A cinder block foundation is one of the cheapest types of foundations. Savings are achieved due to the low price of the material. The process of creating a base using such raw materials is not very complicated, so even a beginner in the construction craft can cope with such work. This article will discuss in more detail the procedure for building a foundation for a cinder block house, its advantages and disadvantages.

Types of foundations

Construction work of any object begins with the construction of the foundation.

Foundations are classified taking into account their structural differences. The most popular options are:

- tape;

- pile;

- columnar;

- slab.

There are possibilities for combining different types of bases.

Stages of work execution

You should start by choosing the right types of cinder blocks for the foundation. Hollow material will not suit us, but blocks filled with crushed stone will come in handy. This variety is characterized by maximum strength; everything else is adjusted using additional materials.

The construction of the foundation should begin in dry weather and try to complete the construction of the foundation before the start of the rainy season.

Taking into account the peculiarities of masonry work, the parameters of the blocks and other little things, one person can handle the construction of a cinder block foundation for a decent house with his own hands within a week. You just have to solve the issue of protecting the foundation from moisture, quickly erect walls and make a roof.

Preparatory work

To equip the foundation for a house, you will need to follow a strict sequence of actions:

- first, a trench is dug and a bed of sand and gravel is laid;

- it is covered with roofing felt material in one layer. Instead, it is allowed to use bitumen or fiberglass.

Preparation of mortar for cinder block structures

When building a foundation from cinder blocks for a house with your own hands, you should understand that it must form a solid and durable structure, in which each element is connected with sand-cement mortar with a seam thickness of no more than one centimeter.

To prepare the mortar mass, use cement material M400, clean sand, and add clay or plasticizer components.

In most cases, the proportional relationship looks like this:

- cement - one share;

- sand - four shares;

- a third of the share of clay for every four is a sand-cement mixture.

The dry ingredients taken in the required quantities are mixed, then water is added. At the same time, mix the solution thoroughly to achieve the desired consistency and obtain a plastic mass.

The prepared solution must be produced within one to one and a half hours.

Masonry work

Reinforced concrete blocks are installed on the roofing felt strip. On top of them, the first row of cinder block material begins to be laid out. Subsequent rows are laid out from the corners to the center; a solution is used to connect them. Reinforcement is performed on top of the last row.

As soon as the main part of the cinder block strip foundation is completed, mastic is used, on top of which the insulating material is mounted. Water protection should be provided on each side to prevent its penetration into the blocks.

The trench is filled in and construction of the walls begins.

This is how the foundation for a wooden house is made. The design will fully support an object with two or even three floors. For a barn, greenhouse and other outbuildings, you can build simpler foundations - columnar foundations made of cinder blocks.

Making cinder blocks with your own hands

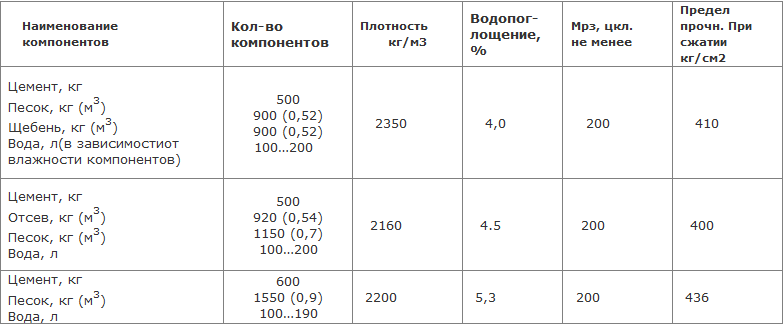

Table of proportions for making cinder block.

Cinder concrete can be prepared manually from a mixture of cement, sand and slag with the addition of lime paste and water. The finished mixture is used within 2 hours. Forms of any size can be made from boards. To make blocks you need a flat area. It can be installed in the courtyard of the house. It needs to be covered with plastic film. Work is only possible in good weather. It is better to build a canopy over the site to protect from precipitation. To prepare the working mixture, the following composition is used:

- water – 1 part;

- slag – 9 parts;

- Portland cement M-500 – 1 part;

- expanded clay sand - 3 parts.

All components are poured into a concrete mixer and mixed. The finished mixture, when squeezed in a fist, should provide some resistance and not disintegrate.

Another recipe:

- screening – 4 shovels;

- granulated slag – 4 shovels;

- cement - 1 shovel;

- water - about 8 liters.

Mix everything thoroughly.

The following mixture is possible:

- slag – 7 parts;

- coarse expanded clay sand – 2 parts;

- gravel fraction 5-15 mm – 2 parts;

- cement M-500 – 1.5 parts;

- water – 3 parts.

- The finished mixture is placed in molds with a small slide. The vibrator turns on for 2 seconds. The concrete in the form will settle, it needs to be leveled with a trowel.

- Place a clamp on top and turn on the vibrator for 4-5 seconds.

- Raise the vibrating machine - the block remains on the platform.

It is not recommended to use cinder blocks to build a house foundation: on heaving soils, on wet soils, for buildings whose weight exceeds 100 tons.

You can do without using a vibrating machine:

- Prepare molds with internal dimensions of 20x40 cm from plastic or boards.

- Place 3 champagne bottles, placing them vertically.

- Fill the form with concrete.

- Using a welding electrode or wire of a suitable diameter, pierce the mixture in 8-10 places.

- Level the surface with a trowel.

After 48 hours, the blocks will be ready for use. They can be stored in pyramidal stacks with gaps of about 3 cm from each other. After 4-5 days they dry completely.

It is not recommended to use cinder blocks to build the foundation of a house:

- on heaving soils (clay and loam);

- on wet soils, since moisture is the main enemy of cinder blocks;

- for buildings whose weight exceeds 100 tons.

Arrangement of a cinder block base

If you want to build a cinder block plinth on a strip foundation, it is recommended to stock up on additional materials, which include:

- crushed stone, sand, cement material, gravel;

- steel reinforcing bars;

- plasticizers;

- cinder blocks;

- vapor barrier and waterproofing materials;

- insulation.

With this set you can ensure maximum strength of the structure being built and prevent the formation of cracks during subsequent operation. It is worth adding that the base itself for the object should protrude above the ground surface by at least seventy centimeters. This measure is needed to prevent water from being absorbed by the block material in the base.

The sequence of work is as follows:

- a trench is prepared, the bottom of which is filled with a sand and gravel cushion (25 cm for each type of material);

- The formwork structure is installed, the reinforcement frame is mounted. Everything is filled with concrete mixture;

- It is recommended to begin laying blocks seven days after the foundation is poured.

The height of the basement under construction should be three block rows, the lower of which is separated from the concrete base by hydro- and vapor barrier material.

Advantages and disadvantages of a cinder block foundation

The main advantages include the following:

- frost resistance. A cinder block is capable of retaining thermal energy no worse than foam concrete material;

- high strength. The block will withstand pressure of at least one hundred tons. The indicator cannot be considered a record, but for small objects this will be enough;

- acceptable cost. The composition of the block material includes a huge amount of waste raw materials, which significantly reduces the price;

- it is possible to build a foundation from cinder blocks yourself;

- the large dimensions of the blocks and light weight make it possible to quickly carry out work without using special equipment;

- construction requires less time, saving money;

- when working with cinder blocks, there is no need to erect a formwork structure;

- cinder block stones do not shrink.

When constructing a columnar foundation made of cinder blocks, you will have to take into account the negative aspects of the material:

- in cross section the block does not have good strength. For this reason, such foundations are not recommended to be installed in areas with possible ground movements and seismic activity;

- high thermal conductivity. There is a possibility of large losses of thermal energy;

- low hydrophobicity. Absorbed moisture shortens the operating period;

- the strength indicator of the material limits the number of floors of the building under construction;

- objects with a base made of such material should not be placed in areas with high levels of humidity or close groundwater to the soil surface;

- It must be remembered that slag is a toxic material that can cause harm to the human body.

Wall masonry

Four weeks after pouring and laying the base, you can begin building the walls. This time is necessary for the cement to gain strength.

Naturally, the question arises of how to lay a cinder block on the foundation. Hollow cinder blocks have average heat resistance, but when filled with bulk materials, this quality becomes no worse than that of brick. But when building walls for a residential building, it is necessary to use external insulation, because due to the large volume of the room, the blocks will not be able to retain a sufficient amount of heat.

It is necessary to prepare scaffolding in advance; due to the large weight of the elements, using the ladder is inconvenient. You will need a trowel and trowel to work with the mortar, and a rubber hammer to compact the blocks.

When laying out walls with your own hands, you need to pay special attention to their evenness, since large sizes of building elements can cause problems with level adjustment. To do this, you need to lay out a block in the corners of the building and check their horizontal plane with a level. Then, between the finished vertices you need to pull a guide and make walls along it. The initial three rows must be done especially carefully; the quality of the entire building depends on this.

Apply a layer of solution no more than 15 mm, otherwise “cold bridges” will appear. To make the blocks fit more tightly, it is advisable to tap them with a rubber hammer. After the walls are erected, the top row is strengthened with an iron coupling. Do not delay the construction of the roof - cinder blocks need protection from precipitation.

The cavity of the finished building can be filled with sand or other bulk materials, but if the wall is several blocks thick, this is not necessary. A living room or bathhouse made of cinder blocks must be insulated from the outside. It will be enough to plaster a garage or other room.