Bulk soils

Construction of foundations on bulk soils

1. We specify in the project the type of bulk soil (sand, gravel, loam, etc.). It is not advisable to fill with clay, because... it is capable of swelling (SP22.13330.2011 clause 6.6.1).

2. Bulk soils must be compacted layer by layer to a coefficient of 0.95.

3. We assign the calculated soil resistance Ro according to the table. V.9 SP22.13330.2011.

4. Determine the required dimensions of the foundation.

5. Depending on Ro, we set the deformation modulus E and perform a check for settlements (Sorochan “Foundations, foundations and underground structures” tab. 11.18).

6. Before construction begins, it is necessary to confirm the bearing capacity of bulk soils with static loads under field conditions in accordance with GOST 20276-2012 (SP22.13330.2011 clause 6.6.11).

7. In field conditions, the deformation modulus E is determined, as well as f (angle of internal friction) and C (soil adhesion), from which the design soil resistance Ro is calculated. The obtained characteristics of the bulk soil must be no less than those accepted in the project.

Notes that need to be written in the project when designing on bulk soils:

1. Backfilling should be done with a sand-gravel mixture with layer-by-layer compaction in layers of no more than 200 mm to a compaction coefficient of 0.95. The thickness of the compacted layer is determined by volumetric compaction, based on the characteristics of the compacting mechanism. Work on the construction of the embankment should be carried out taking into account the requirements of SP45.13330.2012.

2. The foundation dimensions were calculated for bulk soil with a design resistance Ro=180 kPa and deformation modulus E=15 mPa.

3. Before starting construction, it is necessary to confirm the design characteristics of the embankment Ro and E in field conditions with static loads in accordance with GOST 20276-2012.

Notes that need to be written in the project in case of possible support on bulk soils:

1. If bulk soils are found under the base of the foundation, it is necessary to replace them with a compacted sand-gravel mixture. Backfill the soil to the design level with a sand-gravel mixture with layer-by-layer compaction in layers of no more than 200 mm to a coefficient of 0.95. The thickness of the compacted layer is determined by volumetric compaction, based on the characteristics of the compacting mechanism. Work on the construction of the embankment should be carried out taking into account the requirements of SP45.13330.2012.

2. The foundation dimensions were calculated for bulk soil with a design resistance Ro=180 kPa and deformation modulus E=15 mPa.

3. Before starting construction, it is necessary to confirm the design characteristics of the embankment Ro and E in field conditions with static loads in accordance with GOST 20276-2012.

Calculation of the bearing capacity of bulk soils

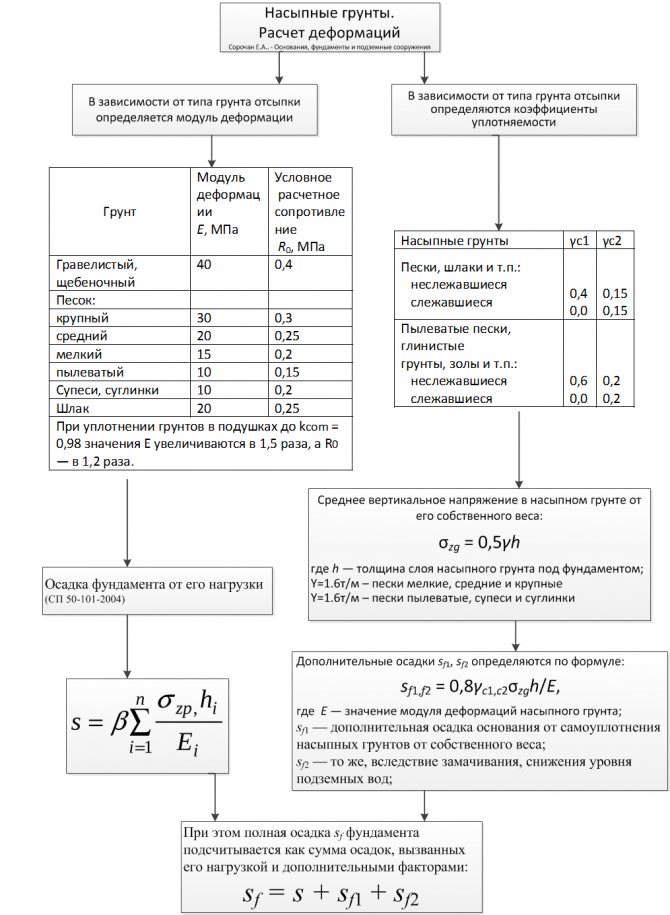

Determination of deformation of bulk soils

— .

These include dumps of waste from various industries, dumps of construction waste and household waste, etc. The bearing capacity and compressibility of such soils fluctuate over a wide range and depend on the material of the artificial embankment, its homogeneity and the age of construction. Therefore, the question of the suitability of bulk soil as the foundation of a structure must be decided in each case by a particularly competent organization or specialist. Bulk soil with a large amount of organic impurities cannot serve as a natural foundation due to its heterogeneity and strong compressibility.

In order to be able to technically soundly resolve questions about the types of foundations and foundations, a hydrogeological survey of the construction site (engineering geological surveys) is carried out with exploration by drilling soil layers and studying their properties, as well as determining the groundwater regime and its aggressiveness. Drilling

Wells are laid in the quantity necessary to fully determine the properties of soils throughout the construction area. Drilling is carried out using special drilling rigs for manual rotary impact drilling to a depth of 10-20 m, depending on the complexity of the geological

site structures. Soil samples with an undisturbed structure are taken from the wells, which are tested and examined in laboratories. During the process of drilling wells, groundwater levels are measured, samples are taken and a chemical analysis of the water is performed to determine the degree of its aggressiveness towards concrete and masonry. According to the drilling log and laboratory studies, geological sections are drawn up, indicating the thickness and characteristics of soil layers and groundwater levels. Regulatory pressure is applied according to the “Norms for the design of foundations of buildings and structures” (SNiP II-B. 1-62). All this work is carried out by specialized organizations, which give an opinion on the hydrogeological conditions of the construction site.

In cases where the bedding and properties of soils were previously examined in neighboring areas, instead of drilling wells, pits are dug, which are a pit of a rectangular or circular cross-section, with a depth slightly greater than the depth of the foundations. Soil samples with an undisturbed structure are also taken from the pits for laboratory research, and the layering of soils is determined by measurements in the pits in addition to the data previously obtained by drilling wells in neighboring areas.

In case of weak soils and for structures with heavy loads in normal soils, they resort to a device on artificial foundations, which consists of strengthening the natural soil in one way or another.

The simplest type of strengthening of natural soil is surface compaction of the soil below the base of the foundation by compaction. Currently, various machines are used for this purpose (pneumatic rammers, diesel and other mechanisms).

Recently, vibration has been used for surface compaction of soils using self-propelled projectiles called vibrating plates.

With a large area of foundation pits, soil compaction is sometimes carried out by rolling with rollers.

Tamping mechanisms can compact soil to a depth of 1.5–1.8 m, rollers 0.3–0.5 m, and vibration 0.7–1.0 m. It should be noted that compaction and vibration can only be effectively used for sandy and coarse soils, and rolling for all types of soils.

If the soil capable of bearing the load from the structure lies at a relatively shallow depth (up to 3-5 m), so-called sand cushions are sometimes used as an artificial foundation. Here, the entire layer of soft soil under the base of the foundation is replaced by compacted sand, which takes the load from the foundation and transfers it to the underlying soil. The width of the sand cushion should be greater than the width of the base of the foundation to avoid bulging of the soil under load.

To strengthen foundations, soil cementation is also used, which consists of injecting a cement solution of a composition from 1:1 to 1:3 into the pores of the soil under a pressure of 3-6 through wells. After the solution hardens, the soil particles become cemented, as a result of which the bearing capacity of the base increases significantly . The cementation method is applicable to strengthening any coarse-grained soils and fractured rocks.

To strengthen coarse rocks (crushed stone, pebbles) and coarse sands, soil is sometimes used, which involves injecting hot bitumen into the pores of the soil at a temperature of more than 200°. This temperature during discharge is maintained by electric heating. For fine-grained sands, the emulsion bitumenization method can be used - bitumen is injected into the soil in the form of a liquid emulsion. This emulsion is a mobile liquid that consists of bitumen (60-65%), water (35-40%) and an emulsifier, that is, a substance in the presence of which bitumen breaks down in water into small suspended particles.

In addition to the above, other methods of artificial soil strengthening are used in construction practice (silicatization, electric drying, etc.).

| < Previous | Next > |

Features of the construction of foundations of buildings and structures erected on bulk soils

Bulk soils refer to soils of artificial origin or composition and are divided into soils.

Systematically constructed embankments include embankments erected according to a pre-developed project from homogeneous natural soils by filling them with a dry method or hydromechanization for the purpose of planning the territory and using it for development with soil compaction to the density specified by the project.

Systematically constructed embankments are created with appropriate preparation of the surface for its filling, including full or partial leveling, cutting off the vegetation layer, removing garbage and waste from organic production, etc.

Soil dumps are dumps of various types of soil obtained by digging pits, cutting and leveling areas, excavating underground workings, etc.

| CategoriesFor divisions bulk | Division of bulk soils and their characteristics |

| By installation method | 1. Spread by dry means ( by road or rail , scrapers , bulldozers , etc. ) . 2. Reclaimed ( formed using hydromechanization ) |

| By uniformity of composition and composition | 1. Systematically constructed embankments ( backfills ) and bedding ( pillows ). They are characterized by almost homogeneous composition , composition and uniform compressibility . 2. Dumps of soil and industrial waste . They are characterized almost uniform composition and composition , but have uneven density and compressibility . 3. Landfills for soil , industrial waste and household waste . Characterized by heterogeneous composition and composition , uneven density and compressibility , as well as the content of organic inclusions |

| According to the type of source material that makes up the main part of the embankment | 1. Natural soils : coarse , sandy , clayey . 2. Production waste : slag , molding soil , tailings from processing factories , etc. P . 3. Household waste |

| According to the degree of compaction from its own weight | 1. Caked - the process of compaction from its own weight has ended 2. Non-caked - the process of compaction from its own weight continues |

Waste dumps from various industries include: slag, ash, molding soil, mineral processing waste, etc., containing organic inclusions of no more than 5%.

Landfills of soil, industrial waste and household waste are dumps formed as a result of unorganized accumulation of various materials and containing organic inclusions of more than 5%.

Approximate time periods (in years) required for self-compaction of bulk soils from their own weight, after which they can be classified as compacted.

| Name of bulk soils | Time period required for soil self- compaction , year |

| Systematically constructed embankments ( with insufficient compaction ): from sandy soils , clayey soils | 0,5—2,0 2,0—5,0 |

| Soil dumps and production waste : from sandy soils, clayey soils, slag , molding soil ash , flue dust | 2,0—5,0 10,0—15,0 2,0—5,0 5,0—10,0 |

| Landfills of soils and industrial wastes : from sandy soils , clay soils | 5,0—10,0 10,0—30,0 |

Foundations composed of bulk soils must be created taking into account their specific features, which consist in the possible significant heterogeneity in the composition of these soils, uneven compressibility, the possibility of self-compaction from their own weight, especially in cases of vibration from operating equipment, passing vehicles, changes in hydrogeological conditions, soaking bulk soils, decomposition of organic inclusions.

In bulk soils consisting of slag and clay, it is necessary to take into account the possibility of their swelling when soaked with water and chemical waste from technological production.

| Name of bulk soils | Time period for soil compaction | |

| Constant exposure to vibration , soaking , lowering groundwater levels | Periodic exposure to vibration , soaking , lowering the groundwater level _ | |

| Systematically constructed embankments : sandy clay | 0,25—1,0 1,0—2,5 | 0,5—2,0 2,0—5,0 |

| Soil dumps and industrial waste : sandy clay slag , molding earth ash , flue dust | 1,0—2,5 5,0—7,5 1,0—2,5 2,5—5,0 | 2,0-5,0 10,0—15,0 2,0—5,0 5,0—10,0 |

| LandfillssoilAndwasteproductionfrom: sandy soils, slag clay | 2,5-5,0 5,0—15,0 | 5,0—10,0 10,0—30,0 |

Additional compaction of bulk soils under the influence of vibrations, periodic wetting and lowering of the groundwater level begins from the moment these influences occur.

The time periods required for additional compaction of bulk soils are approximately assumed to be equal (in years).

Additional settlements of foundations, floors and other structures due to the decomposition of organic inclusions in bulk soils are taken into account within the layers located above the groundwater level.

Content of organic inclusions in bulk soils:

• sand, slag, molding soil - more than 3%; • clay soils, ash - more than 5%. The soils underlying the embankment can also produce additional precipitation. It can be assumed that the compaction of the underlying soils due to the weight of the embankment is almost complete after: • 7 years - for sandy soils; • 2 years - for clay soils located above the groundwater level; • 5 years—for clay soils located below the groundwater level. Engineering-geological studies at sites where fill soils occur must be carried out according to a special program that allows, in addition to the general survey requirements, to establish the main features of fill soils: method of filling, composition, homogeneity of composition, age of compressibility, thickness of the layer and its changes in the area being built, etc. etc. The creation of foundations for buildings and structures composed of bulk soils involves: • using bulk soils as natural foundations;

• application of construction measures to reduce the compressibility of bulk soils; • cutting through deep bulk soils, including pile foundations. • As natural foundations for the construction of buildings and structures, it is recommended to use compacted bulk soils, which are: • systematically constructed embankments with sufficient compaction; • dumps of soil and industrial waste, consisting of coarse sand, gravel and crushed stone soil, granulated slag.

For light buildings and structures (residential buildings with a height of no more than three floors, one-story industrial, warehouse and livestock buildings and structures) almost all types of compacted, systematically built on rashes, as well as dumps of soil and industrial waste can be used as natural foundations.

Landfills of soil and industrial waste can be used as natural foundations only for temporary buildings and structures with a service life of 10.0-15.0 years. The main measures when creating foundations composed of bulk soils are: 1. Compaction of foundations: • surface compaction with heavy tampers to a depth of up to 3 m with a moisture level of compacted soils G 0.7; • landfills of soils and industrial wastes with a content of organic inclusions of more than 0.05, when the installation of pillows ensures almost complete replacement of bulk soils with a high content of organic inclusions; • areas located from existing buildings and structures at a distance of 10.0-15.0 m.

The choice of materials for constructing cushions is made based on the type of composition of bulk soils, local soil and hydrogeological conditions of the site, and the design features of buildings and structures under construction.

It is advisable to use pillows made of crushed stone and gravelly soils in cases where crushed stone and gravel are local materials. Cushions made from sandy soils are used when installing them in water-saturated bulk soils.

In the absence of groundwater or its low level, cushions can be built from local sandy loam and loam, as well as from persistent slag and molding earth.

The density of soils in pads is assigned depending on the type of soil used and must be at least 0.75 of the maximum density obtained by experimental compaction of soils at their optimal moisture content in field or laboratory conditions.

In the absence of experimental compaction results, it is allowed to take for cushions the volumetric weight of the soil skeleton not less than:

• homogeneous coarse and medium sands - 1.60 tf/m3; • heterogeneous coarse and medium sands - /.65 tf/m3; • fine sands *— 1.6 tf/m3; • dusty sands—1.65 tf/m3

The deformation moduli of soils in cushions when calculating foundations are taken, as a rule, based on the results of direct tests with static loads, as well as based on experience in similar conditions.

In the absence of direct test results, the deformation moduli of soils in a water-saturated state may be accepted for the following cushions:

• gravelly and crushed stone soils E = 400 kgf/m2; • coarse sands E = 300 kgf/m2; • medium sands E = 200 kgf/m2; • fine sands E = 150 kgf/m*; • silty sands, molding soils E = 100 kgf/m2; • sandy loam and loam E = 100 kgf/m2; • slag E = 200 kgf/m2

The design pressure on the foundation when constructing soil cushions should be determined from the physical and mechanical characteristics of compacted soils specified by engineering-geological surveys.

When compacting soils in cushions of at least the volumetric weight of the soil skeleton indicated above, the design pressure may be taken as follows:

• gravelly and crushed stone soils R0 = 3.0 kgf/m2; • coarse sands R0 = 3.0 kgf/m2; • medium sands R0 = 2.5 kgf/m2; • fine sands R0 = 2.0 kgf/m2; • silty sands, molding soils R0 = 1.5 kgf/m; • sandy loam and loam R0 = 2.0 kgf/m2; • slag R0 = 2.5 kgf/m2

The creation of foundations on bulk soils, compacted with heavy tampers or with the installation of soil cushions, is carried out in accordance with the requirements, as on subsidence soils with type I soil conditions, and if there is a layer of subsidence soils below the bulk layer - as on subsidence soils with type II soil conditions. subsidence.

The construction of foundations composed of bulk soils with a relative content of plant residues of more than 0.1 (peaty soils) should be carried out taking into account the instructions of Chapter 6, providing for cutting this soil and installing cushions or cutting through it with foundations.

Source: Barinov V.V. Cottages. Baths. Garages: Construction from A to Z: A practical guide.— M.: RIPOL classic, 2004