A block garage foundation can be built from a variety of materials. The choice in favor of a particular option is determined mainly by the characteristics of the soil at the construction site, the design load on the foundation and the presence of a basement. For the construction of buildings, cinder blocks, foam blocks, FBS and expanded clay concrete blocks are often used. A prefabricated foundation for the structure is also built from them. At the same time, foundation construction technologies are generally similar, but there are some nuances that should be taken into account to achieve a durable, high-quality result.

Pros and cons of foundation blocks

Like any material, FBS also has its pros and cons. Let's take a closer look at them.

FBS block sizes.

Advantages:

- FBS blocks are manufactured in accordance with GOST 13579-78, which regulates their dimensions and characteristics. The strength of the blocks is ensured by the factory control system and automated production. All stages from mixing to hardening are closely monitored, which guarantees the quality and durability of the product.

- Fast construction. With the help of FBS, foundations and buildings are built very quickly, and if the solution is not mixed on site, but is ordered ready-made, the time will be significantly reduced.

- Simplicity. No special skills are required to lay blocks. Well, if something has already gone wrong, then it is possible to easily disassemble and reassemble the entire structure.

- Nomenclature. A large size range allows you to build a room of any size and shape. Any block can be cut to your size.

- Specific additives. They are included in the composition for those PBS that are capable of working in difficult conditions of low temperatures or in soil with high acidity.

- Convenient assembly. Convenience is guaranteed by mounting loops and grooves, as well as dimensional standardization.

Flaws:

- Non-monolithicity. As a result, the seams between the blocks should be waterproofed, and the foundation should be further strengthened against freezing.

- Price. The high cost is due to the price of the FBS itself and the rental of special construction equipment.

- Low strength during foundation construction. A monolithic foundation wins significantly in this matter.

- Demanding requirements for soil. We do not recommend installing blocks on shifting soils or waterproofing them when the groundwater level is high.

As you can see, there are not many disadvantages, so if you want to build yourself a garage, an extension or an entire country house, we advise you to choose FBS and you will quickly get a good result.

Construction

The first step is soil exploration and preparation. The easiest option would be to ask your neighbors. Perhaps they have already taken measurements and are ready to share information. But if this is not possible, you will have to do the research yourself.

To find out the characteristics of the soil, you will need to dig a hole with a depth of 2.5 meters . Then, at every 20 centimeters of the hole, it is necessary to take soil samples to determine the depth of groundwater and the type of soil. If you are not confident in your abilities, you can always resort to the services of specialists .

After conducting the research, you should decide on the number of floors and size of the garage. The more floors a building has, the heavier it is, which means the requirements for the foundation will be higher. For calculations, you need to take into account the density of materials (walls, ceilings) and their volume. By multiplying numbers, you can get the mass of the building and determine the weight distribution.

Please note that a brick building will be significantly heavier than a foam block building; the densities differ by almost two times. To strengthen the foundation, reinforcement is used. For massive (for example, two-story) garages, foundation reinforcement is often the only possible solution.

The last stage is soil preparation and waterproofing. The area must be marked using wooden pegs and nylon thread. The angle must be exactly 90 degrees.

Waterproofing should be installed in both planes - vertical and horizontal. The “walls” and “floor” of the foundation are covered with insulating material.

Waterproofing is made from roofing felt or synthetic film.

Please note that the insulation process depends on the type of foundation , since different construction methods require the presence of different structural elements.

Let us consider in general terms the construction of foundation types:

- Tape

First, you should dig a trench, if groundwater allows, then approximately 60-80 centimeters deep. The width of the trench is equal to the size of the foam block +10 centimeters. Then create sand cushion.The layer of sand is small - 15 centimeters, it is also compacted . Crushed stone is poured on top and compacted in the same way. After this, you can begin formwork and install the frame. The last procedure is pouring concrete .

- Column

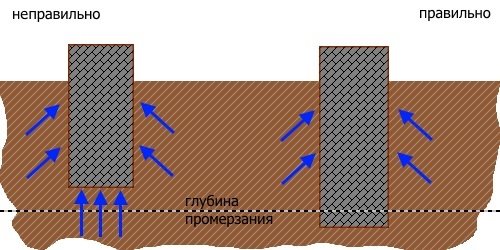

Column foundation is suitable for one-story garages with low mass. In the process of pouring concrete, it is necessary to use reinforcement . It will add additional strength and rigidity to the entire structure. The pillars are placed at intervals of 1.5-2 meters. The depth of the foundation for a garage made of foam blocks, that is, the immersion of pillars into the soil, should be 20 centimeters higher than the freezing level. - Pile

It is recommended to build a foundation on piles in unstable soil . For this you can use long, six-meter piles. They are immersed to solid layers of soil. Then formwork and a monolithic base are made on top of the piles. Using the pile method, the mass of the building is distributed over piles and rests on stable soil. - Monolithic slab

A monolithic concrete slab is used as a foundation for small garages. But the slab cannot support a large mass.An indication for such a foundation is the presence of heaving soil on the site. To install the slab, you need to remove half a meter of soil and fill the hole with crushed stone.

A metal grid is placed in the crushed stone and the mold is filled with cement. The lattice gives strength to the base.

Please note that it is not possible to equip a garage with an inspection hole or a basement in this option.

For the inspection pit it will be necessary to choose a different base.

Features of the FBS foundation

How are foundation blocks made?

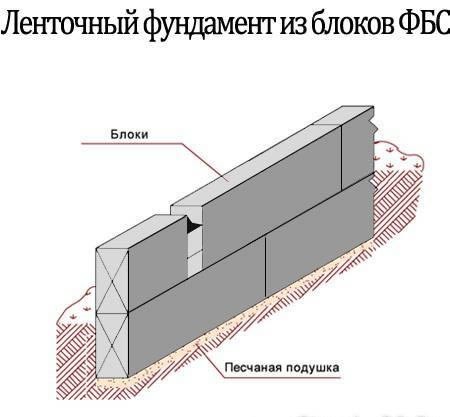

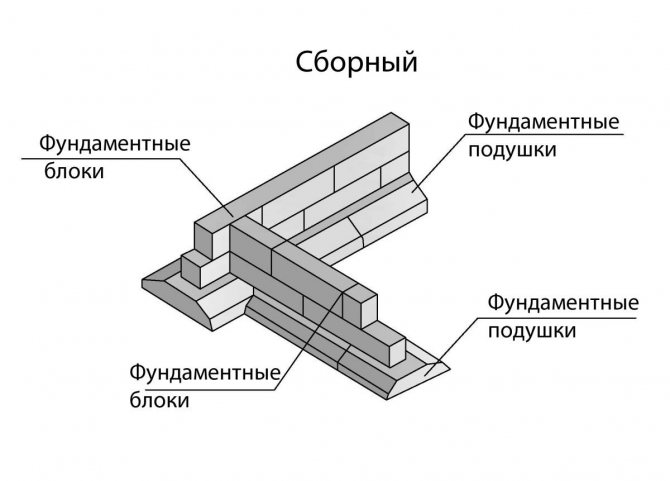

It is a structure similar to a strip foundation. For its construction, heavy FBS concrete blocks are used. Under the foundation it is necessary to pour a substrate of coarse sand measuring 50*100 mm. The thickness of the substrate is 10-15 cm.

One of the features is the need to prepare cement in the required quantity in advance, and then start bonding the blocks. Because by adding water to the solution during the laying process, the strength and integrity of the entire building are compromised. For this reason, the surface where the blocks are installed should not be wet.

The process of building a foundation using blocks is exactly the same as when laying bricks, only you have to use construction equipment due to the dimensions and weight of the building material. The thickness of the seam between the FBS is about 20 cm, and the horizontal deviation of the row is no more than 15 cm for every 10 m.

Types of blocks used for foundation construction

A prefabricated foundation for a garage can be built from reinforced concrete foundation blocks, expanded clay concrete blocks, and cinder blocks. The use of foam blocks for the construction of the foundation for this structure is controversial.

If you build a garage from FBS blocks, then it is convenient to lay them as a support under the building. In this case, both cushion and wall varieties of such products are used. The first ones have a trapezoidal shape in cross-section. They are used to strengthen the created supporting structure by increasing the base area, laying the first row of the base. In this case, the load from the structure on the ground is reduced, which reduces the likelihood of building subsidence.

The remaining part of the foundation and the entire building are laid out from wall blocks. There are varieties of products that have cutouts on the sides. They are designed to improve the joining of elements with each other.

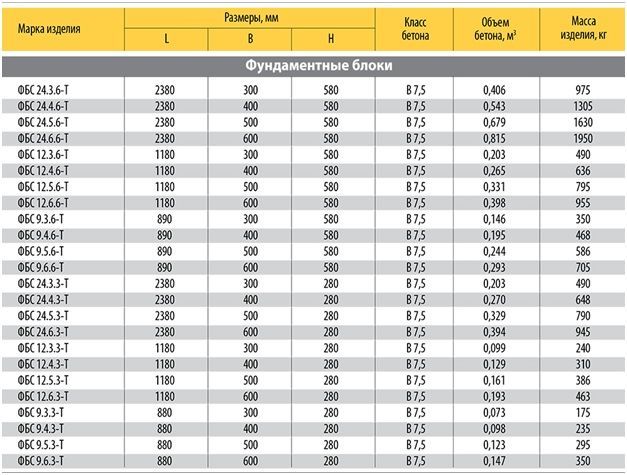

Manufacturers provide the consumer with a large selection of FBS. The table below shows a partial range of products.

The presented brands of blocks differ in their dimensions and weight. Based on the planned dimensions of the structure being erected, it is possible to select a FBS with the required parameters. It is easy to build a garage with a cellar or basement from ready-made blocks. The use of the material will require the use of lifting equipment.

Using foam block

There is no clear opinion regarding the use of foam blocks for constructing a foundation for a garage. The fact is that such material, despite sufficient strength, strongly absorbs moisture. Because of this, over time, its layer-by-layer destruction occurs. Therefore, if you use foam block for the construction of the base, it must be well waterproofed.

Garage made of foam blocks

When choosing foam concrete as a working material, you should weigh its advantages and disadvantages. The advantages include the high speed of construction of a structure made from it. Due to the light weight of foam blocks, it is easier and more convenient to work with them than with heavier blocks. It is very easy to cut the material into fragments of the required size; all you need to do is use a foam concrete saw.

In some cases, a material property such as low thermal conductivity may be needed, which will reduce heat loss through the base.

The garage itself is made from foam concrete much easier than from cinder block or FBS. It is also cheaper to build.

The disadvantages of the material are:

- strong sensitivity to moisture and the ability to absorb it, which requires very high-quality waterproofing work;

- significant weight restrictions for a structure erected on a foam concrete base, caused by the lower strength of the material compared to cinder block or FBS;

- instability to loads arising from ground movement;

- most brands of material are not intended for laying a foundation;

- The frost resistance of a moistened foam block is low.

Recommendations regarding the use of foam concrete are as follows:

- the material can only be used on non-heaving or slightly heaving soils, and the depth of their freezing should not exceed 1 m;

- products with increased density should be used (grades D1000-D1200);

- It is imperative to lay reinforcing bars between the rows;

- The foam block must be carefully protected from water.

A garage built from foam blocks, the base of which can withstand, only the soil must be dry and non-heaving. The laying depth is determined by the level of soil freezing. On average, it is 0.4-0.7 m. The material should absolutely not be used on moist, swampy soils. This should also not be done if the region is characterized by sudden temperature changes.

Experts do not recommend making a foundation from foam concrete. But there are still ways to build a foundation from foam blocks. In this case, it is practically impossible to guarantee the reliability, strength and durability of the supporting structure.

The use of cinder blocks and expanded clay concrete blocks

Cinder block is a relatively inexpensive building material that is highly durable. Its use is a good option when the construction budget is limited and the need to create a reliable foundation for construction.

Cinder block assortment

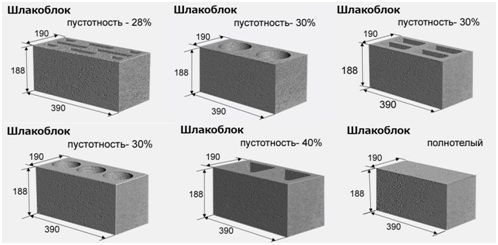

Cinder blocks are divided into two types:

- full-bodied;

- hollow.

Both types of material are suitable for building a garage. At the same time, hollow options have better sound and heat insulation properties. Foundations are built only from solid (solid) blocks.

It is also recommended to waterproof the cinder block base. For these purposes, roofing felt, bitumen and other similar materials are used.

Expanded clay concrete blocks consist of sand, cement and expanded clay. They are durable and resistant to temperature changes. This building material is available in different densities: the denser, the stronger.

Working with cinder block and expanded clay concrete blocks is quite simple: laying them does not require extensive construction experience and specialized knowledge. It is recommended to make the base part at least 0.2 m high from the ground surface. When building a garage from these building materials, the base is made from them or from FBS. The depth of laying a strip or column foundation is determined by the freezing mark of the soil. It should be 20% larger than her.

Construction of a garage from FBS

So, the foundation is ready and it's time to build the walls. Almost all wall blocks are highly hygroscopic, so the base should be at a height of at least 40-50 cm from the ground. If this condition is not met and the height of the foundation is not enough, then we recommend laying several rows of ordinary brickwork.

The base should be reliably waterproofed.

The first row of the block should be laid out very carefully, checking the level of distortions in the structure. To prevent cracks from appearing in the wall, it is necessary to lay a reinforcing mesh every 2-3 rows.

But this is not necessary if it is planned to be faced with brick or siding, and the inside is covered with oriented strand boards or plasterboard.

As in brick construction, when laying blocks, overlap of vertical seams should be avoided; blocks should be laid with bandaging. At the end, a monolithic belt 10-15 cm thick is formed.

When reinforcing, it is worth using reinforcement with a diameter of 14-15 mm. Before pouring, it should not touch the FBS and be closer than 2.5 cm to the edge of the formwork.

What should be the foundation for a garage?

Let's look at how the foundation is made, using the example of building a garage without a basement. At the same time, the walls of the building are planned to be made of slag concrete blocks, which is dictated by their relatively low cost in comparison with other materials. One of the profitable options is a foundation made of FBS blocks.

The garage is a small building, so two types of “sole” arrangement are suitable for it:

- The foundation is made of columnar blocks. This is one of the cheapest options for lightweight buildings. For example, such a foundation will be sufficient for a wooden bathhouse: the “base” for it from blocks can be built in one day. In turn, the “base” for the garage will consist of special support pedestals installed along the perimeter of the garage “box” (under the points of their intersection, the walls).

- A strip block foundation is suitable for heavier, small-sized buildings made of cinder blocks and bricks. Such a foundation is formed as concrete strips located under the load-bearing elements of the building.

Features of a garage made of concrete slabs

Strip foundation made of FBS blocks.

When planning to build a garage, you can select the materials, calculate them yourself, or even easier, buy a ready-made structure that will be cast and installed to order. A FBS garage will reliably protect your car from external influences. Let's consider the advantages and disadvantages of such a garage structure:

Advantages of a garage made of concrete slabs:

- Fire resistance. The walls of such a garage are not afraid of open fire and high temperatures.

- Reliability. A concrete garage can protect your property from robbery, external and atmospheric influences.

- Durability. A garage made from such material is built, as they say, to last for centuries.

- Frost resistance. Exposure to low temperatures does not affect the properties of concrete in any way.

- Environmentally friendly. FBS does not contain any components that can harm human health.

Disadvantages of a garage made of concrete slabs:

A garage built using the right technology has virtually no disadvantages.

But we will tell you something now:

- The walls of a building made of concrete slabs require mandatory waterproofing.

- For construction, it is necessary to use heavy construction equipment, which is not always possible in limited space.

- The large weight of the garage requires mandatory soil preparation. Sometimes a gravel-sand base is used, and in some cases a monolithic foundation is used.

Assembly of foundation blocks.

When choosing a construction site, we first make sure that the site has access to large equipment, then we prepare it for the structure. First of all, you should lay the main slab, which serves as the foundation for the walls.

Then concrete walls are erected, they must be fastened together with special anchors. The front slab with the opening for the gate is installed when the walls are ready. Lastly, floor slabs are laid, with a void inside, thereby reducing the overall weight of the building.

When the walls are ready, you should begin installing metal garage doors. Then the roof is covered with roofing felt or corrugated sheeting.

Monolithic strip construction technology

It is important to carefully mark the area before laying the foundation

If the site intended for the construction of a garage meets all the conditions, you can begin preparatory work.

To begin with, the surface of the site is cleared of household and construction waste, plant debris, holes are filled in and embankments are cut off. If necessary, make a vertical layout of the site - this is easy to do with your own hands.

After completing the planning and cleaning of the site, you can begin marking the boundaries of the future garage. To do this, measurements are taken on the site of the sides of the garage along the perimeter, pegs are hammered in the corners along which string is stretched, which will help maintain an even line when digging trenches with your own hands for the foundation.

Earthworks and formwork

You can dig trenches for the construction of a foundation strip for a garage with your own hands or with the help of mechanized digging equipment, but in both cases it is worth thoroughly cleaning the bottom and side walls of the trenches.

The formwork of the strip base is made of board panels

Sand of large fractions is poured onto the compacted bottom of the trench, which is thoroughly compacted, constantly spilling the sand cushion with water. The compacted layer of sand should be 10-12 cm high. A layer of small crushed stone or pebbles is laid over the sand, which is also compacted with your own hands using hand or vibrating rammers. The formwork is placed in the trenches manually, trying to maintain the vertical position of the panels. Shields should be made from wooden boards, thick plywood and chipboard. You can also use disposable or reusable formwork to install the formwork under the foundation strip; in the latter case, it is very important to clean the reused panels from dirt, dust, and hardened mortar.

The shields are reinforced with struts and wooden struts for a more even position. When making prefabricated formwork from individual wooden elements, it is very important to avoid the presence of holes and gaps between the planks.

Reinforcement and concrete pouring base reinforcement

High-quality reinforcement is the key to the reliability of the foundation of the house

To increase the strength of the supporting base, the strip foundation for the garage needs to be strengthened, for which a spatial frame made of reinforcing steel with a diameter of 10 mm is placed in the formwork, which is connected by welding or tied with knitting wire.

The frame is located in the formwork in such a way that unprotected metal reinforcement does not protrude onto the surface of the foundation. Bars or pieces of rolled metal are placed at the bottom of the trench to lift the welded frame above the sand and crushed stone bed.

Concrete mortar is poured into the formwork simultaneously from both sides; the concrete mixture must be compacted using vibrating rammers. This operation is carried out with special care at the joints of the reinforcement cage. It is very important that no voids form in the body of the strip foundation.

The upper surface of the concrete solution is leveled and watered. Moistening the foundation needs to be done for approximately 2 weeks. To protect the concrete surface from cracking, the strip foundation is covered with several layers of film.

Watch the video on how to properly fill a slab base with your own hands.

The structure gains strength within 28 days, after which it is necessary to waterproof it using rolled materials and begin laying walls from foam blocks.

Influence of soil and building load

You can independently determine the type of soil by color

When planning a foundation for a garage, you need to take into account the influence of soil properties on the finished structure.

Soils are divided into the following categories:

- Weak. These include sandy loam, sandstone, and loam. They are characterized by mobility and hygroscopicity. Suitable for laying slabs or installing piles.

- Average. These are gravelly sandy soils. They have high stability, allow water to pass through without retaining it. Suitable for any type of support systems.

- Dense. Consist of crushed rock. They have a high load-bearing capacity, but are difficult to process. It is advisable to make surface-type bases.

- Clayey. They are considered the most problematic for arranging the foundation. The optimal solution is slabs, piles or deep-buried tape.

The moisture problem can be solved by installing a drainage system with natural or forced water drainage.

Base depth

The depth of soil freezing matters - this indicator will affect the integrity of the walls

The depth of the foundation is the most difficult issue that private developers have to solve. The volume of excavation work, time and cost of construction will depend on it. You cannot make a mistake here, as the consequences can be very unpleasant.

When determining the depth of placement, you need to take into account the following indicators:

- the weight of the object, taking into account the car, permanent and temporary property located in it;

- level of soil freezing in the coldest winters;

- soil moisture;

- the nature of the soil, its bearing capacity and degree of heaving;

- depth of the groundwater layer.

Shallow structures are not recommended to be installed in areas with weak and unstable soil. There is no point in making a slab on hard and stable soil where there are no sources of water nearby.

Characteristics of foam blocks

Due to their porous structure, these blocks have a low specific gravity and therefore walls made of this material will be lighter than brickwork. The density of foam concrete ranges from 400 to 1200 kg/m 3 and its marking, accordingly, is from D400 to D1200.

For the construction of load-bearing walls, blocks with a specific weight of at least 750 kg/m 3 must be used. Lighter material is used for the construction of internal partitions and as insulation.

The important advantages of foam blocks are:

- low thermal conductivity coefficient;

- good sound insulation performance;

- reduced weight of the building, which allows for the construction of a lightweight foundation.

The negative qualities of this material include increased ability to absorb moisture and reduced mechanical strength.

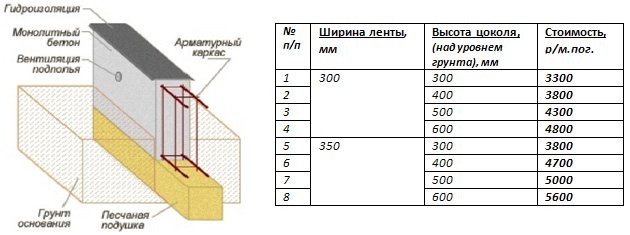

How much does it cost to install a simple strip foundation?

How much will it cost to install a conventional strip foundation if you do the excavation and concrete work yourself? The average price, which takes into account waterproofing and insulation, is up to five thousand rubles.

Useful Video with a detailed description of what is happening:

What you shouldn't save on:

- purchase ready-made poured concrete with additives. The overpayment is small, but the strength and reliability of the mixture is guaranteed;

- do not skimp on waterproofing and insulation; extruded penoplex is an inexpensive material.

When choosing the type of foundation, calculate all costs. In some cases, a simple concrete strip with insulation and waterproofing will cost more than the quick installation of reliable screw piles.

Additional Note

Before starting design, it is necessary to carry out work to study the soil and determine the groundwater level. Based on these data, you should select the optimal type of foundation and perform the necessary engineering calculations. After this, it is necessary to determine the required amount of materials, purchase them and deliver them to the construction site.

The simplest and most affordable is the shallow type of foundation. The rest will be more complex and costly. But in some cases, the type of soil, high groundwater, the desire to have a large cellar and other reasons force one to accept an increase in financial costs and volume of work.

Selection of foundation blocks

When laying FBS blocks, try to use blocks whose length is 2380 mm. The fact is that the fewer vertical seams there are on the foundation, the more durable it will be. And with such blocks, your costs for crane services will be significantly reduced, and the work time will be significantly reduced.

If the soil is weakened, then it is advisable to increase the width of the foundation base. This means that the 1st row should be laid out from pillow blocks, the distance between which should not be more than 0.7 meters. It is filled with soil with layer-by-layer compaction. In this case, in the first row, all block seams (vertical) should be located above the pillows.

On weakened soils, in order to increase the strength of the foundation, a special reinforced concrete belt is built along the top row of blocks, the thickness of which should be about 30 cm. When making a foundation for a garage with your own hands, we construct a frame from four rods 10 mm in diameter.

Due to the massiveness of standard FSB blocks, when constructing a foundation yourself, you can use expanded clay concrete samples with dimensions of 20x20x40cm. However, their weight should not exceed 30 kg.

It should be noted that a foundation made of FBS blocks is the key to reliable support for the garage, but only if you adhere to existing building codes. This means that even if you build a garage yourself, this does not give you the right not to follow the rules. It is best not to rely on intuition, but to follow competent advice.