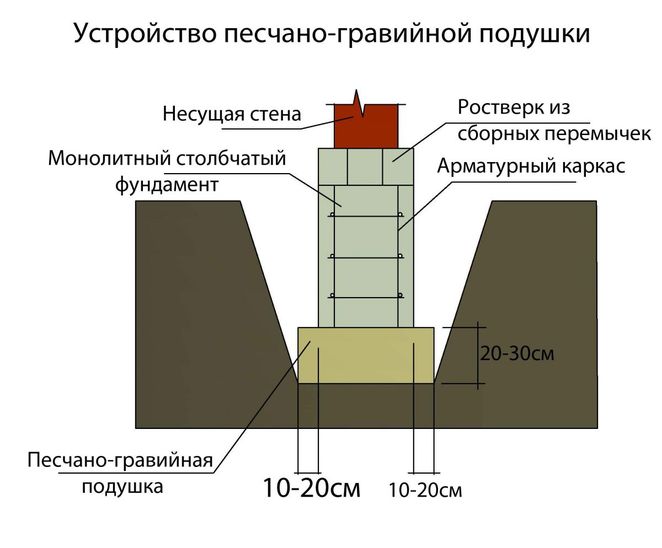

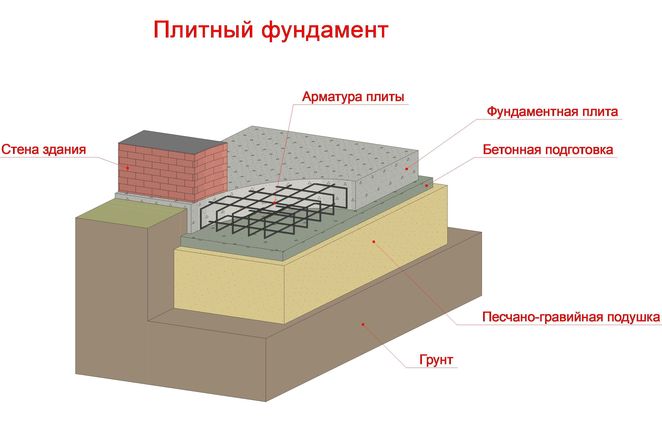

Construction of a house begins with laying the foundation. Since a monolithic slab is subject to deformation and premature settlement, it is worth using a cushion under the foundation. To ensure that the structure does not deform, take into account: topographic plan of the area, geological surveys, hydrogeological indicators.

For medium-sized permanent buildings, the recommended thickness of the cushion under the slab is 0.2 meters. Sand, concrete or crushed stone are typically used. The embankment is compacted with a vibrating plate with a minimum force of at least 180 kg/m2.

Purpose and types of foundation fills

The structural features of the soil at the construction site affect the foundation of the house. At the same time, the strength of the structure decreases; it cannot absorb large loads on buildings during soil subsidence. To reduce peak loads, it is customary to backfill the foundation base.

The sand cushion under the foundation also performs a leveling function, allowing you to save concrete when pouring. GOST and SNiP rules recommend producing several types of filling, depending on the material:

- sand pillow;

- crushed stone or gravel;

- made of concrete.

Each of the materials is good in its own way, but its use is based primarily on the characteristics of the soil. Based on this, the material from which the cushion under the foundation slab is made is selected. For a more accurate choice, according to GOST, knowledge of several more factors is required:

- proximity to the groundwater channel;

- temperature changes, depending on the time of year and other meteorological features of the construction area;

- design features of the house.

Important to remember! Incorrect calculations or working by eye will cause significant shrinkage of the foundation, as a result of significant diverging cracks. The work should be performed with full responsibility and without haste. Foundation pads are made individually for each building project.

Reinforcement

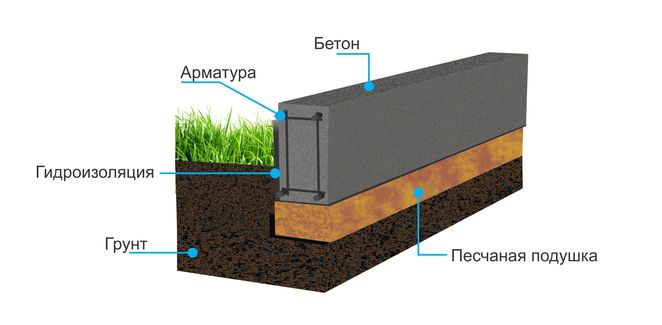

Laying reinforcement under the future foundation adds strength to the concrete being laid, turning it into reinforced concrete. Ordinary concrete withstands compression well, but does not withstand tension and bending well.

This disadvantage is corrected by reinforcement with rods and welded steel frames. Such a foundation does not respond to soil shrinkage and firmly holds the structure.

Reinforcing steel 12 mm – lightweight reinforcement, supplied in quarts. Reinforcement of greater thickness (heavy) is supplied in rods. Before pouring, lathing is performed: two types of reinforcement are connected by welding or twisting wire.

Purpose and advantages of a sand cushion

There are various cases in which a sand cushion is needed for a foundation; it is used not only as the foundation of buildings. Working in any design, it performs a number of functions:

Serves to level the plane. This is the main role of the sand cushion. Leveling the surface for pouring is mandatory, even if a shallow foundation is installed. It is especially important to carry out this operation after the equipment has been working in the pit - this will help save several cubic meters of expensive concrete, and it is important to know which sand is better.

- The cushion under the foundation slab may not fall asleep when equipped with reinforced concrete slabs. When making a strip base, it should be laid on a flat sand bed.

- Sand for the foundation cushion is laid and distributes the loads of the building's foundation. In this case, the distribution occurs not to protect the soil, but specifically the foundation of the building during earth movements. When developing weak soils, sand filling all the cracks and pores increases the soil's ability to withstand loads.

- The cushion under the foundation blocks, filled with sand, performs a drainage function to drain groundwater and storm water. The layer thickness is over 30 cm, all pores in soils are reliably sealed, even with a developed capillary system. But the use of the pillow is made as an addition to the foundation drainage system. Using geotextiles under the sand base of the foundation improves the waterproofing of the bedding layer.

- Knowing exactly what sand to use, they solve one of the important problems for the foundation of a slab device and others - this is the elimination of frost heaving. This is due to the physical property of the material to remove water from the ground.

It is not only the foundation part of the building that requires sand filling. With help. This operation provides protection on pipelines, when embedding piles and supporting power lines.

Important! What kind of sand is needed to cushion the foundation? Depending on the number of floors of the building, the size of sand grains can vary from 0.7 to 3.5 mm, but the most optimal solution to the selection problem, according to GOST, is more accessible river sand.

Design options

The versatility of a monolithic slab as a foundation is due to the possibility of choosing between a conventional, edge-reinforced and lightweight structure.

An ordinary monolithic slab is a solid base, buried or located on the surface of the earth, 10-60 cm thick.

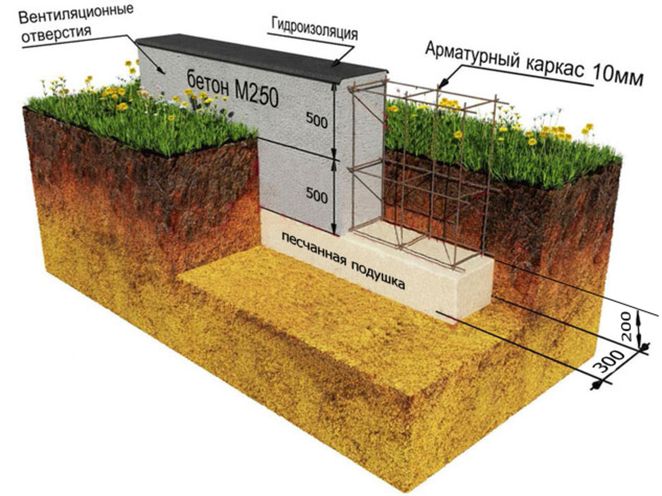

The structure, reinforced along the edges, can be located at any convenient depth (usually 1.5-2.5 m) and is an even layer of monolith, along the perimeter of which stiffening ribs rise above ground level.

With the help of formwork, they are also filled with concrete and can subsequently be closed at the top, forming a monolithic box that can simultaneously serve as a foundation for a garage, a basement or a ground floor. Due to its high cost and complexity, such a design is rarely .

The lightweight version of the foundation is simple to implement and allows you to save on concrete and reinforcement. It is suitable for garages made of light materials : wood, foam blocks, light frame structures. The lightweight foundation is poured on the basis of a reinforcing mesh, forming squares with walls from 1 m to 1.5 m.

It is similar to the strip one, but in the strip type the reinforcement poured with concrete is the support for the load-bearing walls. When installing a lightweight monolithic foundation, the load is distributed evenly over its entire area. A small layer of concrete can be poured on top of the lightweight foundation to form a floor, but any other floor suitable for a garage can also be laid.

Purpose and advantages of crushed stone filling.

In order to understand why backfilling with crushed stone is needed, you need to know its positive and negative sides. A crushed stone cushion for a foundation made of FBS slabs has properties that can withstand heavy loads. Crushed stone filling is superior to sand filling in its characteristics:

- it will help level the surface for a shallow or shallow foundation;

- when crushed stone is used for a foundation cushion, it has better resistance to temperature changes. It is important to know what crushed stone to use;

- high thermal insulation and waterproofing properties of the crushed stone cushion.

Important! For greater savings in materials, sand and crushed stone filling is used. This method does not degrade the quality, but the layer thickness is significantly reduced.

During operation, operations are performed similarly to the production of sand filling. A layer of crushed stone is poured and compacted well. Thus, voids are removed and the gravel layer is compacted.

The disadvantages include the high cost of the material, but this is a controversial statement. In the areas where it is produced, the price of the product decreases significantly. Heavy weight increases transportation costs. Crushed stone is produced from gravel, granite fractions and durable lime masses. Gravel is not susceptible to the effects and accumulation of radiation and is quite durable.

It is produced by crushing or sifting rock in special devices. The low price makes such material more in demand. Granite crushed stone is very durable, but more expensive. Produced by processing a granite base. Limestone material is less durable, but no longer susceptible to environmental influences. It is produced by processing limestone.

Tricks for installing a monolithic slab for a garage

Sometimes it happens that a reinforced foundation is needed for a garage. For example, if it is operated by heavy special equipment or a two-level garage with massive walls. In this case, they resort to strengthening the monolithic reinforced concrete slab with stiffeners.

The ribs are located along the perimeter of the slab and inside the perimeter in the form of a grid. A reinforced perimeter belt involves preparing an additional trench about 0.45 m wide and 0.5-0.55 m deep. Its base should be reinforced and reinforced with a screed of crushed stone and sand.

In the reinforcement belt, the reinforcing mesh is brought inside the monolithic slab under the foundation, and connected into one united frame.

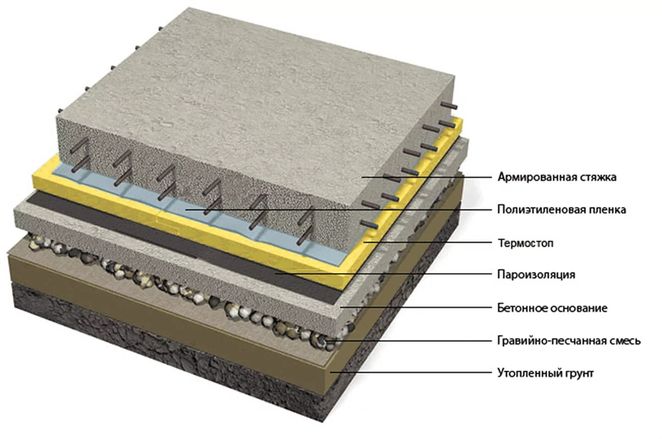

To insulate the garage floor, you should put 2-3 layers of polyethylene film, it will perform a thermal insulation role. We recommend building a monolithic foundation slab wider than the intended garage.

It is important to smooth the concrete floor surface using a special sealing mixture. This method will avoid dust formation and surface unevenness after the concrete mixture has completely hardened.

Concrete pad for monolithic construction

This type should not be used when pouring a shallow foundation. GOST prescribes its use in the monolithic construction of high-rise buildings or in the construction of private households using permanent formwork. We have decided why we need a concrete pad under the foundation. It is important to know its advantages and disadvantages.

The advantages of this method are:

- equipping with an additional layer of reinforcement for the foundation slab. In this case, you can link them into a single system;

- an additional layer of concrete increases the strength and durability of the foundation;

- with this method, low-grade concrete can be used without harming the strength of the building;

- when equipping buildings with concrete, there is no need to pay for and deliver crushed stone or sand with an additional layer;

- the level of fire safety increases.

The main disadvantage of this method is the low level of tensile strength, which results in the formation of cracks. To do the job well, it is not enough to know how to make a pillow for the foundation; it is important to be able to do it well.

Step-by-step instructions for making a sand pillow with your own hands

A sand cushion is the most common and reliable method of backfilling, so let’s look at it in more detail. All work is carried out in several stages:

- Before performing work, depending on the quality of the soil and the height of the building, you should determine the thickness of the finished backfill layer. This size can be in the range of 100 – 250 mm;

- marking the work site. In this case, you should check the dimensions of the future foundation and its diagonal. To do this, you can use a long tape measure or a rope with knots;

- then we level the bottom of the trench to save sand and concrete;

- we lay geofabric in the trench so that its ends are at the same height of the trench walls;

- a layer of sand is poured in and compacted. The process of compacting the sand layer should be treated responsibly and carefully. The thickness of each layer of sand before compaction is no more than 200 mm. This makes the seal better.

We can say that we have made such a thing as a sand cushion - a simple but very important job of arranging the foundation with sand filling has been completed. Now you should begin reinforcing the foundation and pouring concrete.

What sand do you need?

Sand backfill is created from coarse-grained and medium-heavy sands, which have increased moisture permeability, high compression resistance and are able to resist shrinkage.

Fine-grained sand fractions are not used, since their use leads to subsequent subsidence of the building.

The most suitable are:

- River sand, containing a minimum amount of impurities. However, increased compaction of the sand layer will be required due to the round shape of its particles.

- Construction sand extracted from quarries. It is cheaper, but contains clay impurities. It is used to create a cushion only after screening and washing, since clay inclusions can provoke subsidence of the foundation.

- Sea sand. It is used less often than quarry and river. After cleaning and hydromechanical treatment it becomes almost similar to river water.

It remains to draw a conclusion.

The operation of arranging the foundation of a building with a cushion made of various materials is one of the possibilities for extending the service life of not only the foundation, but also the entire building. The best option, capable of combining excellent physical qualities at an affordable price, is a sand and crushed stone cushion. But for each project, a base of different materials should be provided depending on the characteristics of the soil.