What is FBS?

The abbreviation FBS does not mean anything secret; it only contains an explanation of what the “wall foundation block” is intended for. Such impressive bricks are obtained by molding heavy concrete into which reinforcing steel reinforcement is placed. The size and structure of the elements make it possible to well distribute the load from the building onto the base laid out with such blocks. It is believed that such a foundation is stronger and more reliable than a monolith cast in concrete.

FBS can be of several types (column, tape, massive, etc.), but they are all produced the same way and are subject to thorough testing, so when purchasing, make sure that the manufacturer is legal. The only significant difference in the production process that occurs in factories is the drying mode. Like any concrete, such a block must be brought to a given strength for a certain amount of time. Under normal conditions, this will take 28 days, but you don’t always have time to wait that long.

There is a way out in which strength is gained faster; this is forced drying, the so-called steaming. Only in a properly equipped production facility can a steaming process be established that meets all GOST requirements. In any other case, the concrete will not only not gain the required strength, but will also be filled with mechanical stress and become covered with cracks. The reliability of such a foundation will be very doubtful, so choose the manufacturer correctly.

Foundation made of FBS blocks - pros and cons

Of course, you can make a columnar foundation from blocks with your own hands, or a strip foundation, but all of them will not only shine with their advantages, they are not without their disadvantages. Therefore, let's look a little into this issue. An alternative to FBS can be considered a concrete monolith, after all, it is the same material, and everyone will name the installation process as the first advantage of a block foundation. This is more convenient than building formwork, waiting for the composition to set and reach strength, and the weather can negatively affect the quality of the final product.

FBS undergoes quality control at the factory and does not depend on the weather at the time of construction, and the assembly of the structure itself is easier and faster.

It would also be useful to point out the economic benefits of using this material, since it reduces labor costs, therefore, fewer workers are needed, and the construction time itself is reduced. The blocks have proven themselves to be reliable and durable, they tolerate temperature changes well, and of large amplitudes, are resistant to moisture, fire, frost and do not conduct heat well.

One of the significant disadvantages of FBS, which has been noticed over time, is the subsidence of some sections of the structure if the soil reacts to sudden temperature changes. After all, the foundation turns out to be composite, i.e. from many blocks, and this allows them to sometimes behave independently of each other. But we have learned to cope with this, in order to prevent this behavior; when laying the foundation, they use sections of strip slabs that are placed between the FBS and the soil, this distributes the pressure of the blocks evenly over the entire area of the foundation. Also, for the reliability of the foundation, protection of the seams will be required; any foundation of the building needs at least waterproofing. And if you have large blocks, then construction will not be carried out without special equipment.

Information on the purpose of the calculator

Online building block calculator

designed to perform calculations of building materials necessary for the construction of walls of houses, garages, utility and other premises. The calculations can take into account the dimensions of the building's gables, door and window openings, as well as related materials, such as mortar and masonry mesh. Be careful when filling out the data, pay special attention to the units of measurement.

Technologies do not stand still, including construction technologies. For the construction of walls, wood has been replaced by brick, and today its place is increasingly being taken by building blocks obtained artificially, and depending on the raw materials used, they can have different characteristics.

C building blocks are popular in the construction of low-rise buildings and walls of monolithic frame buildings. They can not only be used to build external walls, but can also be used for internal partitions and interior walls. Concrete blocks are also suitable for making prefabricated foundations for light buildings.

The advantages of building blocks are obvious. With their help, you can build a building in a short time without the use of special equipment. They have good thermal insulation and the necessary strength. Therefore, the funds spent on insulation will be significantly lower than when building with brick. And if we compare building blocks with wooden log houses, then this means not only less additional funds and work, but also a higher durability of the building.

Construction of a foundation from FBS blocks - mathematics on site

Before we begin installing the foundation from FBS blocks, we will calculate the required amount of material. To do this, you will need to clarify the dimensions of the foundation, its height, width and length. You also need to find out the exact parameters of the blocks from which you will lay it out; as a rule, they are standard, but let’s talk about marking, in case your requests deviate somewhat from the generally accepted ones.

To calculate the foundation parameters, examine the soil on your site . Important indicators are its looseness, the depth of freezing in winter and the depth of groundwater. Even if the soil guarantees minimal subsidence, the foundation must have at least 2 rows of blocks. If the soil is loose, then its depth will be greater, most importantly - below freezing or groundwater. The width of the future structure is determined by the width of the walls of the house, and the length is determined by the perimeter of the house, including all load-bearing walls.

The FBS block itself most often has parameters 24-4-6, this is its marking, the first number is the length (measured in decimeters), the second is the width, the third is the height. There is also a length of 1.2 meters, then the brand looks like FBS12-4-6. There are other, less popular sizes. When ordering, you should take a small supply of blocks, since in case of a mistake it will be very difficult to buy several more pieces; no one will just drive the car to you. So, if possible, then get the stock up to a full car, in any case it will be useful on the farm, and you can sell it to someone, taking into account pickup.

Consumption of mortar for fbs masonry

FBS are foundation blocks of walls suitable for the construction of buildings for various purposes. During operation, temperature fluctuations are allowed no higher than +50 and no lower than -70 degrees Celsius. The use of FBS concrete elements in the construction of houses in different climatic conditions and on different types of soil. In comparison with the monolithic type of foundation structure, the installation of FBS blocks is carried out under different weather conditions, and it is recommended to begin laying the walls after the installation of the structure has been completed. The consumption rate of the solution for the installation of FBS blocks will be 10-20% of the volumetric part of the building elements. Much will depend on the type and dimensions of the products.

Knowing the consumption of mortar for the installation of FBS blocks, they install building units in the shortest period and do not involve qualified craftsmen to carry out calculations. This technique will significantly reduce the list of costs without losing the characteristics of the quality and reliability of the building being built.

Popular brands of precast concrete blocks:

The density characteristics of the block material are 2.15 t/m3. The density of the construction mixture is 1.55 t/m3. The solution consumption when installing FBS blocks will be 0.07 m3 per 1 m3 of masonry. For example, let's take the layout of blocks for the foundation of 28 building units type FSB 12-4-6 and 8 blocks FBS 9-4-6.

Installation of a foundation made of FBS blocks - strip type - step-by-step diagram

Step 1: Making the pillow

To begin work, we dig a trench of the planned depth (freezing level + 25 cm). We lay out a pillow there, which consists of two layers: crushed stone - 10 cm and a layer of sand about 5 cm. To compact everything as efficiently as possible, water it with water and then press it. Then a small cushion of concrete about 2 cm thick is made, and time is waited to gain strength. After this, you can begin laying the first row.

Step 2: First row

Its peculiarity is to create a foundation that does not allow individual sections of the foundation to sag later, as discussed in the disadvantages of FBS. To do this, you need something flat, for example, laying a concrete slab. Many people do not bother themselves with additional expenses, but use the same blocks for this, only laying them on their sides, as if using the height as width. Or there is the option of purchasing a number of cushion blocks even before construction, these are FBS only of a slightly different shape, flatter. Laying begins from the corners, the blocks are joined tightly, coating the seams with cement mixture. Check the horizontal layout of the first row.

Step 3: Laying out the next rows

The next rows are laid out like brickwork, in a band, that is, the vertical seam of each block should fall into the middle of the block from the bottom row. In the corners of the house, try to lay the outer blocks with an overlap, that is, in one row the edge of the block from the left wall hits the corner, and in the next - from the right, and so on in turn. The seams are thoroughly sealed with cement. Do not forget to control the horizontal and vertical level of the masonry. First, the outer walls are made, then the inner ones are laid out. If a hole forms somewhere that a block will not fit into, do not try to saw a piece out of it; it is better to fill it with ordinary brick or cement.

- Author: Manager Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(2 votes, average: 1 out of 5)

Share with your friends!

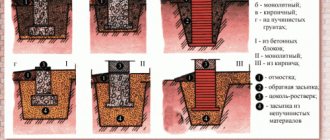

Waterproofing foundation walls

Protection of walls from capillary moisture is achieved by installing horizontal adhesive waterproofing at a level above the blind area, coating waterproofing of the vertical surfaces of the walls of the basement (technical underground) in contact with the ground and laying a greasy cement-sand mortar in the preparation level under the floors of the basement (technical underground). Horizontal waterproofing of 2 layers of waterproofing on bitumen mastic on a leveled surface should be carried out along the entire perimeter of the external and internal walls at a level above the blind area (and above the snow that melts in the spring). Horizontal waterproofing from a layer of greasy cement mortar with a composition of 1:2 and a thickness of 20 mm should be carried out at a level below the basement floor. Vertical waterproofing of basement walls, porches, and entrances to the basement in contact with the ground should be carried out by coating with hot bitumen 2 times.