A grillage is an element used in pile-strip and pile-screw foundations. Its function is to distribute the load between the base supports. On unstable soils, craftsmen use a combination of various methods to strengthen the foundation. One of the options for this combination was a monolithic slab with a grillage. The article will discuss the features of the manufacture and use of a grillage, the pros and cons of combining it with a slab foundation.

Advantages of monolithic slabs with an upper grillage

A solid slab with a grillage, like any other monolithic structure, has a list of obvious advantages over other types of foundations for a house:

- Carrying out work on the construction of a monolithic foundation does not require a long time and fits into a fairly short period of time.

- The distribution of the load from the gravity of the building over the entire surface of the base makes it possible to erect the structure in any area, on any type of soil.

- A monolithic slab, additionally reinforced with reinforcement structures, enhances the overall load-bearing capacity of the base and makes the future building more stable and reliable.

- A slab with a grillage makes it possible to raise the entire building to the desired height from the ground.

- The space that remains free above the monolith can be used as a place for thermal insulation materials, which makes the house warmer and more resistant to frost.

In addition, you should also take into account the fact that monolithic slabs are very resistant to moisture and can withstand external influences, and therefore there is a good opportunity to equip a basement that is protected from flooding and the penetration of groundwater. The materials used for the construction of monoliths are affordable. However, it is worth considering that for a monolithic foundation, some materials, for example, concrete mortar, will be needed more than when arranging a strip or other types of foundation.

Types of slab-grillage foundations

Structural differences are manifested in the degree of penetration into the ground and the location of vertical stiffeners. Depending on the first factor, there are:

- Foundations without deepening, with the monolith being raised above the zero mark or laid directly on the ground. The advantages of this option include a reduction in work time, but it is not possible on all types of soil.

- A monolithic shallow slab, which is the most common and in demand and requires the preparation of a pit with a depth of at least 50 cm.

- Foundations buried below the frost line.

The last type is the most expensive and is selected when a number of conditions coincide: the presence of a basement in the project, the absence of stable layers at a depth of up to 1.7 m and the need for a base with high load-bearing capacities. In this case, the grillage is supported on a monolith poured over the ground and, if necessary, protected with insulation, and brought up to the upper level of the base; its width coincides with or exceeds the thickness of the load-bearing walls. Compared to a conventional buried tape, this option is considered more reliable; when implemented, the basement is well protected from flooding.

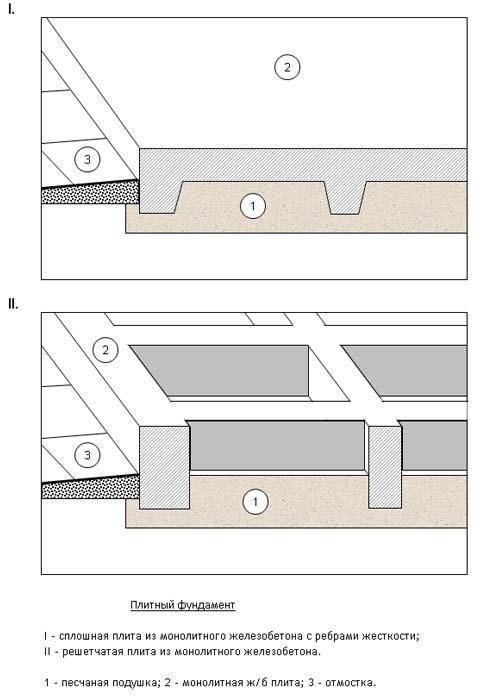

The term slab or bowl with grillage bowl is used in relation to the first two types. Depending on the structural location and functions of the vertical ribs, two groups are distinguished:

- Bases with grillage down. With this design, the slab always serves as the floor of the first floor and there is no basement in the project. The advantages include the uniform distribution of weight loads and the absence of the need for additional covering, the disadvantages are the difficulties in hiding communications and carrying out the concreting stage; the formwork for such stiffeners is most often made permanent.

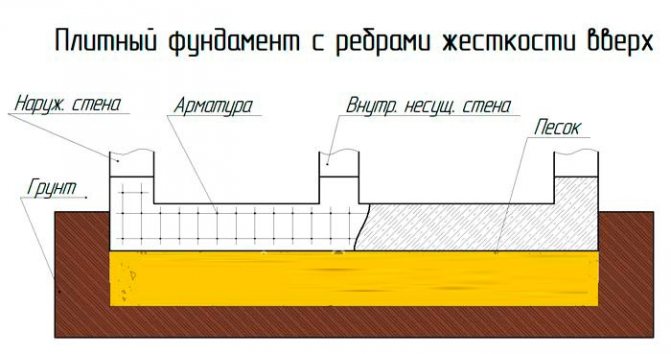

- Slabs with an upper grillage, making it possible to arrange an underground and raise the walls of the basement to any desired height. With this design, the advantages of the monolith are fully manifested; the degree of depth is limited only by the budget. The additional space between the slab and the ceiling of the first floor is used for various purposes: from hiding communications and elements of the heating system to placing insulation.

Choosing the second option only partially simplifies the process of placing pipes; in any case, the structure must be monolithic. In practice, this means that the location of holes for water supply or sewer pipes is thought out at the design stage; drilling a slab or basement walls is considered a gross violation of technology. To increase maintainability, it is recommended to install all communications through the side faces; if such installation is not possible, the pipes should be protected with appropriate channels or casings.

The stages of constructing a monolithic foundation with a grillage are generally standard: based on these calculations, building materials are purchased or concrete is ordered, markings and excavation work are carried out, the substrate is prepared, the structure is reinforced and filled with mortar. Among the distinctive and mandatory conditions are:

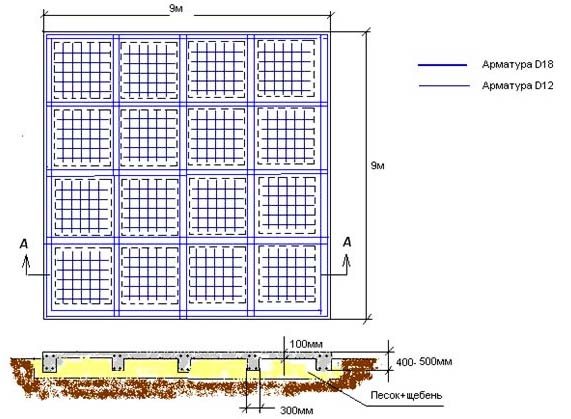

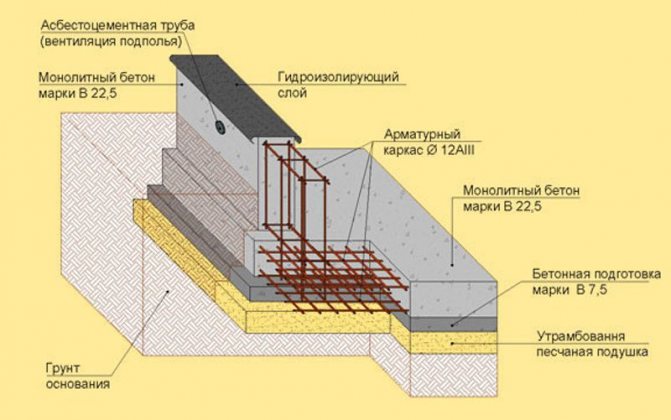

1. Laying a slab with a thickness of at least 20-25 cm with at least two rows of longitudinal reinforcement. The structure is reinforced with a three-dimensional mesh with a cell pitch of no more than 20 cm and the attachment of the grillage frame. The total cross-section of the reinforcement exceeds 0.3% of the slab area in size; for the plinth this minimum is 0.1%.

The protective layer of concrete is maintained at a level of 3 cm from below and 4 cm from above, a deviation upward is permissible (within 7 cm), a deviation downwards is not.

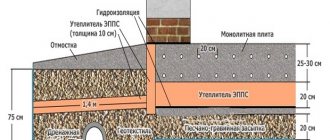

2. Ensuring free access to the slab foundation formwork from all sides, careful preparation of the walls and bottom of the pit. To extend the service life and increase comfort, it is recommended to protect it with dense and moisture-resistant insulation (a layer of Penoplex or its analogues with a thickness of 10 cm), waterproofing the sole and walls is carried out in any case. The best results are achieved by combining rolled and coating products.

3. Laying a cushion under a slab made of a layer of sand and crushed stone with a total thickness of 20 to 40 cm. Every 10 cm of such a layer is carefully compacted using vibration equipment or manually, the soil and bulk material are separated with geotextiles. The need for laying drainage pipes along the perimeter of the base depends on the groundwater level and is determined by analyzing the soil on the site. They are included in the pie diagram with the condition of a mandatory slope, integration into a single contour and the presence of inspection pipes at all corners of the building. There is no need to expand the pit; drainage elements are placed directly under the base of the slab or grillage.

4. Carrying out the concreting stage without interruptions with careful removal of air voids. The outer side of the foundation formwork is laid in advance, the inner side is laid immediately after the slab has set. When placing the grillage from below, concreting the entire structure is completed in 1 day.

5. Providing standard moisture care. A monolithic floor made of a slab and grillage gains its final strength a month after pouring; during the first week, the concrete is sprayed with water and covered with film. Work is carried out exclusively in the warm season.

6. Protection of concrete base surfaces with waterproofing compounds before erecting walls.

Laying moisture-resistant insulation, drainage pipes and increasing the thickness of the pillow are optional but recommended measures, the ultimate goal of which is to achieve maximum service life.

Related article: Chise foundation

Special equipment and vibration equipment used in preparing the pit, compacting the cushion and compacting concrete helps to reduce the labor intensity of the work. Given the large volume of the structure being poured, the solution should be ordered from the factory; a detailed action plan helps to avoid mistakes.

Varieties of monoliths with grillage

A monolithic type foundation structure can be erected in two main variations:

- Foundation cushion with lower grillage. This type of base is characterized by the fact that the surface of the monolithic slab simultaneously functions as a floor for rooms located on the ground floor. The main inconvenience is that it is impossible to arrange basements in such buildings. In addition, all communications have to be placed in specially made utility rooms, since there is simply no way to do this underground.

- Base plate with top grillage. In this case, it is possible to arrange a basement to accommodate communication equipment. The grillage in this case is located upward, away from the monolith, and its height will depend on the height of the technical underground required to accommodate utility networks.

Advantages and disadvantages of a grillage base on a slab

Slab grillage has serious advantages compared to other types of foundations:

- long service life. The durability of the foundation structure exceeds seven decades;

- versatility. A monolithic slab with a grillage can be constructed on various soils, as well as without taking into account the features of the relief;

Concrete grillage is used exclusively for load-bearing walls

- increased strength characteristics and reliability. The use of reinforcement cage increases performance properties;

- expanded scope. The design ensures the stability of various types of buildings;

- simplicity and accessibility of technology. The methods for performing the work are clear and allow you to build your own foundation;

- uniform distribution of forces over the surface of the base. This avoids cracking of the concrete.

Disadvantages include increased costs. Compared to other types of foundations, the costs of construction activities are higher, which is associated with an increased need for concrete mortar and the need to perform excavation work.

The grillage is the support of the entire building

As a rule, concrete or reinforced concrete is used as the material for making the grillage. These types are the most durable and durable. When constructing a wooden structure, logs or beams are prepared in advance for the grillage. It is worth considering that wood is a material that is highly susceptible to moisture and other weather conditions. Contact of wood with soil can lead to rotting and destruction of timber or logs. That is why a grillage made of wood is considered to be the least reliable and durable.

Sometimes metal is used as a grillage material, since this material also has strength and durability. However, we should not forget that metal is often susceptible to corrosion, which also destroys it. In this case, the metal must be treated with a special substance that prevents rust. This type of grillage is used mainly for small structures and utility rooms.

Since the grillage is the structure on which the entire building rests, it is important to install it correctly. An important point in the installation process is the calculations and further installation of the support belt. There are three main types of grillage:

- Short. This grillage is buried in the soil. This type of foundation is used mainly in the southern part of the country, where the depth of soil freezing is not great, and groundwater runs low and does not rise to the surface.

- Elevated. Such a base is located directly at the ground level and is used on stable soils.

- High - this type of base is located above the ground level, used mainly for small objects.

Thus, the choice of foundation for a house depends on many factors. However, monolithic slabs are very popular today, largely due to their versatility and reliability.

What it is?

From a structural point of view, a pile-grillage foundation looks simple - it is piles and a monolith slab. The load on the slab is distributed evenly, which is why its magnitude can be very impressive. If we briefly formulate the tasks that a slab grillage performs, we get the following list:

- connect the piles together;

- distribute the load evenly over the entire base;

- rigidly fix the piles to eliminate the possibility of their movement;

- eliminate the possibility that the foundation will shrink.

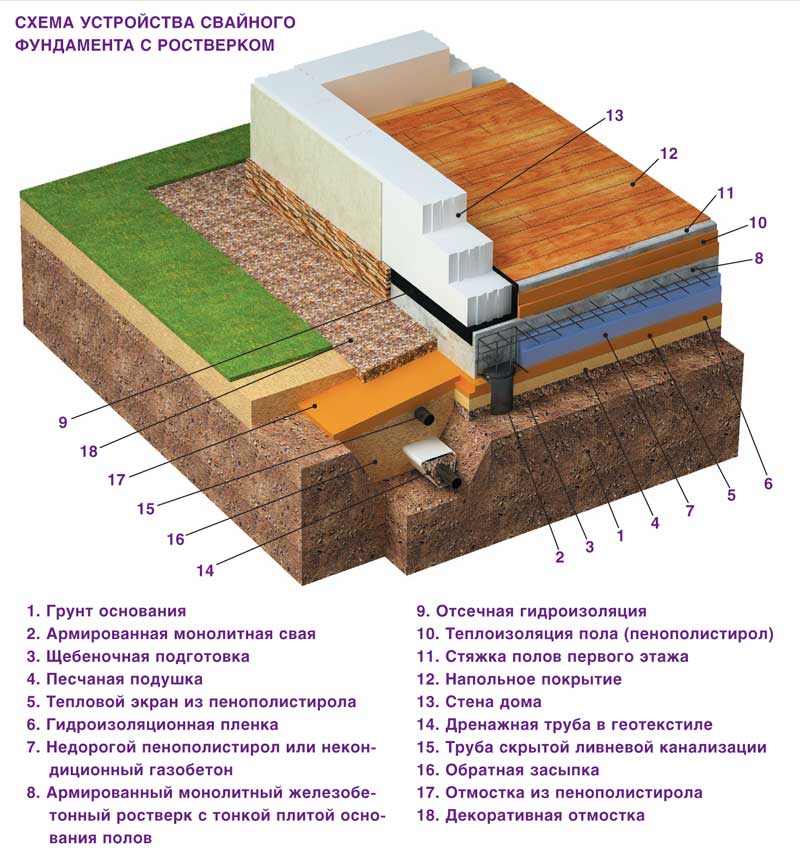

Diagram of a pile foundation with a grillage

Grillage on monolithic slabs can belong to one of three types:

- metal - to connect the piles, a channel or I-beam is used, and the size of the section depends on the purpose of the walls. Load-bearing walls have a larger cross-section, while any other walls have a smaller cross-section. This option requires serious financial investment, so it is used infrequently;

- concrete - it is used only for load-bearing walls. Piles are installed in the dug trenches, if necessary, they are trimmed, the ASG is filled, after which the reinforcement is tied up and formwork is made;

- suspended - it looks the same as concrete, but the slab is placed directly on the piles. A monolithic slab with a grillage in this version also requires reinforcement and a rolled profile.

Related article: Reliable foundation waterproofing

Slab reinforced concrete foundation with monolithic grillage

Sometimes, when it comes to building a small building, a slab grillage can be installed on wooden beams. However, in this case, you should make sure that they can handle the planned load. The most common is the classic option, when the piles are covered on top with a monolithic slab.

During the installation process, you should remember that a concrete slab grillage can only be installed at temperatures above zero. Otherwise, it will quickly shrink, which, of course, is extremely undesirable.

At the same time, experts recommend not to skimp on the quality and quantity of concrete - the reliability and durability of the entire structure will depend on this. The manufacturing technology itself looks simple - concrete is poured into the formwork with reinforcement. However, care should be taken to ensure that the composition of the mixture is correctly selected and its quantity is sufficient.

The diagram below shows how a monolithic slab grillage is constructed and what elements it consists of.

The reinforced concrete slab itself is a fairly high-quality foundation, and if it is used in conjunction with a grillage, which absorbs most of the effort, the result is simply an excellent foundation