Strict competition requirements in the field of modern construction force us to look for ways to reduce costs, including the use of new materials. New formulations of building stone, special grades of concrete, foundation compositions, facing and thermal insulation materials are appearing. At the same time, in a market previously traditional for metal reinforcement and special structures, manufacturers of various composite products are actively trying to win their “place in the sun.” Most often these are non-metallic strength elements and fiberglass reinforcement.

Why did fiberglass reinforcement appear on the construction market?

Composite materials, including fiberglass reinforcement, are manufactured using a relatively simple technological principle of impregnating glass or basalt fibers with an epoxy or polyester matrix resin. Next, the bundle is formed on a machine into a rod of composite reinforcement calibrated in diameter, and baked at a low temperature in a special drying oven. Typically, the length of one piece of reinforcement does not exceed 100 m.

Fiberglass reinforcement does not require the operation of complex and expensive equipment, so the production costs themselves are relatively low, most of the cost is the price of the resin for the matrix and the fiberglass tow. And yet, if you compare the cost of fiberglass and steel rods of the same diameter, metal reinforcement has a warehouse price that is 10-20% less, and this is a very big difference for such an area as construction.

Nevertheless, fiberglass material has quite strongly replaced rolled metal products, not least because of a number of specific properties, but the main factors were slightly different reasons:

- Fiberglass reinforcement has increasingly begun to be used in private low-rise construction. It is more accessible to use, it is easier and much cheaper to transport, store, and cut. It does not need to be straightened and leveled before use, as is the case with the steel version. The material can be bought in a whole bay and cut into pieces of the most non-standard length. Whereas a standard 11-meter steel rod would require a lot of waste if your foundation, for example, has reinforcement 8 m long;

- The availability of equipment for the production of reinforcing strands has allowed many small enterprises - manufacturers of building materials - to establish in-line production of fiberglass reinforcement in a wide variety of rod surface designs. A huge number of offers, a competent sales policy and hidden advertising allow you to diversify the market;

- The desire of contractors to save money in construction work by using a more profitable material for reinforcement, for which a formal, “blind” recalculation of the strength equivalent of composite materials and steel reinforcement is often used.

How to make the calculation correctly

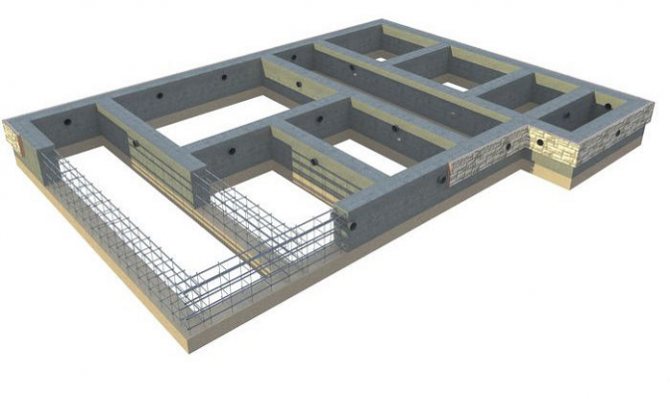

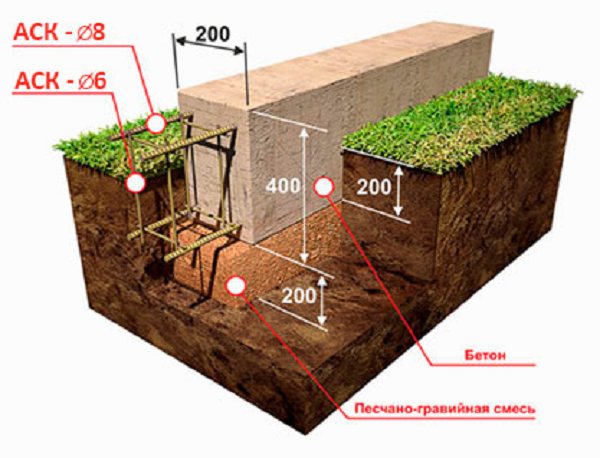

When reinforcing the strip base, it is necessary to ensure reliability and strength. Therefore, the amount of reinforcement and its diametrical cross-section must comply with all GOST standards. Let's give an example of how to calculate the required number of rods for a base with dimensions of 60x40 cm.

We take as the norm the GOST indicators, which indicate that the area of the rods used should be 1/10 of the area of the base itself. Therefore, the calculation must be made according to the following principle: divide the cross-sectional area of the tape by the total cross-section of the rods used. Based on the given dimensions, we get the result of 2.4 cm2 - the cross-sectional area of one rod. From here, using special formulas, you can calculate both the diametrical cross-section and the total number of rods themselves.

Please note that the calculation is quite complex, so it is better to contact specialists. Only with correct calculations can the required quality of the foundation be guaranteed.

Reviews from experts, advantages and disadvantages of composite thread

If you wish, you can find the most complex calculations and quite simple primitive arguments about why fiberglass reinforcement is good or bad. As a rule, serious research and reviews from specialists in most cases do not give specific recommendations, in fact, the “hot” problem of the foundation; in many ways, the capabilities of fiberglass-based reinforcement must be assessed at your own peril and risk.

Attention! Among the numerous reviews of specialists, there are practically no real professional experts in the field of structural mechanics of composite materials. Their opinions and reviews, as a rule, are reflected in estimates and custom calculations for specific construction projects, cost a lot of money and are not presented to the public.

An approach can be called professional if reviews from certain experts evaluate the specific situation of using, for example, a fiberglass rod in the foundation of a house using practical results and analysis of the reasons. Otherwise, such expert reviews can be called, at best, advertising or anti-advertising.

Specifications

Fiberglass reinforcement is a mixture of strong fiberglass and heat-resistant resin.

In the above-mentioned year, GOST was published, which clearly established its parameters:

- Diameter - from 4 to 32 mm

- The temperature at which the material can be used is from 60 degrees Celsius

- Maximum tensile strength is a measure of the force with which a material is stretched and its cross-sectional area. For fiberglass reinforcement, the norm is 800 MPa.

- The maximum compressive strength is 300 MPa.

- Maximum strength is more than 150 MPa.

Using fiberglass rods in the foundation

The use of reinforcing mesh based on fiberglass load-bearing elements began in the 60s of the last century. In addition, a fairly large number of buildings and technological structures made of stone and concrete have been built and are in operation, in the foundations and walls of which fiberglass-based reinforcement is used. Feedback on the condition of buildings with elements of steel and fiberglass reinforcement and many years of operating experience will give more than all the theoretical calculations of “experts” combined.

Almost everyone who makes videos or posts their opinion about the shortcomings of fiberglass reinforcement is either sales managers of competing steel products, or amateurs who confuse the causes and consequences of the basic principles of strength and rigidity of structures. For the most part, such discussions about the disadvantages of fiberglass reinforcement are accompanied by formulas and data on the strength of steel and composites. But there are no clear reasons or processes why fiberglass reinforcement cannot be used. If a person who undertakes to comment on the advantages and disadvantages of fiberglass reinforcement has not demonstrated in practice a fragment of destroyed concrete or a piece of foundation with fiberglass reinforcement, all his reasoning remains fantasies on an arbitrary topic.

Fiberglass reinforcement has been used in construction, mechanical engineering, and special projects for more than 40 years. If this issue is of fundamental importance to you, refer to old Soviet textbooks from the 70s of the last century, magazines on construction topics; these sources reveal the physics and mechanics of foundation destruction processes and provide numerous examples of errors.

Possessing high specific strength, fiberglass reinforcement can work perfectly in the most difficult conditions, but at the same time it has a number of disadvantages that limit its use in construction:

- The fiberglass nature of composite reinforcement has almost zero ductility of the material. In human terms, a frame for a highly loaded foundation or walls made of such a rod will not be able to plastically adapt to the redistribution of load in a loaded concrete stone. As a result, in some places the building’s foundation will experience overload, which can cause cracks to appear;

- The fiberglass base takes tensile axial loads very well, but compressive loads much worse, and tolerates shear forces catastrophically poorly. This means that any transverse shearing force, of which there are many in “fresh” foundations due to sedimentary processes, will lead to destruction of the integrity of the reinforcement;

- Unfortunately, during the time that the concrete of the foundation gains strength, the fiberglass frame behaves somewhat differently, and precisely at this stage, therefore, each specific case in the arrangement of reinforcement requires a very careful and careful analysis.

Therefore, in those units where it is permissible to replace metal with a composite material, instead of a traditional eight-millimeter rod, a six-millimeter fiberglass reinforcement strand can be used. Few people know, but today building slabs from stressed concrete with fiberglass reinforcement are already being produced. But in production such material is much more expensive, so almost 90% of the range, including for foundations, are custom-made products.

What is composite reinforcement?

The main raw materials in the manufacture of such products are various non-metallic materials. These include carbon, basalt, glass and aramid. During the manufacturing process, they are connected to each other into a single rod, over which a rib is wound. The resulting product is fired in a kiln, after which it acquires qualities such as hardness and strength.

Due to the fact that composite reinforcement is still considered a new material in the construction market, it is important for buyers to familiarize themselves with the existing pros and cons before purchasing it. This approach will help you weigh the pros and cons when purchasing polymer equipment.

Application options for glass reinforcement

An undeniable advantage of steel reinforcement is the very well predictable behavior of the metal under the most difficult loading conditions. All existing skyscrapers and high-rise buildings are built only on steel reinforcement; moreover, most of these “wonders of the world” have an internal metal frame.

Glass reinforcement is not suitable for high-rise buildings or heavily loaded foundations. The structural mechanics of foundations is, in general, a whole science, primarily due to the complex interaction of individual parts of the foundation with the soil, with the walls of the entire structure.

In the existing foundation model, the most problematic areas are the corner zones, where the reinforcement experiences tensile, bending and shear loads. In these places, not every steel reinforcement is able to provide a rigid connection of corner blocks. The metal reinforcement in the foundation block achieves this only due to a combination of high ductility and elasticity. Fiberglass reinforcement cannot be used in these foundation units. Despite its high longitudinal strength, it will not be able to withstand twisting and cutting at the corner contact point of the foundation.

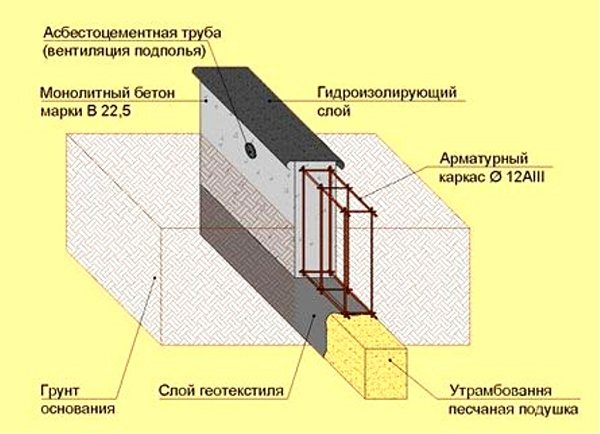

The strength and ductility of fiberglass reinforcement will be sufficient to build the foundation and basement of a one or two-story house. But provided that in the corner joints of the foundation, special couplings will be used to splice the reinforcement at right angles. Moreover, fiberglass is easy and simple to use for a simple strip foundation 70-90 cm deep.

The use of fiberglass reinforcement in combination with special grades of concrete for the foundation is considered successful. Often, when special additives are used in the foundation to enhance frost resistance or water resistance, steel reinforcement begins to corrode intensively. Especially in foundations on soils with a high salt content or in close proximity to transformer substations.

In the walls of low-rise buildings, especially those made of aerated concrete block, arbolite stone and any other building material with low rigidity and contact strength, the use of fiberglass reinforcement is even encouraged. It is much simpler and easier to work with than a steel bar.

In addition, composite reinforcement is simply ideal for attaching external insulation or laying facing bricks, where either galvanization or stainless steel is required. And, even more so, it is worth using a thin glass thread for working on the base blocks of the foundation.

Where are composites needed?

SNiPs and other rules recommend the use of composite reinforcement in the following works:

- In floor slabs: as a rule, reinforcement is laid in the upper or lower zone of concrete, and the concrete class should be B25.

- When reinforcing structures made of concrete and reinforced concrete.

- When constructing foundations that have a zero elevation.

- In reinforced structures that are exposed to aggressive environments.

- During repair work associated with damage to concrete due to exposure to aggressive environments.

- For reinforcing brickwork, especially if it is done in winter.