The question of how many days can the panels be removed after pouring a strip foundation is relevant for most individual developers who do not have practice or specialized education. SP 70.13330 standards regulate the dismantling of removable foundation formwork only upon reaching 70% of the design strength (depending on the brand of the mixture). In practice, it is impossible to measure this parameter at home, so they rely on time and air temperature.

Requirements and standards

According to SNiP 3.03.01-87 “Load-bearing and enclosing structures”, the demoulding of vertical panels is carried out when the concrete base gains 70% strength, or 50% if there are appropriate foundations for this. Exactly the same requirements are voiced in SP 70.13330.2012.

There is also a European regulation ENV 13670-1:20000, according to which the formwork can be dismantled when the strength has reached 50%, if the air temperature is at least 0 degrees. The American standard ACI 318-08 specifies other requirements - it is recommended to remove the wooden frame after 7 days if the humidity and air temperature meet the standards.

As you can see, almost all standards refer to temperature, humidity and other conditions for the “maturation” of a concrete base. Accordingly, if the ambient temperature differs by several degrees, the strength gain will occur faster or slower. From here we conclude that, in order to determine when it is possible to remove wooden formwork from a strip foundation, it is enough to find out exactly when the concrete mass gains strength.

Building codes

If the process is carried out at home, then it is impossible to measure this factor, so they focus on the time allocated for the hardening process and the air temperature. After removal, you can continue work and load the concrete base. It is advisable to start work during the warm period , when the amount of precipitation is low.

Most often this is early autumn, spring, summer, at this time the weather and ambient temperature are most suitable for high-quality installation and quick drying of the base. In construction, there is a term for stripping strength, which indicates the time to remove protection from concrete and further continue the process.

This value depends on the type of structure. For reinforced strip and slab bases, blind areas and armored belts, it is 50% of the branded design strength. In this case, you can quickly continue work and erect a building. When pillars, columns and vertical products harden, the stripping strength is about 30% of the total strength. For monolithic floors and concrete stairs, the figure should be about 70%, since strong pressure will be applied to the base. This can affect the surface and, if not cured sufficiently, will lead to failure.

All floors covering a length of about 6 m or more must be placed on a base that has hardened up to 90%. In the case of private housing construction, the dismantling of the formwork is carried out approximately after reaching 50 percent of the total hardening of the base.

The exception is reinforced concrete flights of stairs, which are installed on a base that has hardened up to 70%. In order for the base to be of high quality and to withstand mechanical loads well, it is necessary to accurately determine the time after which the formwork must be dismantled.

Important question

Although the chemical reaction of crystallization of material particles and their bonding with each other occurs in a standard mode, environmental factors still influence this process. The procedure takes place in two stages. First, setting occurs under optimal conditions, which takes several hours.

Primary hardening cannot be the basis for continuing work, but is an indicator of the quality of the concrete, the level of mixing of the mixture and the ability to take the form provided by the formwork. This is an important element because you can see if the foundation is dense enough and add thickness with cement.

The second factor is the set of brand strength. It occurs after 90% of the expected hardness has been achieved, the remaining percentages depend on how environmental conditions influence. This process can be completed within a few years after construction. Therefore, formwork removal is not a standard process for all types of work, depending on the following:

- type of material;

- environmental factors;

- amount of moisture;

- temperature conditions.

In order to slow down the drying process, the “stirring” method is used. It is relevant when transporting concrete using special mixers. If we talk about standard conditions, with a sufficient level of humidity in the air, the concrete mixture can achieve the required strength in about three days, and harden by 75-80% in a week.

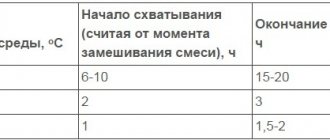

If the air temperature is different, there is a lot of moisture in it, then the hardening time may increase or decrease. Builders advise using a table that reads the air temperature and indicates the strength of concrete. The average daily air temperature is taken as a basis. Thanks to calculations, you can find out how many days later you can remove the formwork from a strip foundation or other type of base.

Factors affecting strength

The influence of the environment cannot be overlooked. Humidity conditions play an important role in the strength gain of the base. In hot weather, the open hardening monolith is susceptible to environmental influences. The first sun strongly heats the surface of the concrete and quickly evaporates moisture. The surface hardens faster, moisture is concentrated in the base, resulting in a crack on the surface .

- Therefore, during the drying process, builders advise moistening the surface.

- The chemical reaction is accelerated, but due to this hardening occurs unevenly. The concrete becomes covered with cracks and irregularities, the upper part begins to crumble and crumble. To avoid destructive processes, experts advise adding water to the surface using sprayers.

- After this, it is necessary to cover the surface to create a greenhouse effect, so that the moisture evaporates evenly from the inside, but the surface does not dry out.

You should also not allow the concrete to become overcooled due to night frosts, as this can also lead to the destruction of the base. For this purpose, there are special heaters and technologies that cover the surface at low temperatures.

How long does it take for concrete to gain strength?

It is believed that concrete gains maximum strength (more than 70%) 4 weeks after it is poured. However, in this case, the air temperature is +5 degrees. Based on this, at a temperature of +10 degrees, the formwork can be removed after 2 weeks. Therefore, if you rely on temperature indicators, you can draw up an approximate concrete hardening schedule, taking into account the fact that according to European and American standards, 50% hardening is quite enough.

Based on this table, we conclude that the formwork can be removed after 2 days if the weather is hot.

Healthy! Concrete gains strength most rapidly during the first week, after which the base continues to harden for 2 years (during this time it gains up to 250% strength).

However, if you used horizontal cast structures for formwork, then these periods increase:

| Average daily temperature, 0C | After how many days can the formwork be removed? |

| 1 | 28 |

| 5 | 21 |

| 10 | 15 |

| 15 | 9 |

| 20 | 7 |

| 25 | 6 |

| 30 | 5 |

It is also worth paying attention to the following recommendations, which will allow you to more accurately determine when to remove the formwork:

- If the length of the structure is more than 6 m, then it is necessary to wait until the base has hardened by 80%.

- Horizontal inclined elements can be removed upon reaching 50-70% strength.

- It is recommended to remove vertical elements with strength indicators of 0.2-0.3 MPa.

However, as mentioned earlier, the strength of concrete is influenced by many factors, so air humidity must also be taken into account, as well as the appropriate treatment of the monolithic surface. That is why for the first 2-3 days the fresh foundation is covered with film and moistened with water 2 times a day. If the moisture evaporates too quickly, the concrete will not hydrate properly, resulting in a decrease in the load-bearing capacity of the monolith.

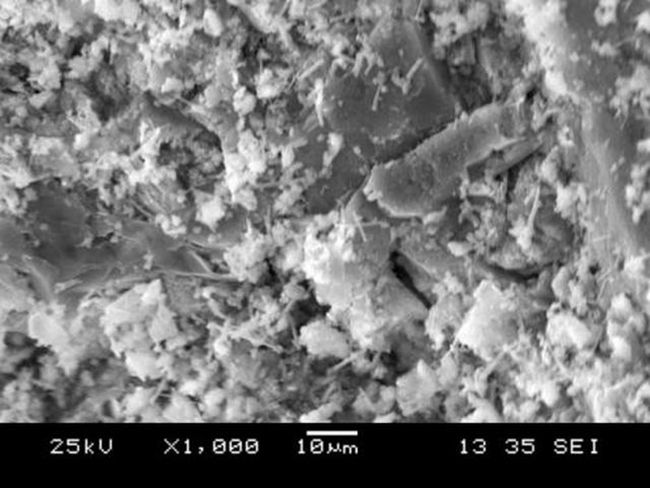

In addition, it is worth taking into account such a “phenomenon” as crystallization of concrete. This chemical process also affects the hardening of the concrete mass.

What is formwork?

This special factory or individually made structure consists of several interconnected panels and blocks. All elements are fixed strictly in the specified order and position in order to obtain maximum tightness of the surface and prevent leakage of concrete solution.

The formwork must be removed after a strictly defined time, and some building codes indicate how long dismantling is permissible. Depending on the type of foundation, its overall dimensions and the depth of the base, the rules for dismantling the formwork will differ significantly.

The timing of dismantling is also affected by the purpose of the frame, because it can be used:

- directly for the foundation;

- when creating interfloor ceilings;

- for the construction of load-bearing walls and partitions;

- when constructing tunnels, mines and large-diameter sewers.

When constructing formwork, you can use metal fasteners, wood or polystyrene foam. Plastic and fiberglass structures are also sometimes found. How much building materials will be used for the construction of such foundation elements depends on the type of foundation, its design, depth and size.

Crystallization of concrete

In order to determine the time it will take for concrete to set, it is necessary to take into account several phases in which the foundation components are located:

- Phase 1 – immediately after pouring the solution. During this period, the solution is considered supersaturated and the process of mixing with water occurs. It lasts only 1-2 minutes, but during this time a “union” of ettrigint and calcium hydroxide is formed in the concrete mass.

- Phase 2 – 1 hour after mixing the cement-concrete mixture. During the induction period (3-6 hours), the cement-sand mixture turns into cement paste, characterized by mobility and impermeability to water.

- Phase 3 lasts from 12 to 36 hours, after the formation of the cement paste. During this period, cementation of the stone occurs, due to which the so-called spatial lattice is formed from “scales” of cement.

If the formwork is dismantled before the completion of phase 3, the physical and chemical properties of the concrete may change, so it is not recommended to remove the frame earlier than after 2 days.

Another nuance is the ratio of water and cement in the mixture, since the speed at which the foundation gains strength also depends on this.

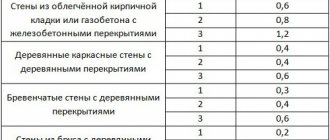

| Volume of water relative to cement | Strength | ||

| In 1 day | In 3 days | A week later | |

| 0,4 | 24% | 48% | 70% |

| 0,5 | 17% | 43% | 66% |

| 0,6 | 11% | 37% | 64% |

| 0,7 | 8% | 33% | 63% |

The sequence and technology of formwork removal should also be taken into account.

How to care for concrete

After pouring, you need to cover the concrete with a protective film. It is necessary to provide proper care - it has a beneficial effect on the hardening time and ease of removal of the formwork structure.

Concrete requires constant maintenance

Requirement – the surface must be well shed. But before the first watering, you need to check the condition of the surface. If it is wet, the concrete “matures” in good conditions.

You need to open the flooring every 2 meters. The water will spread on its own - no “help” is required.

Before the spill procedure, it is necessary to check the concrete for cracks and damage. If so, mistakes were made when laying the foundation.

The optimal temperature for spilling is 25 degrees. It is allowed to shed the base at a higher temperature. The most important thing is that in order for the humidity to exceed 70%, there must be a maximum amount of steam in the air.

You need to pour in as much water as possible. Water temperature - any. If the sea is nearby, water can be used - salt water will not affect the quality of the structure.

Spilling can be done about every other day, for three weeks. But if the concrete under the protective film is wet enough, it is not recommended to water it too often or too much - it will start to get damp and affect the quality.

According to the builders, stripping should be done in about three days.

The tape is allowed to be loaded only after 1.5-2 weeks - depending on the maturation of the concrete.

Experts believe that the tape must withstand the winter (in some parts of Russia this includes part of the spring) - only after this is it allowed to erect the box.

It is necessary to build a base of 3-5 bricks and cover it with floor slabs. You can leave until spring.

How to dismantle formwork

It is necessary to start disassembling the wooden frame from the corners, as well as the protruding parts of the fundamental base. It is in these areas that concrete hardens most intensively. In addition, while you remove parts of the formwork from the corners, the middle part of the foundation will continue to gain strength.

The panels must be dismantled very carefully so as not to damage the integrity of the entire structure. Therefore, you should not abruptly tear off or break out boards using tools.

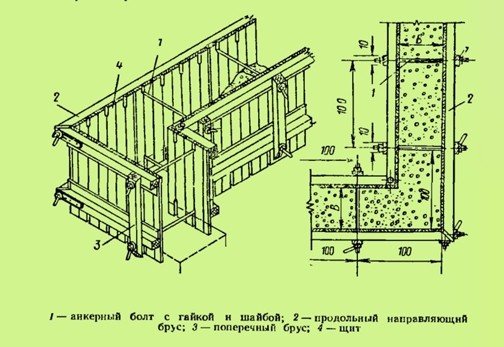

It is necessary to remove the formwork from top to bottom, observing the following sequence of actions:

- Unscrew the bolts and remove the top metal ties.

- Remove the bolts of the lower ties (the ties must be left in the concrete mass).

- Carefully move the shields away from the posts.

- Remove supports.

- Remove the wooden frame.

The formwork must be removed, even if you have temporarily “frozen” the construction until next summer. There are several reasons for this:

- If you leave a wooden structure in the rain and snow, the wood will quickly absorb moisture.

- It is better to dismantle the formwork and waterproof the foundation before the wooden frame bursts, when all the moisture absorbed into it melts in the fall.

It is also not worth leaving the foundation itself for the winter, despite the statements of “would-be-advisers” who are confident that the overwintered foundation will only become stronger from this. If you leave an unloaded concrete foundation for the winter, the structure may simply be pushed out of the ground (especially if the soil is heaving). In addition, a foundation that has undergone wintering without waterproofing will be very difficult to assess - to determine whether it has suffered damage from the expansion of water inside the mass.

In turn, it is also not worth loading the foundation ahead of schedule. The best option is to calculate the work in such a way that the concrete base has time to gain the necessary strength (after 4 weeks) and you have time left to load the base.

Important Tips

It must be remembered that:

- When removing the formwork, you can begin installing other building elements;

- The final stage is the removal of support beams, towers, and tours;

- Dismantling work is carried out from top to bottom. The main direction is horizontal. At the corners of the base the mixture hardens faster;

- It is necessary to dismantle rack elements and panels with the utmost care - otherwise, there is a risk of damaging the layer. Leads to the impossibility of reuse;

- The elements must first be lubricated with a compound that helps reduce adhesion. The formwork is removed faster.

Acceleration of hardening

When work is carried out in winter or during periods when air humidity is high, you need to complete the masonry process as quickly as possible and speed up hardening. In practice, this can be done using several methods. Insulation and heating allow the base to harden faster without destroying the surface.

Both electric heaters and special reinforcement technologies, as well as burlap and fabrics that cover the base, can be used. The addition of superplasticizers allows concrete elements to quickly enter into a chemical reaction with each other and harden.

The disadvantage of this method is the impossibility of quickly removing moisture from the inside, which can then lead to destruction. The use of chemical additives and admixtures is also expected in the process, but here it is necessary to maintain proportion and use those elements that are combined with the grade of concrete.

Preparing a mixture using quick-hardening cement is one of the most effective and inexpensive options. You can buy ready-made cement from the manufacturer, or you can make it yourself using additional components. If we talk about chemical additives, they not only accelerate crystallization, but also protect concrete from low temperatures, preventing water from freezing.

The simplest and most effective method is to prepare the mixture in hot water, pour it into a mold and thoroughly insulate it. Also, to ensure that the reaction does not slow down, internal heating is done using an electric cable. The use of film will not be effective at low temperatures, since the water inside will begin to crystallize, and this will lead to cracking of the base.

It is advisable to combine the film and a heat gun, due to which the surface will be heated. If we talk about when to remove the formwork after pouring concrete in the summer, then the level of drying of the base and hardening of the foundation is taken into account; it should be at least 50% of the total indicator.

Stripping stage

During the removal process, you must be careful not to damage the base. Although the foundation is 50% cured, its texture is not dense enough to withstand mechanical stress or remain uniform after damage. Therefore, you need to follow several recommendations. You need to start removing the formwork from places that have hardened well.

As practice shows, these are angles. When finishing the first panel, you need to make sure that the concrete has hardened enough to retain its shape and will not crumble. It is advisable to work manually; do not use heavy mechanical tools or metal mechanisms that can damage the surface. You also need to give up sharp objects that people sometimes use to remove formwork.