- Strip foundation for a house: advantages and disadvantages, how to make it yourself

- Strip foundation: types of structures and scope of application

- What is a basement?

- What is the difference between a basement and a basement?

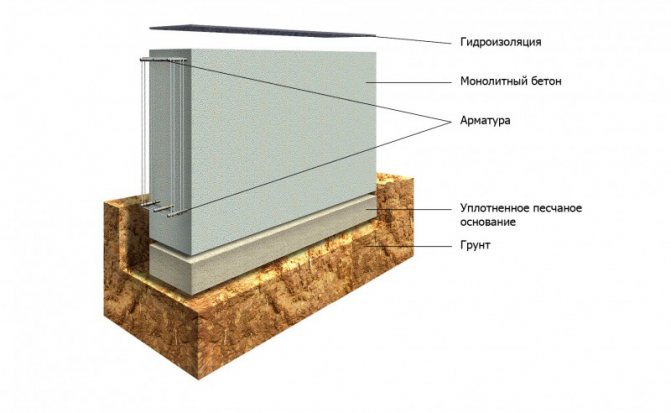

- Monolithic strip foundation

- Sequence of construction of a monolithic strip foundation

- Placing formwork under a strip foundation

- Laying reinforcement

- Prefabricated strip foundation

Strip foundation - types and properties

Content

In construction practice, there are a sufficient number of design solutions for reliable transfer of force from the gravity of buildings to the ground. In simpler terms, we are talking about the support of a building or its foundation. Among them, the strip foundation can be called both the most popular and the most practical. This article will substantiate this and simultaneously describe other qualities of this building element.

Advantages and disadvantages

The monolithic design became widespread thanks to a serious list of positive qualities:

- possible installation on unstable soils;

- high reliability;

- possibility of arranging a basement;

- high load-bearing capacity;

- possibility of independent construction.

The disadvantages include:

- limited scope of application, not suitable for construction on marshy soils;

- high cost compared to columnar foundations or, in some cases, a monolithic slab.

We recommend reading: Pros and cons of strip foundations.

What it is

As you know, the first and main condition for the reliability of any structure is its state that is stable in time and space. Support on the ground is intended to ensure this. One of its varieties is a strip foundation. This is a support for load-bearing and auxiliary walls, closed along the contour and distinguished by:

- Depth of occurrence.

- Material of manufacture.

- Cross section.

It is quite reasonable that the depth (height of the foundation) is directly dependent on the structure of the soil, the massiveness of the structure and the layout of the building. The geographical location of the construction, namely the depth of soil freezing, also plays a big role here.

Strip foundations can be erected directly on the construction site using formwork and liquid concrete. The second version is made from ready-made reinforced concrete foundation blocks. The second option allows for the formation of voids between the components, which are filled with a cement-sand-gravel mixture.

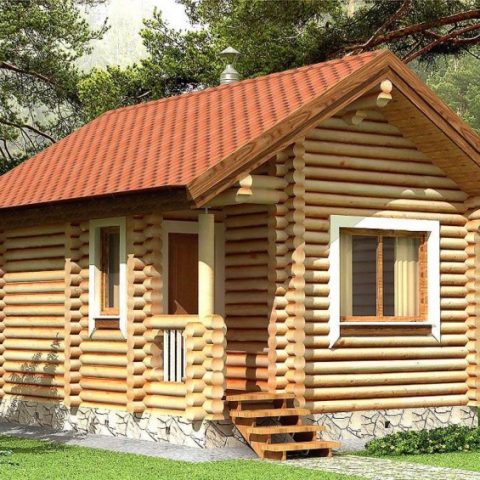

The geometry of the strip foundation is directly dependent on the weight of the future structure. It would be logical to assume that a wooden log house or a house made of laminated veneer lumber will require a lighter foundation than a brick building, or blocks with a high specific gravity.

What does a prefabricated foundation consist of?

Since it is prefabricated, it needs to be assembled from something. What serves as the backbone of such a foundation? There are two main types of elements:

- Trapezoidal pillow blocks that are installed at the bottom of the pit. They increase the supporting area of the lower part of the foundation.

- Wall reinforced concrete blocks having a rectangular shape and reinforced loops. It is from these that most of the prefabricated strip foundation is made. They are installed in a strip and serve to increase the height in the pit.

Note!

The standard weight of one element can exceed 300 kg. As you understand, you won’t be able to do the installation yourself. The good thing about blocks is that they have excellent characteristics. It is not for nothing that such foundations are used for underground parking lots, basements, residential buildings and technical buildings. FBS (Foundation Wall Block) is durable and reliable. You don’t have to worry that the foundation will fail in a couple of years.

Solid cast

The main feature of solid strip foundations is that they are manufactured directly on the construction site. A frame made of reinforcement is laid in the trench. The concentration of metal rods (longitudinal and transverse) is determined using special tables and depends both on the dimensions of the foundation itself and on the diameter of the reinforcement. This type is convenient because it is possible to fill a large volume with a concrete pump, however, preparatory work (formwork, knitting of reinforcement) significantly lengthens the construction time.

Made

The essence of this type of strip foundation is the use of standard blocks. These reinforced concrete products are obviously durable, compact, and their use significantly speeds up this stage of construction. The downside is the need to use lifting mechanisms or equipment. In addition, blocks of standard length are not always able to perfectly fold into the required size, and this is the reason for the appearance of non-uniform inserts and the need for, albeit minor, additional correction work.

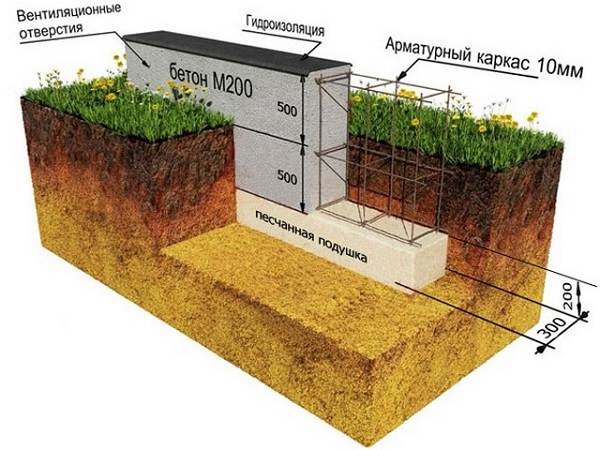

Shallow foundation

As already noted, the type of strip foundation largely depends on the depth of freezing of the soil under the future structure. The impossibility of constructing (for one reason or another) a deep (below the cold level) foundation will have to be compensated for by measures for thermal and waterproofing of the structure.

These foundations are used either in the construction of lightweight houses, or in the construction of fences or outbuildings. At the same time, the requirement for the soil remains unchanged - not prone to heaving at low temperatures and remote from groundwater. In this case, the composition of the soil has practically no effect. Sand, loam, black soil are equally ready to be “accepted” and coexist in the future with a ribbon of concrete.

What determines the choice of type and type of foundation?

It happens that after looking at a photo of a strip foundation, people whose plans include building a country house immediately decide to use this particular structure.

However, it is reckless to be guided only by desire and save on foundation costs. There are other important aspects to take into account. First of all, this concerns the condition of the soil.

Different construction areas have differences in the condition of the soil layers. In addition to this circumstance, the following points play an important role:

Proximity or distance from the zero groundwater level. It is this reason that becomes key when choosing the type of base.

The passage of seasonal swelling of soils at the time of thawing. It is important to know how strong the force of soil movement is and how much it is worth strengthening the structure, and what needs to be done to prevent it from being damaged.

Rules for choosing workwear for builders: an overview of all the features

Brick foundation - main applications, construction stages and tips for strengthening the foundation (105 photos and videos)

Foundation for a bathhouse: step-by-step description of construction, types of foundations and construction features (75 photos and videos)

It may be worth strengthening the reinforcement of the strip foundation or even abandoning this type of structure and installing a slab.

Accordingly, the overall strength of the entire structure will depend on this.

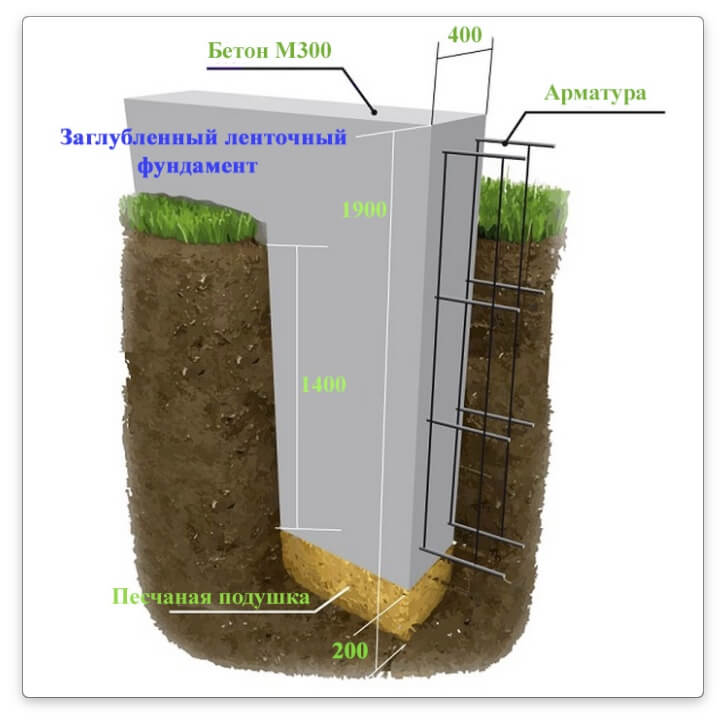

Deep strip foundation

Anyone who begins the construction of a two- or three- or more-story house, or who plans to have a basement or ground floor, must take it for granted that this structure requires a deep foundation.

For reference

There are tables where the relatively exact depths of soil freezing relative to the latitude and climatic zones of future construction are scientifically proven and confirmed by practice. They are a guarantee that your building will be located on reliable ground, regardless of the severity of the winter.

The construction of this type of foundation is quite expensive and entails a large amount of excavation and preparatory work.

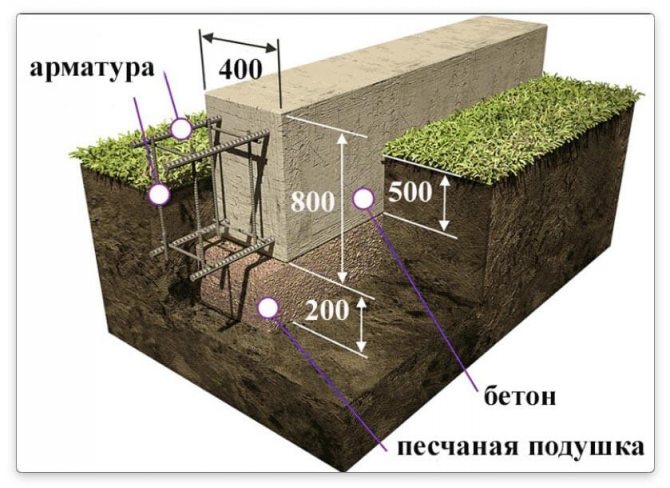

Regardless of the depth of the foundation, it makes sense to equip it with a sand and gravel cushion. You can, perhaps, skip this event if you are constructing a structure that is obviously lightweight. The presence of groundwater will require measures to remove moisture.

Important

Do not forget about communications (water, sewerage) that will almost inevitably enter your house through the body of the foundation. Thus, even at the stage of installing the formwork, installing mortgages will save you from many problems.

Basic and auxiliary materials

Even a carefully calculated strip foundation may require additional building materials. These include:

- Concrete;

- Broken brick;

- Hydro- and heat-insulating materials;

- Bitumen;

- Fittings;

- Boards;

- Beam;

- Sand;

- Crushed stone.

Necessary materials

Don’t know how to build a strip foundation with your own hands? Let's start with the simplest thing - preparing materials.

You will definitely need:

- roofing material or polyethylene to create a waterproofing layer;

- boards 15 - 2 mm, bars with a section of 2 x 3 cm for installation of the formwork structure;

- wire used to tie the reinforcement;

- reinforcing bars with a diameter of 1 - 1.5 cm. From these you will build a frame for a strip foundation with your own hands;

- nails, screws;

- crushed stone and sand under the strip foundation (if construction is not carried out on sandy soil) to create a “cushion”;

- To prepare the “correct” concrete solution, you will need cement material of at least M 400, sand, crushed stone or gravel. The composition of the components is taken at the rate of 1 x 2 x 4. Knowing the mass of each batch, you can clarify the weight of the future strip foundation.

Before construction starts

Surely there is no construction that can be started without having a detailed plan for its implementation. It is in a competent project that the success of future construction in general and the construction of a strip foundation in particular is hidden.

Even at the design stage, corrections to the calculations can be made by:

- Type of soil under the future building;

- Its theoretical resistance to gravity;

- Practical loads;

- Depth of occurrence;

- Design sole width;

- Reinforcement calculation;

- The need for a drainage system;

Practice shows that not every builder can handle foundation calculations, which means it makes sense to immediately trust the professionals. To confirm the correctness of this conclusion, we can say that the quality, reliability and durability of the entire building depend on a correctly calculated foundation, just like the peace and positivity of its inhabitants (inhabitants).

Work order

Step-by-step instructions for arranging a strip foundation with your own hands are as follows.

Preparatory work

Where should I start? The rules for the construction of strip foundations determine that it is recommended to act in stages, and the first stage of construction will be to perform the necessary calculations. This has its own specification, so this work should be entrusted to experienced specialists in order to avoid mistakes.

Now you need to mark the construction site to know exactly what your strip foundation looks like. The building site is cleared of debris and the soil surface is leveled. When laying out the layout, it is necessary to take into account the thickness of the formwork structure, how deep the foundation should be, and the possibility of constructing a floor.

The sequence of work is as follows:

- corner areas are outlined;

- the evenness of their location and distance is specified;

- the cord is pulled;

- the diagonals of the resulting perimeter are checked;

- Internal walls, veranda, porch are marked step by step.

We begin to dig a trench, which should exactly match the markings. If the strip foundation is supposed to be on sand, then it is better to do all the work manually. When excavating, make sure that the vertical walls of the trench are maintained. In difficult areas, preparatory work for pouring a strip foundation is carried out with drilling for piles.

A sand cushion is placed at the bottom of the trench, which helps to properly redistribute the load on the base. There is no waterproofing material to protect against moisture. The material should be wrapped 15–20 cm onto the walls of the trench.

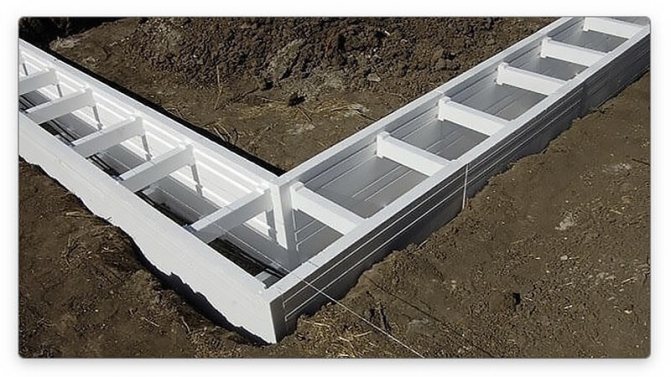

Formwork

How to make a formwork structure correctly? It can be knocked down from prepared boards, which are subsequently dismantled. The second option is permanent formwork, which later serves as an insulating material.

The prefabricated panel structure should rise above the ground to a height of 35 - 40 cm in order to be able to build a base. The shields are fixed with crossbars and posts, twisted with wire so that they do not diverge. Many people are interested in the question of whether it is possible to make holes in the strip foundation for communications and grounding. This is possible for laying pipes, but it is better to lay the grounding wire from the outside. When installing formwork for a strip foundation, it is necessary to periodically check its evenness and eliminate ledges so that the surface of the base is smooth.

Permanent formwork is made of polystyrene foam blocks stacked on top of each other. It will also serve as an insulating material for the stone strip foundation. By the way, in rooms you can pour screed with a heated floor system - there will be no loss of energy resources.

Waterproofing

We discussed how to make such protection yourself in the “preparatory work” section.

Reinforcement

In order for the strip foundation to be made from “a” to “z”, it is recommended to construct a frame of reinforcing bars. The gratings are prepared, the rods are fastened with wire to eliminate discontinuities in the strip foundation frame. If it is planned to lay insulation in the formwork, then the reinforcing scraps must go into it so that the frame is secured even more securely.

As follows from the reviews of specialists and private developers, it is the use of reinforcement that gives the strip foundation its special strength.

Concreting

We already know what walls the strip foundation is laid under, we have also sorted out the preparatory work. The most important step remains - filling the trench with concrete. This work should be done at one time, but in this case the concrete will have to be purchased ready-made and delivered to the site. If there are certain features (removal of the plant, insufficient financial resources), then concreting the strip foundation is carried out in stages, in even layers. In each case, tamping will have to be done to remove air bubbles from the solution. In cross-section, the strip foundation should look like a solid monolithic stone.

Questions often arise: how long does it take to dry or how long does a concrete foundation “settle”? At least four weeks under favorable climatic conditions. Judging by the reviews of private developers who have had the opportunity to pour a strip foundation, this period may be extended.

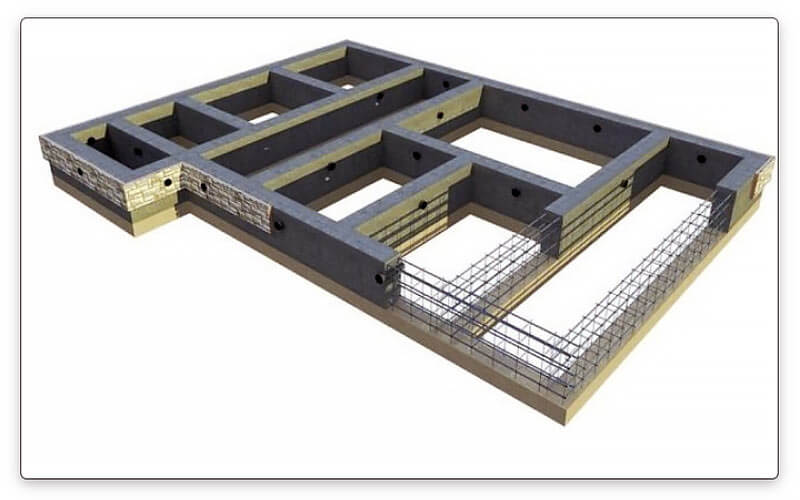

We use a strip foundation to build a basement

Despite the considerable complexity of arranging a basement using a strip foundation, this method is very popular among those who build their own houses.

The construction process will require the following stages:

- Digging a pit;

- Laying a crushed stone cushion;

- Base reinforcement;

- Pouring the floor with concrete;

- Reinforcement of walls (partitions);

- Installation of formwork;

- Pouring concrete walls.

Of the subtleties that should be taken into account when arranging the basement, we note the following:

- When reinforcing the floor, it makes sense to release the reinforcement outside in the places where the walls are installed. This will provide additional strength to the connection between the walls and the floor.

- The height of the basement walls must coincide with the upper level of the foundation of the house.

What should be the depth

The depth of the strip foundation is one of the most important parameters during its construction. The cyclic chemical and physical processes occurring in the soil are quite complex and aggressive. In this regard, it is the level of support of the structure on the ground that is decisive. A depth of at least 25 cm below the freezing level is considered optimal.

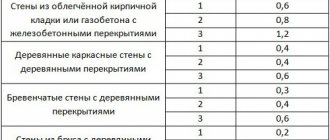

There are special formulas for calculating foundation depths that take into account many coefficients for each region. A simpler solution is to use tables that show statistical data on soil freezing in a particular area. Let's take some data from it as an example.

So for cities such as Vorkuta, Salekhard and Nizhnevartovsk, the depth of soil freezing is 240 cm

Kirov, Kazan, Ulyanovsk - 170 cm

Smolensk, Volgograd, Kursk - 120 cm

When building a house in Rostov-on-Don or Krasnodar, you should focus on a level of 80-90 cm

Stages of strip foundation construction

Despite all the complexity and responsibility, foundation construction can be done without the involvement of specialized teams. Punctuality, strict adherence to the plan and accuracy will be the best helpers here. Like most large-scale construction projects, it is best to start by drawing up a diagram. It will not only serve as a guide to the work, but will also help to calculate the necessary materials, and also indicate the time frame for this stage of construction.

The classic version here looks like this:

- Preparation of the base;

- Installation of formwork;

- Hydro- and thermal insulation;

- Installation of fittings;

- Pouring concrete.

Before installation work comes down not only to choosing a location, marking, but also to geological surveys to determine the proximity of groundwater and soil composition. Taking into account the specifics of the last two, it will be quite difficult to do without specialists.

The marking of the strip foundation should be approached with maximum responsibility. If the construction is carried out according to the project, it will be a good help to you, namely:

The front side is made parallel to the border of the site. Marking should begin from one of the corners. We pay special attention to diagonals. So, with standard house building dimensions, the difference in distances between corners should not exceed 2 cm. Less is better. For measurements, it is better to use minimally elastic measuring instruments - for example, a metal tape measure, a rod, etc. After marking the outer walls and corners, you can begin to orient the inner rooms (their walls) and partitions.

When the markings have been made and control measurements have been taken, it’s time for excavation work. Digging a pit is usually entrusted to technology.

On a note

In some cases, instead of a pit, an ordinary trench may appear. These are options when a basement under the house or other premises are not provided.

The bottom of the burial in the soil is covered with a sand cushion. Its optimal height is 45-50 cm. An alternative to sand here can be slag, gravel or crushed stone. The main requirements are environmental friendliness and a minimum size fraction. After compacting the sand (or other cushion material) and making the surface relatively horizontal, the bottom is filled with thin concrete 8-10 cm thick. The cushion can be compacted either using a vibrating rammer or using manual means, including spilling water.

For reference

“Skinny” concrete gets its name not from its “fatness.” This is a solution of cement, water and gravel of various fractions with a reduced content of the first two components. Lean concrete is denser, but quite fragile, which does not prevent it from being an excellent option for the base of a strip foundation.

Construction of a belt from industrial blocks

. The block system is not anything complicated, but requires a special approach to construction. Answering the question of how to properly make a strip foundation, which will consist of blocks, we can recommend the following step-by-step steps.

First of all, it is necessary to mark the area where the trench will be dug. It is necessary to clearly highlight all load-bearing walls, corners and other special places of the structure. Carry out preparatory work, which includes preparing the working area (a distance of 1 meter around the future trench) and the necessary tools.

Also at this stage it is necessary to determine the depth of the trench. According to the general rules, the block structure is laid at a shallow depth and is perfect for one-story houses. Therefore, you need to dig a trench of shallow depth.

The second step is to start digging the trench. According to general rules, it is better to do this yourself, since earth-moving equipment makes uneven surfaces. You need to dig a trench after the site has been marked.

When the trench is ready, it is necessary to create a sand and gravel cushion. Taking into account the fact that the depth of such a base is not large, the height of the pillow should not exceed 50 centimeters. First, sand is taken and covered in a layer of 30-40 centimeters. All this is watered and compacted.

Crushed stone of small fractions is poured on top of the sand layer. Which also needs to be compacted. Some experts advise putting a layer of waterproofing on top of the pillow. When the installation of the pillow is completed, you can proceed to the next step, laying the blocks.

Installation of prefabricated strip foundation from reinforced concrete blocks

The installation of blocks has a clear sequence. They are laid using lifting equipment, which can be done at home. The blocks are placed next to each other, and the distance between them should not exceed 2-5 centimeters.

This installation method is necessary in order to give them good adhesion using a cement-sand mixture.

As stated above, the blocks are connected only with the help of a cement-sand mixture, so its preparation must be approached with all responsibility.

The cement-sand mixture is made at the rate of one bucket of cement and two buckets of sand. To make the connection more reliable, you can use reinforcement.

The connection with reinforcement occurs as follows:

- first you need to cut the reinforcement to an equal length and securely fasten it to two adjacent blocks, and do this along the entire perimeter of the tape;

- after this, you need to fill the entire space between the blocks with the prepared mixture, wait for it to harden, you need to cover the entire tape with a layer of cement-sand mixture (the so-called screed) 5-10 centimeters high so that the reinforcement is not visible.

Such a connection of the blocks will be reliable, and they will be able to provide a reliable structure and not crack when the ground moves.

- The next step is to apply a layer of waterproofing to the tape. Its installation is not difficult at all.

- The last step is to install the thermal insulation. According to modern concepts, it is necessary to thermally insulate the entire foundation, even along the side surfaces of the tape.

As you can see, laying a strip foundation made of blocks is not difficult.

Installation of formwork

Here you can choose to use either reusable (removable formwork) or disposable (fixed formwork). For the first type, metal sheets, thick plywood or edged boards are used. For the second, you can use polystyrene foam, which can later play the role of an insulating material. As is known, this material is practically neutral to moisture and at the same time protects the base well from extreme exposure to low temperatures.

With both options, you cannot do without supports. Depending on the material of the formwork, their pitch ranges from 50 to 120 cm. In the case of working with a pit, supports are installed evenly on both sides of the cavity, where concrete will be poured in the future. The height of the formwork should rise above the foundation by at least 10-12 cm. The “zero” level of the foundation (top point) is marked with a marker on the inner surface of the formwork. This is necessary to level the level at the final stage (during leveling) of foundation formation.

In order for the marks to obey a single plane, it is necessary to use a level (water, laser or other).

On a note

Experts recommend using polyethylene film when arranging formwork. It will prevent the “cement laitance” (a mixture of water and additives) from leaking out.

With your own hands

You can do the work yourself. To do this, you need to make the correct markings. Regarding the general points on the ground, pegs are driven in around the perimeter of the future house. In this case, it is necessary to check the diagonals.

This will help you understand how perfectly you laid the base, so as not to make a mistake by a few centimeters or by a larger amount. After the pegs are hammered in and the thread is taut, it is recommended to gouge the soil. This is done with a regular shovel to transfer the plane of the thread to the terrain.

Even if you miss a little somewhere, it’s okay, it won’t actually affect the strength. When the gating is finished, it is recommended to remove the string. Next, they either hire special equipment or go deeper to the required depth themselves.

The depth of the depth should be no less than the amount of clay in the base. It is recommended to go deeper to an extent where the soil will no longer freeze, since this is convenient from the point of view of laying communications and the overall strength of the foundation.

When you have dug to the desired depth, the base is leveled, then they begin to fill in the sand cushion. The size should be at least 5-10 cm, after which it should be spilled with water and smoothed out a little. Next, he performs reinforcement, where 12-14 mm reinforcement is often used for a private house. It should not touch the sand, and should not reach the surface by at least 5 cm.

It is connected to each other using knitting wire or welding equipment. When the work is finished, start mixing, or order a ready-made solution. Nothing could be easier with a ready-made solution. The grade of concrete for the strip foundation M200-250 is quite suitable for the job.

You just need to use a little shovel technique to rake the concrete evenly over the surface. If you do the manufacturing work yourself, then mix in a consistency of 1, 2, 4. Where for one cement there are two buckets of crushed stone and four buckets of sand. Add water when the material is ready.

When the work is completed, it is recommended to allow the base to dry, which can take at least 28 days. During this time, the design strength will be achieved, and further construction can begin.

Strengthening (reinforcement)

Metal reinforcement is used to form the skeleton (skeleton) of the building support.

On a note

Lately, fiberglass reinforcement has been gaining popularity. The debate about its complete replaceability is not over yet, but for complex foundations (along the radius) it will clearly be a priority.

A scheme with two rows of reinforcement is considered standard, however, when constructing powerful buildings, three-row reinforcement is also allowed. The most popular for these purposes are rods with a diameter of 10 to 16 mm. Winding will increase the coefficient of adhesion of metal (carbon fiber) to concrete.

In both cases, the reinforcement is fixed with tying wire using hand tools or a special gun. The knitting pitch of the reinforcement is 25-30 cm, decreasing at the corners of the structure to 10-15 cm. Recently, special clamps have been designed to facilitate the procedure for fixing the reinforcement, among which a distinction is made between vertical and horizontal.

Calculation of the required amount of reinforcement will be more accurate if you use special tables, where you will receive a relatively accurate value for parameters such as height, length and cross-section.

Pouring formwork with concrete

One of the final stages of constructing a strip foundation is pouring concrete. In most cases, the required volume is significant, which means the best option is to order delivery of a ready-made solution. This will significantly reduce your labor costs and help you comply with some important rules. Namely:

- The time allotted for pouring the foundation should not exceed one day;

- The break between batches of poured concrete should not exceed two hours;

- It is best to fill the formwork from several points.

Important

You should not get carried away with “stretching” the mortar along the formwork. This will reduce the quality of the finished product. It is not recommended to fill from a height of more than two meters. This will disrupt the structure of the concrete, which will lead to a deterioration in quality.

The optimal weather conditions for the foundation to lay down well, become and strengthen are:

- Air temperature from +18 to +22;

- Normal humidity is from 60 to 70%;

- Moderate solar activity.

In order to maximize the time for moisture evaporation, it is recommended to cover the foundation with plastic film upon completion of work. The complete formation of the foundation, after which it will be possible to begin laying the walls, occurs no earlier than 14-21 days from the moment of pouring. Its final readiness for operation is regulated by an even longer period and depends on the volume, depth and weather conditions.

Advantages and disadvantages

The strip foundation has enough advantages and disadvantages. Let's start with the advantages:

- An inexpensive option available to everyone. At cost, it is 50% cheaper than a monolithic base. Often, many developers equip it with their own hands, which allows them to save up to 30% of the cost. Such a base can be poured in a few days yourself, using a concrete mixer.

- There is no need for special equipment. You can dig such a foundation yourself in a couple of days. Then, you can mix the solution in a concrete mixer and pour it. This will not only save money, but also avoid the use of special equipment. If it is needed and space allows, it is much easier to order a ready-made solution and pour it in a couple of hours.

- Low cost. Compared to options such as monolith, the tape version is much cheaper. It is beneficial for low-rise construction, since it involves deepening to an extent where the soil will not freeze in winter.

- Convenience when laying communications. Already at the construction stage, pipes are laid in the space where the concrete will be poured. As a rule, they are laid in the form of pipes of increased diameter, so that later they can be dug up and introduce water into the house, remove electricity, connect a well pump, or perform other work options.

- Allows you to pour the screed in perspective. If previously everyone built houses on a strip foundation and used wood for the floor, today they use a screed. Inside the space, soil is poured, compacted, waterproofed, reinforced, and then concrete is poured. A strip foundation for a house made of aerated concrete also needs to be waterproofed, since this will prevent the blocks or bricks of the walls from collapsing.

There are few disadvantages, but they do exist. Firstly, it is necessary to raise such a base at least 10 centimeters from the ground. In this case, you will have to build formwork, where the costs of excess concrete will come from. It is not recommended to fill it without formwork, since otherwise the walls of the house will absorb moisture from the ground through the base.

Strip foundation with piles

Secondly, mixing concrete by hand is problematic, so it is best to use the services of special equipment. Unlike such varieties as columnar, pile and other bases, a strip base is more expensive, since the cubic capacity here is larger. On the other hand, it is cheaper than pouring a monolith or using blocks, laying them with a crane.

Thirdly, strict adherence to technology is recommended. Here you need to monitor the filler in concrete, since granite is in great demand. Many people offer quartzite, expanded clay and other materials for this money, but only granite has a minimal level of radioactivity and perfectly retains the internal structure. Fourthly, it is necessary to reinforce. Without reinforcement, in the first or second winter the foundation will burst, which will lead to the appearance of cracks on the walls of the building.

What were we aiming for?

The fact that its construction takes approximately 25-30% of the construction budget of the entire house shows how important the process of building a foundation is. The time that your home will serve you depends on its high-quality installation and the correctness of associated work. Therefore, if you have even a shadow of doubt about your strengths and abilities, entrust this work to professionals.

Strip foundation is the most popular type of arrangement of support for construction projects. Its main advantage is its versatility. It is suitable for any soil and in any latitude. It is optimal both for small-format construction sites and for the construction of large objects. It is reliable and uncomplicated in its range of materials, technology and means for their implementation.

Foundation marking and digging with installation of formwork and reinforcement - Domtvoy RF

Kinds

- Even such a simple base has variations. For example, varieties are characterized by the way they are arranged. That is, if we use concrete for arrangement, then the base is considered a monolith. If, during the installation process, we make a strip foundation for a house from ready-made blocks, then it is considered block. Otherwise, the main types include the following:

- With and without formwork. Formwork means lifting a tree to the required height. Formwork allows you to protect the main walls of the house from the influence of the soil, and not use red ordinary brick to work with the base. Without formwork, the base is poured at ground level. Then you will have to lay out the base, which will also cost a lot of money. Experts recommend installing formwork and raising the base at least 10 centimeters from the ground.

- Shallow strip foundation and buried to the extent of freezing. We have already talked about this. Shallow is considered to be one that is located at a depth of no more than 50 cm. To increase the bearing capacity of the foundation, they drip until the soil freezes and right up to the place where the concrete will begin, fill it with sand and compact it. As for the foundation, which is poured with concrete or lined with monolithic blocks to the extent of soil freezing, such a project is expensive. But it justifies itself, since cracks in such a foundation are excluded.

- Reinforced or not. Reinforcement is almost always used. This is due to the fact that the presence of metal inside the base makes it possible to restrain the monolith from soil heaving and eliminate cracks. Where reinforcement is not used, the foundation can crack, fall into the ground, or collapse in some other way. Basically, capital structures are not installed on such foundations.