Any construction, from a barn to a mansion, has one thing in common - there is always not enough money for the planned volume of construction work, and you have to save. If everything goes well, you can save an extra ten to twenty thousand rubles, but is it possible to fill the foundation without formwork? Refusing to arrange formwork for pouring a foundation into the ground is the same as trying to paint an unprimed wall surface; on the one hand, there is savings, on the other hand, there is a risk of getting a bunch of problems instead of the expected result. What is the right thing to do?

Do you need formwork for the foundation?

Experience and common sense suggest that if formwork is widely used in construction and a lot of money is spent on its manufacture and installation, then the presence of a formwork frame in the ground is necessary and important for obtaining the design characteristics of the foundation strip.

Formwork is necessary for pouring the foundation into the ground, not because of the whim of the architect or the developers of SNiPs; the wooden frame of the formwork in the ground allows you to achieve additional advantages:

- Form a correct and geometrically accurate foundation body of the calculated thickness and width, this will ensure uniform distribution of the load on the foundation strip, without the formation of “weak” sections of the structure;

- The formwork box allows you to fix and ensure the correct location of the reinforcement inside the concrete body of the foundation;

- Formwork allows you to ensure high quality and accuracy of laying the waterproofing layer and thermal insulation.

Important! The main purpose of the formwork is to maintain the foundation strip in a fixed and unchanged state until the completion of the concrete hardening processes and the development of design strength.

If you manage to fulfill all of the above requirements, then you can cast the foundation into the ground without formwork. In practice, in many cases, small and light buildings can be installed with your own hands on a foundation strip poured into the ground or into a trench without the use of formwork. Only a specialized specialist involved in the construction of foundations can say how justified such a decision will be for heavy brick buildings.

How to pour a foundation without formwork in practice

Making a foundation by direct casting into the ground may seem simpler and cheaper than when you have to build a wooden formwork frame, knock down dozens of boards into panels, level and drive dozens of posts and spacers. In the absence of formwork, the role of the form that ensures that the concrete mass is given the required profile is played by the walls of the trench, well or pit.

Sequence of operations for pouring a foundation without formwork

The most difficult and time-consuming will be to build a strip foundation without formwork in conditions of weak and moving soils. Even in the absence of groundwater, the huge mass of uncured foundation concrete without formwork can cause settlement and distortion of the tape profile in the trench.

Thus, the strength of a foundation in the ground without formwork depends 90% on the quality of preparation of the trench or pit for pouring concrete. You will need to perform the following operations:

- Study the nature of the soil as accurately and in detail as possible, determine the groundwater level and the presence of springs, springs and other sources. If it is determined that there is a high water level, wet sand, or oily clay, then in parallel with the planning and digging of a trench for the foundation, it is necessary to drain the area;

- The width of the foundation strip, cast into the ground without formwork, is increased by 20-30% of the calculated value, thus, increasing the trench compensates for the deterioration in the load-bearing properties of the strip due to a possible violation of the geometry;

- If possible, the main part of the earth is removed from the trench with an excavator, the last 30-40 cm is torn off manually with an entrenching tool. This is the most difficult and time-consuming stage of work, since it is necessary to level the walls of the trench and trim the bottom horizontally using a building level and a hydraulic level gauge;

- After finishing and compacting the cushion, the walls of the trench are lined with plastic film, the bottom is lined with isospan or glass roofing material;

- At the final stage, the trench is filled with ready-mixed concrete to give the upper part of the foundation the shaped appearance of a strip; the edges of the trench are laid out with a decking board and a row of bricks. After the concrete has set, the bricks and boards are removed. A protruding part of the foundation 5-7 cm high is formed above the ground surface.

Preparing the soil and trench

Before starting work, experts recommend trimming the soil and fertile layer of soil along the edges of the future foundation. Any available material can be laid on the layer of earth freed from turf: pieces of plywood, boards, planks - anything that will help protect the edges of the trench from shedding of earth and collapse. Before you start backfilling the cushion, you need to carefully trim the walls of the trench, remove traces of the excavator bucket, protrusions, irregularities, stones, tree roots, and clean the trench as much as possible from crumbled earth.

The soil at the bottom of the trench is subject to maximum leveling and compaction. To do this, the surface is covered with a thin layer of crushed stone and wet sand and driven into the base of the foundation in four or five passes with maximum force. The last layer is filled with clean sand or screenings and is also compacted in several passes.

The most suitable tool for packing crushed stone into the ground of a trench would be an industrial motor vibrator, but often the limited construction budget does not allow the use of such equipment. In this case, the preparation of the pillow is carried out in two stages. First, large crushed stone is driven into the ground with a three-kilogram hand hammer, then the mixture of screenings and sand is compacted with a two-handed thirty-kilogram tamper.

Next, you need to waterproof the base and walls of the trench. Most often, the pillow and walls are laid out with thick plastic film, the edges of which are glued together at the joints with construction tape. Waterproofing can be laid on the bottom of the trench in one solid sheet and simply fold the edges 15-20 cm onto the walls, if the geometry of the trench allows. Otherwise, the canvas has to be cut into several parts and laid out on a pillow, folding the edges onto the walls. The joints between pieces of roofing felt must be glued with mastic or a mixture of resin and bitumen.

Pouring concrete

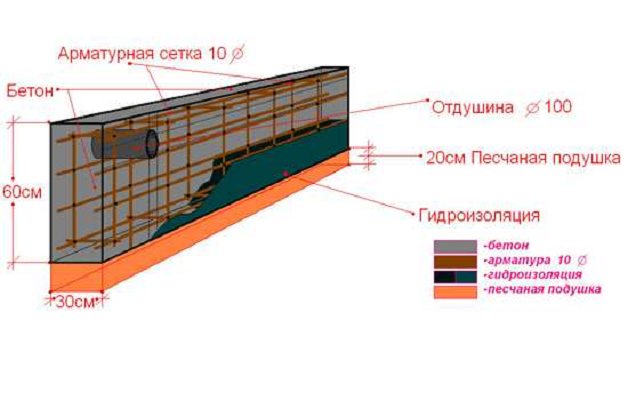

After completion of the preparatory work, reinforcement is carried out, laying reinforcement cages, pre-connected on the surface of the earth. Most often, the frame is made of three layers of reinforcing rod tied with soft wire. Since the most loaded part of the foundation is the bottom and surface part of the concrete casting, one layer of reinforcement is laid on brackets at a distance of 4 cm from the bottom waterproofing. The second and third rows are installed on top of the first on the same supports. The distance from the walls to the reinforcement should be no more than 4-5 cm.

Concreting a foundation without formwork can be done in two ways. The simplest option would be to purchase the required volume of concrete solution and carefully pour it into the trench, evenly dispersing it along the contour of the foundation with shovels. If the concrete is prepared using a homemade method at home, then you can pour the reinforced volume of the tape with your own hands in several layers, and the thickness of each layer should be at least 25 cm. After pouring, the surface of the concrete foundation tape is covered with film for at least 20 days. After the concrete has hardened, the turned-up edges of the waterproofing are wrapped and fused onto the foundation strip.

Stages of work production

Strip foundation poured without formwork

The technology for pouring a strip foundation without formwork differs little from construction work on constructing a classic foundation structure and is carried out in several stages:

- Excavation.

- Sand cushion installation.

- Waterproofing.

- Manufacturing and installation of reinforcement cage.

- Concrete works.

Perform foundations in the ground without formwork only at positive outside temperatures, in the warm season. During this time, the entire range of work can be carried out, the concrete mixture will gain maximum strength, and the foundation strip will be ready for use for further construction of the building.

Excavation

After the preparatory work, it is time to develop an earthen trench for the foundation strip.

Earthen trench strip foundation

Depending on the level of soil freezing, the bottom of the trench can be at a depth of up to 120 cm. According to building codes and regulations, the width of the earth foundation should be 300 mm wider than the thickness of the designed load-bearing walls. The trench configuration follows the contours of the foundation structure.

The fertile soil layer is carefully cut off and moved to the storage site. It is recommended to lay pieces of sheet material - boards, plywood, slate - along the trench. This will help protect the edge of the earth preparation from shedding and collapse. The bottom is thoroughly cleaned of possible tree roots and carefully cleared of crumbled earth.

sand cushion

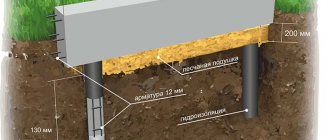

Design diagram of a monolithic base tape without a formwork system

The bottom of the cleaned trench is filled with sand to a depth of 100–150 mm, which is distributed in an even layer over the entire horizontal surface of the trench. Sand backfill has several functions:

- Depreciation of a uniformly distributed load from the concrete mass of a strip foundation.

- Smoothing out uneven ground surfaces and leveling the bottom of the trench.

- Creation of drainage to drain groundwater.

The sand bed must be compacted using a hand tamper or a vibrating roller.

To achieve the tightest adhesion of sand particles, you can pour water on the sand base and compact it thoroughly. The result is a smooth and dense sandy base.

Foundation waterproofing

Waterproofing strip foundation without formwork

After completing the laying of the sand cushion, it is necessary to protect the bottom and walls from water ingress using any waterproof rolled material: roofing felt, plastic film. This will be the waterproofing of the trench, which it is advisable to lay in one solid piece or sheet. The joints of the rolled material are glued together with tape or, in the case of using roofing felt, glued with bitumen mastic. Sometimes, in order to protect against the collapse of earth masses, the walls of the trench are covered with a special film - geotextile. This coating is appropriate to use when trees and shrubs grow next to the strip foundation.

Geotextiles will not allow tree roots to grow into the body of the foundation.

Reinforcement works

Scheme of reinforcement with reinforcing cage

Filling the concrete body with a reinforced spatial frame made of steel or composite reinforcement will significantly increase the strength of the strip foundation and protect its structure from shrinkage cracks and deformations. The reinforcing bars are connected to each other with tying wire. As working main elements, rods of larger diameter from 10 to 16 mm with a corrugated side surface are used. Transverse, or as builders call “mounting clamps,” are made of smooth wire with a diameter of 5–6 mm. The spatial reinforced element can be assembled separately and ready-made installed directly into the trench.

In some cases, it is possible to combine assembly and installation simultaneously, immediately in a prepared trench.

Concrete works

It is best to concrete a strip foundation in the warm season, when the threat of frost has disappeared.

Concrete foundation without formwork

According to building rules, concrete of at least class B 15 is used for foundation structures. This grade of concrete mixture can easily withstand the forces of load-bearing walls and roofs and is considered the most optimal for ensuring long-term operation of the building. If the foundation structure has a significant volume, it is recommended to use purchased concrete, which is delivered directly to the construction site by a special machine - a concrete truck. Laying with an automixer is done as quickly as possible and eliminates the long process of preparing the mixture manually.

Filling with concrete occurs layer by layer and with the obligatory compaction of the mixture with a construction vibrator or bayonet shovel.

Curing

After pouring, the concrete mass is occasionally watered with water, and in the hot season it is covered with plastic film. Under the influence of sunlight under the film, the concrete mixture undergoes a natural steaming process, which increases the strength indicators of the bearing capacity of the strip foundation. It is known from construction practice that concrete gains its strength in 28 days. If the load-bearing walls are made of light-weight material, for example, gas-silite, then after 7 days their construction can begin.

Video example of a foundation without formwork:

If you carefully follow the entire technological chain of creating a foundation without formwork, you can carry out such a structure yourself without any problems, and then doubts “is it possible to build a building on a monolithic foundation without formwork” will not arise.

A foundation without formwork facilitates construction work. The filling procedure is simple, but requires certain knowledge. Building a house without formwork can lead to subsidence of the foundation and irreparable consequences. When soil can be used as formwork, is it possible to pour concrete without formwork into a newly dug trench?