The columnar type of foundation is used in private construction in suburban and suburban areas. For the construction of a wooden or frame one-story house, bathhouse, garage, outbuildings, and stationary fences, a foundation made of simple metal pipes is suitable.

This method of forming supports allows you to reduce the volume of excavation work, save money on the amount of concrete and the construction of formwork. The optimal choice of diameter and number of pillars makes it possible to significantly reduce the estimated cost and construction time.

Advantages of a columnar foundation

The columnar base is characterized by simplicity and speed of work. Installation of load-bearing pillars does not require the use of heavy equipment to dig a pit or trench. Concrete for filling the formwork can be prepared on site in a small mixer and poured yourself.

A pipe foundation is a type of columnar foundation and is laid according to the general rules for installing load-bearing supports. This method ensures precise geometry of the pillars, which guarantees uniform distribution of internal loads. The smooth outer surface of permanent formwork helps to resist the forces that arise during winter heaving of the soil.

The pillars are formed from pipes that are driven tightly into the ground and filled with concrete. To distribute permanent and temporary loads evenly across all pillars, they are connected with a grillage. The reliable grillage design reduces the risk of the building overturning due to soil heaving.

Advantages and disadvantages of a foundation made of PVC pipes

A columnar foundation made of plastic pipes has many advantages over a classic strip foundation:

- its installation does not require a large amount of land work;

- installation can be performed by one person;

- consumables are consumed significantly less;

- PVC pipes for external sewerage are not destroyed by external factors and serve as protection for concrete;

- the material is environmentally friendly and chemically inert, which makes it safe to use for the construction of bathhouses and residential houses;

- deepening the pillars below the freezing level of the soil makes the foundation stable - the building does not “walk” when the seasons change, as is often the case with the strip version.

Disadvantages of a columnar foundation made of plastic pipes:

- limited service life of up to 50-70 years (for comparison, a monolith has 100-150 years);

- insufficient strength for the construction of capital buildings - the maximum permissible load is up to 4 tons;

- subsidence of one of the supports can lead to the destruction of the entire structure;

- the need to insulate the above-ground part of the pillars to prevent them from cracking in severe (below -15) frosts.

Note! The columnar foundation formwork is built from sewer pipes for external laying (orange), which were originally intended for outdoor use.

Features of laying pipe supports

The limitation for a columnar base is the significant weight of the building. The use of metal pipes allows you to increase the bearing capacity of the foundation. The metal casing protects the concrete pillar from moisture penetration and destruction. Such pillars do not require additional reinforcement.

Depending on the weight of the building, climate zone, composition and soil moisture at the construction site, there are two ways to install metal supports as a columnar foundation: shallow and recessed.

On dry, non-heaving soils, the laying depth does not exceed 0.8 m. The supports are pressed into holes of smaller diameter, filled with concrete and tied with a metal channel or wooden beam at a distance of 30–40 cm from the ground.

Important! On sites with high occurrence of aquifers and unstable soil such as fine sand, sandy loam (a mixture of sand and clay), loam, clay, load-bearing pillars must be buried below the soil freezing mark. In the middle zone this mark is 1.2–1.5 m.

The wells are drilled to a depth of 1.8 m in diameter, which exceeds the size of the permanent formwork. Coarse sand is poured into the bottom of the hole and a metal pipe is inserted and filled with concrete. The concrete permeates the sand cushion, forming a stable base.

Where is a columnar foundation made of plastic pipes used?

This construction technology was originally used in places where the construction of a solid foundation was difficult.

It is used in the following cases:

- for light buildings - bathhouses, gazebos, verandas, outbuildings;

- for one-story residential and country houses made of logs, timber, frame panels;

- for building a stable foundation in areas with low soil freezing or nearby groundwater;

- for uniform transfer of load to the ground during construction on uneven terrain;

- for buildings with a basement.

The construction of a columnar foundation made of plastic pipes is a profitable solution in cramped material conditions. The quality of construction does not suffer, provided that the building is light and low-rise. Strengthening the concrete base of the pillars and increasing the bearing capacity of the foundation is achieved by laying metal reinforcement during the process of pouring the solution.

Calculation of the number of foundation pillars

To lay a foundation from simple metal pipes, it is necessary to determine the bearing capacity of the soil and calculate the expected loads on the foundation. But first, it is necessary to calculate the area of one support: with a pipe diameter of 30 cm, it will be approximately 700 cm2.

The most common type of soil (dense sand, sandy loam, loam, dry clay) has a resistance of 2.5 kg/cm2. The bearing capacity of one base element on such soil is 2.5 * 700 = 1750 kg.

On wet soil (fine and dusty sands of medium density) with a resistance of 1.5 kg/cm2, one column can withstand a load of 1050 kg. A resistance of 1 kg/cm2 of wet loam and clay allows 700 kg to be distributed onto each support.

Calculation of constant loads on the foundation can be performed using averaged reference values, knowing the quantity and specific gravity of materials.

Constant loads include loads from building structures (walls, ceilings, roofs, foundations), finishing and insulating materials, plumbing, engineering systems, furniture and household appliances. Temporary stress on the foundation of the house is created by seasonal precipitation.

Having determined the required number of supports, they are placed on the plan at the intersection of load-bearing walls and along the perimeter in increments of 1 to 2 m.

DIY metal pipe foundation. Step-by-step instruction

After preparing the necessary materials, you can begin building the foundation. You must follow the instructions:

- Perform foundation calculations.

- Make markings.

- Drill a well.

- Secure the pipe.

- Fill with concrete.

- Connect the pillars.

It is impossible to build a foundation without preliminary calculations. You only need to work according to the project. The posts must be thick enough to support the load of the house. On heaving soils, columns can be displaced, which will lead to soil deformation.

To avoid soil deformation, the columns must have a cone shape. This gives the support a larger area and prevents pushing out.

Marking

It begins with clearing the area of weeds and smoothing the soil. Then the pegs are placed, between which the rope is stretched. All buildings can be depicted on the site plan. This will help to correctly position the buildings relative to each other.

Wells are dug under the located pegs. A garden drill is used for this. The diameter of the hole should be 60 mm larger than the diameter of the pipe. The depth of the well is 20 mm greater than the length of the pipe.

Fixing the pipe

Sand is poured into the bottom of the well and compacted well. A prepared pillar is installed on such a sand cushion. The space between the walls of the well and the pipe is filled with the remaining sand. Then you need to compact it, moistening it with water. This installation ensures that the supports are firmly mounted.

There is another method for installing supports: the wells are made smaller than the diameter of the pillars. This means that the supports need to be pressed into the ground with little force. This method does not allow you to install the posts as evenly as possible, so it is better to use the first option.

Fill

Filling is carried out only after the pipes are level. For this purpose, a concrete mixture is prepared from M500 cement. Then the solution is poured in small portions into the pipe. It is necessary to constantly pierce the poured solution with a metal rod to avoid the appearance of air layers in it. A concrete vibrator will help to significantly simplify the work, as it can reduce the time required to increase the density of the solution.

When the pipes are completely filled with solution, the work is left to dry for at least 7 days. It is necessary to provide the supports with protection from sunlight.

Read this article on how to prepare concrete yourself.

Carrying out work on laying a columnar foundation

The site for the foundation of the house is prepared according to a pre-developed plan. The perimeter of the building is outlined, the places of future supports are staked. Remove the fertile soil layer and level the surface.

Wells are made using a hand drill. The depth of the hole depends on the chosen method of laying the pillars. The diameter of the hole should be slightly larger than the size of the permanent formwork. For the construction of residential buildings, steel pipes with a diameter of over 250 mm are chosen as load-bearing supports.

Concrete is prepared in a mechanical or hand mixer. To 1 part of M500 cement add 6 parts of sand and gravel mixture.

Important! Adding a plasticizer to the solution will help improve the mobility of concrete, which will eliminate the formation of voids in a monolithic structure.

Technology for installing buried foundation pillars:

- A sand cushion is compacted tightly at the bottom of the well;

- The body of the metal support is insulated with bitumen mastic;

- The pipe is buried in a sand cushion and fixed vertically;

- Pour the solution so that it saturates the sand cushion;

- The formwork is fixed in a vertical position and allowed to wait until the base hardens;

- To increase the strength of the base, a reinforcement rod is inserted inside the pipe, which must pass through the concrete base;

- The metal body is filled with concrete to the top edge;

- The space around the pillar is compacted with sand and soil.

During the process of constructing a foundation made of metal pipes, they ensure that the entire supporting system is at the same level. The height of the above-ground part of the supports should be 40-50 cm. After the concrete has hardened, you can begin constructing the grillage.

Work technology

A columnar foundation made of polyvinyl chloride pipes begins with a set of preparatory work, which includes preparation of the building site and the building material itself.

The area allocated for construction should be cleared of debris and vegetation and carefully planned. Along the perimeter of the building, stakes are driven in to mark the corners of the building and the location of the pits. The stakes are connected with construction cord. Plastic pipes are cut to size, but it is important to remember that the length of one column must be greater than the freezing depth of the soil.

Drilling for piles

Wells for plastic pillars are drilled in the same way as for bored piles (these foundations have similar construction technology). Piles and pillars represent individual supports that carry the load from the building. Piles can be cast in permanent formwork, almost the same type as pillars. We should not forget that the size of the well must be at least 5 cm larger than the diameter of the pipe.

If the pillar will be erected with a widening at the bottom, a similar widening should be made in the ground when drilling wells.

It is possible to drill wells for all foundation pillars at the same time, but this method is only suitable for strong soils. In crumbling soils, it is best to drill a well, install plastic pipes (formwork) with your own hands and lay concreting, sequentially for several support pillars.

Next, do the columnar foundation with your own hands according to the following scheme:

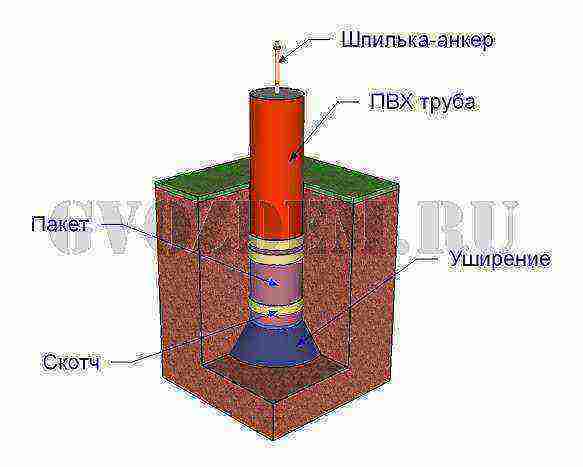

- PVC pipes cut to size are installed in pre-prepared wells as formwork. To form a widening at the ends of the pipes, a plastic or polyethylene bag of sufficient size is secured with tape - when filled with concrete mixture, the bag is an example of the shape of the widening previously prepared in the ground.

- PVC pipes for constructing pole formwork with your own hands should be carefully placed in the wells at the same level, checking the verticality with a laser building level.

Reinforcement and filling with concrete

Reinforcement of plastic pipe formwork is performed slightly differently than for a bored pile. Reinforcing bars are inserted into the plastic, which are bent at the end at 90 degrees if the pillars are erected with widening. For light buildings, when widening of the supports is not provided, it is sufficient to use conventional ribbed steel reinforcement.

Next, pour the concrete mixture inside the plastic formwork with your own hands. The pillar should be poured with concrete mixture in two steps: first, the widened heel is concreted, for which part of the concrete is poured and the shell is raised. The concrete mixture fills the plastic bag, forming a widening of the base. Then the concreting of the structure is continued, pouring in the concrete mixture until the formwork shell (pipe) is filled to the top mark.

Watch the video on how to pour concrete into a pile with your own hands.

A special device (pin) is installed on top of the support column (piles) for fastening structures of a suspended grillage or walls. The hardening time of the concrete mixture in a plastic support does not exceed several days; during this time, the top of the column should be moistened and covered with polyethylene.

Grillage

Bored piles and a columnar foundation are required to be equipped with the construction of a single load-bearing belt, which is a grillage. Pillars and piles can be equipped with a hanging grillage, which is made of lightweight materials, performing a protective and decorative role. A more powerful ground grillage is used to connect pillars (piles) to finish external surfaces with heavy facing materials, as well as to ensure heat conservation, protection from high humidity and low temperatures in winter.

Watch the video on how to make a grillage.

A grillage belt combines supports of this type, such as piles and pillars. A ground grillage on a columnar base can be erected from monolithic and prefabricated reinforced concrete, brick and rubble stone. A heavy grillage will require the construction of a separate shallow band support.

In this article we will describe another type of columnar foundation using permanent formwork made of plastic pipes (PVC) for external sewerage.

Recommendations for constructing a foundation from pipes

Work can be carried out in any weather conditions. But it is very important to do everything correctly.

Basic recommendations:

- The metal body is protected from corrosion with bitumen mastic or several layers of roofing material;

- If pipes of the required diameter are not available, several smaller pipes can be installed in one well;

- Before the concrete hardens, a threaded pin is placed in the upper part of the post for convenient fastening of the grillage elements;

- After pouring the concrete, construction continues within 7 days;

- You can use a wooden beam, a steel channel, an angle or pipes as a support frame;

- Ready-made supports must be loaded before the soil begins to freeze;

- Additional supports should not be installed for safety reasons. With the light weight of the structure and heaving soil, the increased base area contributes to the extrusion of the underground structure.

Required Tools

In order not to waste time during construction work, it is worth purchasing the required tools in advance:

- Shovel;

- Master OK;

- Hand mixer or concrete mixer;

- Boer;

- Construction level and tape measure;

- Black marker;

- Containers for solution (large buckets);

- Cord;

- Sledgehammer;

- Bulgarian.

Materials:

- Fittings (0.5 m longer than PVC pipes) at the rate of 3 pieces per post and wire for tying;

- Fine crushed stone;

- Wooden pegs;

- Cement grade M300 or M400;

- The required number of external sewer pipes with a diameter of 110-180 mm.

After purchasing the necessary materials and equipment, you can begin the installation work, which consists of several stages.

Design and preparatory work

For a columnar foundation, it is necessary to draw up a project; the following information will be required as initial parameters:

- the nature of the soil and the characteristics of its behavior;

- soil freezing level;

- depth of groundwater, probability of floods;

- volume of precipitation in winter;

- the total mass of the superstructure, which consists of the weight of the material for the walls, ceilings, roof and other additional loads.

Based on the initial data, determine:

- Depth of the columnar foundation.

- The diameter of the pipe, which depends on the material used and the design load on the base.

- Number of pillars and frequency of their installation.

Advice! It is advisable to place the supports below the soil freezing line.

The arrangement of a columnar foundation begins with marking the area according to the design documentation. Pipe holes are formed using a hand or gasoline drill. The drilling depth exceeds the soil freezing line by 30 cm, approximately this value is 150-180 cm. The diameter of the hole depends on the size of the pipe chosen as support for the columnar foundation. The pillars should rise approximately 50 cm above the ground. Further actions depend on the type of pipes selected.

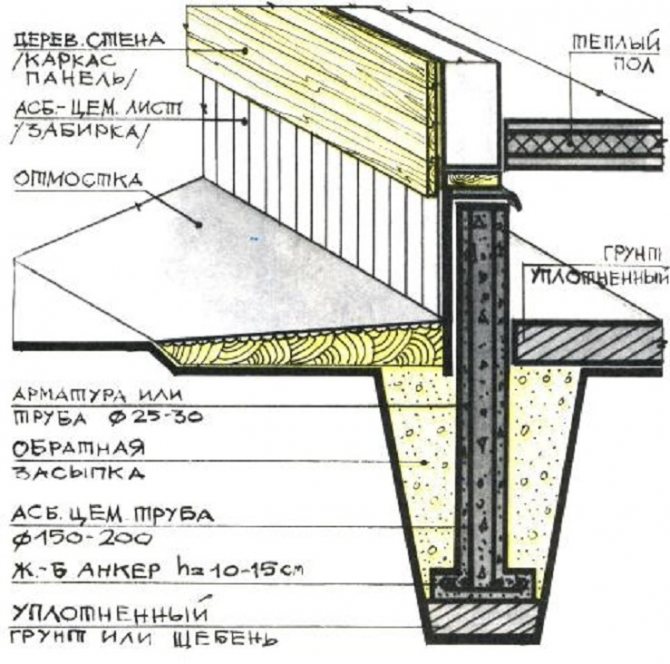

Construction of a foundation from asbestos pipes

Asbestos-cement supports require additional strengthening with reinforcing bars. Approximate dimensions of the pillar: height – 200 cm, diameter – 20 cm. After it is immersed in the well, actions develop along one of the following paths:

- metal fittings are being installed;

- concrete mixture is poured.

The essence of arranging a columnar foundation in the first way:

- Rods are installed in the pipe at a distance of 6-7 cm from each other.

- The approximate length of the rods is 250 cm; they should sink into the ground and protrude outward from the pipe by 20 cm on each side.

- The upper part of the reinforcement is used to connect to the grillage.

- After completing the frame, the pipes are filled with concrete.

Drying of the columnar foundation lasts within one week.

The application of the second option is as follows:

- The support is filled with 1/3 concrete mixture.

- The pipe is raised 10-15 cm so that the concrete at the base spreads, forming a base for the columnar foundation.

- The important point is that all raised supports are the same height. The reinforcement cage does not protrude beyond their edges.

- Next, the support is completely filled with concrete, a pin is fixed at the top, which rises 30 cm and serves to connect the pipe and grillage.

Comment! If the soil under a columnar foundation is highly friable, before installing the supports it is necessary to create a sand and gravel cushion, which must be covered with roofing felt.

Treating them with protective compounds will help prevent premature damage to reinforcing bars due to corrosion.

Plastic support structure

As in the previous version, the process begins with leveling and marking the construction site. The work is carried out using pegs and thread or rope.

The main stages of forming a columnar foundation using sewer pipes:

- A trench is dug along the perimeter, in which the installation points of the supports are marked.

- The weight of the future structure and the characteristics of the soil determine the interval between the pillars, which should not exceed 2 m.

- Before installing a plastic pipe, a drainage cushion of gravel and sand is made at the bottom of the well. The waterproofing function is performed by polyethylene or roofing felt.

- The recess is filled with a mixture of concrete and left for an hour for the solution to set.

- After the allotted period of time, a plastic pipe is installed, which is pressed in until it stops.

- Further inside the column, reinforcing rods are installed, which protrude beyond the edges by 20-25 cm.

The setting period of concrete in a columnar foundation lasts 6-8 days, depending on the ambient temperature.

Features of using metal pipes

The formation of an iron column structure also has two options. In the first case, the supports are installed 50 cm below the level of the drilled well. It is not important to choose a metal pole with a diameter of 20-25 cm; you can install two or three supports of smaller thickness. In this case, the gap between the pipes is up to 5 cm.

Important! This method involves the formation of a grillage using a steel profile, which is welded to the pipe.

The proposed algorithm for arranging a columnar foundation is characterized by high reliability of fixation and provides the structure with maximum strength.

The second method requires the preliminary formation of a drainage cushion based on sand and gravel. The diameter of the pillars is 15-20 cm. Since the metal support must fit tightly to the walls of the well, when drilling its base is reduced by several millimeters. The next stage is filling the pipe with a solution of cement and sand. If a construction above one floor is planned, there is a need for additional strengthening of the columnar foundation with a reinforcement frame.

After five days, after the concrete has hardened, they proceed to forming the grillage. It can be made of wood, a metal profile or in the form of a strip foundation. The choice depends on the severity of the entire structure.

Pouring concrete into formwork

Figure 3. Installation of formwork is carried out approximately at the level of the lower plane of the future grillage.

Having collected a bucket of concrete, pour it inside the plastic pipe. After pouring about 2 buckets of concrete, pull out the plastic pipe from the top to a height of 10-15 cm. In this case, the poured concrete will crawl out of the plastic pipe and spread along the widened part of the hole, forming a thickened heel of the pillar. This heel increases the area of pressure on the ground and will not allow the column to be squeezed out of the well during soil heaving in severe frosts. Then they fill the well around the pipe with the existing soil and, controlling its verticality, compact it with a long object.

To form the heel, some people use a method with a garbage bag attached to the bottom of the pipe. This is necessary when the diameter of the well is much larger than the diameter of the plastic pipe. Then the level of poured concrete can rise along the well to the level inside the pipe, and it must be limited. However, if the diameter of the hole is 5-10 cm larger than the formwork being inserted, then after lifting the pipe, the poured concrete occupies only the expanded space of the well. At the point of contact between concrete and soil, a stable adhesion is formed. It does not have enough energy to rise higher, and during further filling this is prevented by the soil filled and compacted on top.

In addition, when installing the formwork, the plastic bag may become wrinkled, and after pouring and hardening of the concrete, the heel may become disconnected from the body of the column.

Next, reinforcing rods or the made frame are inserted or driven into the plastic pipe into the already poured concrete so that 20-30 cm of reinforcement rods remain above the pipe (for connection with the grillage frame).

Figure 4. When pouring concrete into a pipe, it is important to compact it thoroughly throughout the entire pouring stage.

To increase the adhesion of the heel to the body of the post, some people insert a reinforcement bent with a hook at the end, which is turned before pouring. This can be unnecessary work and a waste of time because the ribs of the reinforcing bars adhere quite well to the compacted concrete, and therefore such precautions are unnecessary. When building a frame house, the timber frame is connected to the post using a pin with nuts, which are first poured into the concrete of the top part of the post.

After pouring each bucket of concrete, it is carefully compacted with a metal rod or a construction vibrator. When bayoneting using reinforcing bars, in order not to damage the above-ground part of the formwork (that is, so that the plastic pipe outside the soil does not crack during bayoneting), clamps can be placed on top of it or tightened by other means. You can put a metal pipe on it, the inner diameter of which is approximately equal to the outer diameter of the plastic pipe.

Next, several more buckets of concrete are poured into the pipe, filling the pipe to the level of the ground surface. Then, using a hydraulic level or laser level, mark the plane of the lower part of the grillage on all PVC pipes and cut the pipes to this level. Then concrete is poured to the edges of the pipes and left to harden completely (Fig. 4).