. The total area of the base of the foundation: length 53.5 m x width 0.4 m = 21.4 m 2.

Structural elements and materials used:

- foundation - strip, monolithic reinforced concrete;

- base - solid brick;

- external walls - solid bricks (2 bricks) with insulation, internal walls - hollow bricks (0.5 bricks);

- The roof structure is wooden, gable. The tilt angle is 30 degrees. Wood volume of the roof truss structure: 13.9 m 3 ;

- Windows - wooden, double. External doors are metal, internal doors are wooden;

- roof - ceramic tiles;

- facade - thin-layer plaster;

- the heating boiler is installed on a separate foundation;

- floor - wooden beam, floorboard;

- ceiling - floor slabs made of aerated concrete;

- basement floor - floor slabs made of aerated concrete;

- insulation, waterproofing.

Quick calculation table

These two methods of calculating bricks for building a basement are, in fact, approximate. There is no need to talk about ideal accuracy here, because the bricks will have to be connected to each other with cement mortar, provided that the thickness of the connecting seam often exceeds even 10 mm. The seams, in turn, are located between the rows of masonry (horizontal and vertical seams, respectively).

When calculating quantities, size is taken into account, but weight is not taken into account. And when delivering building materials, weight is a very important parameter.

The following should be remembered:

- When calculating the amount of material, it would be correct to take into account a certain thickness of the connecting seams. However, in practice it is very difficult to calculate in advance the exact thickness of these seams.

- Also in the base there are almost always ventilation windows, the area of which must be subtracted from the resulting value.

- In addition, during transportation, delivery and unloading, debris will certainly form. Often it reaches 5-10% of the total amount of material. This also needs to be taken into account when making calculations.

The approximate amount of red brick per basement extension can also be calculated using the table of average values given below:

Determining the depth of the base

Before building a foundation for a brick house, the type of soil is determined by drilling. The type of soil affects the load-bearing capacity of the building. Natural soil has the following characteristics:

- 1 kgf per square. cm – wet dusty sand;

- 2-2.5 kgf per square. cm – fine, medium sand fraction;

- 3 – 3.5 kgf per square. cm – gravelly and coarse sand;

- 4-5 kgf per square. cm – gravel;

- 1-3 kgf per square. cm – clayey and hard soil.

Using test drilling, the type of soil under the main cushion is determined. The trench under the house should not exceed one meter if the soil on the site is homogeneous and has little moisture. Experts recommend digging a foundation depth for a brick house 30 centimeters below the soil freezing level. This will avoid deformation and distortion of the concrete structure.

If the monolithic foundation is laid above the soil freezing index, the soil will swell. When determining the depth of the foundation strip, the freezing index of the ground must be taken into account. Its meaning varies in different areas. In the south, the soil freezing parameter is no more than 1 meter, and in the north the soil can freeze more than 2 m.

Calculator for calculating the amount of bricks for laying a plinth

When building a foundation for a future house, this approach is often practiced - the lower part of the base is a reinforced concrete monolithic strip, placed just above ground level, and then the base is laid out of brick to the required height. This significantly lightens the entire foundation structure and makes it warmer, which is extremely important for maintaining a comfortable microclimate in the premises of the first floor.

Calculator for calculating the amount of bricks for laying a plinth

Many owners prefer to carry out most construction work, if possible, on their own, and laying a brick plinth is no exception in this regard. But once such a decision is made, it is necessary to correctly determine the amount of materials required. A calculator for calculating the amount of bricks for laying a plinth will be an assistant in this matter.

Some brief explanations on working with the calculator will be given below.

Calculator for calculating the amount of bricks for laying a plinth

Explanations for the calculation

The principle of calculation is simple: the total volume of the brickwork is determined and then compared with the volume of one brick. But there are several important nuances:

- The calculation is carried out only for building bricks - single (65×120×250), one-and-a-half (88×120×250) and double (130×120×250). Numerous formats of finishing bricks are not included in the program - simply laying out the base from facing material seems like an unreasonably expensive undertaking.

- In the corresponding input field, you must indicate the thickness of the masonry, expressed in bricks, that is, a brick, one and a half bricks, and so on. Half-brick masonry is not practiced when creating a plinth, but, nevertheless, it is also indicated in the general range of options.

- The height of the masonry is in accordance with the expected height of the base.

- The program adjusts the size of each brick for the presence of joints filled with masonry mortar. The most commonly used seam thickness is 10 mm.

- The length of the base is indicated as the total length, measured along the outer perimeter. If the building plan contains internal foundation lintels, on which a brick base is also erected, then their length should also be included in the overall value.

- Finally, the number of internal and external corners of the plinth is requested. This data is necessary to make adjustments to the total volume of brickwork. If there are areas of abutment or intersection of the walls of the plinth, then they are also indicated in the external corners field.

- Usually, when calculating any building material, it is customary to include a certain reserve. Its value may depend on the level of qualification of the master, on the quality of the purchased material and on other reasons. In this case, the user has the opportunity to independently choose what supply of bricks to include in the calculation - from 0 to 15%.

The calculation result will be indicated in pieces.

How to learn to do proper bricklaying?

You should not assume that building a brick wall is a simple task, and the matter will immediately go smoothly. Practice shows that before obtaining impeccable masonry, a novice master will still have to go through a considerable training path. To help those who are taking their first steps in this field - an article from our portal How to lay bricks .

Checking and adjusting foundation dimensions

Based on the obtained calculation data, to save money, it is advisable to reduce the size of the foundation. We will look for the best option step by step.

We reduce the width of the foundation by 15 cm (i.e. we take the width to be 25 cm), while the area of the base of the foundation will be 13.4 m2.

We determine P, which will be: 238.0 / 13.4 m2 = 17.76 t/m2, which slightly exceeds the permissible P = 16.0 t/m2.

Due to the reduction in the weight of the foundation, we will carry out a refined check R. The weight of the foundation with a base width of 25 cm will be 53.5 x 0.25 x 1.0 x 2.5 = 33.4 tons. In this case, the total weight of the house with loads will be 238 - 53.5 + 33.4 = 217.9 tons.

We determine P - 217.9 / 13.4 = 16.26 t/m2. This value is also higher than the control value - 16.0 t/m2.

This means that it is necessary to increase the width of the foundation. Let's take a width of 0.3 m. Then the area of the foundation will be 53.5 x 0.3 = 16.05 m2. Foundation weight = 53.5 x 0.3 x 1 x 2.5 = 224.63 tons. Specific pressure P = 224.64 / 16.05 = 14 t/m2. This value fully satisfies the control value. The obtained calculation results can be considered final.

Before starting to build a house, it is important to determine the exact dimensions of the foundation. The foundation of the building must be strong and remain intact for many years of operation. When building a brick house, a monolithic strip-type foundation is used. It must withstand various soil loads and weather conditions. How to calculate a strip foundation for a brick house? To do this, it is necessary to determine the depth of its laying, taking into account the characteristics of the soil, its freezing and the groundwater level.

In the construction of private buildings, strip foundations are widely used for the construction of buildings. The structure is installed on a pre-prepared bed of screenings or coarse sand. Waterproofing materials must be installed. Roofing felt is used for this purpose. For the base, a prefabricated or monolithic foundation with a reinforcement cage is used. In order for a brick structure to be durable and maintain its technical characteristics, it is necessary to accurately determine some indicators - the level of laying the foundation, its volume and future loads.

How to calculate seasonal loads

They take as much snow as possible, which is typical for the region. Then you need to determine the number of seasonal loads. To do this, S of the roof coverings (on the slopes) is multiplied by the possible weight of the snow masses. For example, S = 81 m2, and the amount of snow is 100 kg per square meter. meter. To calculate the value correctly, you need to use a certain coefficient for pitched roofs - 0.86. That is, you need to calculate the required value like this: 81x100x0.86. The result will be 6966 kg. This will be an indicator of seasonal loads.

Construction of a brick house is a complex process. It requires the accuracy of all quantities and parameters. Otherwise, the brickwork may become deformed and crack. Any construction work requires correct values, checks and calculations. When calculating seasonal load, it is especially important to take into account the topography of the soil, the type of soil, and the proximity of groundwater. An important role is played by the climatic features of the region in which construction is carried out.