Construction is preceded by a series of works aimed at determining the design of the future building. Such actions include geological exploration of the site, when the qualitative composition of the soil is determined. Making a topographical survey of the building site to determine the level and location of the building.

Drawing up technical specifications for the development of design documentation and its actual production. After a whole range of preparatory work, you can begin purchasing materials and starting construction. Often, at the stage of choosing a foundation design, a reasonable question arises: what is better, a monolithic slab or a strip foundation? What basis should be laid in the project for the future building? This article will explore possible answers to these questions.

Strip foundation

A strip foundation is the foundation of a building, made in the form of a closed loop. It can be made from FBS blocks or in a monolithic manner. The base is installed under all load-bearing walls of the building and may have several lintels within its perimeter.

On a strip base, it is possible to manufacture enclosing structures from any materials, which can be light wood or heavy concrete when constructing monolithic walls.

When making the underlying layer, concrete preparation is arranged under the tape. This is a non-reinforced monolithic structure, manufactured in one horizontal plane. It should protrude beyond the edges of the main tape with a height of about 100 mm. The main task of concrete preparation is to remove uneven ground and create a dense surface on which the main foundation can be made.

A sand and gravel cushion can also serve as a base for the tape. In some cases, construction without underlying layers is allowed.

The absence of an underlying layer under the tape is typical for shallow foundations. Similar structures are used in dense soils for relatively light buildings. For less dense soils with a sufficiently large freezing depth, the tape is made deeply buried.

Pile base - a structure made of combined piles

The pile frame is similar to the columnar one, differing in the depth of penetration. Kinds:

- driven, installed by machinery;

- pressed, similar to columnar, but soil is used instead of formwork;

- drilling rigs, in which reinforced concrete structures are inserted into wells;

- screw, have a helical shape, are screwed into the ground.

For strength, individual piles are tied together with a grillage. Made from metal, wood, concrete.

Piles with grillage

Where can I use it?

They are used like columnar ones, but penetrate much deeper. Screw types are suitable for private construction. Used on any soil except rocky ones. Stackability allows for use where solid ground is deep underground.

Advantages and disadvantages

Advantages:

- simplicity;

- more affordable than strip or slab;

- high installation speed;

- work related to the ground is kept to a minimum;

- can be dismantled and reused;

- reliability.

Flaws:

- except for screw ones, when installing the rest you will need equipment;

- screw ones are used for small, lightweight structures.

Device Features

If necessary, the strip foundation can be insulated both from the inside and from the outside. Insulation is possible for all types of strip foundations and depends on climatic conditions and soil composition. Due to positive climatic and other factors, many monolithic structures do not require insulation. The tape in such buildings is only covered with a layer of waterproofing.

In a house with such a foundation it is easy to make a basement or ground floor

The design of the strip base is ideal for constructing a basement or semi-basement. When building a block strip foundation, you can make a base of the required height, which will allow you to do without lengthy monolithic work.

The strip foundation experiences the main loads in the corners. Therefore, the reinforcement of the corner parts of the tape must be carried out with maximum precision in accordance with building codes and regulations.

This type of foundation has become widespread in the construction of outbuildings, country houses and industrial low-rise buildings.

Monolithic slab foundation

A slab foundation is a monolithic structure that completely fills the internal perimeter of the base of the building, creating a single horizontal surface.

Reinforcement of a monolithic structure is carried out depending on the loads. In some cases, a monolithic slab can be made without reinforcement. Such a device is permissible only on dense soils for lightly loaded foundations.

This foundation can be made both below ground level and above. When building below ground level, a distance is provided for a semi-basement or basement. When installing a slab foundation shallowly buried in the ground, the construction of a basement floor is not provided.

A sand and crushed stone cushion is required under the slab

The slab foundation is placed on a sand-crushed stone bed. In this design, the pillow not only performs a supporting function, but is also used as drainage, preventing water from accumulating at the base of the building.

In some cases, the design of a slab foundation includes stiffening ribs, which are located under the load-bearing walls of the building. These ribs can be either on the underside of the slab or on top, forming the lower part of the walls. Due to such ribs, it is possible to reduce the thickness of the slab in lightly loaded areas.

If it is necessary to insulate a slab foundation, this process is carried out after installing a sand-crushed stone cushion. A layer of rigid insulation is placed on the pillow, reinforcement is placed on top of it and concrete is poured.

A heated floor system can be partially built into a monolithic slab foundation. It is installed in areas where load-bearing and partition walls will not be installed, and the presence of heavy pieces of furniture is not planned.

The construction of a monolithic slab foundation is justified when constructing heavy buildings, since this foundation can withstand heavy loads. Also, if the design of the building provides for rough concrete floors, it is advisable to consider the option of making a slab foundation.

Stages of work execution

So, how to make a strip foundation for a house with your own hands? First, a soil study is carried out, after which the thickness, height and width of the strip foundation are determined. In addition, the climate of the region determines the depth of laying the strip foundation not only for a one-story house, but also for other structures. If at this stage your knowledge is not enough, the work should be entrusted to experienced specialists. There are certain nuances that should not be neglected.

If you decide to build a strip foundation for a private house with your own hands, we recommend that you carefully study the step-by-step instructions given below.

Preparation and calculation

Suppose you have stocked up on the necessary materials and tools, drawn up a diagram of the strip foundation, and determined the characteristics of the soil composition.

We begin to learn step by step how to pour a strip foundation on a site with our own hands.

First, let's evaluate the site. Existing vegetation in the form of bushes or trees will have to be removed, garbage and remains of old buildings removed from the working area, the site leveled, temporary lighting installed, and water supplied if possible.

Now you need to make markings to transfer the dimensions of the strip foundation to the terrain. To do this you will need a tape measure and a level, a cord and pegs.

Digging trenches

As soon as the main dimensions of the foundation have been transferred to the terrain, it is allowed to begin to develop the soil. There are two ways to do this:

- preparing a trench for a house without a basement;

- construction of a pit for an object with a basement.

The second method is considered labor-intensive, but makes it possible to use the usable area of all premises with maximum benefit.

Soil development is carried out manually, or you can use an earthmoving machine. The depth of the ditch is determined taking into account the level of the foundation and the size of the cushion under it.

Digging of a trench or pit begins from a corner located below the rest, so that it is possible to control the evenness of the entire bottom. The walls are made smooth; they should not crumble.

Based on the type of soil composition, when digging a trench, it may be necessary to brace the walls. As a rule, this need arises at a depth of one to one and a half meters. This means that the construction of a strip foundation for a house will require additional safety measures on the site.

During work, it is recommended to periodically monitor the depth and evenness of the passage.

Foundation cushion

The soil can be developed in any of two ways, but you will still have to create a foundation pad designed to perform certain functions:

- surface leveling;

- uniform redistribution of load effects from the foundation to the soil;

- drainage.

To arrange this pillow you will need the following materials;

- sand and gravel;

- crushed stone;

- slag.

When preparing the sand layer, large or medium fractions of the material are used, because fine sand can shrink. A sand cushion, in addition to its main functions, prevents the formation of heaving from severe frosts, which can occur directly at the strip base.

The sand cushion can have a thickness of 30 to 50 cm, and if the soil is bulk, then this size increases to 1.5 - 2 m to replace a base that has unsuitable characteristics for construction. To do this, use one of the following methods:

- vibration;

- spilling with water;

- compaction with weights.

The sand-gravel mixture provides an opportunity to increase load-bearing capacity, but increases the financial costs of the entire construction process. If you decide to make a pillow from crushed stone, it is recommended to choose granite stones, the fraction of which is 2 - 4 cm.

Slag material is least used for such purposes. It is quite cheap, but cannot provide a high level of reliability.

Formwork

Now let's look at how the formwork structure is made for pouring a strip foundation. This is the ground part that forms the base of the future facility. Height may vary. In cold regions it is fifty centimeters; for warmer regions this value can be reduced by one and a half to two times. For the construction of shields, you can use various materials - boards, plywood, asbestos-cement pipes, etc.

The formwork structure can be of two types:

- removable - after pouring the concrete solution, it is removed after a certain time;

- non-removable - is part of the base element.

Naturally, the first option will cost you much less. It’s just that it will take more time to set it up. The non-removable type provides additional protection and acts as an insulating layer.

The main condition that is observed when installing formwork is evenness and reliability. The side panels must be secured with supports and the top must be pulled together.

To make the formwork panels easy to remove, they are covered from the inside with plastic film.

Reinforcement

This work is performed using volumetric frames. Most often, two rows of longitudinal reinforcement are used, but if the foundation base is high, then the number of reinforcing rows may increase. To strengthen the structure, corrugated steel rods are used, the length of which is selected taking into account the geometric parameters of the tape. You should also provide concrete layers of 2–3 cm on each side in order to completely hide the reinforcement cage in the solution.

How to make a frame correctly? The reinforcement is connected with knitting wire; for ease of operation, it is allowed to use clamps made of plastic material. It is faster to connect reinforcing bars using a welded method, but the strength of the entire frame is significantly reduced. It is allowed to use welding on small structures, while the corner sections are still connected with wire.

Pouring concrete

We figured out how to make formwork and reinforcement cage yourself. Now we move on to concreting the base. A concrete mixture of M200 - 300 is suitable for this. If you plan to build a large multi-story structure, you will need a concrete solution of greater strength. You can prepare it yourself or purchase it from a factory. With the second option, a more reliable base is obtained, because on a construction site it is difficult to strictly follow the technological features of preparation.

There are a couple of ways to do the job:

- continuous;

- layer by layer

Using the first option, you can ensure the reliability of the entire foundation structure. If work is planned to be carried out intermittently, then the concrete mixture is poured in layers. At the same time, the upper edge of each of them is not leveled in order to create conditions for better adhesion.

If you order ready-mixed concrete, the solution will be delivered by concrete mixers, poured into the formwork and leveled by vibration.

It is recommended to fill the foundation at a temperature range from fifteen to twenty-five degrees Celsius. If such work occurs during a colder season, special modifier components are added to the solution and the issue of heating the construction site is considered.

Maintenance of poured concrete

The instructions on how to make a strip foundation for a private house include one more point - the rules for caring for the concrete mixture poured into the formwork.

We already know how long it takes for the foundation to dry - at least four weeks. But there is one condition - ensuring the temperature regime and the appropriate level of humidity. To prevent cracks from forming on the surface of the foundation, the poured concrete will have to be moistened from time to time. After completing the pouring work, the concrete is covered with polyethylene or burlap to prevent rapid evaporation of water and uneven hardening of the mass.

They begin to moisten twelve hours after pouring, but if the weather is hot or windy, then such measures are resorted to three hours after completion of work. After this, water the area generously at intervals of a couple of hours; if the weather is not sunny, then it is enough to do this once every three hours. At night, moisturizing is carried out twice.

Concrete hardens without additional moisture if the air temperature does not exceed five degrees Celsius.

As a rule, such care for ordinary concrete lasts at least a week.

Pros and cons of strip foundations

It is inappropriate to compare a strip foundation with a pile or column type for one simple reason. They are used in different soils. Monolithic pile structures are used in unstable soils with high groundwater. Strip foundations are used in dense soils when groundwater lies at a considerable depth. For information about the positive and negative aspects of this type of foundation, watch this video:

A comparison can be made with a slab foundation, since it is suitable for the same types of soil as a strip foundation. Here everything will depend on the dimensions of the building. The slab can withstand slightly greater loads than the tape.

To build a house of 1 - 2 floors, a simple strip foundation is enough

On the other hand, for low-rise buildings there is no need to pour an expensive slab, but you can lay a strip foundation.

The presence or absence of a concrete subfloor will also be an important factor.

If the ceiling is made of wood, then a strip base will be most suitable.

Positive aspects of tape bases.

- This type of monolithic base is the easiest to manufacture.

- For relatively light buildings with a small load on the foundation, this is the most economical type of foundation.

- This type of construction is easy to insulate and waterproof.

- The design of the base allows it to be prefabricated from FBS blocks, reducing construction time to a minimum.

- The strip foundation is resistant to temperature changes.

- Such a base can be made independently without the involvement of specialized organizations.

- When installing a belt in the ground, no formwork is required.

Disadvantages of a strip base.

- A small range of soils is suitable for constructing such foundations.

- It is not always possible to do without the use of expensive special equipment.

There are enough pros and cons for all types of foundations. The main indicator will be the price-quality ratio. When choosing the type of structure, much depends on the composition of the soil, the presence or absence of a basement floor, the load on the foundation and other factors.

It is necessary to choose a basis by weighing all the pros and cons, starting from the maximum set of indicators. A strip foundation, the pros and cons of which meet the selection criteria, can be included in the construction project.

Quantity calculation

In principle, there are no difficulties with the calculations, because a lot will depend on the type of soil, the level of soil freezing and the groundwater level.

Experts recommend using foundation blocks laid in two rows one on top of the other for all types of buildings, regardless of their complexity and weight. This is the minimum.

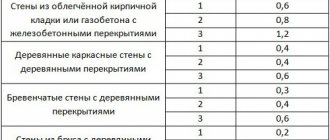

Everything else depends on the above parameters. For example, the thickness of the block should not be less than the thickness of the walls. Therefore, when choosing a base for a house, consider what materials the walls will be built from. If this is brickwork with one brick, then the width of the wall with finishing will be within 30 cm. This means that to build a prefabricated foundation you will need an FBS 9-4-6 t block from the above table.

Its height is 58 cm. And if the foundation is laid to a depth of 1.5 m, then three rows of blocks will have to be installed. Now we need to find out how many foundation elements can fit in one row. Let the length of the foundation be 100 m. The length of the described block is equal to 88 cm or 0.88 m according to the table. All that remains is to carry out a simple calculation: 100/0.88 = 114 pieces. And this is in one row. Multiply by three rows, we get 342 block elements.

The most important thing is that there will never be an extra block on a suburban plot , if suddenly after assembling the strip foundation there are several left. And selling them is not a problem.

The material will be transported by trucks. So you need to load them to capacity, so that later you don’t have to carry two or three blocks on one car.