A builder who often comes across pile foundations and is familiar with the technology of their construction often does not know how piles are buried in the ground and what kind of pile-driving equipment is used in this process.

The most common method of deepening piles is to use a hydraulic or diesel hammer. Despite the fact that their use is quite noisy, reliable penetration occurs to the designed depth.

At the same time, compression of the soil and high-quality compaction of the pillow also occur.

Types of pile elements

The production of pile elements is carried out in production conditions, on the construction site. Metal and reinforced concrete elements are produced ready for use. It is necessary to organize the transportation of equipment, loading and unloading to the destination. The driving of such supports into the earth's cavity is carried out by construction units and mechanisms. Pile structures can be made with your own hands. A well is created to match the diameter of the pile. Its cavity is filled with concrete.

Pile elements are divided into categories:

- driven - rods made of reinforced concrete. Rarely used for independent construction. High cost of renting technical equipment. The piles themselves are also expensive. Calculations are carried out in advance: immersion depth, impact force and operating time of the pneumatic construction hammer;

Driven supports

- screw. Made of metal. Recommended for low-rise buildings. The introduction of a screw support is possible using your own resources and equipment;

- bored A borehole is drilled into the ground with a drill. The cavity is filled with concrete.

In what cases are piles needed?

The use of piles is necessary if there are problematic soils on the site, namely:

- With a high groundwater level;

- Significant soil heterogeneity;

- Swampy terrain, when performing work on which it is necessary to get to the dense bearing layer.

In the construction of low-rise buildings, screw or bored supports are mainly used, and powerful piles with a large cross-section, made of reinforced concrete, are mainly used for the construction of civil and industrial facilities of significant weight and area.

All piles available on the construction market are divided into two main types:

- Manufactured in factories;

- Gathering directly on the construction site.

How do you drive piles into the soil?

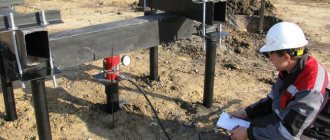

The screw and bored type of rods requires the use of large-sized construction equipment. It is impossible to insert driving elements into the soil cavity with your own hands. The mechanism is used. Machines are used on caterpillar tracks or on wheels.

Tracked mechanisms cannot always get to the construction site. Organize the order of the trawl. Additional investments are required. Wheeled units are characterized by mobility. The process of using them is economical when compared with the previous option.

Pile driving technology

Technical construction equipment differs in the method of immersion:

- Pile driver. The mechanism of operation is striking the pile support with a hammer. The hydraulic hammer is powered by a drive. Impact force can be adjusted. The diesel analog works by burning diesel fuel.

- Pile pressing units. They are distinguished by the smooth pressing of the supports into the ground. The blows are performed at the end of the dive, when the rod reaches dense soil layers. The use of equipment near residential buildings is permitted.

- Vibrator. It is typical to create vibration along the axis of the pile element. The unit can be powered by an electric motor or a hydraulic drive.

Vibrator

Driving piles

Stages of support immersion:

- You first need to prepare the reinforced concrete product. It is installed in a vertical position for driving in.

- Indentation of the rod element.

- Applying precise blows to the pile until it is completely immersed.

Use of special equipment

Piling installations are used when it is necessary to deepen powerful supports. This technique was developed two centuries ago, during a period of intensive development and use of steam engines.

Modern units, of course, are not much similar to their predecessors, but the basic principles of operation have remained virtually unchanged.

In dense urban areas, the pile driver (also called a pile driver) is practically not used, but away from densely populated areas there is still work for such equipment. The pile driver is the machine itself, with the help of which the installation and driving of piles is carried out, but the rod is struck by a special hammer, or “baba”.

Separately, it should be noted that there are several types of hammer, as well as methods for installing and deepening a pile into the ground:

- Diesel hammer, running on diesel fuel and using impact force during operation;

- Hydraulic installation operating on a hydraulic drive;

- A vibratory driver that uses an eccentric pendulum to drive the support into the ground;

- A pile-pressing installation that deepens a pile by creating a force of enormous magnitude.

In urban environments, it is the piling machine that is most often used, when due to too dense buildings the use of impact mechanisms is impossible.

The operation of a pile driving installation can be generally depicted in the following sequence:

- The pile is installed in the design position;

- Pressing the support structure into the ground until natural deepening stops;

- Driving the pile into the ground to the depth required by the project.

It should be noted that in addition to driving, there are other methods in which the machine uses not only a hammer blow. One of these methods is vibration driving, in which vibration acts as the main force for deepening the pile.

In addition, in modern construction the following methods are widely used:

- Hydraulic driving, in which water pressure is used to clear the penetration path for the pile;

- Quiet indentation;

- Screwing in;

- “Puncher”, a special installation is used to make a preliminary hole for the pile.

We recommend watching a video of how piles are pressed in using special equipment.

Operating principle of a pile driving machine

The drilling and piling mechanism operates using continuous auger technology. He creates a hole for the pile. A diesel hammer is used to insert the supporting element into the prepared hole.

The operation of the machine is controlled and monitored from the driver’s cab. When starting the next stage of work, the position of the unit is not changed or re-equipped.

Thanks to the drilling and piling machine, the following tasks are performed:

- The pile structure is being raised. Its top is inserted into the socket of a construction hammer.

- The support is fixed into the guides where the driving will be done.

- The support product is driven into the thickness of the subgrade to the required depth.

- The tops of the supports are cut off according to the previously made markings.

The dive is carried out until failure is received according to the design documentation. Failure - the depth of insertion of the pile with one hammer blow.

Deviations from the exact vertical immersion of the supporting structure must be corrected. Otherwise, you need to remove the rod and reinsert it into the ground.

Types of supports

Foundation piles are divided into 3 types:

- bored,

- screw,

- driving.

Each type of support is buried using a specific technology. At the same time, driven piles are considered the most reliable foundation, therefore they are recommended for use in the construction of heavy buildings.

Houses on stilts are a very old construction technology. Only the material of the supports and the machines driving the piles change.

| Material | Constructive | Specifics |

| Reinforced concrete | They are made of concrete grade 300 and higher, and are reinforced inside. They come in various shapes: round, square, I-beam, and have a pointed end. | Before installing, the monolithic support is inspected for cracks, chips, and damage. The top of the pile is protected with a steel cap, which prevents damage to the monolith from hammer blows. |

| Wood | Made from hard wood. They have a pointed recessed end with a metal tip. The upper impact part is secured with a metal ring to prevent cracking during impacts. | To increase the strength of the base, “packages” are used - a bunch of several piles that are driven together. |

| Metal | Pipe with a point and a head. | Most often used in private construction. Steel is more technologically advanced than concrete and much more reliable than wood. Can be driven into the ground using a hand hammer. |

Piling hammer

The technical feature of the design of the guides ensures that the hammer for driving supports is divided into two types: tubular and rod. In the first case, two guides are used, located parallel to each other. The firing pin moves along them. In the second case, the hammer is made structurally closed. The movement of the striker is carried out inside the steel pipe body.

In addition to the guide elements, the hammer includes a drive, an impact striker, a hammer and a head.

Diesel hammer

The mechanism of operation of a diesel hammer is not so complicated. The striker is moved to the upper position. At the same time, the combustion chamber is injected with fuel. The release and impact of the striker on the striker provokes instant combustion of the fuel mixture. It turns out to be an explosion. The pile sinks into the ground. The firing pin is thrown upward. The process is cyclical. It will continue until the supply of fuel raw materials stops.

Diesel hammer

The hammer is very noisy during operation.

Hydraulic hammer

Not a self-installation - an attachment to a pile driver. It works until it clogs the support. He will not be able to move to another pile until this time.

Hydraulic hammer

The operating mechanism of the hydraulic hammer is different. Combustion cylinders are missing. Equipped with a hydraulic mechanism. Control is performed when the striker is raised to the desired position and lowered. The devices are more advanced. The amplitude of the impact action can be adjusted. The efficiency of introducing piles on sandstone increases.

Diesel and hydraulic hammer devices differ in the weight of the impact part. A diesel hammer weighs no more than 3 tons. Its hydraulic counterpart weighs up to 7 tons.

The hydraulic device can be rented. The work will go several times faster. Some work is impossible without hydraulic equipment.

A construction excavator can simultaneously perform loading, bulldozer and hydraulic hammer operations.

Methods for pressing piles

There are several types of such technology. Many circumstances will influence the determination of the method of indentation. Most of them are determined based on data from pre-design calculations.

Spot

The technique is used when working near other buildings. With this method of deepening, the supports are installed 1 m from the existing wall. This method is appreciated when dismantling the existing foundation, carrying out work in basements or elevators. The point method of indentation is characterized by low productivity compared to other options, but has an advantage in relation to adjacent structures.

Linear

It is used on an open construction site and makes it possible to implement a single-row position. The equipment is moved along the longitudinal axis of the pile field, which ensures the highest efficiency of indentation during the construction of production facilities and the construction of hydraulic structures.

Coordinate

The arrangement of supporting components on the pile field in several rows is provided. The technique involves alternately moving special equipment for deepening along longitudinal and perpendicular rows of piles of the future foundation. A characteristic feature of the technique is increased productivity, which is almost twice as high as vibration immersion of supports.

The coordinate method of pressing piles is used in situations where the main emphasis is on maximizing the acceleration of the construction process. This method of indentation is used during the construction of continuous fields of residential and industrial buildings, as well as hydraulic structures. Since during implementation the period of time for moving the IED around the construction site is significantly reduced.

Classification of pile supports

Blanks for constructing a pile foundation can be found in different designs. This applies to both form and material. There is also a method by which supporting elements are manufactured directly on the construction site. Here it is enough to form a well and fill everything with concrete. Let's take a closer look at the classification of piles.

By material

Initially, solid wood logs were used as point supports for buildings. Today this material is also in demand. Only hard rocks are used for the production of piles. The blanks are sharpened at the root end, and a metal cone immersed in the ground is placed on it. To avoid cracking, the upper part is protected (tightened) with a metal ring. For reliability, the pile foundation is forgotten from the packages. These are several pillars interconnected.

Blanks for wooden piles Source sublima.cz

See also: Catalog of companies that specialize in calculation, installation and repair of foundations

Reinforced concrete blanks are also common. For casting, a solution with a strength of at least M300 is used. The cross-section of the product can be round, polygonal or I-beam, but the immersion tip is always pointed. The protruding edge is protected by a steel cap. Before driving piles during the construction of a house, the blanks must be rejected. Defects such as chips or cracks are unacceptable.

Metal samples are in great demand in the private sector today. These are hollow pipes with a pointed end and a protruding head. The reason for the popularity of steel piles is the ease of installation and durability of the materials.

By type of installation

Depending on the type of foundation, there are three types of piles. Initially, the option of driving the elements into the structure of the support base was considered. Today, reinforced concrete samples are more often used for installation. The work is carried out using special equipment. This is the main reason for the low prevalence of the material in the private sector. Justification - a tangible estimate for the cost of work, piles and equipment rental.

Installation of reinforced concrete blanks Source static-ru.insales.ru

Briefly about the main thing

Piles are rods with a head and a submersible pointed tip.

The main advantage of a pile foundation is its independence from seasonal freezing and thawing of the soil.

The piles are driven below the freezing level of the soil.

Installation is carried out by screwing, pressing, drilling or hammering workpieces.

Driving piles requires the rental of special equipment. The advantages are the speed and reliability of a reinforced concrete foundation and the possibility of constructing a supporting foundation for a building close to an already constructed structure. The disadvantages are the high final amount of the estimate for installation work.

Ratings 0