Everyone knows that a reliable load-bearing foundation is the key to the success of a future building. Even a light extension is no exception. It is clear that the foundation for a 3-story house and a light structure will be slightly different. Let's take a closer look at how to make a foundation for a gazebo with your own hands, their types, and choose the best option for your case.

A few recommendations when choosing a base

Types of load-bearing foundations and their choice

The bases for different structures are selected depending on the level of complexity of the building itself, this applies both to residential buildings and light buildings, in our case, gazebos.

The foundation of the gazebo may differ in the choice of material and the technology itself in the creation process.

What is recommended to pay attention to when choosing a foundation?

Pillar construction

- Plan your gazebo in advance and calculate the approximate weight.

- Pay attention to the quality of your soil on the site.

- The level of the soil also plays an important role.

Note. It doesn’t matter what kind of foundation you make for the gazebo yourself. It is important that it is reliable and practical for many years.

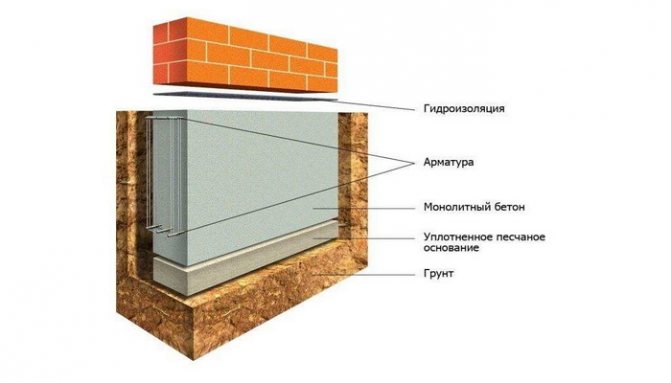

Tape for future construction: features and stages of work

This type of load-bearing base is used for more complex and heavy structures. This category includes:

- Brick structures.

- Gazebos made of timber or log frame.

Schematic drawing for a brick gazebo

This design also requires special attention

Note. In other cases, creating a tape will not be an entirely practical solution. Only if the site has a weak soil foundation.

If for some reason the gazebo requires a solid foundation, it is not necessary to pour the foundation for the gazebo with your own hands, but you can limit yourself to installing narrow ready-made concrete blocks.

Stages of work

The tape is perfect for those who want to create a structure of any complexity and type, as it can withstand any load.

If you eventually want to install a grill or barbecue of a complex model inside the structure, it is recommended to take care of a concrete mixture cushion.

Let's take a closer look at how to make a foundation for a gazebo yourself. What you will need to work independently:

| To accurately mark |

| You will need to dig a trench |

| If the base is very rocky |

| For backfill |

| Installation of formwork |

| For filling |

| Waterproofing |

| Armature |

Instructions for carrying out work

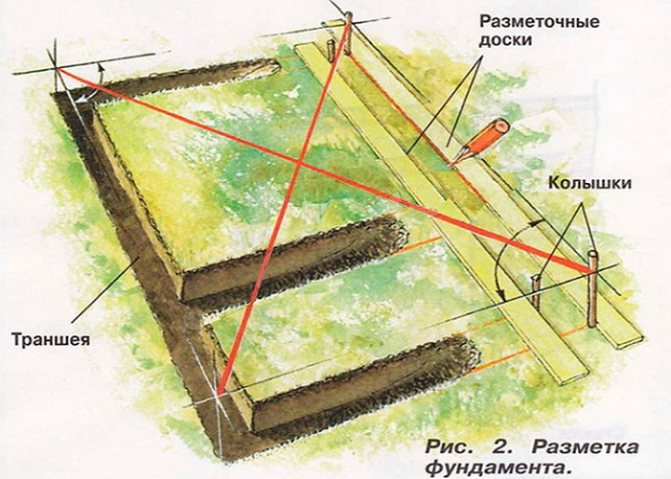

Marking for the base

| Site cleaning and marking: | Before making the foundation for the gazebo, as in any construction, it is necessary to clear the site for further work. Then, based on the created project, we make markings and hammer pegs in the corners. At the same time, we strictly observe the dimensions of the future structure. We fix everything with a cord and measure the diagonals (they should be the same. The same work needs to be done on all sides every 20-30 cm. |

Gazebos, foundation: making a trench

| Making a trench: | Next, we dig a trench along the entire perimeter, relying on the previously completed markings. We take a shovel in our hands and go ahead. In this case, a mandatory condition: maintain a clear verticality using a plumb line. The depth of the pit should be from 60 cm to 1m 50 cm. This value depends on the soil foundation and the depth of the water. |

Creating a pillow

We fill in 10 cm of sand and tamp it down, and then gravel and tamp it down.

Formwork, concrete mixture as support.

| Making formwork: | Before pouring the foundation for the gazebo along the entire perimeter, you need to organize a 40 cm formwork. The frame is made from reinforcement and sheathed with plywood or boards. The inner part is poured with concrete evenly. Be sure to level it, cover it with plastic and leave it for a month. |

Advice. If you have the financial means, but not enough time, you can use one of the options: ready-made blocks or bricks.

After the time has passed, we install our design.

Block foundation

This type requires minimal labor. This is the simplest foundation. To install the gazebo, you should use rectangular blocks without holes. It is best to use products measuring 20x20x40 cm. They are easier to both transport and install.

Example of a block foundation

Step-by-step instructions for constructing a foundation

First stage. Marking

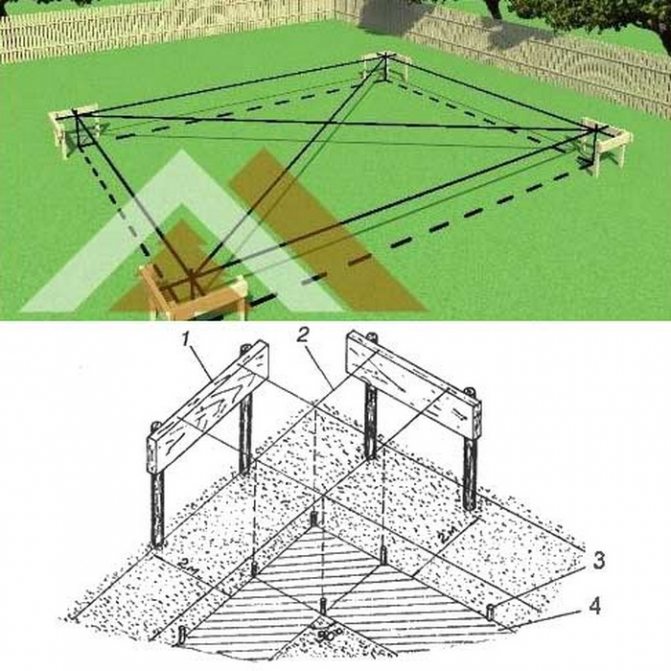

There are a number of special techniques for marking the foundation. You should study them carefully before starting work. Twine is used for marking, which is then secured with metal or wooden pegs.

Marking for the foundation

Attention! The foundation must be wider than the planned wall or support. This should be taken care of in advance.

Second phase. Excavation

The area of the pit for installing a concrete block is 1.5-2 times larger than the area of its base. The depth of the pit depends on the type of soil on which the building is being built. Typically the depth is between 150 and 300 millimeters.

Third stage. Preparing the base

The resulting shallow holes are filled with crushed stone or sand. Then they are compacted. It is recommended to fill the sand with water so that its shrinkage is maximum.

Fourth stage. Laying

First, the blocks are installed strictly in the corners. Then they are placed at a distance of 1.5-2 meters from each other over the entire area of the building.

Fifth stage. Waterproofing

During the operation of the structure, water rises and moistens the supporting structures. This occurs due to the capillary effect. To protect the lower part of the building from destruction, it is necessary to lay several layers of roofing material. Or coat with bitumen mastic or liquid rubber.

When all the work is completed, you can place the gazebo or install the frame - the frame of the base of the building.

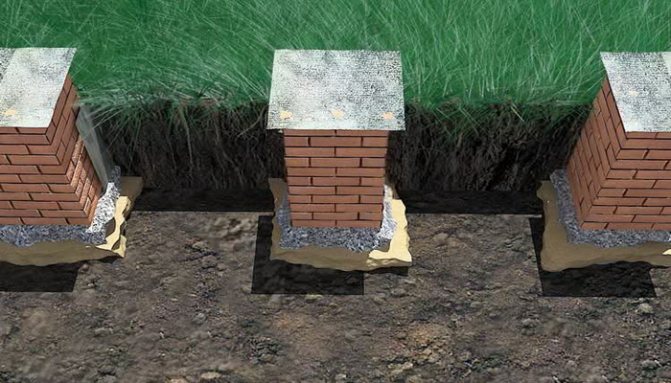

Do-it-yourself columnar foundation for a gazebo - a universal solution to the problem

This type of load-bearing base is used in most cases, since it is the most affordable and can be constructed quite simply without unnecessary problems.

Simple columnar foundations

In addition, the columnar base can be created from different materials and different interpretations:

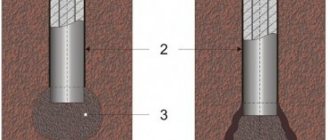

- Using asbestos-cement material. The pipes are dug into the ground and filled with reinforced concrete. This device is most often used to create wooden gazebos.

Base made of asbestos-cement material

- Using metal pipes. There is no need to pour concrete after installation. They just need to be installed in the ground and compacted well.

Welded version from metal pipes

Note. Before compacting, it is recommended to coat the pipes with a special anti-corrosion mixture.

- Creating a foundation using wooden pillars.

Based on wooden pillars

- Using concrete blocks. This is the most durable and reliable option. Such a load-bearing foundation is suitable not only for massive gazebos, but also for country houses, bathhouses, and fences.

Based on concrete blocks

- Brick supports. Inexpensive and common option. It is used for almost all gazebo designs.

From bricks

A few rules for creating a columnar load-bearing base

- Depending on the design, the pillars are distributed evenly at the corner of the external walls. If there is a partition in the building, then it is also necessary to install an additional pillar under it.

- The installation of pillars is carried out around the perimeter in increments of 120-150 cm on average (it all depends on the weight of the building).

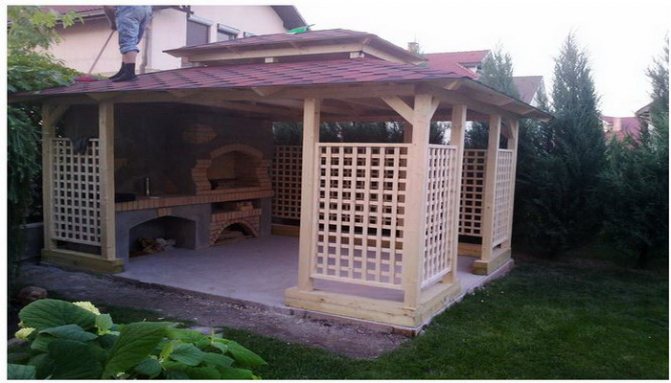

- A closed building with a complex barbecue must be built with additions for a load-bearing base. In addition to the foundation, a brick base is laid. Then you can be confident in the final result.

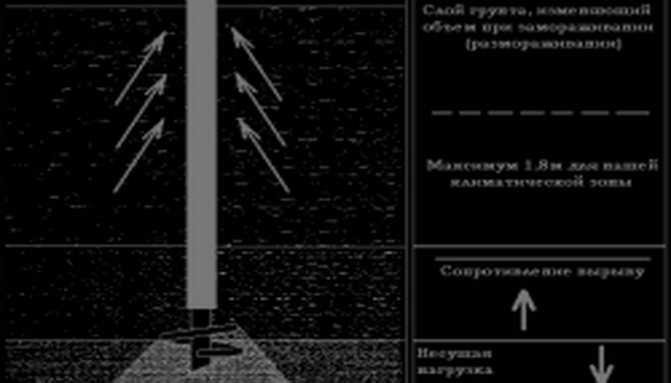

- If the soil base is made of clay, then the pillars are installed strictly along the perimeter. If, installing an additional pillar inside will entail consequences in the form of distortion of the load-bearing foundation due to freezing of the soil.

- To prevent the pillars from being squeezed out, you need to provide high-quality waterproofing.

Having studied all the rules, you can begin to create a columnar base. As an assistant, we recommend that you read the review “Gazebo with Foundation”, a video lesson on creating a columnar base.

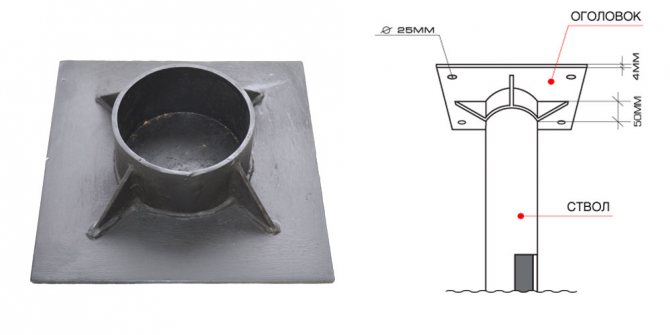

Self-installation of piles

The theoretical part is over, now you can consider the process of self-construction of a screw foundation.

Foundation marking

Marking the site for a pile foundation

The first thing you will have to do is mark the contours of the future foundation and mark on it the places where the piles will be installed. Here a lot depends on the architecture of the gazebo, but you need to keep in mind that the distance between adjacent supports should be no less than 2 and no more than 3 meters. First of all, you need to mark the places for installing piles in the corners of the gazebo. Then, at equal distances, mark intermediate supports. Installation locations can be marked by digging holes with a bayonet shovel. But you need to keep in mind that their depth should not exceed the height of the blades.

Pile twisting

Now about how to properly tighten the piles. To do this, a lever is inserted into the hole in the upper part of the support. You can use scrap or fittings of suitable diameter. The length of the lever depends on the ground. The heavier it is, the longer the metal pin.

The pile is installed strictly vertically, this is checked using a level. At the initial stage, the support is twisted by one person. This will keep it vertical. The deeper the pile is twisted, the more force you will have to apply and closer to the finish line, you will not be able to do this without an assistant.

Screwing the pile manually

Foundation piles are twisted at least to a blade height lower than the freezing depth of the soil. The height of the above-ground part depends on the base of the gazebo. You need to keep in mind that the support cannot be unscrewed later, so it’s easier to leave a little more on top. The optimal height is 50cm.

During the installation of the foundation, it may happen that you have to twist the pile to another place. The cause may be a stone or a root. In this case, the new installation location should be at least three blade diameters away from the previous one.

Leveling and tying

As soon as all the foundation supports are screwed in, they need to be brought to the same level. The best way to do this is with a laser level. If this is not the case, you can get by with the usual one. True, it will take more time and the accuracy will not be the same. Marks on the piles are made with masking tape. When all the pillars of the future gazebo are marked, it is necessary to double-check everything again, and then saw off the excess with a grinder.

Screw pile head

Now all that remains is to weld the heads onto the piles and the screw foundation for the gazebo is ready. You can do the strapping, i.e. connect all the piles together into a single base for the gazebo. It is best to do this with a wooden beam, screwing it through the holes in the heads with anchor bolts. Experts do not recommend welding piles together. This will reduce the life of the foundation due to galvanic corrosion. The foundation is ready, you can build a gazebo according to the previously chosen project.

Features of a pile-bearing base for gazebos

Such a foundation is not so often used in the construction of gazebos, but it is considered no less reliable than the previous ones, and the cost is acceptable.

Luxurious option on a pile foundation

The piles are simply screwed into the ground at the corners and along the walls of the structure. Even if the soil foundation is not reliable, such a building will stand for a very long time. Great option for a slope or right on the water.

Load-bearing base on slabs

A foundation slab for a gazebo is used in cases where you need to build a reliable heavy structure made of closed brick, with a barbecue or barbecue.

Example of slab construction

If it is necessary to build a load-bearing foundation for both the house and the gazebo, then the use of special equipment will be required. But in the case when you plan to create a small building, you can create a slab foundation manually, yourself.

Carrying out work

- Before building the foundation for the gazebo, you need to thoroughly clear the site.

- Next, we make traditional markings; we will need pegs and a cord.

- We proceed to the foundation pit, the same shape as the structure itself. The depth of the pit directly depends on the occurrence of water.

Stages of work

Advice. If the water is very close to the top layer, then it is better to organize a drainage layer.

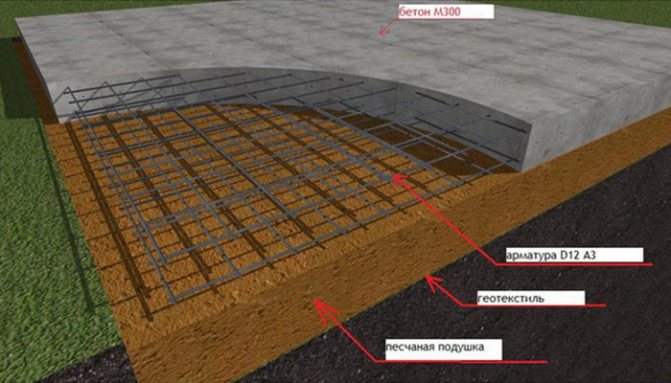

- Broken brick, crushed stone and sand are placed at the very bottom of the pit and compacted well. And then the surface is wrapped in a special waterproofing layer. The slab foundation of the gazebo is laid on top.

Option with pouring concrete

When concrete is poured, we do the following:

- We install a frame layer of reinforcement on the drainage surface and make formwork.

- The reinforcement is laid and concrete is poured on top.

A diagram of how to properly make a foundation for a gazebo from slabs

The surface needs to be properly leveled, be sure to expel all the air, and it is advisable to wait a month for the strength. After about two weeks, the formwork is removed.

Car tire

Increasingly, owners of country houses began to use car tires for foundation construction. This is an inexpensive and easy way to make a good base for a gazebo. This method has several advantages:

- Durability. It's no secret that rubber is a durable material that is not exposed to various external influences. She is not afraid of moisture, frost and heat. You will get a reliable foundation with a long service life.

- Reducing loads. The advantage of rubber is that it can be deformed without losing its integrity and properties. Therefore, under heavy loads, car tires will be able to soften the pressure by evenly distributing the entire weight over the surface.

- Significant savings. Other materials mentioned above (pipes, blocks, concrete, etc.) cost a lot, especially since it is not enough to get by with just the material; you need to purchase a whole complex. But everyone can get tires for practically nothing. Thanks to this, much less effort and expense will be spent on arranging the foundation, which, if desired, is better invested additionally in the building itself and its design.

- Car tires have their own waterproofing.

Solid

The only disadvantage of this method is that when the air temperature rises, the rubber releases harmful substances. Although this drawback can be easily eliminated if you protect the tires from direct sunlight.

Anyone can make such a base from tires. All you need are tires and knowledge, which you can draw from this article. You should know that there are two types of tire foundations:

- Columnar.

- Slab (solid).

If you want the gazebo to stand on such a base for a long time, when installing it you should adhere to the following rules:

- Do not deepen the foundation below the freezing point of the soil. It is better to make a shallow foundation that will perform well in winter.

- When installing the bottom layer of tires, be sure to check with a level that the surface is level. If you miss such an important point at this stage, it will be very difficult to correct something later. Your task is to install the tires so that their top edges are in the same plane.

- When choosing tires, it is better to choose those with a larger diameter, as these tires are much stronger.

- When the foundation is ready, its protruding parts are covered with decorative material.

It is clear that not everyone can immediately decide to build such a structure from tires. But it is worth saying that this technology has been used for a long time and there are examples that prove the success of this method. Moreover, it is appropriate to build a tire base on problematic soil with a high degree of heaving. If you decide to build such a foundation, let's look at the technology for its construction.

What foundation is economically beneficial for a gazebo?

If we talk about cement consumption, then the price for a columnar foundation, in relation to a strip foundation, will be about two times lower. Also, the cost of land work is reduced by 50%.

But if you build a load-bearing columnar base from reinforced concrete, then the costs for installing reinforcement will increase. Well, here everyone decides for himself what is better and cheaper for him.

A few tips for laying the foundation correctly:

- The foundation for the gazebo should be laid below the freezing level.

- The area of the base itself should be almost twice as large as the cross-sectional area of the load-bearing base.

- The width of the sole should be 20 cm greater than the thickness of the foundation wall.

- It is advisable to strengthen the top and bottom layers of the base with reinforcement.

- Carry out waterproofing work at the joints.

If possible, create drainage around the load-bearing base. The work is not mandatory, but it is advisable if you want the future structure to serve you for many years. Finally, watch the video in this article to see what mistakes you can encounter when laying the foundation for a gazebo.

Several reasons to order a gazebo on screw piles

- The main advantage of screw supports can be considered their versatility. After all, they are suitable for any type of soil, including peat soil and soil prone to heaving. They are not afraid of close groundwater and seasonal flooding.

- Installation of screw piles for gazebos can be carried out even on steep slopes, eliminating the need to level the site with large volumes of earth.

- The durability of a pile-screw foundation is 100 years, because the metal parts are treated with an anti-corrosion coating and galvanized.

- Installation of supports does not require the use of heavy equipment and special devices.

- The price of screw piles for gazebos is significantly lower than that of alternative foundation materials.