The technology for constructing a foundation based on a pile structure is considered one of the most reliable and practical. It can be considered universal, since the flexibility of the system and the variety of approaches to the technical implementation of the framework satisfy the requirements of a wide range of buildings. Among them are residential buildings, industrial buildings, communication structures and other objects. However, to achieve reliability of the pile structure, it is necessary to accurately determine the backfill parameters. In the list of the most important of them, experts note the distance between the foundation piles, which can vary depending on a number of characteristics of the building and construction conditions.

How is a pile foundation constructed?

A pile structure can be represented as a set of load-bearing elements and a grillage. Support elements may differ in material and installation method. For example, today the practice is to use driven and screw piles. To determine the distance between piles in a pile foundation, it is necessary to take into account the permissible burial depth, material of manufacture and other parameters of load-bearing products - this is how the number of elements and the step between them is calculated. No less significant is the function of the grillage, which provides a bunch of free-standing supports. It can be implemented in different types and designs, but, as a rule, the design of this component entirely depends on the technique for introducing and strengthening the piles.

Pile pitch calculation

The reliability of the foundation directly depends on the installation step of screw piles. The weight of the building is transferred to the supports, and they transmit loads to the ground. The distance between foundation piles depends on the total weight of the structure and the characteristics of the soil.

The payload is determined according to specifications or SNiP. Thus, a one-story residential building creates a load of about 150 kg per 1 m² of area. Loads created by wind and snow are taken from reference books based on the region of construction. The safety factor is taken to be 1.1-1.25.

Piles for a timber or frame house are mounted at a maximum distance of 3 m from each other. Often the distance is reduced to 1 m. The exact distance can only be determined by calculation. In the case of the construction of non-essential and temporary buildings, such calculations may not be made.

When calculating the pitch, the length of the grillage beams is taken into account, the reference points for both ends of which are the pile head. This rule applies to both timber and frame houses. If a concrete grillage is provided, then it does not work.

General principles of calculation

Typically, engineers focus on taking into account the properties of the soil and the expected mass of the future structure - together, this information allows them to lay the optimal pile-screw foundation. The distance between the piles can be calculated based on their number. To determine how many support elements will be required, you should know the load level and the overall load-bearing capacity of the structure. In particular, the pile can withstand about 2 tons, while the weight of the house structure can be tens of tons. Next comes the layout of the placement of piles throughout the entire area. In some cases, the load is uneven, and therefore the location of the piles is not always correct from a geometric point of view.

Recommended distance between supports

The distance between the supports should be no more than 3 m.

Construction technology on a pile foundation is popular. However, those who want to use this method ask themselves: what should be the distance between the screw piles?

The value is calculated based on the total load of the structure and soil properties. In this case, the calculation is not made for temporary and non-critical buildings. The maximum distance between piles is 3 m, but quite often it is reduced to 1 - 1.5 m.

When determining the pitch of the supports, you must not forget about the grillage. Each end should be located on the edge of the screwed-in pile. This rule applies to frame, timber and log houses.

When pouring a concrete bond, this nuance can be ignored.

The supports are located where the load-bearing walls pass.

When arranging a house with a slab foundation located on screw pipes, the calculation of the pitch and depth is subject to mandatory certification and verification of the design documentation by a specialist.

The technology involves complex calculations, although the procedure for performing the work is similar: piles are immersed in the ground in a certain order, and concrete slabs are placed on them.

The location of the supports is identical - under load-bearing walls, partitions and columns.

Deviations from the “norm”

Despite the development of uniform rules on the basis of which a method for calculating the distance between piles is drawn up, each case involves a huge number of nuances. In this regard, engineers are beginning to be guided by a simple rule: to designate the maximum limit of the permissible number of piles and rationally distribute them over the entire area, taking into account the loads.

Depending on the project for which a pile foundation is planned, the distance between piles may be reduced or increased. For example, if the plan provides for an internal load-bearing wall with floor loading on the sides, then it makes sense to reduce the spacing between load-bearing elements by 30%.

Increasing the distance is also not a serious mistake if technical precautions are taken. In such cases, additional installation of foundation beams is usually required. It is difficult to say what could justify increasing the distance, since such a correction is unlikely to make the pile-grillage foundation more reliable. The distance between the piles, which increases due to savings, also does not justify itself. If only for the reason that additional strengthening will cost more than an “extra” but structurally sound row of foundation piles.

Foundation load calculation

To determine the total load on the foundation, the following parameters must be taken into account:

- the type and weight of building materials from which the walls will be created;

- overall dimensions of the building, including floor heights;

- the weight of all floors, roofing and flooring;

- the number of people living in the house;

- weight of furniture, household appliances and equipment;

- mass of snow cover.

Since not all of the above parameters can be determined with high accuracy, construction organizations usually add a small safety margin to the load, which ranges from approximately 10 to 25%.

Pile location configuration

In addition to the distance between the piles, the way they are organized also matters. The choice of a specific configuration depends on the existing loads. There are several options for arranging supports on the foundation site: individually, in a row, in the form of various geometric shapes and in the form of a continuous field on which a pile foundation is formed. The distance between piles in each case is guided by the general calculation rules, but can be adjusted.

The most common are pile strips (row configuration), solid piles and “cluster” dense methods of arranging load-bearing structures. The technique of installing elements in a row is used to support the walls of buildings - this is a common method of constructing foundations for residential buildings. For structures requiring intense loads, the pile “bush” method is recommended. The continuous field structure is designed to support the heaviest buildings and structures. In this case, the piles are distributed evenly and are united by a monolithic grillage with a strong base.

Calculation of soil bearing capacity

The bearing capacity of the soil depends on the following factors:

- type of soil rock;

- soil moisture saturation;

- characteristics of soil layers;

- soil density.

The moisture factor does not apply to areas where sand of medium and large coarseness is contained in predominant quantities. Maximum loads on the soil that will not lead to significant foundation settlements have been studied and listed in public reference books. The average density of the main types of soil is:

- waterlogged clay 4 kg/cm²;

- dry clay 6.0 kg/cm²;

- loam 3.0 kg/cm²;

- sandy loam 3.0 kg/cm²;

- fine sand 4.0 kg/cm²;

- sand of medium fraction 5.0 kg/cm²;

- coarse sand 6.0 kg/cm²;

- gravel 4.0 kg/cm²;

- pebbles 4.5 kg/cm².

To obtain the geological features of the site, professional surveys are required. In some cases, you can determine the type of soil yourself. This is done by drilling several wells or digging several holes to a depth of at least 2 meters. After this, from a section of the soil you can determine what rocks it consists of, at what depth the bearing layer is located and how moist the soil is.

Screw piles and the required depth of their immersion

In general, a screw pile is a steel pipe of a certain length, which has a pointed tip and a spiral section welded along the pipe. The latter is designed to move soil to the surface and serves as the basis for screwing in the structure. The characteristics of the blades play an important role in screwing in the supports.

Screw structures are very diverse and can be used for any type of soil. They can be installed either manually or using special equipment.

The immersion is performed smoothly and begins with the removal (or passage) of the plant horizon. The screw-in depth of screw piles is set with a small margin of safety to ensure sufficient load-bearing capacity. The minimum immersion depth of the pile must correspond to the depth of soil freezing in the foundation construction area. The corresponding indicator can be taken from SNiP 01/23/99. For example, in the southern regions (Belgorod, Voronezh) the freezing depth is approximately 1 m, while in the northern regions it can be more than 2.4 m. It should be remembered that the freezing depth of sandstones is higher than that of clay soils.

The basic rule for constructing a pile foundation: the deeper the pile is screwed in, the more reliable the foundation.

The range of parameters for screw piles can vary widely. When choosing a trunk for building a foundation for a house, a pile with a diameter of 57 to 325 mm is usually chosen. In this case, the wall thickness is usually from 2 to 5 mm. The support length varies from 1.5 to 12 m. Screw piles can withstand high compressive loads and also show good values for pull-out stress. For the construction of foundations, supports are more than beneficial.

Screw designs

The advantages of piles in the form of a screw are the following:

- Passing through weak soils and reaching layers of sufficient strength is the versatility of construction in any conditions.

- Possibility of reusing supports, which is beneficial when constructing temporary structures.

- Preservation of soil and vegetation during manual screwing work, without the use of machinery.

- Minimal noise during work.

- High construction speed.

- High strength of the material and the created structure.

Economic benefits and high strength are the main reasons for using screw piles. In addition, in some situations this technology is the only one available.

Construction of a screw foundation

Foundations on screw piles are used in the construction of light buildings and auxiliary premises. When constructing heavy residential buildings, it is not recommended to use this type.

The installation instructions for screw bases are as follows:

- Choosing a location. When determining the construction site, you must make sure that no utilities (cable, pipeline, etc.) are laid in the foundation areas.

- Marking. The marking is carried out according to the house design, which also contains all the data about the base, its dimensions and configuration. All marks must be made with maximum accuracy, allowing an error of no more than 2 cm in any measurement.

- Screwing in piles. This is done as follows. A small depression is made at the location of the support (approximately 15-25 cm). A pile is installed in the prepared hole. A crowbar, the diameter of which is no more than 3 cm, is inserted into the hole of the support, then a pipe with a square cross-section is installed, forming a kind of lever. For the lever, it is best to use a metal pipe with a cross-section of 50x50 mm and a length of 3-3.5 m. The length of the lever is 2-3.5 m on each side. Moreover, the longer the pipe, the easier it will be to turn the lever and the deeper the pile will go. The support is screwed in using circular movements made around its axis. In one revolution, the support should go into the ground by about 20 cm. During the process, you need to constantly monitor the even position of the foundation elements. If necessary, the support is leveled. You should ensure the evenness immediately when the support enters, because With each new turn it will be more and more difficult to give the foundation a normal position. The accuracy of installation is checked using a building level or plumb line. The permissible deviation from the axis is 1-2 degrees.

If, when screwed in, the pile does not go into the ground, but only loosens the soil, then the hole should be deepened to 50 cm. And when installing the support, the vertical load must be increased, for which an additional load must be placed on the lever. As soon as the support engages the ground, the load can be removed. It is better to tighten the piles with the help of three or five people.

Construction of a foundation without excavating soil and laying concrete is possible if you use screw piles. You won’t win money, but you’ll save at least six months of time: the concrete base needs to settle, preferably overwintered, in order to identify defects if the pouring was carried out in violation of the technology.

The developer of a frame house is constantly running out of time. Forming a pile field in a working day using mechanized screwing is a common thing. On a hillside, conventional measurements with a tape measure lead to errors: the distance between the points of the zero mark must be in the same plane.

And putting the frame offset relative to the grillage requires additional work: either adjust the size of the wall to fit the error, or remove the supports and drill with screw piles of larger diameter 1.2 m deeper.

Optimal distance between piles

The optimal distance is calculated in accordance with the diameter of the screw piles and their total number. In the case of using a scheme with a single and strip arrangement, the perimeter of the building must be divided by the number of piles. Then the obtained result is compared with the minimum and maximum permissible parameters. At the same time, we should not forget that almost any error in calculating the distance can cause budget overruns for construction work, and in some cases increases the risk of wall subsidence. This is especially true in cases where the bearing capacity of the foundation in places with maximum load is insufficient.

What is good about a columnar foundation (pile)?

Diagram of a columnar foundation made from prefabricated driven piles.

The most important thing that I want to talk about is already a well-known fact. during construction will allow you to significantly save money spent on the purchase of building materials. In order not to waste time considering all sorts of options regarding the installation of a columnar foundation, we will choose one of the most popular and use its example to find out how to save and how much. So, we will talk about bored piles in the foundation. You can install such poles if there is any type of soil on your site.

Basically, the price category of the building material necessary for the construction of the above-mentioned foundation varies over a fairly wide range. It all depends on the demand for it specifically in your region of residence. With great popularity, the cost will be higher. But, despite various market incentives, a pile foundation is one of the most affordable for private construction.

Pay attention to the fact that at the very beginning of the use of piles in construction, they were used only in the construction of bridges.

Return to contents

What is taken into account in the calculations?

The main thing before starting construction is to decide how many screw piles you need per house. To do this, you should carry out a preliminary calculation, which will take into account:

- building size;

- soil type;

- support parameters.

In addition, you need to understand that such pillars have different diameters, and, accordingly, different purposes:

| Pipe diameter, mm | Design load, kg | Length, m | Purpose |

| 57 | 800 | 2,0 | lightweight fences and enclosures |

| 76 | 2000-3000 | 2,5 | heavy stone fences, light utility buildings (garage, shed, etc.) |

| 89 | 4000 | 2,5 | heavy fences, frame houses and one-story cottages, terraces and extensions |

| 108 | 7000 | 2,5 | residential buildings 1-2 floors |

| 150 | 9500 | 3 | residential and office buildings up to 3 floors |

Each of the piles has its own load-bearing capacity - for example, the widest ones can withstand up to 9.5 tons.

The length of the support is also a mandatory parameter - if it is too short, then there is a possibility that the building may sag. The length is determined by:

- soil density;

- differences in altitude in the area.

How to determine the type of soil?

First you need to find out what kind of soil predominates on the site. This is easy to do on your own - dig a hole about half a meter deep and look at the soil.

If sand/clay is visible at a level of approximately 40 centimeters, then you have chosen the right place for construction - in this case, pipes of 2.5 meters will be sufficient.

If under the specified layer of earth there is loose soil, for example, peat or floating soil, in this case it is necessary to carry out additional research:

- take a regular drill;

- install it at the bottom of the hole you dug;

- screw in;

- remove and shake periodically;

- study the soil you get;

- do this until you reach dense soil deposits - they will appear in the form of dense lumps.

Calculate at what depth this soil layer is located and add 2.5 m to the resulting figure - this is exactly the length of the pipe you will need to take.

Height difference of the site

When there are differences in height in the area where the construction of a building is planned, it is necessary to take into account the difference in height.

For example, let’s take a house 6 meters high, which will be built on a plot with a height difference of 1 meter. In this case, it is necessary to use pipes 2.5 meters long, for the middle one 3, and for the lowest one 3.5 meters.

Example of calculating the number of piles

Now let's talk about exactly how many supports you may need for your home. There are also certain rules here.

In particular, we are talking about the distance between each individual pipe along the perimeter and under the building's footprint:

- if this is a structure made of any wood, then the gap should not be more than 3 meters;

- if foam concrete, cinder block or other light stone - then no more than 2 meters;

- for fences - 2.5-3 m, depending on the type of fence and the presence/absence of increased wind load.

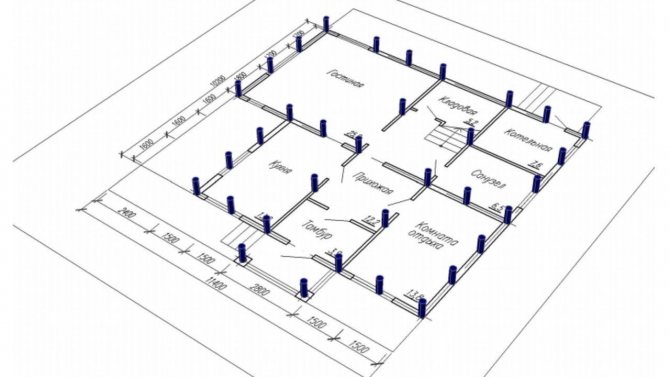

Sequence of calculations

To determine the number of rods yourself, take a plan of your house and make marks on it:

- one support should be at each corner of the building;

- one more - at the joints of load-bearing structures;

- then simply make marks between the corners and supporting structures so that the distance between the piles does not exceed 2-3 m (take into account the building material that you will use);

- if you plan to install a conventional stove or a massive fireplace, provide two more pipes in this place;

- When all the marks on the plan are made, count the number of resulting supports.

In this case, the rods should be installed separately at the corners:

- extensions;

- balconies;

- porch, etc.

Here also take into account the distance rule - no more than 2-3 m between supports, depending on the material used for construction.

Typical results

To make your task easier, we present typical calculation results for how many screw piles are needed for a house of various sizes. We took as a basis the plan of a structure of the correct shape, built from light stone. Naturally, if there are extensions or an irregularly shaped building, the number of rods may vary. Please note that in all cases, correct tying of the foundation on piles is required.

How many screw piles do you need per house?

| House dimensions | Quantity |

| 6x6 | 12 |

| 8x8 | 16 |

| 6x8 | 12-16 |

| 6x9 | 12-14 |

| 6x4 | 9 |

Conclusion

We told you about a simple way to calculate the number of rods that will be required for the foundation of a residential building. You can also use the screw pile calculator.

If you are not sure that you can handle the calculations on your own, or you are afraid that you may miss some details, we recommend that in this case you contact our specialists for help by calling +7-922-661-4468. They will cope with the task, promptly providing you with data from the surveys carried out on the site.

The load-bearing capacity and durability of a pile foundation depends on compliance with the technological requirements of construction and correctly performed calculations. Among other parameters, the distance between the foundation piles is also calculated.

The word “calculation” scares new builders. But for individual construction, this procedure has been simplified so much that even a schoolchild who knows how to correctly operate arithmetic operations can handle it.