A reinforcement frame for piles is a special structure made of metal reinforcement, in most cases made from rods of the same direction, but from different spheres of reinforcement of a reinforced concrete element. The reinforcement is connected to each other with clamps, transverse or oblique rods, thereby forming a solid metal structure. The most common diameter of piles is from 0.6 to 6 m and is determined based on calculations of existing conditions to ensure the required structural strength.

The reinforcement cage is used for reinforcing reinforced concrete products and structures, including at the pouring stage. This makes it possible to significantly increase the strength and resistance of structures to mechanical influences and loads of varying intensity and duration.

Types of reinforcement cages

Today, two types of reinforced frames are in demand in construction:

volumetric (spatial) frames for various purposes: from square and round shapes for piles, to volumetric cage-type metal structures used in the construction of industrial facilities for pouring fairly large volumes of concrete. These frames are three-dimensional structures made from several welded gratings and interconnected by metal rods in a perpendicular plane. To make such frames, rods with a thickness of 12 mm and 8 mm are used, due to which piles are formed, the diameter of which may vary depending on the type of work. According to the forms produced, the production methods also differ. Thus, large frames are manufactured individually, and frames for piles are made using special automated welding lines; flat reinforcement frames consist of two or three longitudinal layers of reinforcing mesh welded together with rods. The longitudinal rods are connected by inclined, continuous (“snake”) or transverse (“ladder”) steel rods.

The main area of use is to increase the strength of linear structures, without creating excessive weight, as well as when laying the foundation (including strip foundation) and reinforced concrete reinforcement.

How to choose piles for building a frame house

The construction of a foundation using frame technology involves the installation of piles, which replace a strip or slab foundation, installation of piping, and anti-corrosion treatment of the resulting structure. The depth of immersion of piles into the soil, their parameters and the required number are calculated at the design stage, taking into account the results of an examination of the soil on the site, the characteristics of the future structure and other parameters.

The following factors can be considered the most significant in this regard:

- Estimated weight of the future structure.

- Its configuration, dimensions.

- Weight of furniture or equipment.

- Specificity of soils in the area being built.

- Soil freezing depth.

- Groundwater level.

In order to accurately calculate the number of supports when constructing a frame on screw piles, determine their location, and choose the right type of product, it is best to use qualified help. To do this, you can always contact us; the engineers of our company will make all the necessary calculations, offer you the optimal type of our products, and calculate the required quantity.

Manufacturing of reinforcement cages

The main raw materials for the manufacture of reinforced frames for piles are corrugated and smooth reinforcing bars, hot-rolled wire rod, VR-1 wire, corrugated and smooth coiled reinforcement with an average diameter of 6-12 mm.

If necessary, metal rods can have a special protective anti-corrosion coating. However, usually for such purposes, metal rods or rods made of low-carbon steel without special coatings and alloying additives are used. Individual metal rods are connected to each other by welding or knitted using wire. Volumetric frames can be made from ready-made flat parts.

In total, the production of reinforced frames can be carried out either centrally in specialized production facilities (in factory workshops) or directly on construction sites. At the same time, the shape of the reinforcement cages can be special or standardized, and often fully correspond to the dimensions of future products.

Currently, two main technologies are used for the manufacture of spatial reinforced frames:

Automated assembly on production lines - includes the following main parameters:

- the type of section can be prismatic or cylindrical;

- length can reach 14 m;

- weight – up to 4.5 tons;

- section dimensions – 200-1500 mm;

- size of working reinforcement (12-40 mm), spiral (6-16 mm);

- type of connection – automatic welding.

Manual assembly requires the presence of several frame indicators:

- section type – no restrictions;

- weight – up to 10 tons;

- length – up to 16 m;

- size of working and spiral reinforcement without restrictions;

- type of connection - using binding wire or semi-automatic welding.

The production of frames of round shapes is carried out by welding load-bearing reinforcing metal rods with reinforcement wound in a spiral. Thanks to these technologies, ideal geometric shapes of the reinforcement frame, high quality welding, and high productivity are achieved.

Considering that at the moment, at many construction sites, certain restrictions are established on the use of driven piles, foundation foundations are built using modern technology based on bored piles.

The construction of a bored pile is carried out directly in the ground. To do this, a reinforcement cage is installed in a pre-drilled well, after which the structure is filled with concrete mortar. Once the concrete mixture has hardened and reached its design strength, the bored pile structure can support high design loads. This technology for manufacturing bored piles has a low noise level, which allows the construction of pile foundations in places where, due to high noise levels, it is impossible to use driven piles with a diameter of 40x40 m, as well as with other sections.

Round reinforcement cages are often used to reinforce bored piles. The main parameters of reinforcement cages are:

- pile diameter;

- diameter of the overall frame;

- spiral pitch;

- spiral diameter;

- maximum frame weight;

- diameter of longitudinal bars.

Grillage reinforcement

A pile-type foundation must be reinforced. And if the piles are reinforced to give them greater strength, then the grillage is reinforced in order to increase its load-bearing capacity. In this case, that part of the reinforcement that protrudes from the frame is most often used as a connecting element between the bored pile and the grillage. In this case, fastening must be done by welding.

To carry out reinforcement of a pile foundation and grillage, be sure to have a reinforcement diagram in front of your eyes. This will simplify the workflow and reduce the likelihood of errors to a possible minimum. As for the reinforcement of the pile foundation grillage, reinforcement should be used for it, the cross-section of which varies from 10 to 14 mm. If a grillage is installed, it is more expedient to make the reinforcement frame in the form of separate belts. They must have a rigid connection between each other, which can be achieved by using vertical rods made of durable metal with a diameter of about 8 mm. This diameter turns out to be quite sufficient, since the rods will not be subject to heavy load. They are necessary solely to give the structure the required shape.

Application of reinforcement cages

The main use of reinforcement cages is the production of new durable and strong structures from reinforced concrete or the strengthening of existing ones.

Reinforcement frames are most widely used in the construction of various types of engineering facilities, such as industrial and residential buildings, bridges, and other specialized structures.

At the stage of pouring the foundations of reinforced concrete structures, a reinforcement frame for the foundation is necessarily used, and floor beams are most often made on the basis of standard three- or tetrahedral frames. The reinforcement frame for floors and walls, depending on the required thickness of future products, can be volumetric, row or flat, and the frames for bored piles can have a square or round cross-section.

Bored piles are used in the construction of foundations with deep solid soil. The bored pile device is a cylindrical structure, which consists of reinforced circles with a small diameter and longitudinal reinforcements of a large diameter.

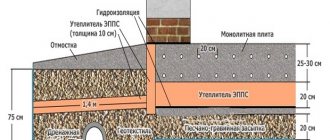

Calculation of a foundation with a grillage

In order to correctly calculate the pile foundation and grillage, the first thing that needs to be done is to determine the composition of the soil at the construction site with maximum accuracy. Moreover, this should be done precisely at the depth at which the pile foundation will be constructed. This is necessary in order to calculate the length and make a drawing taking into account their design features and the distance between them.

When calculating the foundation on bored piles and the grillage for it, it will be necessary to determine with maximum accuracy the loads that will be exerted by the building, both on the piles and on the soil. To get a calculation of the expected weight of a building, you will need to add not only its own weight, but also the weight of all the floors, as well as the roof. The drawing must also take into account some additional loads. For example, a lot of people, furniture, equipment, etc.

Of course, the calculation must be made taking into account the total area of the building. Most often, the installation of a pile-grillage foundation is necessary for those buildings whose area exceeds more than three hundred square meters. It is important that the calculations are carried out and the drawing prepared by experienced specialists whose qualifications will be sufficient to take into account all the nuances.

After the calculation of the pile foundation and grillage is completed, a detailed drawing is drawn up based on it. In addition to bored piles, screw piles can be used in the construction of houses. They will also be somewhat more profitable in terms of financial benefits, since driving them in does not require the use of specialized equipment.

Advantages of using reinforced frames

The widespread use of reinforcement cages in construction provides a number of undeniable advantages:

- reduction of the production cycle;

- increasing the speed of installation work on reinforced concrete structures;

- possibility of disposal of waste fittings;

- Possibility of use on almost any type of surface;

- increasing production profitability;

- increasing labor productivity.

In addition, reinforcement cages for piles are successfully used in construction near existing buildings, which makes it possible to remove dynamic loads from them when constructing a new foundation. Thanks to the use of piles, spot construction, even in cramped conditions, benefits where other technologies cannot be used.

Why is reinforcement necessary?

Concrete is an extremely hard and non-plastic building material. When it stretches, large cracks immediately form.

When a concrete foundation is exposed to a disproportionate load from the structure and natural conditions, the foundation of the house can easily deform.

When the structure of concrete changes, compression appears in one zone and tension in another. It is in the latter place that cracks can appear. To avoid this situation and increase the service life of the foundation, it should be reinforced.

The essence of reinforcement is quite simple, and consists in placing a frame of steel reinforcing bars inside the foundation, on top of the concrete base. Metal elements are more resistant to stretching and absorb all the impact.