The porch is an important element of any building - despite its apparent insignificance, it is impossible to do without it. This is especially true for buildings with a high base, where the entrance from the street is located at a significant height from the ground level. However, in most cases, during the construction of a house, the foundation for the porch is neglected. Most often, the construction of the porch begins after the completion of the main work on the construction of the main building.

Types of house porches

The selection of the fundamental basis depends on the type of porch that is attached to the house. Owners of their own cottages and summer residents choose one of the options:

- open, which has a canopy and railings. The canopy may not be in contact with the main structure - it is supported by vertical pillars (piles or racks);

- closed, performing the functions of an independent room. The walls of the object are formed from translucent polycarbonate or glass. A gazebo or terrace extension requires a slab base;

- hinged, justified by the presence of a ground floor or basement. The product resembles a balcony and is also located on racks.

According to the shape of the protrusion, the thresholds are round or rectangular, are in contact with the load-bearing wall, and are equipped with steps. The choice of foundation laid under the porch - an extension to the house - is determined by the size of the entrance opening, the type of soil and its composition. Practical builders recommend designing the base as a slab, strip or columnar type. The basement structure should be correlated with the dimensions of the building.

How to assemble a porch on screw piles

Many years of experience in the use of screw pile tubular supports confirms the high degree of stability of the supports on soils replete with “water pockets” at the depth of soil freezing. The weight of the largest and most massive porch can easily be supported by a steel frame supported by screw piles. Each of these support pile points can withstand a load of at least three tons. The number of screw supports in this case is determined by the size of the porch and the weight of the entire structure of the building.

What are screw piles and how are they used?

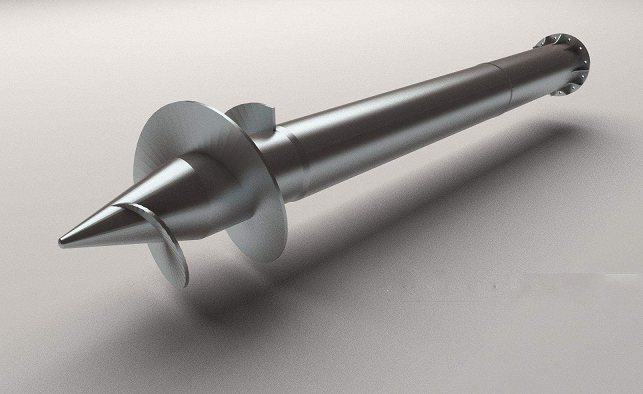

Screw piles are long steel pipes with a specially shaped tip. Most often it is a conical tip with a short cutting edge in the form of a screw. When rotating, the auger surface cuts and squeezes out soil along the peripheral surface of the pile. For clayey and sandy soils, compaction and extrusion of the soil occurs simultaneously at the point of contact with the metal. The depth of penetration of screw pipes depends on the nature of the soil, but rarely exceeds a meter. The information in the video will help you use the screw pile structure correctly.

Most experts consider the use of screw supports for the porch justified for a number of reasons:

- The assembly of the foundation on pipes is carried out in a record short time, without preliminary preparation and planning of the earthen surface;

- The cost of assembling the foundation for a house or porch is significantly less than similar options using a concrete foundation;

- It is quite possible to install screw pile structures with your own hands without a significant reduction in quality. To do this, you can use a special machine or a hand-held device made from an industrial gearbox;

- Screw piles can be easily screwed in even in close proximity to the foundation of the house, which is not recommended for any other supports.

When the pile is screwed in, the auger nozzle compacts a part of the rock in front of it, and after completion of the work, this part of the soil serves as the main part of the surface on which the steel support rests.

If, during the drilling process, the screw pile encounters a rocky vein or, worse, a layer of sand or clay saturated with water, the installation process of the pile is stopped. In the first case, the pile can be cut to the required size of the head if more than half of the support body has been screwed in. In the second case, the pile is either pumped with concrete mixture or removed. Such a screw support cannot be used for the foundation of a house, but it is quite possible to use it as a support for the frame of the porch of a house.

After screwing in all the screw piles, the caps, with the help of which, in fact, the force was transmitted from the drilling machine or device to the pile rod, are cut to one level of the general steel frame. Sometimes, instead of support platforms, screw jacks are installed on the pile. In this case, you can accurately set the level of the steel support frame along the horizon.

Stages of building a porch on screw piles

In this version, it will be possible to build a porch in three stages:

- Marking the supporting surface, driving screw piles into the ground. For a standard 3x1.5m terraced porch, four to six screw support piles will be sufficient;

- A steel support frame from a channel or brand is assembled on screw supports by welding. This procedure is more often called strapping. If the porch is made of lightweight material, the frame can be made with your own hands from larch or oak timber;

- A box formed by a beam - a longitudinal wooden beam, and semi-jogs - transverse beams made of timber - are laid on a welded or knocked-down frame. The box is attached to the frame using long galvanized bolts. The surface of the box is sewn up with a board with your own hands and thermal insulation is laid; if the porch, supported on screw piles, is intended to be made of a vestibule type, insulation may not be used for open terrace structures;

- A staircase and railings are attached to the assembled box. In the corners of the porch area, you can weld vertical posts made of steel profiles to the screw supports with your own hands. The length of the profile is chosen taking into account the extension of the screw piles above the ground surface, so that their height above the porch platform is at least 120 mm;

- Vertical posts made of metal profiles are tied together with a wooden beam with your own hands, as in the photo, and then the railings are mounted.

Advice! Before drilling, you should always perform two or three test points to check exactly what kind of soil is below the soil surface. Therefore, drilling a screw pile requires doing preliminary soil exploration with your own hands.

Most often, screw piles are purchased ready-made and screwed into the ground with your own hands, or a supporting surface made of piles is ordered from a contractor. Such offices, most often, use powerful drilling machines to work with screw piles, as in the photo, and therefore are capable of driving 10-20 piles in a relatively short time of 10-12 hours.

To install 5-6 screw piles under the base of the porch, it is easier to use a manual gearbox and a device, which is well described in the video

Often, such a pile is wrapped with your own hands or in an unusual way by a group of three people. Two of them, using a long steel pipe with a shoulder of at least one and a half meters, wrap the screw pile, the third, with its weight, creates a vertical load, forcing the support to bury itself in the ground, as in the photo.

Important! Most screw piles are sold either painted or galvanized. If the area is located on a salt marsh, you can use only galvanized options with protective mastic coating the entire ground surface of the support.

When screw piles are screwed into the ground, almost the entire surface of the pipe experiences strong abrasive friction, which easily strips off any paint coating. Galvanized pipes are more resistant to metal corrosion in the ground. Sometimes, to reduce the effort to overcome friction, a special solution is supplied into the drilling cavity with your own hands; it acts as a lubricant and a damper at the same time. After a certain period of time, the solution hardens, as if gluing the pile to the surface of the soil.

Disadvantages of using screw piles

In addition to the effect of loss of the bearing capacity of a screw support as a result of sinking to depth, the support can rise as a result of freezing groundwater. In both cases, this leads to deformation of the steel frame and even destruction of the building.

Base in the form of a monolithic slab

Monolithic structures are necessary on heaving soils with close proximity to soil water. In dense soils, with good stability and an optimal level of moisture, the foundation of the porch is not buried; on problem soils, a floating one is created.

Construction of a floating shallow slab

The structures are relevant for small country houses. Thanks to the expanded support area and high load-bearing capacity, the product is optimal for strengthening your threshold. Due to their thickness, the lower layers of the slab disperse the load of the upper layers. Technologically, the process of arranging a shallow floating slab occurs in stages:

- The area is marked - a rope is pulled on the pegs. The stakes are placed in the corners of the future foundation.

- 30-50 cm of soil is removed along the contours of the resulting figure.

- The pit is leveled, watered and compacted. The side parts must be compacted.

- A geotextile is laid along the bottom of the ditch to provide support for the sand layer.

- Sand is poured layer by layer. Every 40-50 mm, the material is watered and compacted with a vibrating plate or wooden beam. Sand is poured to a depth of 15-30 cm.

- Reinforcing material is laid and the base is poured.

- After the concrete layer has completely matured, roofing material waterproofing is laid on it. Moisture protection is not needed when pouring steps and building a door.

A slab shallow foundation for a porch is installed in one go. Interruptions in construction activities will compromise the density of the concrete.

Monolithic slab with thick ribs

The technique of building a slab with thickened side parts is reminiscent of the formation of a floating structure. Structurally, the slab base consists of soil with a compacted sand cushion, on top of which insulation, waterproofing and blind area are laid. The construction process includes the following work:

- Drawing up markings, digging a pit and compacting the soil.

- Laying waterproofing in the form of rolled roofing felt. The sheets are placed with an overlap of about 10 cm.

- Pour a layer of sand 5-7 cm thick, moisten it and compact it.

- Pour a layer of mid-fraction gravel or crushed stone 10-15 cm high, compact it or water it with cement mortar.

- Laying a reinforcement cage in the form of a mesh, installing formwork on moving soils. The material for the wooden frame is sealed with roofing felt, polyethylene film or roofing felt.

- Layer-by-layer pouring of a concrete slab. The structure must be sealed with metal pins to eliminate air.

To prevent the concrete solution from drying out or cracking, it is watered with water in the evening and also covered with a tarpaulin. The formwork frame is dismantled after 5-7 days; 20-30 days are allotted for complete hardening of the slab base.

How to make a base for a wooden porch

A wooden porch is a common solution that will cost the owner inexpensively and will be completed in the shortest possible time. This option requires much less labor than a cast-in-place concrete porch, which is why it remains one of the most popular options. However, despite its light weight, such a foundation needs a foundation, and it must be built with strict adherence to construction technologies.

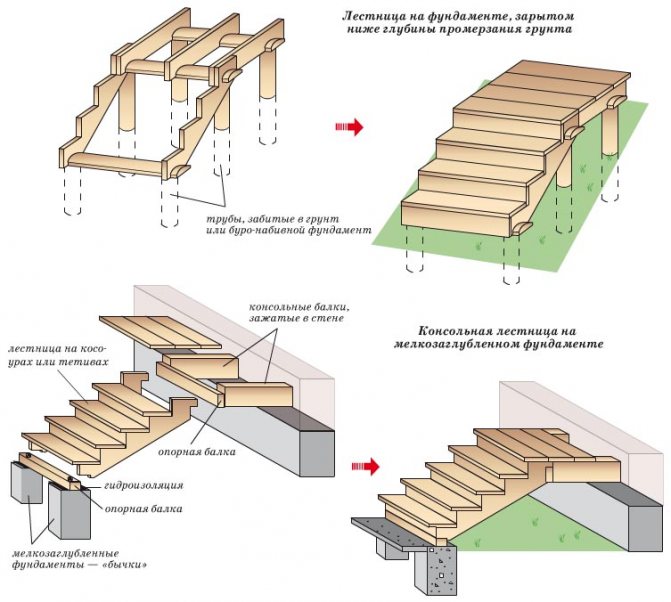

The wooden porch consists of a platform in front of the house and directly a staircase with plank steps. For a site, the most common solution is a pile or columnar foundation: it is located on support pillars dug into the ground and additionally filled with concrete. For the lower edge of the stairs, you will need to lay a concrete base that will support the weight of the steps and the residents of the house themselves.

The columnar base for a wooden porch is built as follows:

- Design work. The number of pillars and their location depends on the size of the area: it can be a small practical porch or a small veranda with various options for filling the walls.

- Preparing holes for pillars. To install the pillars, a site is marked and holes are dug at points of greatest load. Their depth should be about 80 cm; you can prepare holes in the ground using a drill.

- Pillars made of durable timber, pre-treated with an antiseptic, are inserted into the pits. After which the space around the pillars is filled with concrete to create a strong and reliable foundation. It is important that the pillars are installed strictly vertically; their location is checked using a plumb line.

- Once the concrete has hardened, you can install the porch frame on the posts, to which the joists are attached. After installing the boardwalk, the site will be ready, and you can proceed to installing the steps.

Usually the pillars are located at a distance of a meter from each other, their height depends on the height of the basement of the building. The pillars are placed in such a way that the platform is located a few centimeters below the front door. A wooden door swells with high humidity, and it will not be able to open if the platform is located at the same level with it.

In the place where the wooden staircase will rest on the ground, it is necessary to prepare concrete embeds. It can be 2 or 4 columns, or you can prepare a full-fledged support platform, the width of which will be equal to the width of the porch.

For this, a shallow hole is prepared, a layer of sand and gravel is poured into it and concrete is poured. After hardening, it will be possible to place a ladder on it, and it will withstand even high loads.

Threshold on a floating base-tape

Do-it-yourself construction of a strip foundation for a country porch will save the owner’s budget. Unlike the slab type plinth, the work is carried out independently, and less materials are consumed. The design is justified for uneven terrain, as well as for houses located on clay, sandy soils and loams. Filling of the floating tape is carried out according to a step-by-step algorithm:

- The territory is marked with the formation of the internal and external contours of the base. The distance between them is equal to the optimal strip width - 30 cm.

- A ditch 60-70 cm deep is dug.

- A layer of roofing felt waterproofing is laid.

- Sand is poured in a layer of 10 cm. The bulk material must be leveled, watered and compacted.

- Further moistening of the pillow for shrinkage takes 2-3 days. After each watering, the material is compacted.

- The installation of a wooden formwork frame is carried out by analogy with the construction of a slab.

- A mesh of reinforcing pins is installed. The edge of the upper belt is lowered by 5 cm from the edge of the formwork, and the end of the lower one rises above the cushion by 5 cm. The reinforcing mesh is formed from metal rods with a diameter of 8-10 mm, fastened by welding or knitting wire.

- Cement mortar is poured. To prepare the composition, use 1 part water and 3 parts M400 cement. If necessary, a plasticizer is added. The mass is poured in layers.

After a week, remove the formwork, and then wait for the tape to harden (about 30 days).

Strip foundation

After marking and tensioning the center line, you should begin constructing a trench for installing the formwork. Since the porch is a fairly lightweight structure, a depth of 30-40 cm will be sufficient on solid soils. A trench is dug around the perimeter of the future porch along the axial cord so that after installing the formwork in it, the internal width is at least 25-30 cm.

This thickness of concrete tape is quite enough for the weight of light wooden structures. If the soil is dense enough and does not crumble, then it is possible to do without installing formwork inside the trench. It will be enough to put together the formwork on the surface, depending on the height of the foundation for the porch.

A frame made of reinforcement must be installed inside the formwork and trench. Corrugated fittings with a diameter of 8-12 mm, both steel and plastic, are quite suitable for this. The frame can be made by welding and installed in a trench, or assembled directly inside the formwork using tying wire. To do this, rods are driven into the bottom of the trench, and horizontal reinforcement threads are attached to them. After this, concrete is poured into the formwork.

It is advisable to fill the base in one step. If for some reason this is impossible, then at the place where the pouring is interrupted you need to make a slope of 45 degrees. This will prevent cracks from appearing in this area while the concrete dries and shrinks.

Construction of a columnar foundation

The foundation for the porch, which has the form of pillars, is relevant for the construction of small dimensions. For a small structure, 4 supports are enough - 2 near the building and 2 opposite. Practitioners recommend widening the supporting elements using a drill. Channels, asbestos-cement or wooden pipes are suitable for support. Activities for the arrangement of the foundation are carried out as follows:

- The site for installation of the support is prepared - plant roots and debris are removed from the ground, and stumps are uprooted.

- The territory is marked with pegs and rope.

- Depressions are formed in the ground, for which the technique of drilling or digging holes with a shovel is used.

- A grillage is installed for pillars buried 1 m into the ground. Grillage systems are made of reinforced concrete, and then connected to a pile base. The channels are driven in with a sledgehammer.

- The formwork is installed into which the supports are inserted.

- The pillars are given a vertical position by spacers.

- Reinforcement with a diameter of 12-14 mm is placed in the formwork.

- The pit is filled with crushed stone and sand mixture, and then filled with concrete in layers, watered and compacted.

To give the supporting products stability, each pillar is concreted while maintaining its verticality. The type of foundation intended for a do-it-yourself porch is determined by the configuration and parameters of the structure. A structure with a large mass needs a solid foundation.

Semicircular concrete porch

This option requires precise planning and careful markings on the ground. The construction of a round porch with your own hands is carried out taking into account the fact that its diameter must exceed the width of the doorway by more than 60-80 cm. So, with an entrance of 90 cm, the width of the line where the porch joins the house will be 150-170 cm.

After applying the markings, they begin to lay out the formwork. For semicircles, it is better to use sheet metal or galvanized steel - they cut well and bend evenly, or plywood, but before that it needs to be soaked to make it more pliable when working.

Before you make a semicircular porch with your own hands, you should dig a pit, lay and compact a sand and gravel cushion. Then:

- Install waterproofing.

- Tie the first underground tier of reinforcement and place a strip of formwork for the first step.

- Work is carried out similarly for subsequent steps with horizontal and vertical reinforcement.

When everything is ready, the concrete is poured, leveled, pierced in some places and left to harden for a week.

To save solution, you can make a porch as shown in the photo below.

Top 10 tricks to help build a solid foundation

Are you planning to build a foundation yourself that will strengthen the threshold and distribute the load of the house? Refer to the professional tricks of builders who recommend how to make a threshold correctly:

- carefully calculate the amount of materials and measurements of the structure when designing the porch. Correct calculations will create the basis for a solid foundation.

- prepare the area before starting foundation pouring activities. This will save time and stimulate the completion of construction tasks.

- not just level, but improve the quality of the soil adjacent to the house by 0.5 m. It is enough to dig a trench connecting the porch and the house. The channel must be filled with coarse crushed stone.

- reinforce the foundation. To build a small porch, thin rods are enough, and the veranda extension is built using thick metal rods.

- use a concrete mixer to prepare large portions of the solution. The equipment will qualitatively mix the mixture in the required quantity.

- rent a crane for arranging a block structure, which will save effort and time.

- make, if necessary, a connection between the base of the porch and the building - by drilling holes in the base. Reinforcing pins are inserted into them, which will be used for the threshold.

- do not skimp on the quality of materials so that the base remains strong and does not crack or deform over time.

- ideally, to carry out the simultaneous construction of a porch product and a country house.

- Always have a level, shovel and pencil with you.

Useful recommendations will help you create a high-quality foundation structure, ensure its reliability and durability.

Foundation made of FBS blocks

FBS blocks (foundation wall blocks) are used for the construction of house foundations. They are called wall ones because after construction is completed, the side walls of the blocks form the walls of the basement. Such a base can be used for the construction of building structures for various purposes, including porches. The height of such a block is 580 mm. To install them, it is necessary to prepare a trench slightly wider than the width of the block. The bottom of the trench must be cleaned and leveled in a horizontal plane.

After the bottom is ready, a sand cushion is built on it. If the foundation is being constructed on sandy soil, then it is necessary to make a frame from wooden beams with a cross-section of 50*50 or 100*100 mm. The width should be 200 mm greater than the width of the base of the block. The frame is laid on the bottom and leveled in a horizontal plane; a laser level must be used to level the frame. Sand is poured inside the frame, compacted and moistened with water.

When working with concrete, you must remember that after pouring it you need to take a certain break. It is necessary for the concrete to set and gain the required strength.

Is it necessary to match the base with the walls?

Construction experts note that the combination of the foundation poured under the porch attached to the house and the main building can lead to the formation of cracks on the wall. The reasons for the phenomenon are different periods of preparation of the solution, deepening of the structure, differences in mass and load. According to other experts, tying the base eliminates gaps between load-bearing walls and entrance groups. Developers are advised to study the properties of the soil, groundwater level, soil freezing and carefully calculate the likely risks of connecting the wall and the fundamental structure. A foundation for a porch designed using one of the technologies will be an opportunity to create a beautiful entrance group, a functional veranda or a summer gazebo. Independent arrangement of the foundation requires dacha owners to make accurate calculations and thoughtful actions in accordance with the chosen work algorithm.

Article Rating

Options for foundations for a porch to a house

As noted above, all the main types of foundations used in suburban construction can be used for the porch.