An important stage in the construction of a wooden bathhouse is the construction of a reliable foundation.

The use of expensive monolithic concrete structures designed for much higher loads is not feasible from a financial point of view.

A more affordable option is to install screw piles. Such a foundation will provide the necessary strength and load-bearing capacity and will last at least 50-70 years.

We will tell you in the article how to build a foundation on screw piles for building a bathhouse.

Advantages of a foundation on screw piles

Installing a floor in a bathhouse on screw piles is much easier to do than on a massive foundation. Advantages of this design:

- the foundation can be installed very quickly with your own hands;

- screw piles noticeably compact the soil, ensuring the stability of the entire structure;

- the foundation is convenient to repair if necessary;

- installation of screw piles is easy to do using modern devices and devices;

- the foundation can be installed in any weather;

- screw piles provide effective automatic ventilation of the underground space of the bathhouse;

- the service life and reliability of the pile foundation are quite long;

- a properly installed floor will protect the walls of the bathhouse on screw piles from the absorption of sediment and melt water from the soil;

- a screw foundation can be installed on unstable soil, which swells and swells during the season of heavy rainfall.

The foundation for a bathhouse on stilts can be installed even in winter

The advantages of a pile foundation make its installation quick, and its operation reliable, simple and convenient. The main thing is to first study the properties of the soil in the area chosen for the bathhouse, carry out all the calculations correctly and carry out the necessary work in strict accordance with the instructions.

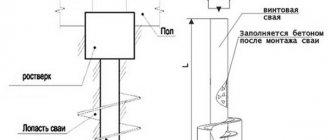

Screw piles must be selected depending on the type of soil

Scheme for installing a screw pile in the ground

Screw piles are installed for all load-bearing walls and elements

Types of pile foundations

When building a bathhouse, the problem of weak soil often arises, which threatens the building's settlement. Unstable soils include:

- loess-like soils, the distinctive feature of which is destruction under the influence of external loads or their own weight in wet conditions;

- permafrost soils;

- quicksand;

- highly heaving soils that can freeze to a depth of one and a half meters.

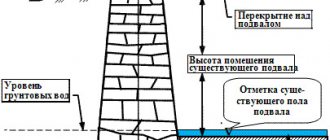

To prevent a bathhouse from “floating” on problem soils, it is necessary to install such a foundation so that its load is transferred to solid rocks, passing through weak and mobile layers, the depth of which depends on the geological characteristics of the site.

This foundation, consisting of piles immersed in the ground, interconnected by reinforced concrete beams or a slab (grillage) and forming a rigid, reliable structure, is, in principle, no different from a columnar foundation. Only in size and load-bearing capacity. After all, a pile is a large pillar, only with a pointed lower end, which is driven or screwed into the ground.

They can be manufactured in advance, or they can be poured into the well itself with the fittings installed in it, right at the construction site. The piles are placed vertically or at a slight angle to a depth of 3–10 m. Each can withstand a load of 2–5 tons.

Foundations on piles

| They differ from each other by: | There are: |

| material; | wooden, reinforced concrete, metal, combined piles; |

| method of immersion in the ground; | screw, driven, driven, pressed piles. |

| the shape and type of grillages; | for a high grillage, the sole rises above the surface of the ground, and for a low grillage, it is buried in the ground; |

| the nature of the work; | hanging and supporting (piles-racks); |

| location; | single (for light buildings), strip (for extended buildings), pile bushes (under massive pillars and columns), in the form of a continuous field (piles are arranged in a checkerboard pattern). |

Building a bathhouse on a pile foundation will be a good option for owners of problematic land plots.

What is the floor in the bathhouse made of?

The floor in a bathhouse on screw piles can be made from different materials. Concrete screed and coniferous wood are mainly used. Installing a concrete floor will require significant material costs. However, such a floor is resistant to constant exposure to moisture. Therefore, the concrete floor in the bathhouse will last for decades. Wood is a lower cost material. However, when exposed to moisture, a wooden floor quickly deteriorates. Treatment with an antiseptic will significantly slow down this process. But after 7-10 years, the wooden floor will need to be replaced.

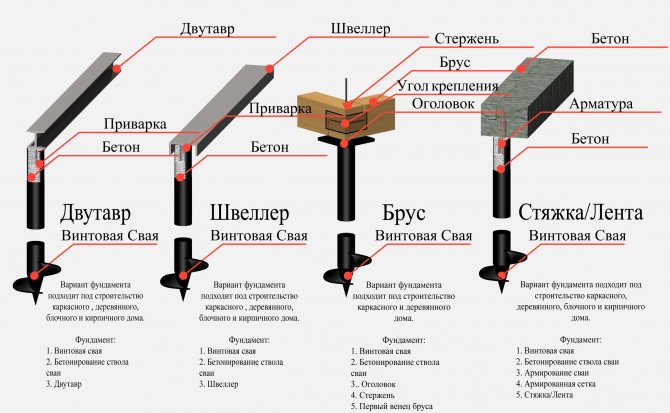

Scheme of fastening various floor materials to a pile

The concrete floor in the bathhouse is most resistant to moisture

The advantages of a wooden floor are not only the low cost of the material. If necessary, you can replace damaged elements without completely changing the coating. If you regularly re-treat wooden components with an antiseptic, you can almost double the service life of such a floor. The optimal option is when a concrete screed is made in rooms of high humidity - steam room and washing room. You can make a wooden floor in the locker room and rest room, because the humidity level here is much lower.

It is better to place a wooden subfloor in a bathhouse in the locker room area

Important recommendations before installing the foundation

- Even for a light frame bath, do not use piles with a wall thickness of 3 mm. Only 4 or 5 mm. Three-millimeter products have a much lower safety margin.

- Entrust the work to professionals. Each pile must be firmly screwed. If you don’t tighten the pile even by 20 cm, it will definitely go down in a few seasons. If several piles sag at once, this will end very sadly for the entire structure.

- Don't hesitate to check and double-check. When installing piles, the angles, diagonals, as well as the evenness of screwing the piles in two planes at once are checked (a bubble level with a magnetic fastening and a stretched guide cord are used).

Preparatory work

So, the foundation is installed and the walls are erected. Now we are making the floor in the bathhouse on screw piles. You need to thoroughly prepare for this work, study the technology, purchase everything you need, and invite assistants.

For work you will need the following materials:

- tongue and groove board;

- beam;

- fastening material - nails, etc.;

- cement;

- coarse sand;

- expanded clay and/or other bulk materials;

- roll waterproofing;

- antiseptic composition;

- mineral wool or other insulation.

Tools and equipment for work will require:

- construction mixer;

- tank for mixing the solution;

- wood hacksaw;

- grinder saw;

- construction knife;

- hammer;

- mittens, work clothes, rags.

The list of necessary tools and materials can be specified after it has been determined from what material and in what way the floor in the bathhouse will be installed on screw piles.

Base for a brick Russian stove

The conventional dimensions of a brick bath heating device are 1.5x1.25 m (LxB). Laying the foundation occurs according to the following scheme:

- The pit needs to be dug 70 cm below the soil freezing line in winter. To eliminate the influence of soil movements on the base for a brick oven, the pit is made approximately 10 cm wider on both sides.

- The bottom of the resulting pit is covered with a layer of sand 15 cm thick. Then it is filled with water. After the liquid is absorbed, it is necessary to add sedimentary rock to the desired level. The procedure is repeated 2-3 times, then a 20-centimeter layer of crushed stone or broken brick is laid and compacted on the resulting base. After this, water is poured in again and sand is added. Such manipulations are repeated until the rock stops settling.

- A layer of crushed stone 10 cm thick is poured on top of the sand cushion After compacting it, formwork is made inside the pit. In this case, a space of 10 cm between the walls of the recess and the wooden form remains empty.

- The inner part of the formwork is strengthened with a reinforced frame.

Floor insulation: general rules

Before installation and insulation of the floor, it is necessary to carry out an antiseptic treatment of all wooden components of the finished structure. A special composition for this can be purchased at a construction supply store. An antiseptic will protect the wood from the penetration of harmful microorganisms that can destroy it.

The depth of floor insulation depends on the premises of the bathhouse

If a bathhouse on screw piles will be used in winter, floor insulation begins with laying insulation between the supporting elements of the building. Most often, mineral wool (layer thickness 25 cm) or polystyrene foam (layer thickness 15 cm) is used for this.

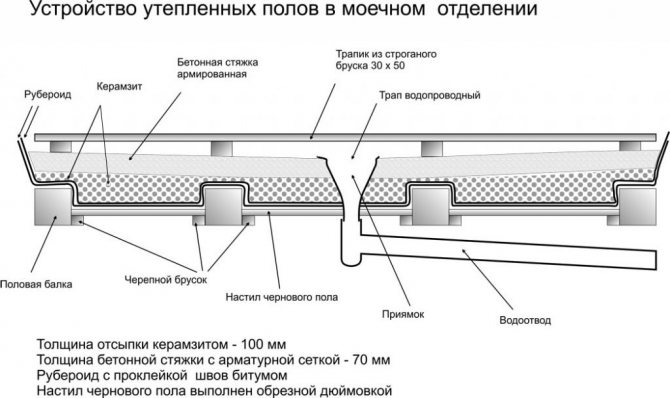

Scheme of insulation of a concrete floor in a bathhouse

If the thickness of the beams is insufficient for laying insulation, additional bars are attached to them perpendicularly. Waterproofing is pre-installed. On top of it, between the beams, the bottom layer of insulation is laid out. The top layer is laid between additional bars. Next, another layer of waterproofing is laid, on top of which the finishing floor is mounted. An insulated layer in a bathhouse on screw piles will extend the service life of the structure and significantly increase the comfort in the bathhouse.

Scheme for insulating a wooden floor in a bathhouse

Advantages and disadvantages

The positive aspects of foundations on piles are high speed and ease of installation without preliminary excavation work and an affordable price. In addition, this increases the strength of the entire structure. Can be installed in almost any soil. You can always make an extension to a bathhouse on a pile foundation, which will not “walk” due to the fact that it has a separate base.

You should also take into account that there is a ventilated base, which reduces the risk of floor rotting. Construction regardless of the time of year and is possible even in winter. The necessary communications are simplified. And finally, another plus: the ability to install it yourself.

The disadvantages of a foundation on piles are:

- susceptibility to corrosion of the steel part due to insufficient coverage with a protective layer of paint;

- impossibility of installation in rocky areas;

- the need for accurate calculations of the foundation grillage on piles in order to avoid possible settlement and distortion of the bathhouse;

- difficulty of installation near nearby buildings;

- the need to build a warm underground space (its cost will be equal to the price of the foundation itself).

If it is necessary to reduce money and time, a foundation on piles will become an indispensable option, since there will be no need to dig a pit and remove the earth. To install a three-meter pile with a diameter of 30 cm, it is enough to dig only 20 cubic centimeters of soil using a drill. The volume of a foundation on piles is several times smaller than a strip foundation, so you will need significantly less reinforcement and concrete. The cost of a pile foundation is approximately 20% of the cost of building a bathhouse.

Base installation

Effective insulation of the floor in a bathhouse on screw piles is done using a base, which is mounted around a pile-screw foundation. The plinth reliably closes the free space under the bathhouse floor from the penetration of cold air and significantly improves the appearance of the finished building.

The empty space of the plinth is covered with some panels

The main materials for the base are thermal insulation boards and decorative panels. An additional layer of heat insulation is laid between them. Typically, penoplex, polystyrene foam and similar materials are used for this. Sealing the joints between the panels after assembling the base is done using polyurethane foam.

To reduce heat loss, insulate the basement under the bathhouse

You can insulate the base of a bathhouse using penoplex.

Installation of a pouring floor

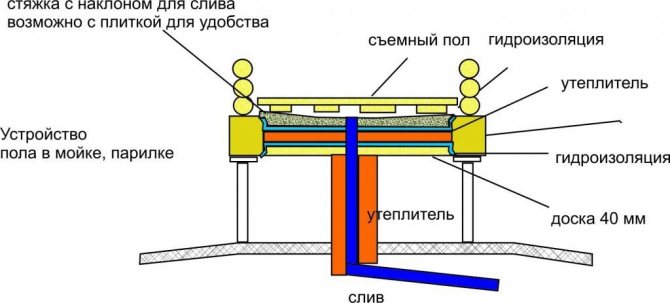

The optimal solution is considered to be a poured floor in a bathhouse on screw piles. In the cold season, it is necessary to carry out mandatory insulation of the entire structure.

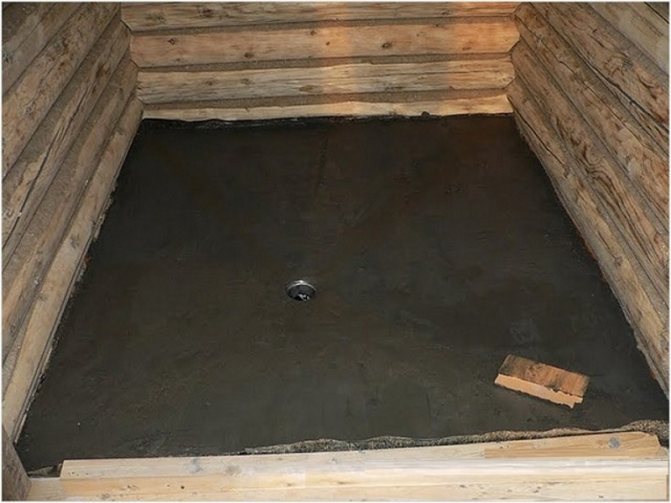

A large amount of water gets on the floor in the bathhouse, so it is necessary to increase its moisture resistance and trouble-free removal of used water. To do this, it is necessary to equip a special drain ladder. Through it, water will flow into the sewer pipeline or into the drainage system.

Diagram of a pouring floor in a bathhouse

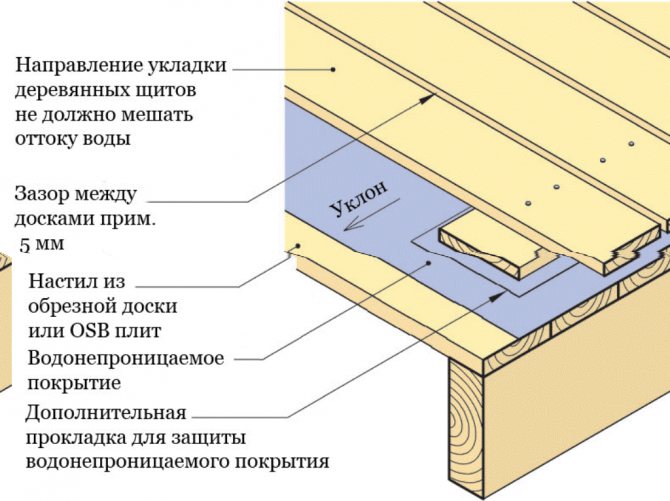

Installation of the pouring floor begins by laying logs on the grillage. They are placed strictly horizontally without tilting. Edged boards made of coniferous wood are fastened to the logs with nails. Gaps 7 mm wide or more are left between them. Even if the wood swells, the gaps between the individual elements will still remain. Used water will pass through them freely.

To protect the subfloor from the accumulation of water, you need to install a concrete screed in it in the shape of a cone with an inclination towards the sewer or drainage system.

Advice! To avoid the appearance of unpleasant odors and/or harmful microorganisms, the concrete structure must be regularly washed, cleaned and treated with special compounds.

To prevent anything from rotting and moisture from accumulating, it is necessary to install a concrete bowl with a drain in the bathhouse

Arrangement of a columnar base

When building a bathhouse on clay and loamy soils, additional financial costs cannot be avoided. After all, the construction of inexpensive slab and strip foundations does not protect against heaving of the earth at low temperatures. Similar ground movements are possible on some types of sandy soils. In order to ensure the safety of the entire structure and extend its service life, a pile foundation is being erected for the sauna stove. Using a hand drill, holes with a diameter of 20 cm are drilled to the freezing depth, which are half filled with crushed stone, then compacted. Peculiar tubes are rolled up from roofing felt, acting as formwork. They are inserted into the recess and filled with concrete to the desired level. After 10 days, when the building material gains the necessary strength, you need to start making a foundation slab for the furnace.

Dry wooden floor in the bathhouse

The dry floor is laid from boards in 2 layers. First, the subfloor is installed. A waterproofing agent is placed on top of the boards. Then the insulation is laid. On top of it - 1 more layer of waterproofing. Finally, a finished floor covering is laid. For this, a tongue-and-groove board made of durable softwood is used. Individual floorboards must be laid close to each other without cracks or gaps. When laying the finished floor, a slope to one of the corners of the room is required. A hole is made here under which the siphon is attached. This will help you easily remove used water during use of the bath.

Concrete floor in the bathhouse

Before pouring a concrete floor, it is necessary to carry out preliminary work in a bathhouse on a screw foundation:

- laying water supply and sewerage pipes;

- installation of a ladder on which the finishing floor will be laid;

- forming a cushion of bulk material under the base of the bathhouse building;

- laying roll waterproofing on foundation sections;

- laying insulation.

Scheme for preparing concrete mixture

Nuance! It is better to fill the pillow for forming a floor cake from bulk material of different fractions, which must first be completely dried.

Insulation of concrete floor

The concrete floor in a steam bath on screw piles begins to be insulated when the screed sets and hardens. The following is usually used as insulation:

- extruded polystyrene foam;

- expanded clay;

- perlite;

- mineral wool.

Before laying the insulating layer, it is necessary to completely clean the surface of the concrete floor from foreign objects, dust, debris, etc. then lay a roll of waterproofing material. Fractional insulation is applied as part of a special mixture. After it dries, a cement screed is poured on top.

Tile insulation requires sealing the joints between panels after installation. This is usually done using polyurethane foam. After it dries, a 2nd layer of roll waterproofing agent is applied. To evenly distribute the load on the floor in a washing bath on screw piles, in a steam room or in another room, a reinforcing mesh is laid.

You can insulate a pouring floor in a bathhouse using expanded clay; it must be laid before the concrete screed

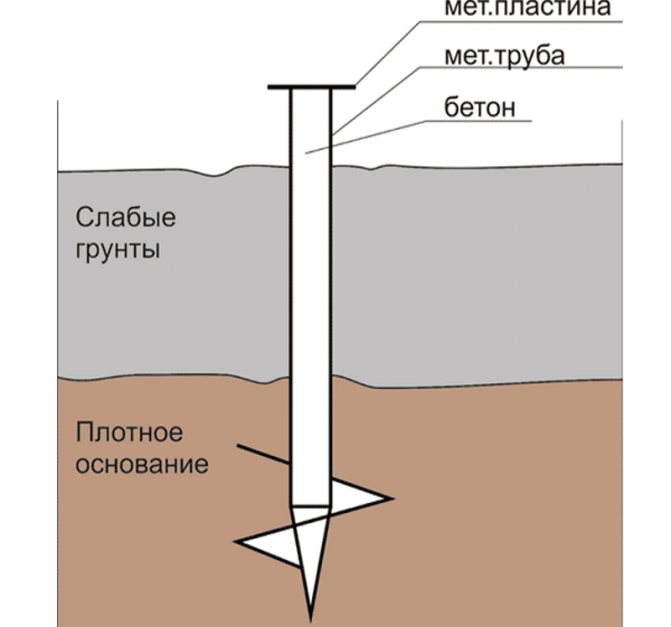

What is a pile and what type are they?

A pile is a metal, wooden or reinforced concrete rod or pipe that is buried in the soil and gives the foundation of a building or structure additional load-bearing capacity. If metal and reinforced concrete products themselves are endowed with sufficient strength under mechanical stress during their installation, then wooden elements, in most cases, require some preparation. The lower end is trimmed into a wedge, and the upper end is protected with a metal plate so that during hammering the upper end does not rivet or “fragment.”

According to the type of load distribution, piles for a bathhouse can be either supporting or hanging:

- Supporting - interacts with the ground, mainly with its lower end. Such piles are long and must rest on the underlying soil layer with sufficient bearing capacity;

- Hanging - interacts not with the end, but with the side walls, due to the appearance of a “soil jacket” on them. The jacket is a layer of soil that adheres to the pile during its penetration into the ground, forms a single whole with it, and already it adheres to the surrounding soil and keeps the pile suspended, without support at the lower point on a solid and durable underlying layer. Such piles can be significantly shorter in length than support piles.

By the way! Quite often, piles can combine the qualities of both supporting and hanging types.

Materials for making piles

As we have already said, a pile foundation for a bathhouse can use various materials for the manufacture of working elements. Let's look at this in more detail:

- Wooden piles. For their production, long-length coniferous trees are used. The most affordable option is pine and spruce. Larch is a slightly more expensive material. In exceptional cases, primarily due to its high cost, oak is used. Such piles can be: single, composite and packaged. In most typical situations, due to the light weight of bath structures, simple type piles are used;

- Reinforced concrete piles are standardized products made of heavy concrete reinforced with metal. The strength characteristics of a standard product with a cross-section of 300 x 300 mm allow confident work in soils of low bearing capacity at a full length of up to 12 meters. Naturally, in the realities of bathhouse construction, the use of such quality is unlikely, however, as an indicator of capabilities, this is demonstrated quite clearly. In addition, piles of this type are characterized by enviable durability, even when used in heavily waterlogged soils or directly in water;

- Metal piles. The most expensive type listed. A pile foundation for a metal bathhouse, in the vast majority of cases, is made of pipes with a diameter of about 6 inches or 152 mm in metric calculus. Practice shows that they are used when the owner has at his disposal material that was obtained by chance and inexpensively and he is attracted by the possibilities of quickly installing the foundation through the use of special equipment. For example, a hydraulic hammer based on a wheeled excavator - loader type JCB - 3. Fast, efficient and quite affordable for the cost of a machine-hour of operation of the installation. Do not neglect the methods of protecting metal made from structural steel. After all, it is susceptible to corrosion in a humid environment. In most practical situations, it will be sufficient to coat the working part of the pile with waterproofing mastic based on modified bitumen.

Attention! In some cases, when using pipes of insufficient cross-section to confidently hold the bathhouse structure, each element is further strengthened by filling the cavity with heavy concrete with intermediate shrinkage of the mass using a manual tamper or vibrator. At the exit we have a kind of combined metal-concrete pile.

Floor tiling

Ceramic tiles can be laid on top of the wooden floor in the bathhouse. In this case, instead of boards, fibreboard, fiberboard or plywood are used for the rough coating.

In the washing compartment you can lay tiles on the floor in the bathhouse

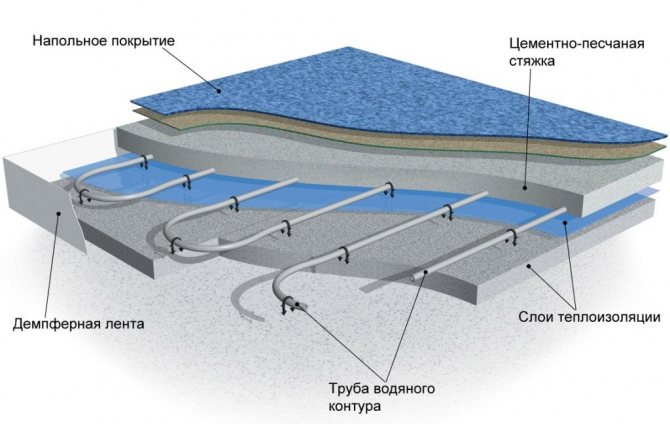

Ceramic tiles are laid on top of the laid sheet covering. This is done in the usual way. Under the tiles, you can lay a system heated floor in a bathhouse on screw piles. You can use a hydraulic or electric infrared option.

In the locker room you can install a heated floor in the bathhouse

Electric heated floor installation

Water heated floor diagram

Features of foundation construction

The range of bath heating devices is large, so the foundation is equipped taking into account each specific type. For example, a stove made of brick requires a massive structure, while one made of metal requires a lightweight one. Moreover, each type of base has characteristic assembly features.

The foundation for the furnace can be either brick or concrete. The latter has a greater margin of safety, but is correspondingly more expensive. At the same time, arranging a foundation for a brick sauna stove will cost much less, and it is easier to dismantle it, but it loses in strength. Which of the described options is preferred is up to the owner to decide.

Preventive measures

A bathhouse on screw piles has a high level of moisture; special preventive measures will help make the floor inaccessible to fungus and mold, which inevitably appear in a humid environment. During the construction process, all structural elements used must be coated in several layers with a special antiseptic composition.

To prevent the floor from rotting longer, it is necessary to cover it with an antiseptic against fungus.

It is imperative to use high-quality waterproofing materials. This can be roofing felt or plastic film. These measures will help increase the service life of the structure and protect it from rotting and premature destruction.

Scheme of waterproofing the floor in the bathhouse

If pockets of rotting of the wooden material are noticed, the entire structure must be dismantled. Damaged elements need to be replaced.

Nuance! After thorough drying, treat all components with an antiseptic and dry again. Before assembly, you need to coat the wooden elements with wax or water-repellent varnish.

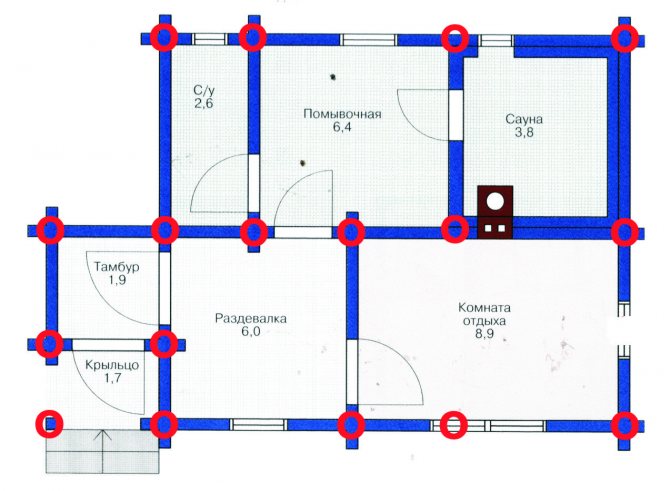

Stages of creating a pile foundation

Before installing several piles under the bathhouse, you need to clear the area of vegetation. Next, according to the foundation drawing, markings are made on the ground and they begin to drill a well with a hand drill with a diameter of up to 300 mm. To determine the number of piles, the weight of the bathhouse is taken into account.

Next, formwork is made - a pipe made of roofing felt or metal, which corresponds to the diameter of the well and exceeds its depth by 200 mm. The part of the roofing felt pipe that rises above the ground is tied together with wire. After which the structure is lowered into the well.

If there is water at the bottom, it must first be pumped out.

To make a reinforcement cage, take 3 reinforcement bars with a diameter of 6 mm and fasten them to each other with crossbars every 500 mm. They must be higher than the piles themselves, poured with concrete, for connecting with a grillage. Then the entire structure is poured with concrete in layers of 60 cm, compacting it using a vibrator.

The piles must stand for 10 days. Next, they begin to install the grillage - the upper part of the foundation. To do this, formwork is made from wood, reinforced and filled with concrete. Do not forget to place pipe sections across for further ventilation of the underground space of the bathhouse. The grillage is made at least 30 cm high and no more than 40 cm wide.

You can also make a grillage from prefabricated reinforced concrete beams, which are carefully secured to the pile heads, welding them to the vertical pile rods, and after installation, all joints and seams are carefully filled with concrete or cement mortar. Before erecting the load-bearing walls of the bathhouse using a level or water level, it is necessary to check the horizontalness of the base of the grillage, leveling it, if necessary, with cement mortar.

To reduce the cost of the bathhouse design, you can install wooden beams directly on the metal supports. And the frame should be reliably reinforced with nails or wire. It is necessary to put waterproofing between the foundation and the timber. The same material is placed between the trim and the walls. All open areas of the timber must be covered with mastic; this will protect the strapping from rotting.