The construction of any permanent structure is a rather complex and labor-intensive process, regardless of the material of the main supporting structures. The correct choice of the type of foundation for the construction of a wooden house is the key to the successful creation of the entire facility. When designing and constructing a wooden house, they try to complete construction work efficiently and in a short time.

Suburban area

Such houses are distinguished by ease of installation, high environmental friendliness, lighter weight of structures compared to stone buildings and fast pace of construction.

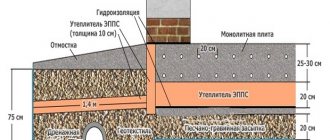

Monolithic foundation

Monolithic base

This type of base is a monolithic reinforced concrete slab and is the most expensive. Due to the fact that it follows the seasonal movement of the soil, it is called “floating”. Because of this, it is applicable to almost all structures, regardless of the type of soil and is able to withstand any load. However, before starting construction work, you should determine the groundwater level, the planned weight of the house and the type of soil.

- The construction of the foundation begins with clearing the site and digging a shallow pit (about 20-30 cm).

- Gravel and sand (10-20 cm high) are placed in the resulting depression, watered and thoroughly compacted.

- Waterproofing is laid on the prepared base to protect the slab from moisture.

- Then the formwork is installed.

- Next comes the installation of a frame made of steel rods. Basically, two layers of reinforcing mesh with a rod thickness of 12-16 mm are used. All this is held together with wire. The ends are insulated.

- After this, they begin pouring the concrete mass. The foundation for a log house is poured in one stage, otherwise its strength may suffer. The concrete is evenly distributed between the reinforcing bars. It will gain its strength within 1.5 months from the moment of pouring.

The grade of cement must be at least M300. The thickness of the slab depends on the building design. To build a house from logs, a slab up to 300 mm thick is required.

Sometimes inexperienced builders use a different type of foundation to build extensions. This is fundamentally wrong. It is strictly not recommended to combine a monolithic base with other types. Seasonal soil movement will cause the foundation for the log house to shift, and if there is a different type of foundation under the extension, then the ground movements will lead to a skew of its roof.

Choosing the right material

When building a private house, you can create a reliable load-bearing foundation only by using high-quality building materials. The use of used bricks is often motivated by the fact that it has stood the test of time, its manufacturing defects have become apparent, and a truly high-quality product can be selected. In this case, do not forget that the frost resistance indicator indicates a certain number of freezing cycles of the product. If for a new brick it is known by class (F 35 - F100), then no one knows how long an old block will withstand.

Bricks are made using various technologies and for different purposes. Only solid red brick of all types is suitable for foundation work.

Thanks to the method of its manufacture (firing), it is significantly superior to its silicate counterpart in its ability to withstand moisture. Hollow options are significantly inferior in strength and are not suitable for the critical laying of the load-bearing support of the entire house.

A brick foundation should be erected using grades M150, M175, M200, M250, M300. They should have a permissible water absorption limit of 6 to 16%.

According to standard sizes (cm), ceramic products are divided into the following categories:

- 25 x 12 x 6.5 single (regular);

- 25 x 12 x 8.8 thick;

- 28.8 x 13.8 x 6.5 modular;

- 28.8 x 13.8 x 8.8 modular, thick.

Manufacturing of products, quality control and rejection must comply with the criteria of GOST 530-2007. A high-quality product has the correct geometry and produces a ringing sound when struck; defective parts are distinguished by a pale color and a dull sound.

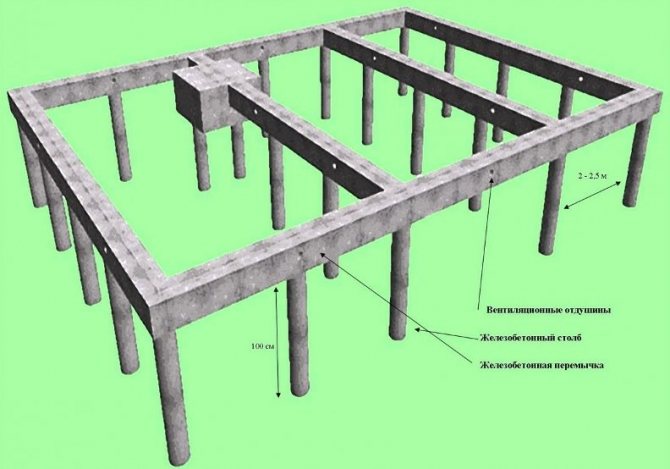

Columnar foundation

This base option is the most economical. It cannot be used on heaving, unstable soils. Suitable for building houses on surfaces with plane differences of no more than 2 meters.

A columnar foundation for a log house is mainly used for light frame buildings or verandas. The pillars are made of brick, wood, asbestos pipes, concrete, stone or reinforced concrete. You can purchase ready-made concrete blocks. They are located in the corners of the building with an interval of 1.5-2.5 meters. And also under frame racks and at the intersections of walls.

Before constructing such a foundation, the depth of soil freezing should be determined.

The laying of pillars depends on this. Depending on the depth of freezing, it will be 10-30 cm. The depressions are filled with crushed stone and formwork is installed. Polyethylene or roofing felt is used as waterproofing. When properly installed, a columnar foundation for a log house is resistant to any frost.

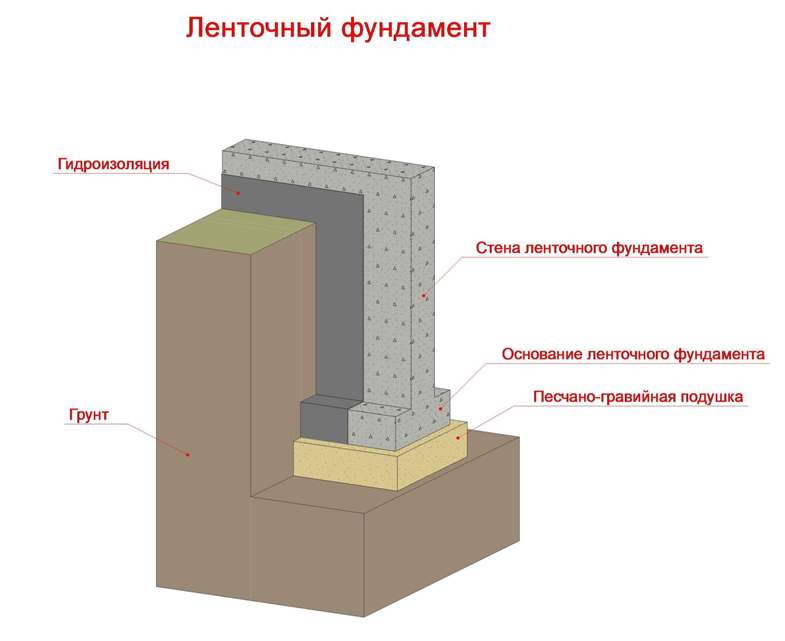

Strip foundation

A strip foundation for a log house is suitable for sandy, sandy-rocky or gravel soil types. To build such a foundation you do not need a large pit. The laying depth for central Russia on non-heaving soils should be 60-80 cm, and on heaving soils - about 1.5 meters. The width of the tape is slightly larger than the width of the wall and is about 30-40 cm.

A strip foundation is made along a closed contour.

- To do this, markings with ropes are made along the entire perimeter of the site according to the project.

- The top layer of soil is removed and a trench about half a meter deep is dug. When groundwater is close, it is increased.

- The trenches under each wall are lined with polyethylene film.

- Washed coarse sand is poured on top of the polyethylene, moistened with water and compacted.

- A wooden formwork is created and a reinforcing mesh of rods 10-12 mm in diameter is mounted into it, fastened with wire so that 30 cm cells are formed.

- A concrete mixture of crushed stone, sand and cement is prepared and poured in a ratio of 5: 3: 1. To evenly distribute the mixture between the reinforcement, it should be stirred with a shovel.

- Drying the base takes at least a month. To prevent drying out, the concrete is covered with damp burlap. And during rain, they are protected from getting wet by covering with polyethylene.

A strip foundation for a log house is very convenient in construction and much more economical than a monolithic one.

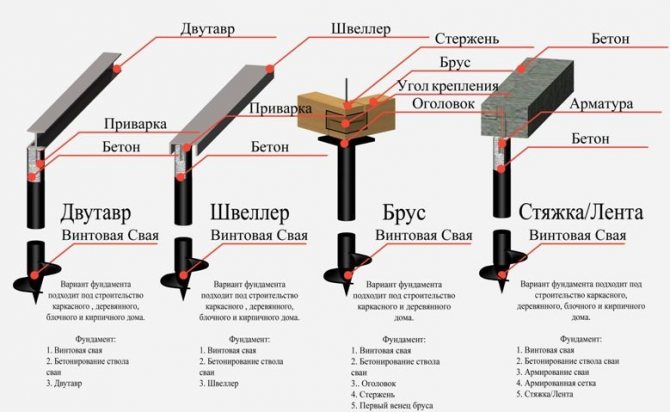

Pile-screw foundation

Installation of such a foundation takes little time and can be used for any type of soil, even loose ones. Piles are made of high quality steel with anti-corrosion coating. The structures look like a metal pipe with a pointed end. Their thickness depends on the load on the foundation. The material is selected for each specific building and piles are sometimes made to order.

Pile foundations for log houses are economical and easy to install.

- After calculating the number of piles, the location for installing the piles is determined. There is no need to clear the site. This foundation allows installation on any landscape.

- In the places designated for screwing in the piles, recesses are made. Then, using the principle of a screw, the structures are screwed in manually or using machines. Piles have a screw and blades with which they are screwed into the ground. Once the tip of the pile touches solid soil, the process is considered complete.

- Excess parts of the pile are removed and concrete is poured.

The foundation makes it possible:

- build a foundation on soft soil;

- build a house on a slope;

- build when groundwater lies close to the surface.

Advantages and disadvantages

The characteristics that a brick foundation acquires after laying and drying the mortar joints can be listed as follows:

- the structure acquires high rigidity;

- strength is average (withstands vertical loads well, horizontal and oblique loads - poorly);

- moisture resistance is low (compared to concrete), so it requires careful waterproofing;

- when destructive influences occur, the wall, due to its structure of individual elements, exhibits some mobility, which makes it possible to identify problem areas at an early stage;

- there is the possibility of partial repair of individual sections during the entire period of operation;

- If the technology and operating rules are followed, the service life will be from 25 to 50 years.

The advantages of laying a brick foundation include the ability to independently create complex shapes, openings, and wall connections at different angles.

Brick can be used in any shape

Since such foundations are allowed to be installed on calm, hard soils, the dependence of their depth on the level of soil freezing is not standardized by SNiPs. Often it is enough to remove the fertile layer and make surface drainage of storm water.

There are examples of incorrect comparison of the costs of building a brick foundation to the cost of branded concrete for a strip under a wooden house. This does not include in the calculation the cost of materials for installing the formwork, the cost of preparing the mixture yourself or delivering it with a rented mixer, the need to use concrete for a maximum of 40 minutes from the moment of preparation (increases the number of workers).

The characteristics of a brick foundation can be improved using modern waterproofing, insulating materials and masonry reinforcement.

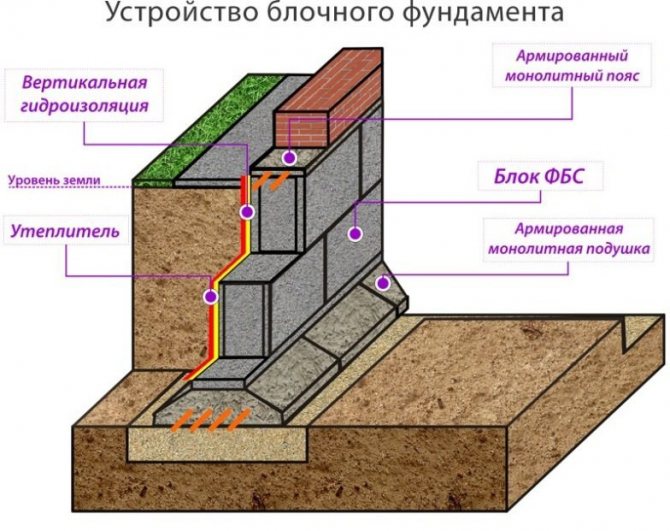

Block foundation

The construction of a block foundation for a log house will not take much time. The use of ready-made blocks gives the advantage of not having to wait for the foundation to dry out. This process usually takes two or more weeks. These types of bases are applicable on almost any type of soil. The finished blocks are equipped with correctly selected fittings.

Advantages of a block foundation:

- Frost resistance. The blocks can be used in regions with large temperature fluctuations due to the fact that special additives are mixed into the concrete.

- Good resistance to acidic soils. This allows them to be used on problem soils. For this purpose, the blocks contain crushed granite stone, which ensures this property.

- Large selection of product sizes. The manufacturer provides a wide selection of block sizes. There are large blocks for high-rise buildings and small products weighing 30 kg, which can be installed without the use of special equipment.

Foundation construction process:

- First, you should dig a pit for laying the foundation. To do this, you should make markings with pegs and tape, and hire equipment.

- Prepare the bottom of the pit. If there are soils of unknown quality at the bottom of the pit, it is better to make a sand cushion of about 15 cm and then compact it.

- Both columnar and strip foundations are built using the same masonry technique.

- The solution is prepared just before work. The strength of the foundation directly depends on its quality. Water should not be added to the solution, as this will worsen the adhesion of the structural elements.

- The masonry is made according to the type of brickwork. You should fill the seams with mortar very carefully, leaving no gaps. The thickness of the seams should be 10-15 mm.

How to make masonry?

The first steps in creating a structure are to prepare for work. In addition to purchasing materials and tools, it is also necessary to carry out markings. If this is problematic, pull special ropes. After this, the following manipulations are performed:

- A layer of sand is poured onto the bottom of a pre-dug ditch.

- After this, waterproofing (roofing felt or bitumen) is laid out.

- To increase strength, pour concrete mortar onto the bottom.

- After the concrete has dried, you can begin laying the brick.

The advantages of this design are manifested in the simplicity of its implementation. In order for the brickwork to last a long time, it is important to follow the algorithm of the work performed and the laying rules. The purchase of quality materials also plays an important role. To study all the details, you can seek advice from a professional builder.

conclusions

Which type of foundation should be preferred for a log house?

From all of the above, the following conclusions can be drawn:

- A columnar foundation is not suitable for a full-fledged wooden house. It is intended only for light wooden structures of a small area, bathhouses, verandas, as well as supports for porches and gazebos.

- The recessed strip foundation is designed for multi-story heavy structures and is redundant for log houses.

- It turns out that the most suitable foundations for a wooden house will be shallow strip and pile-strip foundations. These types of foundations are reliable and durable. Which one is preferable depends on the specific geological conditions of your site.

- You should not skimp on geological surveys - their results will show exactly what type of foundation is suitable for your site. Often this knowledge saves up to 50% of the cost of the foundation, and will also allow you to be 100% confident in the correct type of foundation.

- Shallow strip foundations are more popular due to their efficiency and ease of installation. It can be successfully used for a house made of rounded logs and a wooden cottage on slightly heaving soils or with additional insulation.

- The tape-pile method has a fairly high cost; it is a fairly new method and is not used very often in construction.

In order to decide which foundation is better in each specific case, the entire set of factors should be taken into account, such as the area and weight of the building, the nature of the soil, the region of residence, etc.