Cement is a special building material that acts as a “binder” between the components of concrete and cement mortar for various purposes. Cement in its pure form is practically never used. An exception is the technology of strengthening the top layer of concrete structures, the so-called “iron plating”.

In all other applications, cement is mixed in varying proportions with filler and mixer. Therefore, answering numerous questions from private developers, it makes sense in this article to tell you how to mix cement with sand, water and other components.

Scope of cement application

To better understand the question of how to properly dilute cement, you should indicate the main ways of using this unique and irreplaceable building material:

- Production of heavy and other types of concrete.

- Preparation of masonry mortars.

- Preparation of different types of plaster solutions.

- Production of material for creating sculptures, flowerpots, flowerpots and other decorative products made of concrete.

- Production of paving slabs, curbs and paving stones.

Generally speaking, the use of cement can be divided into two main types:

- Binder for concrete of various types and purposes.

- Binder for solutions of various types and purposes.

Next, we will look at various formats and nuances of using the universal “binder”.

Purpose and composition of solvent for concrete (cement)

This product is used: to remove cement particles from concrete mixers and tools such as brushes, spatulas and power tools; for removing hard residues from bricks or tiles. It will also help when dismantling brick walls: concrete joints are moistened with it to make it easier to separate the bricks, and the remaining building material is removed from the base using a solvent.

The cement solvent is very active; it contains acid and other aggressive elements. When it comes into contact with the solution, intense oxidation starts, which has a destructive effect on the structure of the material. The cement becomes viscous and can be easily removed with a scraper or rag.

It consists of three components:

- Concentrated acid - phosphoric or hydrochloric.

- Inhibitors are substances for active penetration into the concrete structure.

- Substances to prevent corrosion on metal.

Proportions of popular brands of Portland cement for the production of heavy concrete

The most popular type of concrete in the construction of residential and industrial buildings, as well as the most popular material for the manufacture of all types of reinforced concrete products, is heavy concrete prepared on the basis of Portland cement grades M400 and M500, new markings: TsEM I 32.5N PTs and TsEM I 42.5N PC accordingly.

We present to our readers two tables in which you will find answers to popular questions: how to dilute cement for concrete using grades M500 and M400.

Table of proportions of components for preparing 1 m3 of heavy concrete of popular strength grades

| Brand of Concrete | Cement M400 CEM I 32.5 | ||||

| Proportions | Cement | Sand | Crushed stone | Water | |

| M100 | 1:4,4:6,5:1,1 | 175 kg | 755 kg | 1150 kg | 190 l |

| M150 | 1: 3,5: 5,2: 1 | 215 kg | 735 kg | 1140 kg | |

| M200 | 1: 3: 4,5: 0,7 | 255 kg | 715 kg | 1125 kg | |

| M300 | 1: 2: 3,3: 0,6 | 335 kg | 670 kg | 1105 kg | |

| M400 | 1: 1,5: 2,5: 0,5 | 420 kg | 625 kg | 1085 kg | |

| M500 | 1: 1,2: 2: 0,4 | 500 kg | 575 kg | 1065 kg | |

| Brand of Concrete | Cement M500 CEM I 42.5 | ||||

| Proportions | Cement | Sand | Crushed stone | Water | |

| M100 | 1: 5: 7,3: 1,2 | 160 kg | 770 kg | 1150 kg | 190 l |

| M150 | 1: 4: 6: 1 | 190 kg | 755 kg | 1140 kg | |

| M200 | 1: 3,3: 5: 0,8 | 225 kg | 735 kg | 1125 kg | |

| M300 | 1: 2,5: 3,8: 0,7 | 290 kg | 705 kg | 1105 kg | |

| M400 | 1: 2: 3: 0,5 | 355 kg | 675 kg | 1085 kg | |

| M500 | 1: 1,5: 2,5: 0,4 | 425 kg | 640 kg | 1065 kg | |

The table contains answers to one of the most common questions asked by non-professional developers of low-rise buildings - how to dilute cement for the foundation of a house, summer house or cottage.

In accordance with current regulatory documents - GOST and SNiP, the best option for pouring 99% of foundations is the grade of heavy concrete M150 or M200. For severe operating conditions, it is allowed to use concrete grade M400. Accordingly, when faced with the task of how to dilute a cement solution for pouring a foundation, you should use the proportions given in this table.

Many unprofessional and inexperienced developers ask the question: is it possible to dilute cement without sand, using existing granite screenings or small construction waste as a replacement for this material.

The answer of a private builder with sufficient experience in the construction of low-rise buildings and structures will be as follows. If it is necessary to build structures that are not heavily loaded, such as: a blind area around the house, a garden path, a platform for drying clothes or a one-story house made of furnace slag, an underground cellar of small dimensions (2x2x2 meters), a deviation from the existing GOSTs is allowed, in terms of replacing sand with small construction waste or small granite screenings.

Types of PGS

Ordinary (natural). Consists of no more than 20% gravel, the remaining 80% is sand.

Enriched (OPGS). The share of gravel is much higher and amounts to up to 75% of the total volume of the mixture. Based on the amount of gravel, there are 5 groups of enriched sand and gravel mixture:

over 15%, but less than 25%; over 25%, but less than 35%; over 35%, but less than 50%; over 50% but less than 65%; over 65% but less than 75%.

In construction, both types of ASG are used for concrete work, but in different proportions.

Proportions for solutions

All cement-sand mortars are divided into three main types: material for laying bricks (cinder block, foam block, shell rock, Inkerman stone), mortar for plastering surfaces and mortar for floor screed. Let us consider the preparation of these solutions in order.

How to dilute cement for bricklaying? Two types of mortar are used in construction:

- Cement-lime material consisting of Portland cement CEM I 32.5N or CEM I 42.5N, carefully sifted sand, water and lime paste. This is the so-called “warm” solution. This type of material has excellent ductility and is considered optimal for all types of brickwork. Proportions of components: cement: lime: sand: water: 1 part cement, 0.8 parts lime, 7 parts sand, 0.8 parts water. First, the dry ingredients and lime are mixed, then water is added and everything is thoroughly mixed until smooth. If necessary, increase the amount of water.

- Cement mortar. Consists of Portland cement CEM I 32.5N PTs or CEM I 42.5N PTs, sand and water. Characterized as "cold, stiff and inactive." Component proportions: 1 part cement, 5 parts sand (for CEM I 32.5N PC) or 5.5 parts sand (for CEM I 42.5N PC) and 1 part water. The procedure for preparing the working material is similar to the procedure for preparing cement-lime mortar.

As you can see, you can make masonry mortar with your own hands right on the construction site, the main thing is to maintain the proportions and mix the components thoroughly.

How to dilute cement for plaster?

In general, for ordinary plastering of walls, three types of cement-sand mortar are used:

- Brand 50. Recommended for finishing grouting. Proportions for Portland cement CEM I 32.5N: part binder, 6.3 parts sand, 1.3 parts water. Proportions for Portland cement CEM I 42.5N: part cement, 7 parts sand, 1.5 parts water.

- Brand M100. Recommended for interior decoration. Proportions for Portland cement CEM I 32.5N: part binder, 4 parts sand, 0.8 parts water. Proportions for Portland cement CEM I 42.5N: part binder, 4.5 parts sand, 0.9 parts water.

- Brand M150. Recommended for plastering damp rooms, facades and plinths. Proportions for Portland cement CEM I 32.5N: part binder, 3 parts sand, 0.6 parts water. Proportions for Portland cement CEM I 42.5N: part binder, 3.3 parts sand, 0.7 parts water.

If we talk about how to properly dilute cement with sand for plaster mortar, then two points are very important here. The first point is to sift the sand very carefully. The mesh size of the sieve for sifting sand for preparing primer plaster should be from 2 to 3 mm and 1 mm for preparing finishing plaster.

The second point is to mix the dry ingredients very thoroughly, maintain the proportions of water and then thoroughly mix until smooth.

How to dilute cement and sand proportions for floor screed?

To fill the floor screed, the following grades of cement-sand mortar are used: M150 and M200. The choice of solution brand depends on the maximum load. Next, we will tell you how to dilute cement with sand to prepare mortar M150 and M200, and the reader will choose the appropriate option depending on the specific operating conditions.

- Solution M150. Proportions for Portland cement CEM I 32.5N PC: 1 part cement, 3 parts sand, 0.6 parts water. Proportions for Portland cement CEM I 42.5N PC: 1 part cement, 3.3 parts sand, 0.7 parts water.

- Solution M200. Proportions for Portland cement CEM I 32.5N PC: 1 part cement, 2.1 parts sand, 0.5 parts water. Proportions for Portland cement CEM I 42.5N PC: 1 part cement, 2.5 parts sand, 0.6 parts water.

As for the order of operations, it is standard. First, mix the dry ingredients, then add water and mix everything thoroughly.

How is white cement diluted?

To conclude the story, it is worth answering another common question: If white cement is used as a “binder,” how to dilute concrete and solutions based on it correctly?

White cement is used to create colored structures. Therefore, it is very important that the fillers and sealer do not interrupt the color of the concrete or mortar. Therefore, to prepare concrete and mortars based on white cement, you should use white, thoroughly cleaned quarry sand, clean water and clean tools: a trough, a sheet of iron, buckets and a concrete mixer.

Basic factors

The key question is how to prepare cement, and how to prepare it correctly. An incorrectly prepared solution is doomed to rapid destruction. The formed building will begin to crumble, over time layers of plaster will begin to peel off, and the release of sand from the outside of the wall increases.

All these factors provoke, in the near future, the reconstruction of the building or one of its elements.

Correct placement of cement can only be done by knowing its purpose, since the corresponding requirements are provided for each individual type.

To properly dilute the cement mortar, several factors should be taken into account:

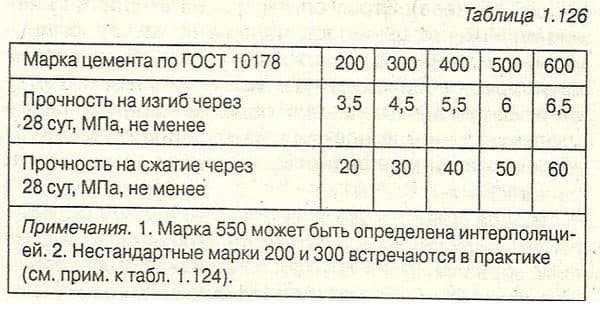

- you need to take into account the brand of cement and decoding;

Stamps

- water is needed, for a stronger and more integral structure it is better to use rainwater or obtained from snow, since tap water contains additives;

- filler. They can be various slags, sawdust, sand, clay and crushed stone . Sand is necessarily used, and other fillers are considered auxiliary, which are used for specific tasks;

Sand

- purpose of cement. Depending on the purpose, the consistency and components of the solution differ. Most often used for laying foundations, plastering, forming floors, laying tiles, etc.

Proportions for forming the mixture in buckets

Using buckets to measure proportional compliance is a very common solution. For example, this approach is used in cases where work is planned with a volume of cement of no more than 4 m3 or small areas are being gradually filled.

To begin with, it is important to consider that the components for the solution will have different volumetric weights. Thus, the weight of a bucket of sand is about 20 kg, the weight of cement in such a container reaches 15.5 kg, and crushed stone - 17 kg.

Taking into account the proportions that apply to 1 m3, we can conclude that the composition of concrete for the foundation proportions in buckets will be as follows: 9: 5: 2 , where 9 parts are allocated to crushed stone or gravel, and 5 to sand . Cement for 2 shares in this ratio .

In some cases, a combined mixture of sand and gravel . The ratio of buckets for preparing a solution with such a component will be as follows: 1:5 , that is, for one share of cement there are 5 buckets of sand and gravel mass.

Return to content

ASG concrete for foundation

Concrete grades are prepared from an enriched mixture of gravel and sand:

- M150 - for foundations for small one-story buildings;

- M200 – for strip and slab foundations;

- M250 – for monolithic and slab foundations;

- M300 – for monolithic foundations;

- M400 – with accelerated setting for particularly strong foundations.

To improve the adhesion of the mixed components, Portland cement with a calcium silicate content of up to 80% is used to prepare concrete. This allows you to mix concrete at low temperatures, but not below +160C.

The content of foreign impurities in cement should not exceed 20%. Special marking of cement, designated by the letter “D”, indicates the percentage of undesirable additives in it.

Floating foundation

The technology for constructing a floating foundation is one of the simplest . At the same time, it allows you to create a base that can be used on different types of soil.

For example, it is arranged on weak-bearing and heaving soil, while the groundwater level should be low - the only limitation.

The construction of a floating foundation, as in the case of a strip counterpart, also involves the creation of a trench . But in this case, the dimensions of the trench will be different - the width is 50 cm and the height reaches 70 cm.

After this, filling . But the composition of the concrete solution will be non-standard - technologists recommend using rubble concrete, laying it throughout the entire trench.

Special attention is paid to reinforcement . To do this, it is necessary to lay a mesh of reinforcement bars on top of the created coating. All connecting points should be secured with a welding machine or tied with wire.

The drying period for such a foundation usually requires no more than 10 days.

Return to content

Cement wash problem

If drops of mortar on the walls and floor were discovered in time, while they had not yet set, they can be wiped off with an ordinary rag or scraped off with a spatula or scraper. This method is the simplest and absolutely safest for any reason. But when cement has a strong adhesion to the product or when it is necessary to remove the old concrete layer, big problems arise. In this case, you will have to use one of the following methods:

- Mechanical. The stains are scraped off with a chisel, spatula, cut off with a grinder or cleaned with a grinding machine. In this case, there is a high risk of surface damage and scratches.

- Folk (chemical). If the stain is small, you can use improvised means - citric acid, vinegar, household chemicals. Discolored spots may appear on some materials after such measures.

- Professional. Specialists use special solutions - cement removers, which quickly soften it and allow you to wipe off streaks without difficulty.

Cleaning concrete with cement solvent

Monolithic columnar foundation

In this case, the foundation structure will be formed not only by concrete, but also by pillars , which are distributed over areas with the highest loads. As a rule, these are corner points and places where it is intended to create overlaps.

The difference between this foundation and a strip foundation in terms of the use of concrete is that the mixture covers the entire area on which the building will be placed. In this case, the composition of the concrete mixture involves the use of material of different classes - for example, both B15 and B25 . But, before pouring, it is necessary to lay layers of sand and crushed stone .

The greatest difficulty in constructing such a foundation involves the installation of formwork. This is due to the fact that the coating will have a large area , for the maintenance of which an appropriate amount of lumber will be required - wood beams, racks, joists, etc. But, thanks to the high strength of such a foundation, there is no need for additional reinforcement in the form of reinforcing elements.

Return to content

Water is also an important main component of any solution.

There are special tables for calculating the proportions of water consumption in a solution. But practice shows something else: every builder prefers to add water himself, since the consistency of the solution required is different, somewhere thicker, somewhere thinner. But in concrete production plants, each component is added strictly in certain proportions, based on this, concrete of different markings and different purposes is obtained.

A little construction trick. When preparing the solution manually in a special container, first of all, sand and cement are poured in the required proportion, then water is added, then it is all mixed. The trick is this: after adding water, you need to wait 10-15 minutes and only then stir. During this time, the water will be completely absorbed into the mixture of cement and sand, the resulting mass is very easy to mix, a few stirrings are enough. If you stir the mixture immediately after adding water, you will have to work hard.

If you do not have a special container at hand, then the solution can be kneaded without it; for this, the following method is used. Sand and cement in the required proportions are poured into one heap on a flat surface, the resulting mass is thoroughly mixed. Then, using shovels, a hole is made in the middle of the pile into which water is poured. After this, starting from the edges, the dry mixture is carefully poured into the water. So, gradually, a solution is obtained; if necessary, you can add water.

Strip foundation

The foundation strip is formed from concrete mortar, since this material provides the highest strength characteristics . It is advisable to use for this purpose a concrete composition for the foundation, the proportions of which are calculated based on the use of grade B15 . Such concrete has optimal compressive strength parameters and high resistance to deformation processes.

It can be used both on the ground and in formwork. When installing on formwork, the trench should be arranged so that it exceeds the width of the tape by 15 cm on both sides. In this case, the height of the formwork will be about 40 cm.

If you plan to install a foundation on the ground , there is no need to leave indentations - the solution should fill the entire niche. The surfaces of the formed trench are covered with waterproofing materials , which will not allow the solution to spread and will contribute to the rapid acquisition of strength characteristics. In some cases, for greater reliability, the solution is reinforced with reinforcement .

For example, you can use four reinforcing rods with diameters of 1.2 cm. They should be laid longitudinally and then secured with clamps across. When finished, this tape is 40 cm in height and up to 80 cm in width. However, if reinforcement is not expected, then these parameters increase.

Return to content