The service life of any building directly depends on how reliable the foundation is built under it. Houses can be built on columnar, slab, pile, and strip foundations. The most popular is the last type of base. Strip foundations can be considered the best option in terms of price and reliability. Such structures can last the entire life of the building without the need for repairs. The dimensions of the strip foundation depend on the weight of the house and the bearing capacity of the soil on the site.

What varieties are there?

Bases of this type are classified mainly according to two criteria:

- the type of material used for construction;

- degree of depth.

Strip foundations can be built from brick or concrete. Also, prefabricated reinforced concrete structures of this type are often used as supports for buildings.

For the construction of strip foundations, only solid ceramic bricks of good quality are used. Concrete structures of this type are the most popular variety and are most often poured under buildings and structures. To enhance the tensile strength of such tapes, metal reinforcement is used.

Precast concrete house foundations are assembled from long, strong blocks. The latter are laid in a trench in a tape, connected with reinforcement and the joints filled with concrete.

The dimensions of strip foundations are determined, of course, including their height. Both conventional structures of this type and shallow ones can be erected under buildings. In private housing construction, for example, the most popular is the second type of foundation.

Such foundations are usually buried into the ground no more than 30-40 cm. Of course, such foundations can only be built on very reliable, strong soils. Conventional strip foundations are poured to a depth below soil freezing - that is, 0.7-1.5 m, depending on the region.

Columnar foundation calculator

Instructions for calculating the dimensions and quantity of materials for a columnar foundation

The presented program helps to perform an example of calculating the cost of a pile or columnar foundation with a reinforcing grillage. Output data will include the required quantity and price of the following building materials:

- Crushed stone;

- Fittings;

- Sand;

- Cement.

In accordance with your entered data, the online calculator will generate a drawing of the future project.

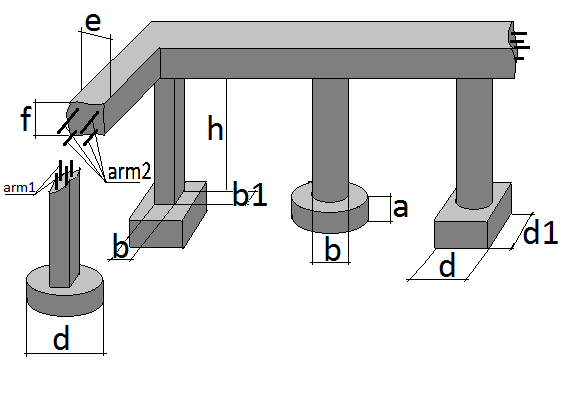

Selecting the type of pillar

When entering the calculator parameters, you are given the opportunity to select pillars and their bases of two main shapes: round or rectangular.

All dimensions must be specified in mm

H - Height of the main section of the post.

B — Specify the diameter or width.

A - Height of the base of the pile. If you are using columns without a base, you do not need to specify this size.

D - Diameter or width of the base of the foundation pile.

D 1 - Length of the rectangular base.

B 1 - Width of a rectangular pile.

If the foundation pillar has a round cross-section, then these dimensions are not used in the calculation.

Foundation dimensions

Y - Length.

X - Width.

Y 1 - The total number of pillars along the entire length of the monolith, including pillars in the corners.

X 1 - The total number of piles along the width of the monolith, including pillars in the corners.

S - If this parameter is checked, then the calculation will be carried out for pillars that are located evenly under the entire building. If not marked, then only piles that will be located along the perimeter of the entire foundation.

Grillage dimensions

F - Height.

E - Width.

In the case where the calculation of monolithic grillages is not required, there is no need to indicate these parameters.

Armature

ARM 1 - Total number of reinforcement bars for one column.

ARM 2 - The total number of rows of reinforcement in the grillage strip.

ARMD - Reinforcement diameter. These values must be specified in millimeters.

If your project does not require reinforcement, then this value is set to 0.

We indicate the amount of cement required to produce 1 m³ of concrete. All data is indicated in kilograms.

We indicate the proportion by weight for preparing the concrete solution. The meaning of the parameters in each individual case will be different.

First of all, the above parameters will depend on the construction technology, the diameter of the crushed stone fraction and the grade of cement. You can check this information with suppliers and sellers of building materials.

Indicate prices for building materials, which will allow you to make an approximate calculation of the total cost of the project.

Based on the entered results, the program will perform calculations:

- The volume of concrete mortar for one column, separately for the lower and upper parts.

- The distance between the piles and their number.

- Total weight and length of the required amount of reinforcement.

- Volume of solution for grillage.

- Ready-made drawings with a general plan, according to which you can correctly design a pile foundation.

- The total cost of all basic materials for the installation of a pile with grillage or columnar monolith.

Scope of application

Today, a columnar foundation is used when installing a strip-type structure is not advisable, for example, for buildings with light walls, without basements, for bathhouses or garages. Thanks to our program, the calculation will not only not take up much of your time, but will also help you get rid of the labor-intensive calculation process. You will only need to correctly fill out all the fields according to the detailed instructions, and you will immediately be able to obtain all the necessary and sufficient information for the construction of a columnar monolith, you will find out the volumes of building materials, as well as the total cost of the project.

Total information

A columnar foundation, as a rule, consists of reinforced concrete pillars, each of which has an extension at the bottom, and is interconnected by a grillage. This type of support structure helps it prevent soil heaving and withstand heavy loads. Columns should be located at intersections, in the corners of the future building, under heavy walls, load-bearing walls, beams or critical structures. Piles should be in all places with high loads. The grillage is used to strengthen the structure, made between the columns in the form of a reinforced lintel.

Where you should not use a columnar foundation

It is strictly not recommended to install the structure on moving soils, as well as on clay or weak soils, watery soils or peat. It is not recommended for use in areas where there are sudden changes in elevation.

Where is it used?

A foundation on concrete piles will be an ideal solution for building a house, garage, bathhouse or cottage without significant costs.

Materials

First of all, it is necessary to determine the number of floors of the future building and its mass. Next, the selection of materials and calculation of the project is carried out, where brick, concrete, reinforced concrete, and also stone can be used. According to the type of material selected, the cross-sectional size of the columns is selected. For concrete piles, the section size is at least 400 mm, for stone - at least 600 mm, for brick - 380 mm, if the masonry is above ground level, and at least 250 mm in the case of using dressing technology with retraction.

Advantages

Thanks to their design, columnar structures have a number of advantages that make them an ideal solution for the construction of residential and non-residential buildings. This type of construction is much cheaper than strip or block monoliths, consumes less building materials and their construction requires significantly less time and costs. This project allows you to reduce the construction area and gives slight shrinkage. This type of home base perfectly resists the heaving of frosty soils and the destructive effects of groundwater.

Phased construction

Before starting construction work, you need to determine the maximum freezing depth of the soil and the type of soil. All this is necessary so that, if necessary, it is possible to measure the level to which groundwater can rise, and then carry out waterproofing correctly. Installation of a columnar foundation is carried out in the following sequence.

- We are clearing the site, preparatory work.

- According to the project, the site for the structure is being marked.

- Preparing holes for columns.

- The formwork for future supports is being installed.

- Installation of fittings.

- Concrete piles are being poured.

- We make a grillage.

- Construction of walls between columns or fences.

- We carry out waterproofing around the perimeter of the entire foundation.

Filling period and time

Pouring concrete is the final stage and should be done in layers of 25-40 millimeters. Each layer must be developed with a vibrator, which will eliminate the formation of air layers that significantly weaken the monolith. It is best to complete the entire pouring in one stage, pouring a concrete layer, breaking it with a vibrator and at this rate until the end of the support.

It is not recommended to fill the supports with an intermediate interval of one day, as seams may form at the junction of the layers, which will negatively affect the strength of the supporting structure of the structure.

Important

You can calculate the foundation for a house for all types of buildings: frame, block, monolithic, wooden and brick.

In the case when it is planned to build a house on heaving soil, it is not recommended to postpone construction that has already begun. If the frame is started and left for the winter, it will become deformed.

Poured concrete supports must withstand for at least 30 days. During this period, it is not recommended to subject these supports to load.

It is best to use M400 series cement to make concrete mortar; coarse sand or fine gravel are best suited as a filler.

Features of use

Strip foundations can be erected under buildings of absolutely any type:

- chopped;

- frame;

- brick;

- concrete;

- metal, etc.

It is allowed to fill such structures, however, only on sufficiently strong soils. Foundations of this type are not erected, for example, on quicksand, slopes, marshy soils, or areas prone to movement. In such cases, buildings are built on more expensive slab or pile foundations.

Strip foundations are usually not poured for very light buildings - small wooden houses or bathhouses, gazebos, verandas. In this case, columnar foundations are most often erected. Such designs are reliable and at the same time cheaper than tape ones.

Characteristics

The advantages of strip foundations primarily include their not too high cost. The price of such a structure, provided it is properly designed, will be low, no matter what its size. It is worth choosing a strip foundation for a house because in this case, in the future it will be possible to equip a basement or cellar. The advantages of such grounds are also:

- reliability and durability;

- the most uniform distribution of the load from the walls of the house;

- versatility;

- ease of construction.

There are practically no downsides to foundations of this variety. The only disadvantage of structures of this type is that they cannot be erected on soft soils.

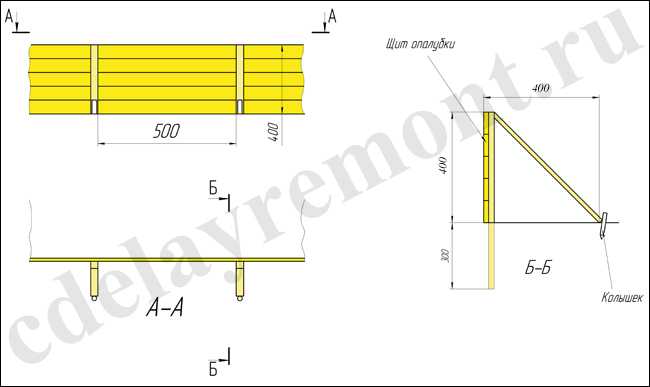

Calculation example

Let’s assume that our plans include pouring a shallow slab foundation 300 mm high. We take into account that the height of the formwork panels should be at least 50 mm higher, for a total of 350 mm. But because It’s easier to use boards 200 mm wide; we take the formwork height to be 400 mm or 0.4 m. In one of the following articles we will give an example of a complete foundation calculation, which will include all calculations for various types of foundations. In the meantime, let's look at the thickness of the boards, which is sufficient to resist bending of the material.

We calculate the load: G=2500×0.4=1000 kg/m2. For reliability, we take the distance between the vertical supports-braces equal to 0.5 m - I = 0.5 m. During pouring, we will compact the concrete with vibrators, so n = 1.2. We substitute all values into the above formula: h=√(0.75×1000×1.2×0.52/800000)=0.017 m or 17 mm.

Features of the choice of materials

The strip foundation built under the building, of course, must first of all be as reliable as possible. Therefore, we always try to choose the highest quality materials for such structures. Sand-lime brick, for example, since it is not moisture resistant, is not allowed to be used for the construction of strip foundations.

Cement for pouring concrete strips is purchased in high grades. In this case, coarse sifted river sand is used. To reinforce concrete foundations of this type, a metal rod of 8-12 mm is purchased.

In addition to sand and cement, crushed stone is added to the solution for strip bases. For such foundations, you should choose only moisture-resistant, durable material of this type. Crushed limestone, for example, is completely unsuitable for this purpose.

Calculation of reinforcement diameter for foundation

Calculation of the diameter of transverse and vertical reinforcement

The diameter of transverse and vertical reinforcement must be selected according to the table:

In the construction of one- or two-story private houses, as a rule, rods with a diameter of 8 mm are used as vertical and transverse reinforcement, and this is usually quite sufficient for strip foundations of low-rise private buildings.

Calculation of the diameter of longitudinal reinforcement

According to SNiP 52-01-2003, the minimum cross-sectional area of longitudinal reinforcement in a strip foundation should be 0.1% of the total cross-section of the reinforced concrete strip. This rule must be taken as a starting point when choosing the diameter of the reinforcement for the foundation.

Everything is clear with the cross-sectional area of the reinforced concrete strip; it is necessary to multiply the width of the foundation by its height, i.e. Let's say your tape width is 40 cm and the height is 100 cm (1 m), then the cross-sectional area will be 4000 cm2 .

The cross-sectional area of the reinforcement should be 0.1% of the cross-sectional area of the foundation, so the resulting area is 4000 cm2 / 1000 = 4cm2 .

In order not to calculate the cross-sectional area of each reinforcement rod, you can use a simple plate. Using it you can easily select the required diameter of the reinforcement for the foundation.

There are very minor inaccuracies in the table due to rounding of numbers, please ignore them.

Important: If the length of the tape is less than 3 m, the minimum diameter of the longitudinal reinforcement bars must be 10 mm. When the length of the tape is more than 3 m, the minimum diameter of the longitudinal reinforcement should be 12 mm.

And so, we have a minimum calculated cross-sectional area of the reinforcement in the section of the strip foundation, which is equal to 4 cm2 (this takes into account the number of longitudinal rods).

With a foundation width of 40 cm, it is enough for us to use a reinforcement scheme with four rods. We return to the table and look in the column where the values for 4 reinforcement bars are given, and select the most suitable value.

Thus, we determine that for our foundation 40 cm wide, 1 m high, with a reinforcement scheme of four rods, the most suitable reinforcement with a diameter of 12 mm, since 4 rods of this diameter will have a cross-sectional area of 4.52 cm2.

Calculation of the diameter of the reinforcement for a frame with six bars is carried out in a similar way, only the values are already taken from the column with six bars.

It should be noted that the longitudinal reinforcement for a strip foundation must be of the same diameter. If for some reason your reinforcement is of different diameters, then rods of larger diameter must be used in the bottom row.

Strip foundation dimensions: calculations and design

Foundations of this type are poured in such a way that all the external and internal walls of the house subsequently rest on the tapes. When designing, in addition to the depth of the foundation, they are determined by the width of the foundation, as well as the height of the base. The calculation of indicators is carried out taking into account:

- weight of the building;

- bearing capacity of the soil.

The weight of the building is determined by adding:

- weight of materials used for construction;

- the foundation itself;

- snow in winter;

- all items that will subsequently be in the house (on average - 180 kg/m2).

Next, the total mass of the house found in this way is divided by the estimated area of the foundation (the length is multiplied by the width). In this way, a specific load per 1 cm2 is obtained. Next, using a special table, they will find out whether the soil under the foundation will withstand such pressure.

If the bearing capacity of the soil is less than the load from the house, the necessary adjustments are made to the project. That is, they are revising the width of the foundation upward.

The dimensions of the strip foundation relative to the wall thickness can be different. For example, quite often low-rise buildings are built in which the façade bricks protrude several centimeters beyond the base strip. Sometimes the foundation, on the contrary, can be wider than the walls. In this way, it is poured when in the future, for example, the facades are supposed to be faced with decorative bricks. But still, most often when building houses in our time, the vertical planes of the base and walls coincide.

Which foundation to choose?

- Tape;

This type of foundation is laid throughout the building. Also within a given perimeter, along the trajectory of the load-bearing walls. Its characteristic features are a sufficient amount of digging work and consumption of materials, when viewed from above it will resemble a tape. First, you need to dig even holes in the ground. First, concrete is poured into them, then formwork is created for the base above ground level. It is used most often for private low-rise buildings.

- Columnar (pile);

This type is already used for buildings in swampy or peat areas. Others are not applicable here due to the high depth of solid ground. The amount of excavation work is reduced and there is no need to dig holes. Used for depths from 3 to 12 m. The end of the pillar/pile has a cone-shaped end, which is why it is driven into the ground. Before this, the depth of the soft soil must be measured in order to determine the length of the pile.

- Slab;

It is made of reinforced concrete and has another name – floating. It is called that because if the ground moves, the slab will also move. This type is poured over the entire area of the house. It is popular when constructing buildings for wet soils and buildings that have basement floors or underground parking. The cost of this type is, of course, higher than the others.

- For houses made of foam blocks;

For them, the high production costs are not justified. That is, there is no need to make a slab from piles. The tape version is recommended. Of course, if the ground allows. If the groundwater depth is below 3 meters, a shallow foundation is made. The ground for such houses is 50 cm deep and about the same in height.

- Monolithic pile.

This type is similar to a combination of strip and pile. The lower part consists of piles, which are connected from above to each other by horizontal beams. It is used on weak surfaces and in northern regions, since the level of freezing is quite deep. It can be metal, concrete, aerated concrete or reinforced concrete.

Dimensions of strip foundation blocks

Prefabricated foundations of this type are built from standard blocks. Such structures are delivered to the site using special equipment. You can purchase them at enterprises engaged in the manufacture of reinforced concrete products.

The markings of such blocks always contain the letters FL. The dimensions of a strip foundation of this type are determined by the numbers following them. Beams FL6-24, for example, have dimensions of 240 x 60 x 30 cm, FL8-12 - 118 x 80 x 30 cm, etc.

Thus, it determines the dimensions of the GOST prefabricated strip foundation blocks. Calculations in this case are made according to the same principle as for monolithic foundations of this type.

In some cases, they can be used in the construction of prefabricated strip foundations and slabs. The dimensions of such reinforced concrete structures are also standard. Their width can vary between 600-3200 mm. Reinforced concrete structures of this type are used to distribute the load from the walls.

Formulas for approximate calculation of foundation formwork

To calculate the thickness of the board, we will use the following formulas:

h=√(0.75×G×n×l2/T), where h – minimum board thickness, m; G – load on the formwork from the concrete mixture. We take G to be maximum and calculate it using the formula G=q×H, where q=2500 kg/m3 is the volumetric mass of concrete, H is the height of the concrete layer, m; n is the vibrator coefficient, which is taken equal to 1.2. If concrete is poured without vibration compaction, then n=1; I – distance between vertical supports-braces, m T – permissible wood resistance. We take T as minimum, equal to 8×105 kg/m2

Pouring technology in brief

After calculating the dimensions of the strip foundation, you can begin its actual construction. Most often, monolithic foundations of this type are built under buildings and structures, as already mentioned. Their advantage, in comparison with brick ones, is the speed of construction, and in comparison with prefabricated ones - they are cheap. Monolithic strip foundations are poured using the following technology:

- the site is marked using the Egyptian triangle method;

- a trench of designed depth is dug;

- a sand cushion is placed at the bottom of the trench with water compaction;

- the pillow is lined with roofing felt;

- formwork made of wooden panels is installed in the trench;

- using a knitting wire, a frame is assembled from a rod;

- special small stands 5 cm high are installed at the bottom of the pit;

- a metal frame is installed on the stands;

- The concrete mixture is poured.

The dimensions of the reinforcement for a strip foundation should be such that there is 5 cm between it and the formwork walls and the level of the top of the future base. In this case, after pouring, the frame will be completely immersed in the solution and will not subsequently begin to rust.

Cement mortar for the foundation is prepared in a concrete mixer. This allows you to make it as high quality and uniform as possible. Mixing is done in the proportion of cement/sand/crushed stone 1/3/4. The dry components of the solution are first swirled in a concrete mixer. Then water is added to them.

We build a foundation for a house from foam blocks, make an accurate calculation

It is better to carry out an accurate calculation using the formula by specialists. It looks like this: S > γn · F / (γc · R0).

In it:

S is the area of the base, in brackets the operating conditions coefficient (yc) is multiplied with the soil resistance (R0), and in the numerator the base load (F) and the safety factor (yn) are multiplied

- Calculation of load characteristics;

It always depends on many factors. This is the placement of water, the individual perimeter of the structure being built, the angle at which the roof is located. Also, the topography of the surrounding area, the number of floors, the total height, the materials from which it is planned to make the load-bearing walls and roof and the bearing capacity of the soil are influenced.

- Determination of strength;

Strength will also depend on the location, perimeter and thickness of the walls. If it is not possible to measure the strength, you should deliberately underestimate the available data or carry out strengthening.

- Example of calculations.

For example, the perimeter is 5m * 10m. The height of the walls from the inside is 15 m. The width of the tape is 0.4 m, and its depth underground is 0.5 m. Then: (5+10)*2 + 15 = 45 m. 45*0.4*0.5 = 9 cubic meters of concrete required.

To make 1 m3 of concrete, we take sand and concrete grade M250 in proportions 4:2. Then, 1344 kg of sand will be required, and 672 kg of concrete. And also the right amount of water.

Then, for 9 cubic meters you will need 9*1344=12.096 tons of sand and 9*672=6.048 tons of concrete.

Formwork boards and reinforcement will be required separately.