How to bend rebar at home

The main purpose of reinforcement is to reinforce concrete, which can collapse under bending loads.

In all reinforced concrete structures, compressive and tensile forces are taken over by a metal rod. It is impossible to build a sufficiently strong, reliable foundation of any house without a reinforcement frame. At the same time, reinforcing corners and various junctions by crossing straight rods is a serious violation of technology, which weakens the entire structure, which will inevitably lead to concrete delamination. If you need to make corner ties, you need to install curved reinforcement with an overlap on each side of at least 80 cm. In addition, bending of rods is necessary for the manufacture of various connecting elements designed for tension (for example, a tab, a standard hook, etc.).

Stages of bending reinforcement:

Not everyone knows how to bend reinforcement at home so that it retains its strength characteristics. It is almost impossible to bend reinforcement made of fiberglass without any damage, so steel is subjected to this treatment.

Experienced builders know that it is allowed to bend the rods only mechanically, avoiding the formation of sharp corners at the bending point. Any roundings should be made smooth - the most optimal radius is 10-15 diameters of the reinforcement.

The most common ways to bend reinforcement incorrectly:

- the bend area is heated with a blowtorch (autogen, welding, over a fire);

- in the place where bending will take place, a notch is made using an angle cutting machine or a similar tool.

After the “preparatory” work, a handy tool (hammer, sledgehammer, pipe, etc.) is used to bend the reinforcement. Both methods significantly weaken the rods, which leads to their subsequent destruction under the influence of loads. It is necessary to remember that all types of reinforcement bend only in a cold state without permanent damage.

How are the fittings connected?

Before asking about how to knit reinforcement correctly, it doesn’t hurt to consider all the ways to connect reinforcing frame elements. There are currently three methods. This:

- welding;

- wire knitting;

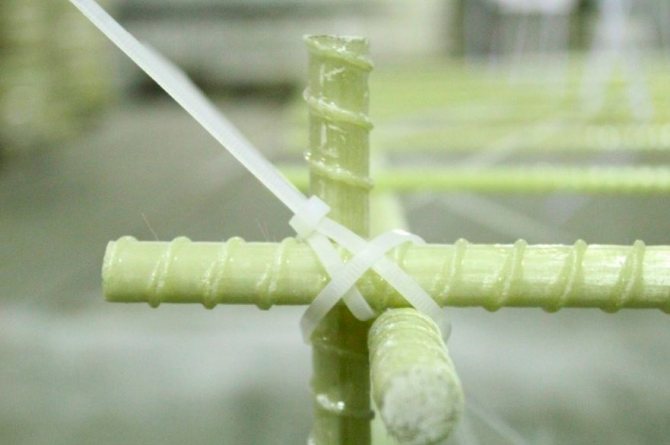

- use of plastic clamps.

Each option has not only disadvantages, but also advantages, so they are used depending on specific conditions.

Welding connection

This method has been known for a long time. More often it was (and is) used in the construction of super-strong foundations for multi-story buildings. However, welding has several weak points.

- In order to complete the work efficiently, experience with a welding machine is required. Since not every craftsman who has conceived the idea of building a house with his own hands is familiar with such work, he will have to hire a professional welder to complete the operation, and this promises additional costs that one wants to avoid during large-scale construction.

- Unreliability of the reinforcing frame. During welding, the metal is heated to temperatures that provoke a breakdown of the steel structure in the heating zone. In addition, the welded joint does not respond well to bending, so deformation of the material is possible even at the compaction stage when vibrators are used. The result is a partial loss of rigidity by the frame.

It is not recommended to bend metal close to the welding site. Complete destruction of connections during vibrator operation is another potential and serious problem, so this method is not recommended, despite the speed and relative simplicity of the solution.

Wire knitting

The biggest advantage of this method is its simplicity, since there is no need for additional equipment, and no special skills are required from the builder. If there is an error, it is very easy to fix. The entire reinforcement process is easy to perform in formwork. The cost of the work is minimal, but the master still needs to know how to properly knit the reinforcement on his own.

The disadvantage of wire knitting is the relative instability of the created structure

If the reinforcing frame is made outside the formwork, then maximum care is required during its subsequent installation

Using plastic clamps

The main advantages of the method are the highest speed of work, reliable fixation of reinforcement, and simplicity that does not require skills. Such plastic ties also have disadvantages. These include:

- the large amount that will be spent on the purchase of this material, if you compare these costs with the purchase of practical, inexpensive knitting wire;

- possible defect: if the clamp was not fixed correctly, then you will have to bite it off, and this promises extra expenses, since the element will become unusable;

- negative impact on elements at subzero temperatures: such plastic clamps, especially inexpensive ones, can burst in frost.

If you make a choice, then any method from the last two options can be considered as the main contender. However, wire knitting outperforms plastic competitors, since in this case the work will cost less. Additionally, not all professional builders approve of plastic products. They say that good ties are expensive, and cheap products simply do not stand up to criticism: they break quickly.

What devices can be used to bend reinforcement at home?

Over the entire history of the development of metalworking and construction technologies, humanity has invented many devices for bending reinforcement. All of them are united by one principle of operation, and the difference lies in the diameter of the bending reinforcement and the design of the equipment.

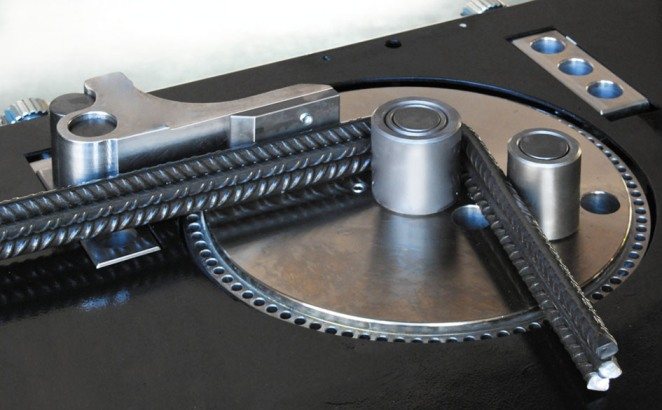

Any part that is subject to change is fixed between the thrust and central roller (shaft) of special equipment. The third bending roller bends the metal in the required direction at the desired angle. Rounding can be done either clockwise or counterclockwise. The thrust shaft serves as an obstacle to deformation. It does not allow the unused part of the workpiece to move or rotate.

There are two main options for such devices:

Drive machines, in addition to special ones, operate according to the same scheme. The working element is a disk mounted on a vertical shaft that rotates in a horizontal plane. On the disk itself there are fixed central and bending fingers, between which the reinforcement is laid. The thrust roller is fixed on the stand; when the disk rotates, the reinforcement rests against it and, under the action of the bending pin, bends around the central bushing.

Machines can differ in productivity, power and, depending on their purpose, are divided into three groups:

- super heavy – rod diameter 40-90 mm;

- heavy – 20-40 mm;

- for light reinforcement – 3-20 mm.

Such a device can bend several rods at the same time. Equipment for small diameters from 3 to 90 mm is also manufactured. If you need to create a complex structure with different bending angles, then you should use a hydraulic machine, which can bend rods much better, without the formation of kinks and masonry on the surface of the workpieces. On such a machine, bends are made at an angle of up to 180°.

Hand tools are produced in different types, including portable ones. They are quite easy to use and affordable. To work with fittings, you can acquire both a special machine and a pipe bender. This device is mounted on workbenches. Most of them are intended for private construction and are practically not used for large volumes of work.

The selection of bending equipment is based on the diameter of the reinforcement and the complexity of the work. Before you start processing metal, you need to take into account that different parts of the rod are subject to different stresses, the inner part is subjected to compression, and the outer part is subjected to tension.

The wrong choice of a machine or its use will lead to deformations (folds and kinks), which will lead to damage to the reinforcement. For this reason, accurate determination of the dimensions of the workpiece, proper adjustment of the equipment and rigid fixation of the rod are required.

How to bend reinforcement at home: homemade devices

Do-it-yourself reinforcement bending machines are often used in private construction. There are many options for their manufacture, but almost all of them are similar to factory manual ones. A stop angle or pin is welded to a metal plate or frame. Then a turntable is installed, equipped with a lever, bending pins and a central pin. The distance between the structural components depends on the diameter of the reinforcement that will need to be bent. The legs of the frame need to be attached to the floor, which will make it possible to work with rods 6-12 mm thick.

The structure made on the floor will be a portable option. However, it requires a method of fastening at the place of work. As a rule, these are holes for bolts. You can also weld two or more pins on the back side of the tile, which will be inserted into the holes in the base. However, it must be taken into account that the capabilities of such a machine will be limited - the diameter of the bent reinforcement is no more than 10 mm.

How to bend reinforcement at home with your own hands

When special equipment is not available, this does not mean that all options have been exhausted, since you can bend the rod yourself. However, it must be remembered that manual bending is much more dangerous and more difficult. Any thoughtless movement or action can cause the fittings or improvised equipment to spring back or slip out.

Thin rods up to 8 mm, with sufficient physical training, can be bent manually without any equipment. However, it should be taken into account that the quality of the bend will be appropriate. Such fittings are unlikely to fully meet the required parameters.

Reinforcement bending - process features

At any construction site today you can see various equipment, many tools and devices, and almost every one of them has a machine for bending reinforcement. This is no coincidence: the most effective technology for strengthening fragile concrete structures, protecting them from destructive loads in compression, tension and bending, is reinforcement, which is performed using metal rods - reinforcement. Without a high-quality reinforcement frame, it is almost impossible to build reliable concrete walls and foundations.

It would seem much easier to reinforce corner concrete structures and adjacent wall areas using straight reinforcing bars. However, in this case, the concrete structure will be greatly weakened and may delaminate. In addition, this is a gross violation of building codes. In any corner concrete structures, it is necessary to use only bending, with an overlap of at least 80 cm on each side. A machine or a simple device for bending metal rods is also useful if you need to quickly produce connecting elements of various types - hooks, claws, etc.

When bending steel bars used for reinforcement, it is very important to know how to bend foundation reinforcement so that it does not lose its strength characteristics. To comply with this requirement, it is necessary to perform such an operation only mechanically, using special machines for cutting and bending reinforcement. In this case, it is important to ensure that the bend angle is not sharp, and that the radius of curvature at the bend is from 10 to 15 diameters of the rod itself. It should be remembered that a steel reinforcing bar bends without losing its strength characteristics up to an angle of 90 degrees, then the strength indicators begin to decrease.

When bending steel reinforcing bars with your own hands, two mistakes are often made:

- a notch is made at the bend site using a grinder or other tool;

- The section of the reinforcement where the bend will be located is heated using a gas burner or blowtorch.

After such procedures are completed, some primitive means for bending is used: a heavy hammer, a sledgehammer, a piece of pipe, a vice, etc. These bending methods lead to a significant weakening of the reinforcement, which can cause the destruction of concrete structures. In such cases, you should always remember that you need to bend the reinforcing bars without violating their integrity and only if they are in a cold state.

In general, everything here is expensive and serious - full automation and many settings. For home craftsmen, this video is provided for informational purposes only. Since spending 130-180 thousand rubles on such a unit for non-professional use does not make any sense.

Required wire

When choosing wire, the following factors must be considered:

- Manufacturing accuracy class. The accuracy class is determined by the production method. There is a wire of a higher accuracy class, its deviation of the actual size, diameter, from that declared by the manufacturer along the entire length of the wire is less than that of a wire of a lower accuracy class. However, for knitting reinforcement, the accuracy class is not particularly important.

- Wire rolling method. There are two types of rolled products: cold-rolled and hot-rolled. Cold-rolled steel is rolled out from blanks by presses without heating. With the hot rolling method, rolled steel is rolled out in a heated state, which gives greater strength.

- Which group in terms of tensile strength does the wire belong to (there are the first and second groups);

- Degree of corrosion resistance. On this basis, there is only one difference - whether there is a galvanized coating on the wire or not.

The criterion for choosing a wire is very simple; you need a wire that is called “knitting”. It has a full set of necessary characteristics: sufficient softness with the declared strength, abrasion resistance and reliability when fastened.

Galvanized wire is considered overkill. The optimal diameter of the binding wire is 1.2-1.4 mm. A wire with a diameter of 1.6-2 mm takes a lot of force, as a result of which construction slows down, and the piece is too weak, it will simply burst.

Care must be taken to ensure that the reinforcement connection remains rigid after tying the knot: the frame must remain motionless during pouring. This will ensure the reliability of the structure after hardening.

The length of wire recommended for one knitting point is from 30 to 50 cm. The wire itself is extremely cheap - about 50 rubles. for 100 meters. To avoid running out of it at the wrong time due to loss or excessive consumption, it is recommended to buy it with a double supply. 100 rubles for 200 meters is quite inexpensive.

Machines and devices for bending reinforcement

In the process of development of construction technologies and metal processing methods, more than one machine for bending reinforcement was created. All such equipment works on the same principle; the difference between the models consists only in certain design features and the maximum diameter of the bending rod.

Any bending machine, including a homemade machine for bending reinforcement, works on the following principle: the rod is fixed between two rollers (central and thrust), and with the help of a third roller (bending), the reinforcement is bent at the required angle. Conveniently, the machine for bending metal reinforcement can bend a rod both to the left and to the right. The required bending radius is ensured by the thrust shaft, thanks to which the reinforcement does not deform along its entire length.

Machines designed for bending reinforcement, including those made by yourself, can be of two types:

The main working element of mechanically driven machines is a rotating disk on which the bending and central fingers are fixed. There is a gap between these fingers, into which the rod to be bent is placed. The reinforcement placed in this gap rests at one end against a roller rigidly fixed to the device body. As the disc rotates, the bending pin acts on the reinforcement and bends it around the central shaft.

A specific machine for bending reinforcement, depending on its purpose, may belong to one of the following groups:

- light (for bending rods with a diameter of 3 to 20 mm);

- heavy (diameter of processed rods - from 20 to 40 mm);

- extra heavy (for fittings with a diameter of 40 to 90 mm).

Power driven equipment can be used to bend multiple rebar bars at the same time. Modern industry produces machines that can be used for bending rods whose diameter ranges from 3 to 90 mm. For those cases where it is necessary to bend reinforcement at different angles, it is best to use hydraulically driven equipment. Such a universal machine for bending reinforcement allows you to obtain a bending surface without cracks and folds, which can lead to the formation of internal stresses. This equipment also makes it possible to adjust the bending angle to 180 degrees.

You can make such bending devices yourself. However, they are used for bars with a diameter of no more than 14 mm and are not intended for cases where high productivity is required. Most often, such devices are used in private construction.

Devices for bending reinforcement

Today there are many different machines for bending reinforcement. They all operate on a similar principle, but differ structurally and technically. The most popular version of a bending machine is a device equipped with a central and thrust roller where the reinforcement is attached. The bending of the rod is carried out by the 3rd roller. You can bend it either clockwise or vice versa. With this machine you can bend a reinforcing bar to the required bending angle. For partial bending in the desired location, you can limit the bending area with a stop roller.

Modern craftsmen use 2 main types of bending machines:

- Manual type;

- Mechanical type.

All mechanical devices are approximately similar in appearance and structure. They have a shaft located vertically. A disk is mounted on it, which has bending and central fingers fixing its surface. On the stand of the bending machine there is a special roller where the rod rests at the moment of bending. There is a special method for bending reinforcing bars using similar devices. The product must be placed between the bending and central fingers. When the disc turns, the reinforcement rests on the roller. The process then involves a bending pin, bending the rod around the roller in the center.

All machines have differences in power and ability to bend particular reinforcement. Devices are classified by bending reinforcement by weight:

- Lightweight (diameter 3-20 mm);

- Heavy (diameter 20-40 mm);

- Extra heavy (diameter 40-90 mm).

Each of the machines serves a specific purpose. For example, on devices for extra-heavy reinforcement it is possible to bend several rods at the same time. If you need to process a large number of workpieces, then this option is very convenient. Today there are universal machines that bend 3-90 mm reinforcement.

Some purchase devices that have a hydraulic drive. They are provided with a large working space, thanks to which the machine can not only bend rods, but also create complex reinforcement structures. If necessary, the rod can be turned into a ring. Such a professional device will help you bend reinforcement at a high level: you can bend rods even 180 degrees. In addition, the products will be obtained without creases and folds, which will not allow the use of such reinforcement for construction purposes.

Manual devices for bending reinforcing bars are also in demand among craftsmen. There are both small portable models and large stationary ones. If you need to bend a reinforcing bar for your own purposes, you can use a special pipe bender. It can handle simple work, for example, bending rods with a diameter of no more than 14 mm. Typically, machines of this type are installed on a table or workbench for convenient use. For those who need to bend reinforcement constantly, this device is not suitable. You will need more expensive professional equipment.

In general, the choice of a rebar bending machine should be made taking into account 2 main factors.

- Product diameter;

- Number of blanks.

If the device is selected incorrectly, defects may appear on the surface of the rods. Under excessive load, they break or become compressed like an accordion. Therefore, it is important to first decide what kind of fittings you will work with. Based on this parameter, it is necessary to select equipment. Also remember about the correct setting of the device for better and more accurate bending of rods.

How to bend reinforcement without a special device

Quick option. The main thing is to have something to make cuts in the channel

With good physical preparation, bending reinforcement with your own hands can be done without using a machine, if its diameter does not exceed 8 mm. However, you should be prepared for the fact that the bend radius will be too large, and such bent reinforcement will not meet all the requirements that are placed on it.

A homemade device consisting of two steel pipes, with the help of which you can even bend large-diameter rods at home, can significantly improve the result. The diameter of bendable fittings can be increased by using longer pipes. The scheme by which such a homemade reinforcement bender works is quite simple: one end of the reinforcement is fixed in one pipe, and the second pipe is put on the free end of the rod. In order to bend the rod, you need to step on one of the pipes, and lift the second one, together with the end of the fittings that are in it, up. For more reliable fastening, one of the pipes with fittings can be clamped in a vice, dug into the ground, or even concreted.

How to properly knit and bend reinforcement for foundations: installation technology

In all modern foundations, construction is not complete without the use of reinforcement - interconnected metal rods that absorb tensile stresses when used in conjunction with concrete. The frame creates vertical and horizontal belts, serves to increase the strength of the structure and uniformly distribute loads.

If the reinforcement is weakly or incorrectly connected, it will creep apart, thereby compromising the integrity of the foundation. This will lead to its slow destruction. Tying the rods together is quite simple, but highly specialized specialists know well how to properly knit reinforcement for the foundation. The frame connection scheme is almost the same for all types of foundations, except for columnar wooden or metal ones, where a frame is formed on top of the pile head using reinforcement or beams. They are connected to the head and welded, in which case the rods or wire rod have to be bent at a specific angle.

Types of fittings used

Before starting to analyze the topic of how to properly knit reinforcement for a foundation, you need to understand the reinforcement itself. Indeed, today the market offers two varieties of it:

- This is regular steel.

- Composite.

Everyone has long been accustomed to using ordinary steel. But what is the second model, how does it differ from the first, and is it better?

Steel

Metal reinforcement consists of six classes, which differ from each other in the percentage of alloying additives. And the more of the latter, the higher the class, the higher the characteristics.

The reinforcing bars themselves are rods with a smooth or grooved surface. The first class is smooth, the rest are grooved.

The relief structure is an increase in the area of adhesion between reinforcement and concrete mortar. In addition, the protrusions act as restraining sides when the reinforcement structure begins to work in tension.

Rods with higher characteristics and sizes are too expensive, but they perform the same functions with not the heaviest loads. And the lower class reinforcement for foundations is rather weak. But we must add that even smooth reinforcement is used in reinforcing frames. It is not the main one, but it is used for jumpers, braces, ligaments and other non-loaded units.

When choosing, you need to pay attention to the product labeling, especially the indices. Here are just two of them:

- “C” is a designation that the reinforcement can be welded.

- “K” - anti-corrosion additives were added to the steel. This type is the most expensive, so it is not used in private housing construction.

As for welded reinforcement, it is also not the cheapest option. Therefore, for private owners, the best option is knitting with steel wire. As for the question of what kind of wire is used to knit the reinforcing frame, we will talk about it below.

Composite

This variety is a relatively new material. It is based on plastic, to which filling components are added: glass, carbon, basalt.

The most popular is the fiberglass variety, because it is simply cheaper than the other two with almost the same strength characteristics.

If we talk about the technical characteristics of this material, then:

- The tensile strength of plastic reinforcement is 1000 MPa, and that of steel reinforcement is 390.

- It is 3.5 times lighter than metal.

- Steel corrodes, plastic does not.

- It does not conduct electricity.

- It has low thermal conductivity.

As for the negative aspects:

- Metal reinforcement is better in elasticity.

- Plastic belongs to the category of slightly flammable materials.

- When heated, it softens.

- Fiberglass reinforcement can only be tied with clamps or wire; steel can be welded.

Today, clear recommendations on the technology of using composite reinforcement have not yet been developed, so experts recommend using it in foundations for lightweight buildings. It is better to lay steel under heavy ones.

Three methods of tying reinforcement cages

To form the metal frame of the base, three strapping methods are used:

- Welding. At first glance, welding is the simplest and most effective way to connect reinforcement, but in practice everything looks different. During welding, the metal is heated to high temperatures and deformed, which results in a partial loss of rigidity. You also have to hire a professional welder who knows about the properties of the metal and can avoid burning it, and this is an additional financial expense. There is also a risk of destruction of the welding site during operation of the industrial vibrator. Difficulties arise if you bend metal close to the welding site.

- Connection using bent wire or plastic clamps (ties). This method is popular among many developers, since the connection can be made with your own hands in a matter of minutes. If flexible wire is used, then a special tool must be used to connect the links. Plastic clamps are more reliable than wire, but are more expensive. The connection diagram is similar, only then you have to bend the rods at the required angle.

- Overlapping. This method involves overlapping reinforcement with further fixation with wire. It is practiced more for horizontal belts made of mesh, and a vertical smooth rod is used inside the joint.

Any of the above methods can be implemented with your own hands. In this case, you have to bend the metal, which is quite problematic, given the rigidity of the reinforcement and its minimum diameter for horizontal chords of 12 mm.

Ways and methods of tying reinforcement for the foundation

When creating a strip foundation for a private house, the reinforcement for the foundation plays a very important role; it eliminates the possibility of its deformation during seasonal soil movements and ensures integrity.

Each metal frame in a strip foundation consists of two or more horizontal tiers, which are fastened together by transverse rods (crossbars). All frame elements are connected to each other using electric welding or wire for tying reinforcement.

Reinforcement calculation

Before purchasing the required amount of reinforcement for the frame, it is necessary to carry out some mathematical calculations that will help determine the amount of material.

It is also important to take into account some features, such as:

- Corrugated reinforcement (metal rods with ribs) can withstand a greater load on horizontal structures than smooth reinforcement and provides better adhesion to concrete;

- When making calculations, it must be taken into account that the frame should not rest against the formwork, but should be located at a distance of 5-10 cm from it. This will protect the metal from exposure to air and moisture. For example, if the width of the concrete foundation strip is 60 cm, then the width of the frame will be 45-50 cm;

- Smooth rods can be used as crossbars to support longitudinal tiers.

If you plan to build a one-story house, then the distance between the transverse and longitudinal rods is approximately 50-55 cm. But if the building has two floors or a massive attic, then this distance is reduced to 20-30 cm, which significantly increases material consumption.

Options for bundles of reinforcement bars

In order to connect all the elements of the metal structure with each other, use mounting wire with a diameter of 0.8 or 1.2 mm, which is pre-cut into small pieces of 20-25 cm. Installation of reinforcement for the foundation can be done in several ways, depending on the tool used:

- crochet hook for reinforcement, this knitting method is described below;

- special clamps. In this option, special disposable plastic or metal clamps are used. This is how fiberglass reinforcement for the foundation is usually knitted.

Before knitting reinforcement for the foundation, you need to provide yourself with protective gloves and use only working tools.

Step-by-step manual twisting process

The fastest and most common method in private construction is knitting reinforcement under a strip foundation using a special crochet hook for reinforcement.

In order to do everything correctly and quickly, you must strictly follow the procedure below:

- the wire for tying the reinforcement is cut to a length of 20-25 cm and folded in half;

- we place the wire under the junction of the rods and insert the hook for tying the reinforcement into the loop;

- We tie the second end of the wire around the reinforcement connection and place it on the hook;

- then we rotate the crochet hook for the reinforcement clockwise, holding the second end of the wire so that the ends are intertwined;

- remove the hook from the loop and bend the ends of the wire inside the frame.

Using this simple algorithm of actions, knitting reinforcement for a strip foundation using a knitting gun is much faster and more efficient.

PS And for dessert, I suggest watching a video clip: Knitting reinforcement cages with a screwdriver

Knitting reinforcement with your own hands

With all the variety of specialized construction tools, not all private developers have the opportunity to buy or rent them. Knitting rods does not require expensive tools; moreover, you can do it yourself.

To do this, you need to purchase steel binding wire. It is quite flexible and durable, has a diameter of 2-3 mm. To bend it, you will have to use pliers or a specially made hook, which subsequently twists around the reinforcement and fixes it. Some craftsmen who perform reinforcement with their own hands sometimes use a screwdriver as a simpler and easier way to knit. If you knit with wire, you will need:

- One of the options for knitting the base frame using a hook. Craftsmen sometimes use a screwdriver as an easier way to knit reinforcement bars with their own hands.

cut a piece of wire about 30 cm long. You can do more if you don’t mind it, but the ends will get in the way (including excess waste);

- then fold the wire in half to increase rigidity and strength;

- bend it diagonally around the reinforcement joint and make a small loop;

- Place the hook in the loop and twist clockwise evenly, without unnecessary effort, until it becomes difficult to wrap or the connection becomes strong enough. The main thing is not to use force, since it is easy to break the wire and then you will have to start all over again;

- Cut off the ends of the wire with pliers and discard.

In the case of reinforcement of a columnar foundation, the reinforcement cage can be bent and then fixed to the heads with special clamps. Some manufacturers already supply metal or wooden piles with special clamping brackets and couplings. In this case, it is enough to bend the rod and insert it into the bracket. Clamp the bracket and boil it on top; you can do all this yourself, using a minimum of tools. In the case of using smooth reinforcement, the tying process is more labor-intensive, since the hooks will constantly bend and cannot be done without a specialized tool at hand, as well as without outside help.

Materials and tools used for reinforcement

Since the reinforcement cage increases the stability of the structure by taking on a significant part of the load, its quality becomes fundamental. The frame is formed from interconnected reinforcing bars. Various are used for knitting the frame:

Types of fittings

Manufacturers offer fittings that can be divided into:

Material of manufacture. Steel reinforcement is a classic, time-tested option; It is divided into 6 strength classes, it can be bent and welded. Composite reinforcement contains carbon, basalt, glass or aramid fibers. It is lighter, cheaper, does not corrode, does not bend and cannot be welded.

Reinforcement with a periodic profile has improved characteristics

Profile. Reinforcement with a smooth profile is more often used as connecting jumpers. Reinforcement with a periodic profile has a relief surface, which improves adhesion to concrete.

Connection materials

Knitting of reinforcement for a strip foundation, the pattern of which can change, is done using:

- Knitting wire.

Reliable and common knot connection technology. There are different knitting patterns.

- Threaded and crimp couplings

(at places of mechanical joints).

- Metal paper clips.

The reinforcement elements are connected without tying a knot.

- Plastic clamps and clips

(fasteners). Plastic products provide simple and quick installation and are resistant to corrosion. Their use is not approved by all professionals.

Composite reinforcement bars secured with a clamp

Welding. The process is fast, but the welds form a rigid connection, differ in density from the base metal and are susceptible to corrosion. When the load changes, they burst and reduce the strength of the foundation. The method is suitable for connecting rods of large diameters (in industrial facilities); To obtain a high-quality weld, you need a highly qualified welder.

Types of tools for tying reinforcement

Tying reinforcement for a strip foundation is considered more practical than welding: the strength in the nodes is not reduced, a qualified welder is not needed, the work takes place directly in the formwork (or nearby). A spatial frame made of reinforcement can be assembled either manually (which is not easy to do with gloved hands) or using a tool. For knitting use:

Knitting gun. The fastest way. The gun is inconvenient to use in hard-to-reach places; besides, it consumes a lot of wire. Its main drawback is the price. Models from leading manufacturers cost about 30,000 rubles, a Chinese pistol is enough for 1 foundation.

Professional tool - gun for tying reinforcement

- Crochet hook.

It looks like a curved and sharpened nail with a handle instead of a head. It is often used as an attachment, clamped in a screwdriver chuck. The industry produces screw hooks that are effective in operation, but slow down the knitting process (they leave long tails).

- Folk remedies.

If the amount of work is small and you don’t have any tools, use pliers or make a hook from a suitable nail. It is impossible to obtain a high-quality result using a homemade product; this approach will invariably affect the strength of the structure.

About the reinforcement of a shallow strip foundation in the video:

Tying reinforcement for the foundation according to all the rules

It is quite possible to knit reinforcement using available materials. But it is worth noting that correctly tying the rods together does not guarantee compliance with all building codes and high-quality installation. Since the pattern of knitting the frame depends on the type of foundation, its size, thickness and type of material used. Therefore, you need to take into account several key rules:

- If mesh is used as a reinforcement frame, then the strapping must be overlapped.

- Taking into account the type and cross-section of the reinforcement, it is necessary to calculate the length of the bypass at the connection points.

- The rods must be bent strictly at a certain angle and evenly.

- The grade of concrete and working conditions at the joint are taken into account. The minimum overlap length is at least 25 cm.

If reinforcement is carried out at a height of 3 meters or more, then scaffolding or scaffolding is indispensable. The strapping technology turns out to be more complex, due to existing safety rules for working at height. Tying is carried out in three stages:

- First prepare the reinforcement and tie slings to it.

- Raise to the required height, level and place in plastic guides.

- Tie the rods using any of the listed technologies.

Work at height should be carried out only with several workers at a time, provide insurance and control the process of lifting the rods and then installing them in the specified places. Doing this yourself without insurance is strictly prohibited.

The cost of strapping is relatively low, since craftsmen can process several square meters of frame in an hour. And when using special knitting tools, it’s even faster. And they guarantee the quality of the knitting of the rods and compliance with all construction standards, especially since the rods will be bent with special pliers.

Tying the reinforcement of a strip foundation – Do-it-yourself foundation

The foundation is the main part of any house. Its service life, and therefore the comfortable living of its residents, largely depends on what the foundation will be. You can build a strong and reliable house only by knowing how to tie reinforcement when constructing the foundation of a building.

Step-by-step instruction

The beginning of the correct reinforcement of the strip foundation

To perform the work, hot-rolled steel of periodic profile of classes A3 and high-strength wire BP are used. The choice of diameters depends on the expected (design) load on the base. Installation work is carried out directly on the construction site.

After purchasing and delivering the material to the construction site, you must do the following with it:

- arrange by diameter;

- clean from dirt;

- align the rods (if required);

- cut workpieces of a given size.

Laying the finished reinforcement cage

Before proceeding with the installation of reinforcement blocks, it is necessary to install the formwork. Next, two belts are installed: lower (above the ground) and upper. Each layer is poured with concrete.

The work process itself consists of the following stages:

- drive clamps (pieces of rods) into the ground at the bottom of the foundation to form a protective layer of concrete;

- sequentially, lay all frame blocks;

- connect all joints of the nodes with knitting wire;

- check the installed elements.

Knitting steel frame

The best option is a strip foundation reinforced in a rectangle or square. This is due to the ability to easily identify and install the axes. Knitting is a labor-intensive process, but is considered effective.

The work is carried out manually, using a special hook or pliers.

For greater stability, the reinforcing frame is connected with a cage, and the corners are positioned at an angle of 90 degrees.

A piece of wire up to 30-50 cm long is cut, folded in the center and applied to the joint. Then, a hook is threaded into the resulting loop, the ends of the rods are inserted into it, which are subsequently turned out all the way, forming a strong bond.

There is another way of knitting - using mechanical tools: a screwdriver (special attachment) and an electric hook. In this case, the technological process is significantly accelerated.

It is more difficult to carry out reinforcement work at the ends of the foundation. Here it is advisable to use bent rods that reliably connect the adjacent ones. The blanks are attached to the block using harnesses (clamp), and reinforcements (U- or L-shaped) are mounted at the joints.

Useful tips and tricks on how to knit reinforcement in a strip foundation

Particular attention should be paid to the reinforcement of the corners of the building, i.e. in these areas the base bears the load in several directions. To avoid moisture ingress, the rods should not come into close contact with the formwork and the soil. The products are made from high quality metal that is rust-free and unused. It is not recommended to “grow” an already finished frame

There must be a calculation for any addition. Practical skills are required for tying reinforcement. During the work process, you can alternate different methods of connecting frame nodes. Knit reinforcement only if there are overlaps.

Why bend the reinforcement?

Creating corner connections by simply intersecting straight elements is a technological mistake. Such structures will not strengthen, but weaken the foundation and contribute to its delamination.

The right solution would be to bend the joining rods and overlap them. The size of such a corner overlap is made at least 80 cm.

The bend should be rounded, and the radius of curvature should be approximately 10–15 diameters of the structure.

Bent reinforcing bars are also used as connections for those structures that are subject to tensile and compressive forces: legs, hooks, clamps, staples, fasteners.

Purchased bending devices

Have you decided to pour the foundation yourself? It is better to bend rods for reinforcement with a professional tool.

There are many such devices on the market. Choosing the right one depends on the following factors:

Mechanically driven devices have a vertical shaft on which a disk is mounted. Two “fingers” are fixed on its surface - the central one and the bending one. Use a roller to bend the rod. It is fixed on the device stand.

All mechanical devices are divided into three groups. They can:

- Bend light elements (from 0.3 to 2 cm in diameter);

- Work with heavy reinforcement (2–4 cm);

- Bend extra-heavy reinforcement parts (up to 9 cm).

The machines differ in power and productivity, but the latter category assumes the ability to bend several rods at once.

There are also universal models that bend reinforcement from 3 to 9 cm. And equipment with a hydraulic drive allows you to create complex structural elements up to metal rings.

Stationary and portable manual bending devices are also available in the range. Pipe benders are popular; they allow you to bend a rod with a diameter of up to 1.4 cm. It is easy to attach such a tool to a workbench, but the device will not be able to handle large volumes of work.

Select devices taking into account the required bends and the fittings used. In order for the work to be of high quality, the correct setup of the machine is important.

Making a homemade device

The equipment can also be made at home, taking into account the diameter of the fittings. The dimensions of the device and the distance between parts depend on this.

The metal frame needs to be secured to the workshop floor by attaching legs. If the device is oversized, its base is bolted to the workbench.

A thrust pin and a rotating platform are welded to the frame. The first part can be made from a simple metal corner. The central and bending “fingers” are fixed to the turntable. The platform is rotated during bending using a lever.

Correct ways

The strength characteristics of the rod are preserved only by the cold bending method.

Bending reinforcement on a machine:

- Secure the rod between the thrust and central elements of the device;

- Move the rotary disk until it stops, pre-set to obtain the desired angle;

- Watch how the bending “finger” moves along the outside of the bend being formed so that creases do not occur;

- Thin reinforcing bars (up to 0.8 cm) are sometimes bent by hand, but this is dangerous and will not provide quality. For one-time bending, you can use two pipes. One of them must be secured by concrete or buried in the ground, and the second must be used as a lever.