An unprepared person usually knows little about foundations, only what he comes across in passing in the literature or on the Internet. However, when faced with the problem - starting construction, many discover that, in fact, they really don’t know anything. It turns out that there are many varieties, they cannot be built without exact knowledge of how it is done, and most importantly, information from other sciences is needed - geology, physics, strength of materials, etc.

Attempts to build at random usually lead to loss of time, money, and, in the long term, the building itself. Therefore, it is worth spending a little time studying the issue. And here we will look at the types of foundations for a bathhouse; for more detailed information, follow the links in the text.

DIY sauna foundation tape

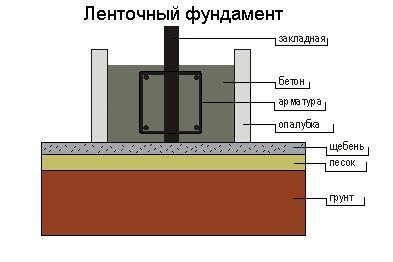

A strip foundation for a bathhouse is used quite often in construction and is a continuous strip of concrete mortar, blocks of different configurations or red brick, which is laid in the ground below the groundwater (but above the freezing level) and rises at least 20 centimeters above the surface.

When is a strip foundation for a bathhouse optimal:

- If you plan to use the basement floor for different purposes (as a utility room, tool storage area, pump, etc.)

- If the building is planned to be large with considerable weight (assembled from rounded logs, bricks)

- When there is a high groundwater level

A strip foundation for a bathhouse is capable of taking on loads from the entire structure and transferring them to the soil. The base protects the base from cold, wind, moisture; its walls can simultaneously serve as a basement or ground floor. The cost of the foundation is in the average range - higher than columnar, but lower than monolithic. Ideal price-quality ratio, especially if you build a strip foundation for a bathhouse with your own hands.

Selecting a location

The construction of a base for a bathhouse from blocks can be carried out on almost any type of soil. Blocks are usually used on coarse, rocky, clayey, biogenic, sandy and ordinary soils.

Many experts recommend installing foundations from blocks for low-heaving soils, since they have the necessary qualities to neutralize their properties and give the structure reliability and strength.

In Russia, blocks are the optimal solution for construction, since they are able to minimize possible deformations during soil freezing in winter.

Calculation of the foundation for a bathhouse

When pouring a strip foundation for a bathhouse with your own hands, step-by-step instructions will definitely not be superfluous.

You cannot perform the foundation “by eye” (like any construction work). It is necessary to calculate everything in advance, draw a diagram, draw up a work plan, a project, and then strictly follow the standards, maintaining all values and parameters, without skimping on materials.

To correctly calculate the foundation, you need to know the weight of the future bathhouse (with all the floors, interior fittings, roofing) and the level of freezing of the soil layer and the flow of groundwater in the prepared area. By examining the soil, the depth, width and height of the strip foundation for the bathhouse can be correctly determined. Research can be entrusted to specialists or performed independently.

To implement the first stage of calculations (to study the groundwater levels and the soil freezing limit), it is necessary to drill wells at the construction site in several places until water appears. For clayey and dense soils, with low groundwater levels, a shallow strip foundation 40-60 centimeters high will be sufficient. For middle strips, choose a strip base buried 1.6-1.8 meters (below the soil freezing line).

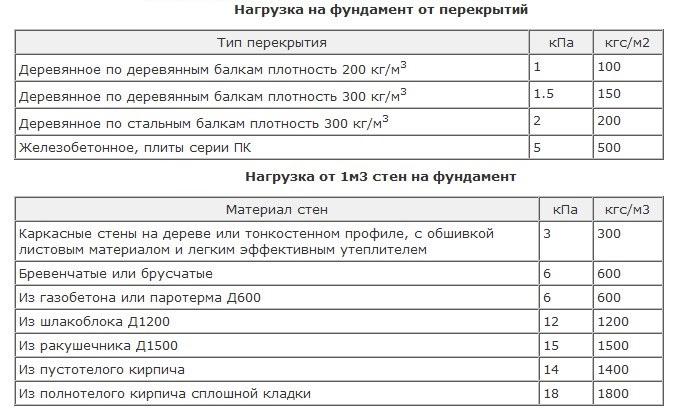

The loads on the strip foundation, which are placed on the structure, are calculated using special tables that contain approximate weight indicators for all elements of the bathhouse.

Much depends on the materials used and design features. The weight of all bathhouse equipment and people (in the amount that can be in the building at the same time) are added to the indicators. The tables also determine soil resistance.

The dimensions of the strip foundation are determined by the total load from above, which is divided by the soil resistance.

We build a slab foundation

Terrain marking

If there are unreliable soils on your site from the point of view of construction, you cannot do without installing a slab foundation. There are two main ways to obtain it - make it yourself, saving significant money, or involve one of the many teams of volunteer assistants. Thanks to the attached instructions, the first option will be the most acceptable for you.

The first stage of construction after drawing up the project and calculating the parameters of all structural elements is marking out the area for the slab foundation. It represents the drawing of the boundaries of the future pit, the dimensions of which are 1-2 meters larger than the external dimensions of the building.

It is advisable to first level the construction site to a level as close to horizontal as possible. This will make it easier to maintain the horizontality of the bottom of the pit in the future. This can be done manually using a bayonet and shovel or by renting a grader with a driver.

Marking the terrain for a slab foundation

Unlike a columnar foundation, a slab foundation is marked around the perimeter using a set of reinforcing bars 0.5 meters long and a strong cord. To do this, you first need to orient the future foundation in the direction relative to the house and the cardinal points. The technology for marking a monolithic foundation is as follows:

- In one of the corners of the future pit we drive a steel rod to a depth of 30 cm.

- We set aside the required distance along the direction of one of the walls of the bathhouse, controlling it using a tape measure, and drive in the second stake. We tie the rods with a strong nylon cord.

- From the first rod, perpendicular to the first line, we set aside the required width of the future recess for the slab foundation. The following methods can be used to control squareness:

- Using the Pythagorean theorem, calculate the length of the diagonal based on the known legs - the sides of the pit. It is convenient to set aside this distance using the free end of the cord, having previously measured its required length.

- Builders are well aware that the sides of a right triangle have a ratio of 3:4:5. It is enough to set additional marks at these distances in meters and get the desired right angle.

- Next, from the second rod, we determine the location of the last rod, install it and control the rectangularity of the marking. To do this, it is enough to measure the diagonals of the resulting quadrilateral. They must be equal.

Having completed the planar marking, you can proceed to other stages of work on the construction of a floating foundation for a bathhouse.

Digging a hole to fill the slab

One of the most physically expensive stages when building a monolithic foundation with your own hands is excavation work. With the help of a shovel, the process takes quite a long time. In addition, in work it is often necessary to use an ax to cut off the existing roots of fruit trees or bushes.

Preparing the base for a slab foundation

The digging depth depends on the specific soil conditions of your site and can range from 0.5 to 1 meter. Construction engineers or communication with neighbors who already have a slab foundation for a bathhouse or other structures will help determine the required level of depth. The soil removed during digging can be used to fill lower areas of your property or distributed evenly over its entire area.

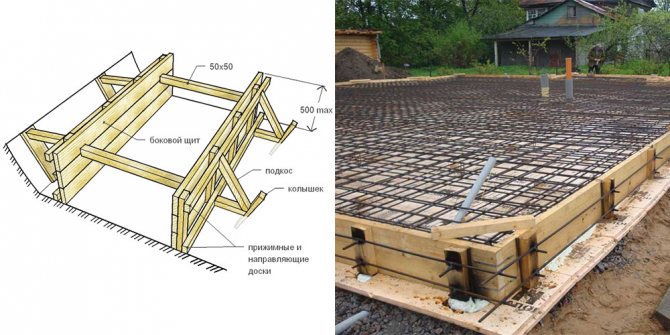

Installation of formwork is an important stage of work

To ensure that the monolithic slab for the bathhouse has the correct shape, and that the concrete after pouring does not flow beyond the boundaries of the future monolithic foundation, it is necessary to install formwork along the edges of the pit. It consists of shields, the width of which is 30-50 cm greater than the depth of the pit. This value will allow the future foundation to be raised above the soil layer.

Formwork panels are made from edged boards, moisture-resistant plywood, OSB, and flat slate. On the outside of the future slab, the formwork must be fixed with spacers, which rest on scraps of boards driven into the ground. They install the panels directly at the construction site of the slab foundation or use ready-made ones. Installation, for example, of a columnar foundation does not require formwork.

Formwork for a monolithic slab

Often, slab insulation is also installed on the inside of the formwork for a floating foundation. This is due to the small thickness of the slab, which in turn does not allow it to have high thermal insulation properties.

Mandatory element - filling the bottom of the pit

After finishing the excavation work and resting for a couple of days, you can continue making a floating foundation with your own hands. The next stage is filling the bottom of the pit with crushed stone and sand. This is necessary to create a compensation layer that reduces the influence of ground movement on the base of the bathhouse. The technology for performing this stage of work is as follows:

Filling the bottom of the pit with crushed stone and sand

- The bottom of a pre-leveled pit for a floating foundation is lined with several layers of geotextile - a special woven material that is widely used in the construction industry;

- Clean, seeded quarry or river sand is poured onto the material. It is advisable to fill in several layers, moistening and compacting each one. The total thickness of the sand bed for a monolithic foundation should be at least 30 cm. The bulk material can be compacted manually using a simple device made from a meter-long piece of timber or log, to the ends of which a piece of thick plywood 40x40 cm and a handle made of a wooden block are nailed. There is also a mechanical assistant for performing such work - a vibrating plate.

- Crushed stone of the middle fraction is poured onto the sand layer and also compacted.

Making a concrete pad

To obtain a perfectly flat base for pouring the main concrete layer and giving the base a horizontal surface, builders recommend making a small concrete pad for the future floating foundation. Before its installation, the entire bottom of the pit is lined with waterproofing and tightly laid polystyrene foam insulation. As noted above, the small thickness of the slab does not help retain heat inside the bathhouse.

Various rolled materials are used as waterproofing for floating foundations. The most common and affordable is roofing felt. Instead, it is also possible to use the already mentioned geotextiles. A layer of waterproofing is also necessary when installing other foundations for a bathhouse, for example, a columnar foundation.

The use of a high quality mixture helps to impart high strength to the first concrete layer. Since the consumption of the composition is not high, in this case it is better not to skimp on its components. After pouring the pillow, you need to let it harden completely and gain sufficient strength, which happens in 7-10 days.

Installation of reinforcing frame

It is impossible to obtain a high-quality slab foundation without using a reinforcing frame. It is made from rods interconnected into a mesh with large cells. To obtain high structural strength, reinforcement is carried out in both horizontal and vertical planes.

The first armored belt is installed at a height of about 5 cm from the pre-poured concrete pad. To fix this distance, pieces of crushed brick are placed under the rods. The rods laid lengthwise and crosswise are connected by welding or twisting knitting steel wire. The second layer of reinforcement is laid at a distance of 20 cm from the first using a similar technology.

Reinforced frame for foundation slab

To vertically connect two meshes, cut many pieces of reinforcement 25 cm long and install them vertically in the corners of the cells. The fastening of the connecting rods is carried out similarly to the connection of the reinforced belt rods. The upper ends of the inserts should be located 5 cm below the border of the slab.

Installation of water drainage and power supply systems

An important stage in the construction of a slab foundation for a bathhouse is the installation of sewerage systems. For ease of subsequent operation, drainage elements can be placed directly in the foundation slab. This is much more convenient and will keep the sewer parts in working condition for a long time.

Similarly, elements of the water supply system that ensure the operation of the future bathhouse can be installed in the installed sewerage system. The absence of overhead water lines allows you to not worry about their thermal protection to avoid freezing.

Installation of communications

In addition to water mains, when building this type of foundation for a bathhouse, you can also install an electrical supply system. The absence of overhead lines will allow construction equipment to move around the territory and plant fruit trees without any restrictions.

Since a slab foundation can serve as a floor in a bathhouse, the pouring process is often combined with the installation of its heating systems. They are a spiral or winding plastic or metal pipeline embedded in concrete through which heated water will move. This design is called a water heated floor.

Filling the slab foundation with concrete

If a columnar foundation does not require the use of concrete in its manufacture, then the installation of a floating foundation requires quite a lot of mixture. In this case, the slab should be filled in full in one step. It will not be possible to produce the required amount of concrete using a small household concrete mixer.

To obtain the mixture in sufficient volume, it must be purchased from the nearest concrete plant. The advantage of such a purchase is delivery of the full volume on the desired day using automobile mixers. The disadvantage is the high cost of concrete. This is another important element of the total cost of making a slab foundation with your own hands.

The delivered concrete is poured onto a pre-prepared base, gradually filling the entire space inside the formwork. With this method of pouring the foundation, you can get a slab of low quality. This is due to the presence of air bubbles in the concrete mass. To remove them and compact concrete, use a special construction tool.

We are talking about a concrete vibrator, which during operation creates far-reaching vibrations in a viscous composition. Thanks to this, the density of the future monolithic foundation increases significantly, which leads to an increase in its strength characteristics. Without vibration compaction, it will be very difficult to obtain high-quality concrete pouring.

The final stage of construction

After the floating foundation is completely filled with concrete, it is necessary to give it time for the concrete to acquire maximum properties. To do this, the slab is covered with a large woven cloth and periodically moistened to prevent drying out. If this is not done, a network of small cracks may form.

Final steps after pouring concrete

The duration of exposure of the slab, in contrast to the columnar foundation, can range from several weeks to several months, depending on weather conditions and the thickness of the base of the bathhouse. After this, you can dismantle the formwork. On the finished slab, the construction of bathhouse walls from blocks, bricks or wood materials begins.

Foundation installation methods

Before making a strip foundation for a bathhouse with your own hands, it is important to decide on the materials and geometry of the structure, the method of installing the structure, and other important points that influence the choice of foundation parameters.

Brick strip base

A bathhouse can be built exclusively from red brick, since white silicate brick is resistant to moisture and deteriorates quite quickly. When choosing a brick base, be sure to pay attention to the seams - they must be well waterproofed, since the concrete solution allows water to pass through.

Brick is an ideal choice for those who build a bathhouse with their own hands on sandy, dry soil. If the groundwater level is high enough, it is better to make a foundation of concrete mortar with mandatory reinforcement with steel rods and screed. A reliable brick foundation is installed on a sand-crushed stone bed, well compacted. You can do everything yourself, since the brick is light in weight and is relatively simple and quick to lay.

From blocks

When designing a strip foundation for a bathhouse with your own hands, you can choose reinforced concrete blocks, but the work will require special equipment, since the blocks can weigh a lot and you won’t be able to lift them yourself. For a small structure, you can make a block base from blocks measuring 20x20x40 centimeters, which are laid preferably in a checkerboard pattern and require a cement connection. The blocks are laid clearly according to the markings on a sand bed, installation takes a maximum of 1-2 days.

From stone

A high-quality rubble concrete base can also be made with your own hands; it consists of cement and most often river stone, preferably flat in shape (preferably the same size). The stone is carefully laid out in the formwork in layers, poured with a concrete mixture - this way a strong, beautiful base is created, which will be relatively inexpensive, provided that the stone is not delivered from afar.

With permanent formwork

Installation of a strip foundation for a bathhouse with permanent formwork is a new technology that involves the use of two expanded polystyrene slabs. They are connected with metal pins, the inside is tied with reinforced steel wire, and everything is filled with concrete on top. The strength of the base can be compared with any other installation method; it does not require additional waterproofing or insulation.

Made from concrete

A concrete base is the simplest and most affordable option for making a monolithic foundation. To create it, formwork is installed, steel reinforcement is placed in it (tied and correctly installed on clamps), and filled with durable concrete. Pouring is carried out at a time, so the work will have to involve several more people to supply the solution or use a concrete mixer to supply the solution to the site.

The concrete hardens for 28 days; after the initial setting, the formwork is dismantled, and the base is ready for further construction work.

Features of the operation of baths

First of all, the developer needs an inexpensive, reliable foundation. Therefore, even before studying the soil and the depth of groundwater, special attention should be paid to the operating features of the bathhouse:

Intermittent heating

In most cases, a deep foundation will cost more than the bathhouse itself. Therefore, non-buried and shallow-buried structures on soils with normal bearing capacity or piles in swamps, steep slopes or in the coastal zone are more often used.

To insulate the MZLF and the floating slab under the entire bathhouse, you will have to make a thermal insulation circuit from slabs of extruded polystyrene foam. This is necessary to eliminate swelling of clay soils, as indicated in the album of technical solutions of the manufacturer Penoplex for buildings with periodic heating. In the absence of heating in winter, the thermal insulation layer will retain the heat of the subsoil and prevent the soil from freezing.

By choosing bored piles, screw piles or a columnar foundation with a grillage, these costs can be avoided. The piles do not need insulation; the pillars are insulated similarly to MZLF along the entire perimeter of the building.

Unlike a cottage with constant heating, it makes no sense to insulate a bathhouse from the outside. But inside you need a frame with a heat insulator placed in its sheathing to reduce heat loss. In this case, the sauna will warm up faster and less energy will be consumed. Therefore, it is better to choose a lightweight frame structure that can be supported even by pillars made of brick or concrete blocks.

Availability of a washing room

In these rooms, water pours onto the floor; proper drainage is required. The floating slab and floors on the ground inside the MZLF are ready-made screeds, in which it is enough to make slopes towards the ladder, collect water, and divert it to the septic tank.

In hanging grillages on pillars, bored and screw piles, it is impossible to make floors on the ground. The floor slab is too expensive and seriously loads the foundation. Therefore, either a slab grillage is poured under the washing room and steam room, or a galvanized sheet is attached under the floor, in which there is a drain for the sewage system.

Important! Communications in the underground grillage foundation will have to be additionally insulated, since the soil under the bathhouse freezes completely.

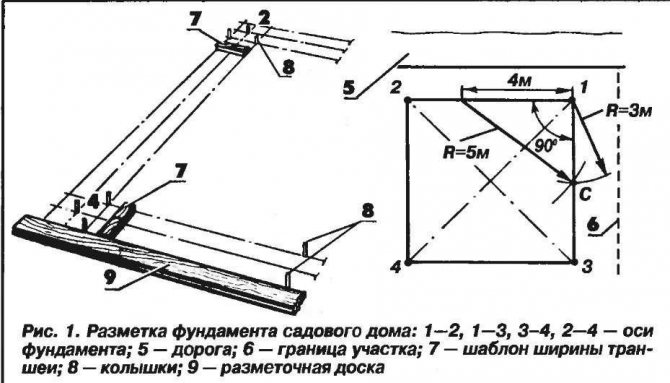

Marking

Before you properly pour a strip foundation for a bathhouse, you need to know how to mark the territory. The marking corresponds to the project and involves marking all internal and external boundaries of future walls.

To perform external markings you will need: a cord, a square, a plumb line, regular pegs, and a large tape measure.

The starting stake is driven into the point where it is planned to locate any of the corners of the building (with mandatory control of the vertical level). The remaining stakes for the corners are also driven into the ground, and the diagonals of the perimeter of the structure are checked. Then a cord is pulled between the stakes, the horizontal level of which corresponds to the height of the foundation. Check the evenness of the cord with a level.

Next, mark the internal walls around the perimeter, noting the locations of the partitions. Then they retreat from the outer perimeter to a width equal to the strip base, drive in stakes, pull the cord, and mark the location of the partitions. Here, too, everything must be level, so you can’t do without a tape measure, a plumb line, or a construction square.

Columnar foundation made of blocks - work algorithm

- Clear the construction site and remove the top part of the soil.

- Mark using stakes and rope. It is necessary to simulate the external and internal boundaries of the foundation. The rope must be pulled strictly horizontally, horizontality is checked strictly by level. Mark the installation locations of the support pillars. They must be installed under places where walls will intersect, at corners and under walls every one and a half meters. It is also necessary to install several support pillars under the floors.

- In places where the pillars are installed, holes are dug 30-50 cm deep. The width of the holes should be slightly wider than the pillars. If the soil on the site is heaving, then it is necessary to fill it with a sand cushion or a cushion of crushed stone. It is spilled with water to compact it, then covered with roofing felt on top for waterproofing.

- Using the rope as a guide, the pillars are laid using cement. Each row should have 2-3 blocks.

- When the cement solution dries, it is necessary to waterproof it. For this purpose, it is recommended to use coating waterproofing.

A solid concrete block for the foundation weighs approximately 30 kg. Their size is 190*180*390. For a shallow foundation, 1 pillar will require 6 - 12 pieces.

Excavation

The depth of the foundation directly depends on the type of soil on which it is built. A trench is dug along the marked elements, the bottom of the ditch is compacted manually or with a vibrating plate, making sure the base is even. Then they are covered with sand 7-40 centimeters thick, which is directly dependent on the type of base.

Thickness of the sand layer depending on the type of foundation:

- 7 centimeters – shallow foundation

- 7-15 centimeters – deep foundation

- 15-40 centimeters - if a floating base is laid

A layer of sand is poured horizontally, watered, and compacted. If you need to lay a lot of sand or add a layer of crushed stone, the work is carried out in stages, in layers of 5-7 centimeters. Further work is allowed after 2-3 days, after the pillow has completely dried.

Formwork for concrete screed

The formwork of a strip foundation for a bathhouse is constructed from pieces of slate, fiberboard, any boards, plywood panels and any other materials. Collapsible structures made of metal or plastic can even be rented. The material is wrapped in polyethylene, mounted inside the trenches, the outer sides are immovably supported with stakes and lumber.

Between the walls of the formwork you need to insert transverse struts and attach metal pins every 50 centimeters. This will eliminate the possibility of a mass of mortar escaping from ruptured seams. The shields are fastened to the ground with 20-centimeter nails and secured to each other with a stapler or self-tapping screws.

Special holes for communication pipes are made in advance in the panels, so that later you do not have to drill into the concrete and make it less durable. Using film or glassine to protect the formwork will not only preserve the panels, but also reduce the absorption of moisture into the wood (because of this, concrete often becomes covered with cracks).

Reinforcement

Making a foundation for a bathhouse is impossible without reinforcement. For strengthening, choose reinforcement with a cross-section of 12 millimeters (for laying longitudinally) and 6-8 millimeters (for laying vertically and perpendicularly). To perform reinforcement, you need to prepare: wire, steel rods, an angle grinder, a tape measure, a welding machine (if you plan to weld the frame rather than knit it).

The structure is made up of 4 or more rods lying in three planes (longitudinal, perpendicular, vertical). The finished frame rises above the ground by at least 5 centimeters, the corners are further reinforced. The work is completed correctly if the cut of the armored belt turns out to be either a square or a rectangle.

Stages of creating a reinforcement frame for a bath:

- Measuring the perimeter, cutting the reinforcement to the required length.

- Laying out the reinforcement on the ground, tying it with wire - the longitudinal rods are laid with an overlap of 30 centimeters and tied together. Between vertical and perpendicular rods there should be a step of a maximum of 50 centimeters. To lay a foundation wider than 120 centimeters, a frame is made from a larger number of rods.

- Strengthening the foundation in the upper part with special clamps in the shape of the letter P.

- Complementing the frame with steel rods, which are placed at an angle of 45 degrees with respect to the horizontal rods.

Filling the tape

It is best to pour the foundation for a bathhouse in one day (preferably in one go), which will ensure the strength and reliability of the structure. You can’t do this without a concrete mixer, but if you don’t have one, you can order the required volume of cement mortar.

DIY recipe for mixing concrete mortar:

- Clean sand – 2.5-3 parts

- Cement grade M400 at least – part

- Clean crushed stone - 4-5 parts

- Water - in sufficient quantity to obtain a mixture of medium consistency

The solution is poured into layers of 20 centimeters, leveling each with a tool (trowels or shovels). Then they are compacted by piercing or a vibrating drill, tapping the walls of the formwork. If the work is completed in the evening, it is better to cover the foundation with a polyethylene film at night. During the day you need to spray water on the surface for the first 10-12 days. Then the formwork is dismantled, they wait until it reaches full strength (28 days), lay a layer of insulation and continue work.

Block subtype

The type of such base differs in its manufacturing technology and raw materials. Cement mortar is poured into the finished trench, and brick or rubble blocks are placed in it, held together with cement mortar. This subtype of foundation makes it possible to use a smaller volume of solution.

Due to the fact that the blocks can be laid with gaps, an intermittent foundation is created, which has noticeably lower shrinkage rates. This leads to the fact that the mass of the bath can be increased by 20-30%. Thus, a shrink-wrapped bathhouse made of timber will be more reliable and durable.

It is worth noting that all types of strip foundations should not be laid in heaving and watery soils. They are also more difficult to install than pile foundations.

Pouring a warm strip base under the bath

A relatively new technology that allows insulation of castings in the soil based on porous polystyrene boards. To create the formwork, in this case, take plastic plates of a permanent type, install them in a trench, connect them end-to-end, and fix them with steel spacers. After pouring, the concrete mixture fixes the thermal insulation, creating complete insulation of the structure.

Creating a strip foundation for a bathhouse is a task that can be done with your own hands. Provided that preliminary calculations are carried out correctly, quality materials are purchased and technology is followed, it will be possible to obtain a high-quality, strong and reliable, durable base for a bathhouse.

Foundation for construction

For a bath, you can use several different types of bases, including:

Strip foundation diagram.

- Strip foundation made of blocks. Such a base can be shallow or ordinary, while the first option is usually recommended for slightly heaving soils, for small baths made of wooden beams. Typically, such a foundation made of blocks has a laying depth of 50-70 cm.

- Columnar consists of supporting pillars or slabs that are installed at the corners of the structure, at the intersection of walls. Such bases are used for slightly heaving soils and baths, which are small in size. The supporting pillars are usually metal and asbestos-cement pipes, but pillars can also be constructed from brick; blocks are used much less frequently.

- Pile foundations are used when the bathhouse is planned to be quite massive and large, but if the soil on the site is very heaving, it is best to make a regular slab foundation that will withstand all the loads.

- A slab base for a bathhouse is used extremely rarely, since the cost of such a design is high, it is more suitable for a residential building.

- The floating type of foundation is suitable when the soil is highly heaving; for this purpose, a structure made of concrete and reinforcing mesh is used.