Brick is a universal building material used for the construction of residential buildings and small outbuildings. But is it possible to make a foundation out of brick? Absolutely yes!

The brick foundation is quite simple to construct; all work can be done without the involvement of professionals and special equipment, using only your own resources.

Brick is used in the construction of two of the three types of foundations - strip or columnar; a monolithic foundation cannot be made. Most often it is used for a gazebo, for a fence, for a brick garage, for a wooden house, for a bathhouse or for a light-weight frame-type house.

For buildings made of materials that have a lot of weight, for example, reinforced concrete blocks and slabs, foam and gas blocks and multi-story buildings, brick is not suitable, it will not be able to withstand the load and will deform.

In this article, we will look in detail at the features of building a strip and columnar brick foundation, study its advantages and disadvantages, and also learn how to strengthen a brick foundation and carry out all the work with your own hands.

How to make a brick foundation with your own hands?

- How to choose a brick for a foundation of this type?

- Brick foundation construction technology

- How to reinforce a brick foundation with your own hands?

Quite often, when choosing a foundation for a private house, a brick foundation is not considered because of its unreliability. It is worth understanding that this is a misconception.

DIY brick columnar foundation.

Brick foundation diagram.

A brick foundation has the following strength indicators:

- average strength indicators;

- high rigidity;

- poor resistance to low temperatures and moisture.

Due to these parameters, it is recommended to use this type of foundation in dry, hard soil that is not prone to heaving and has low groundwater levels.

The service life of this type of foundation, subject to installation rules and regulations, is about 40 years.

Advantages of a brick foundation:

DIY broken brick foundation.

Brick foundation diagram.

- A partially destroyed base can be easily repaired by restoring the brickwork elements in the necessary places.

- The absence of large heavy structural elements allows you to independently build the foundation without the use of special equipment and hired workers.

- There is no global destruction when the ground moves (this foundation is more flexible than a monolithic one).

- This design can be given any shape to the tape without the use of formwork.

Disadvantages of a brick foundation:

- The hygroscopicity of this building material allows moisture to easily penetrate its structure, which negatively affects the stability of the base. The number of defrost/freeze cycles for a red brick foundation is limited, so reliable waterproofing is required.

- Shorter service life compared to a concrete foundation.

- Limited area of use. When laying a foundation on unstable soil, it will be necessary to increase the strength of the brickwork from mechanical loads by performing reinforcement.

Materials that will be needed to build a red brick foundation:

- insulation;

- brick;

- waterproofing materials;

- cement mortar;

- materials for reinforcement (masonry mesh, reinforcement).

Repair

If the destruction of the foundation is obvious, and it is necessary to preserve the structure unconditionally, it is worth doing:

- fragmentary repair of supports;

- major foundation repairs;

- complete replacement of the base when worn more than 50%.

The true state of the foundation can only be determined by opening its underground part for viewing , which allows for a ditch dug along the wall of the building. How to strengthen a brick foundation during repairs or by replacing it with a different type of load-bearing support:

- External reinforcement of pillars.

- Restoration of the columnar foundation using an additional reinforcement belt made of reinforced concrete (using strip foundation technology).

- Replacing one or more pillars with temporary supports or piles made of another material (metal, pipes).

- Complete replacement of the foundation due to an increase in the required depth of the supports. This is carried out using special equipment (powerful jacks). When using this technology, the house is raised above the old foundation by no more than 2 cm. Having dismantled the old masonry, a new foundation is built using a strip type.

Repair is an inevitability that can be delayed by regularly inspecting the foundation of the house and responding to minimal signs of change.

Other types of columnar foundations presented on our website: rubble, reinforced concrete (made of blocks or prefabricated), bored (with a grillage), wooden.

How to choose a brick for a foundation of this type?

Brick is the main material for this type of foundation. The reliability and durability of both the foundation and the private house as a whole depends on the correctness of its choice.

DIY brick foundation step by step.

You should know which bricks are not allowed to be used for the construction of such a structure. The construction of a foundation made of any hollow or sand-lime brick is unacceptable. It does not matter at all how well the waterproofing is done.

For laying the underground part of the base, you must choose a solid red ceramic brick that is well-fired. It is characterized by high compression resistance and is less exposed to moisture than others.

The above-ground part of the base, the upper floors and the base can be laid out of white silicate brick. The use of this building material for an above-ground foundation is allowed only on a dry layer of soil with low groundwater levels.

It is important to choose the right brand of material. In this case, you will need to take into account 2 main parameters: F (frost resistance) and M (load per 1 sq.cm). To build the foundation, bricks of the M300, M250, M200, M175, M150 brands with frost resistance F 35-100 should be used. For underground masonry, the water absorption value should be in the range of 7-15%.

Prices for brands of ceramic solid bricks vary between 8-20 rubles per 1 piece. The final figure will depend on the characteristics of the building material and the size of the purchased batch.

In 1 cubic meter There will be approximately 400 bricks laid. To calculate the total amount of material required, you will need to multiply the resulting volume by the number of bricks in 1 cubic meter of masonry.

Technology for constructing a brick foundation.

Do-it-yourself brick foundation for a house.

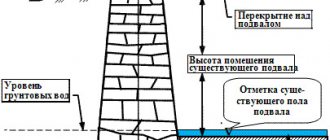

Diagram of a brick columnar foundation.

First of all, on the site you will need to develop the configuration of the foundation and calculate its volume, taking into account the possible load (weight of floors, walls, roof) and the existing soil properties. The width of the base should be calculated so that the tape is half a brick larger than the walls of a private house. This will make it possible to conveniently lay the logs on the internal ledge when installing floors.

Excavation. The trench under the brick foundation is dug so that a layer of waterproofing material can be laid on both sides. On heaving and clayey soils, backfilling will need to be done, so the width of the trench should be increased by at least 1 m.

Construction of a sand cushion 0.1-0.15 m high. The sand will need to be moistened and compacted until a flat surface is obtained.

Laying a layer of waterproofing. For a simpler option, it makes sense to use ordinary roofing felt, which is folded in several layers.

It is recommended to use polymer materials for the waterproofing layer.

How to make a brick foundation with your own hands.

Waterproofing scheme for a brick foundation.

Installation of formwork and pouring a concrete pad 100 mm high. With the help of a concrete pad it is possible to increase the bearing capacity of the base. Concrete can be reinforced with metal rods or steel wire.

Laying process. This work should begin after the concrete mixture has completely hardened. The laying should begin with the removal of the corners and continue by bandaging the seams of minimum thickness.

If you do not plan to plaster the foundation in the future, the seam should be made flush. Otherwise, you can use regular internal seams. The seams between the foundation bricks will need to be filled with mortar. External basement seams are facing, so they do not need to be filled with mortar.

Next, you will need to wait approximately 2-3 weeks for the foundation to fully cure and the solution to completely set.

As mentioned earlier, in areas with high groundwater levels, backfilling will be necessary. A sand cushion must also be placed around the perimeter of the base. The space between the foundation walls and the trench walls should be filled with gravel, crushed stone, construction waste or coarse sand. Such a layer will facilitate the rapid drainage of water during snow melting and prolonged rains.

To effectively protect the foundation of a house from atmospheric moisture, a beating is installed; for this purpose, the soil surface is concreted along the perimeter of the foundation with a slope to the outside, which allows water to flow freely.

Before erecting walls, it is necessary to make hydro- and thermal insulation of the horizontal upper part of the foundation.

How to reinforce a brick foundation with your own hands?

Diagram of the foundation and brick pillars.

Diagram of the foundation and brick pillars.

If the existing soils on the site where it is planned to build a private house are not stable enough, a foundation of this type will need to be reinforced. This base design allows it to withstand severe mechanical loads even on problematic soils.

It is necessary to ensure that the reinforcement is hidden under a layer of cement mortar by at least 2 mm. This may lead to an increase in seam thickness. For reinforcement, metal rods are used, which have a diameter of approximately 6-7 mm. They will need to be laid at a distance of half a brick from the side surface of the tape along the entire perimeter.

For transverse reinforcement, it is necessary to use a steel wire mesh, which has a diameter of approximately 3-5 mm. If you use wire with a thickness of more than 5 mm, you will need to perform a zigzag weave.

A brick foundation is more expensive and less durable than a monolithic foundation, but this brick structure also has a fairly large number of advantages.

Columnar foundation made of brick.

The most affordable option for a columnar foundation can be made of brick. This foundation construction technology is easy to master on your own, and it is ideal for houses and other buildings that have a lightweight structure. Brick supports are reliable enough to support the weight of a frame house of two residential floors or even more. It is also important that a columnar brick foundation is a very economical option. And finally, about durability: this type of foundation can have a service life of 30 to 50 years. The specific figure depends on three factors:

- the nature of the soil at the site where the house is being built;

- quality of materials;

- quality of brickwork.

Insulation and cladding

The work includes the use of facing bricks. When the structure is located on a strip foundation, the masonry rests directly on the base. To finish, you should dig the area underneath and measure the free protrusion. To organize cladding with white brick, the width of the base must be at least 13 cm. This is due to the typical construction of the brick. Insulation and cladding at home is carried out according to the customer’s wishes. The type of material is chosen independently, provided that it is appropriate in this situation.

Permanent address of the article

Which brick to choose?

For the construction of the foundation, you should choose only solid burnt red ceramic bricks. It is characterized by high strength and low moisture permeability. Provided proper waterproofing is installed, a foundation made of such bricks can be used for many decades without losing its original characteristics.

The most important parameter of solid ceramic bricks chosen for the construction of a foundation is frost resistance (F). It shows how many freezing and thawing cycles the material can withstand. For example, if the frost resistance index is F35, then the manufacturer guarantees that a brick of this brand is guaranteed to last 35 years without visible signs of destruction of the foundation. Don't forget about this indicator when purchasing material. The higher the parameter F, the higher the service life of the foundation.

The bricks that are supposed to be used to build the foundation are selected especially carefully. For this purpose, only burnt bricks that do not have cracks are suitable; they produce a ringing sound when struck. Preference is given to red solid brick of grades M-150, M-200 and higher. Material grades M-100 and M-125 are not recommended.

Once again, we draw your attention to the fact that the use of silicate or lightweight hollow bricks for a brick columnar foundation is not allowed.

Advantages of a brick foundation.

- Possibility of self-construction of the foundation (Absence of heavy elements and large structures. No need to involve heavy construction equipment).

- Ease of restoration of brickwork by replacing its individual fragments in case of partial destruction of the base.

- General advantages of columnar foundations.

Waterproofing protection of columns

The side edges of the columns are insulated with hot bitumen. Roofing felt sheets are installed on top.

Waterproofing

The horizontal part of the column can also be reliably insulated. Roofing felt is laid on mastic heated by a burner.

Proper insulation of the base will extend the service life without losing previous parameters for decades.

Rules for self-construction of a brick foundation.

- Basic rule: strict selection of bricks for foundation masonry. You should choose only solid red clay bricks, which must be burnt, since the main reason for the destruction of bricks is high humidity, and burnt ceramic bricks are characterized by low moisture permeability.

- The brick foundation is laid using high-strength cement-sand mortar (1:3) with waterproofing additives.

- It is mandatory to install thorough waterproofing when constructing brick foundations in areas where groundwater lies close to the surface of the earth.

- Making the base of the base with concrete casting and its special filling are necessary to improve operating conditions and strengthen the brick foundation.

- Calculation of the depth of a brick foundation is carried out according to general rules, but a prerequisite is its construction on a layer of stable, hard soil.*

* Columnar brick foundation is not recommended:

- on weak horizontally moving soils (possibility of foundation overturning);

- in areas with differences in ground heights of 2 meters or more.

Application

- frame-panel structure (house or outbuilding);

- wooden structure made of timber (sauna, extension, gazebo);

- free-standing pillar or column (veranda or terrace);

- a one-story house made of aerated concrete (one stone) on plain soil.

The cost of columnar supports is more economical and will be only 15% of the total cost of the house, with 30% of the cost of other types of foundation. It can be laid independently, without the use of complex equipment and technology, and completed in a short time.

Important: columnar supports are not suitable if a cellar or basement is designed.

Construction of a brick columnar foundation.

The pillars must be erected in all corners, at the intersections of walls, under heavily loaded purlins and piers, at other points with heavy loads, and also at a distance of 1.5-2 meters from each other (the heavier the walls, the smaller the distance between the pillars) according to the entire perimeter. The specific foundation layout depends on the layout of the building and design documentation data. On top of the pillars, to evenly distribute the load, they are tied with beams, which should be stronger the greater the distance between the pillars.

When determining the cross-sectional size of brick supports, they are guided by the calculated values of the sole area required according to the project. Most often, pillars are erected with a square or rectangular cross-section. For one-story buildings, in the first case, the rib size is usually chosen to be 380 mm, and in the second case, the dimensions of the sides of the rectangle are 380 and 510 mm; The cross-section of the intermediate pillars is 380×250mm. The pillars of a brick foundation for a two-story building must have a cross-section of at least 510x510mm.

There are two types of brick columnar foundations based on their depth:

- Shallow-recessed. It is used for sandy, rocky, coarse soils and is buried into the soil to a depth of 0.4-0.7 meters.

- Recessed. It is installed in an area with a low groundwater level. It is buried to a depth of up to two meters (0.3-0.5 meters below the freezing depth).

Construction of a shallow foundation.

The construction of a brick columnar foundation involves the sequential implementation of the following work:

- Excavation

.

The first stage in the construction of a brick columnar foundation is the construction of pits for the pillars. The soil is selected taking into account the size of the pillars and in order to ensure the possibility of masonry at a depth of up to 70 cm. Holes can be dug by hand or using machinery. One way or another, the main requirement is the exact location of each hole along the axes, according to the drawing. To calculate the depth of soil freezing in your city, you can use our calculator: Calculation of the depth of soil freezing. - Preparing the base

.

Crushed stone and sand are poured into the bottom of each pit (layer thickness 10-15 cm), followed by compaction and waterproofing (roofing felt is laid on top of the sand base, protecting the brick from moisture that will penetrate from below, from under the sand and crushed stone). To strengthen the foundation and improve its operating conditions, a concrete base can be built for laying bricks. To do this, first install a mesh of reinforcement with a rod diameter of at least 3 mm (you can use a masonry mesh made of wire of the same thickness). The mesh is filled with a layer of concrete. The recommended base thickness is at least 15-20cm. After 1-2 days, the concrete will set and you can proceed to laying bricks. The specific setting time of concrete depends on the quality of the solution. To calculate the composition of concrete, we suggest using our service: Calculator for calculating the composition of concrete. - Bricklaying

.

Usually 4 bricks are laid in one row of a pillar. The masonry is carried out using a cement-based mortar of grades M-400 or M-500.

In the process of laying supports, it is necessary to observe the tension. To make the pillars stronger, they can be strengthened horizontally using a reinforcing mesh made of wire with a diameter of 6 mm every 3-4 rows of brickwork (every 25-30 cm).

At the intersections of the walls, pillars of 510x510mm in two bricks are installed. In places with less load, it is enough to install pillars of one and a half bricks 380x380mm at a distance of 1500-2000mm from each other.

To ensure that the foundation is level, each laid row of bricks is leveled. The pillars are checked with a vertical level, making sure that the deviation does not exceed 2 degrees. The exact placement of bricks and pillars in general is very important for the reliability of the foundation and the further operation of the house.

The brickwork is continued until each pillar rises above the upper edge of its hole by at least 20 cm. On a site that has a slope, all pillars are raised along the upper edge to the same height, and the minimum height of the pillar above the edge of the pit should be no less than 20 cm.

The masonry is carried out in half a brick, constructing a square-section column with a void in the center. To strengthen the foundation structure, the empty core of the pillar is filled with concrete and pre-reinforced with a reinforcement bar.

- Waterproofing of pillars

. Upon completion of the masonry, the brick foundation supports are waterproofed to protect them from external moisture. To do this, the pillars can be coated with bitumen mastic, and polymer-bitumen membranes can be used for horizontal waterproofing. - Filling up free space

.

It will take about 5-7 days for pillars made of brick to dry, stand and gain strength. After this, the free space between the supports and the walls of the pits is filled with crushed stone, slag or gravel. This makes it possible to reduce the impact of active seasonal soil movements on the foundation. - Waterproofing the top of the supports

.

Each brick pillar is covered with roofing felt on top, on top of which the walls of the house will be built in the future. - Pickup

.

To prevent cold air from the street from penetrating under the floor of the building, a fence is installed between the pillars located along the perimeter of the building.

Comments

03/24/2016 21:35:09 Sergey Pro

Hello! Please tell me the depth of the brick pillar should be below the freezing level of the soil. That is, here, as I understand it, in the same way as with a bored columnar foundation, we dig holes below freezing. It's just not clear from your drawings. And the second question is, if the UPG is 1.5 meters, is it worth making such a foundation? I understand if the depth is small, but 1.5 m is somehow a waste of time to dig a hole. Plus, all this will need to be done with a shovel; I think it will be easier if you do it with a drill.

Answer

03/24/2016 21:35:19 Anton

Sergey, if the soil is good (sand of medium and higher coarseness), then the depth does not depend on the freezing depth and is taken to be at least 50 cm. If there is clay, it is better to dig below freezing, or replace the soil and insulate the replaced soil. I have seen such recommendations for high groundwater level.

Answer

03/24/2016 21:35:33 Sergey Pro

Isn't sand a heaving soil?

Answer

03/24/2016 21:35:45 Anastasia

Hello! It is planned to erect a small frame house (OSB slabs) 5*6 m on the site, which will serve as temporary housing for the period of the main construction. Location: Tyumen. Loams. Question: does it make sense to dig holes for pillars so deep (if, according to the soil freezing table, our indicator is 1.73 m)? Accommodation is planned only in the warm season; this housing is expected to be used for 3-5 years, then demolished. If the pillars are installed on a sand cushion of 15 cm, + waterproofing, + reinforced mesh and a concrete base, there are a total of 5 rows of bricks, 2 in each row. There are 16 such pillars. How to find out whether the foundation is strong enough for a relatively light structure made of OSB boards? Thank you!

Answer

03/24/2016 21:35:55 Maxim Gvozdev

Anastasia, hello! Well, if the frame is 5x6m, then a better quality foundation can be made, namely a bored one. https://www.gvozdem.ru/stroim-dom/fundament-stolbchatyy-monolitnyy.php It’s just that such a foundation will last for a very, very long time. Concrete still gains strength over time. Even if you are building a temporary shed, then you can put a bathhouse, or a garage, or some other building on these pillars. Just in terms of labor costs, provided that you want to make a concrete pad under the masonry, it will definitely turn out the same. Now about the depth of freezing. Your soils are heaving. Consequently, the pillars must be made below the freezing depth. This is if we are talking about doing everything efficiently, even if only temporarily. Still, I advise you to look towards the foundation, which will remain alive after the demolition of the temporary building.

We build a red brick foundation on our own.

Brick is the main material used in construction, without which no construction project can take place. In addition to the construction of walls, it is also used in the construction of foundations.

DIY brick foundation base.

Advantages and disadvantages of brick masonry.

Brick foundations are used in the construction of terraces, cottages, dachas, and houses made of reinforced concrete slabs. It has a number of important advantages:

- not susceptible to natural factors and does not harm human health;

- A brick foundation can be laid quickly with your own hands. A person can cope with this work on his own (if he has certain skills, of course).

- the cost of brickwork is much less than a reinforced concrete base;

- better thermal insulation than reinforced concrete slabs;

- masonry is much easier to repair. It is easier to remove damaged foundation elements and insert new ones.

- there are no volumetric monolithic slabs in the brick foundation, and in a situation where the soil begins to move, it will not collapse, but will only lose its rigidity;

- durability.

With many advantages, a brick foundation also has several disadvantages:

- porous structure, therefore, due to moisture ingress, the brick can freeze very much;

- the masonry will have to be insulated;

- The work of building a foundation is labor-intensive and requires a lot of time and effort.