When constructing buildings and premises of various types of functionality, one of the most important points of the work performed is the installation of a reliable foundation. If the load-bearing foundation is not made very well, not in accordance with existing norms and standards, any house will probably not last long - at least regular cracks and major repairs will be ensured. Therefore, the issue of strengthening the fundamental structure with the help of reinforcement is always very acute - special metal rods, the iron base of any reinforced concrete product. You can achieve the desired strength in two ways:

- viscous reinforcement elements using tying wire;

- welding reinforcing bars into a single fixed frame.

For professional builders, when the question arises whether to knit or weld, and whether it is possible to weld reinforcement for the foundation, each specific case is considered, and the decision is made individually, taking into account all the conditions involved.

By the way, construction experts have not yet come to a consensus on which reinforcement method is considered more preferable. Both knitting and welding of foundation reinforcement have their supporters.

Welding for foundation reinforcement

Pros and cons of welding work

Before choosing one of the methods of reinforcing the foundation for a building under construction, even at the design stage, you should consider the strengths and weaknesses of each of them. Among the advantages of welding for connecting reinforcing elements, one can immediately note their speed and the production of a more durable, indestructible frame. This method is the most optimal for the construction of large, large-scale objects, for example, industrial premises of various types. However, welding reinforcement for the foundation also has its disadvantages, which are discussed below.

- It is highly not recommended by experts to use a welded connection of reinforcement in areas with increased seismic activity, or on moving soils (which, by the way, also include loose soils). Soils that are too mobile will inevitably, over time, cause the foundation produced by this method to shrink. Because of it, rigid welded joints in the structure can break. In such conditions, it is recommended to use wire and a method of connecting reinforcement - knitting: it holds the frame together relatively movably and firmly, but allows the foundation elements to move within certain limits even with noticeable ground movements. This limitation significantly reduces the scope of welding when laying load-bearing structures of buildings.

- The welding process also affects the elements being connected. The fittings are exposed to very high temperatures. As a result, some destruction of the metal structure occurs in the places where welding work is carried out, which negatively affects the overall rigidity and strength of the frame itself.

Nevertheless, welding still remains the leading method of equipping foundations for large buildings.

Welded reinforcement for the foundation - application features

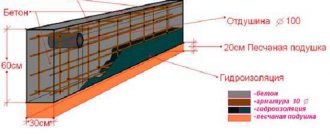

In the construction of architectural structures, the main task is to prepare a strong foundation that will withstand the internal compression reinforcement of the wall supports and the underlying soil. The basis of the foundation is concrete, which consists of sand, cement and water; when hardened, it can withstand heavy loads. The physical characteristics of the cement material cannot guarantee the absence of deformation of the base of the structure.

To withstand foundation shifts that occur due to temperature changes and other natural factors, metal is used that provides reliable fixation. Reinforcement is a mandatory process during construction. During the operation of the structure, settlement occurs, and the soil under the foundation becomes compacted. The process should take place evenly along the entire length of the strip foundation. In such cases, internal forces do not arise in the foundation.

You can achieve uniformity and reduce settlement by using foundation strips with reinforcement, the width of which determines the magnitude of the load.

The foundation is the basis of an architectural structure; when laying the foundation of connections, two methods are used for strength: welding and bonding. Each of them has its pros and cons. Some builders prefer to use welding to strengthen the foundation; in this case, the connection is made at the intersection of the reinforcement. The method is quite simple and reliable; special attention is paid to the reinforcement of the corners so that the steel elements are the connecting link of one and the other wall.

Reinforcement cage welding process

For large volumes of construction work, the elements are welded together in the factory. Briefly, this process looks like this.

Preparation of reinforcement

- Preparation of reinforcement; checking the quality of elements. At this stage, reinforcement blanks are selected that meet the standards and certain characteristics.

- Cleaning of workpieces. At this stage, not only dirt and dust are removed from the reinforcement, but also traces of corrosion, if any. And the material is processed accordingly.

- Marking and cutting elements in accordance with the building plan. Measurements are taken according to the design and the material is cut into the required quantity.

- A horizontal structure is assembled from rods and tacked by welding.

- Vertical elements are placed at the calculated distance; their perpendicularity to the frame frame is checked.

- The rods are once again verified for adequacy of the entire reinforcement structure.

Welded reinforcement

At the last stage, final welding work is carried out to finally connect the elements into the frame planned by the project.

Welding process

Types of fittings welding according to GOST

According to the GOST 14098-91 standard, joining of reinforcement can be:

- electroslag semi-automatic;

- bath-suture;

- electric arc manual;

- contact;

- bathroom.

In this case, the welded joint itself can be:

- lap (for electric arc manual welding);

- butt;

- tee (resistance spot welding, which uses one electrode in the bath).

Let's take a closer look at the most common methods of welding reinforcement.

Connecting reinforcement elements

This process can be carried out in several ways:

- end-to-end;

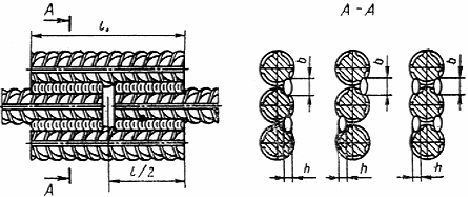

- overlap;

- crosswise;

- in a T-shaped manner.

Taurus and end-to-end are considered not very desirable. In both cases, the elements are connected at right angles, which means that the final product will show insufficient bending strength. However, such connections are still sometimes used if it is not possible to avoid such a connection for some objective reason. Usually, the length of the reinforcement is welded with an overlap, and the crossbars are fixed with a cross. Although, we note that, for example, American standards do not recognize cross intersections in the construction of foundations.

Before carrying out work on the frame, test welding must be carried out. Two small rods are taken for it; the elements are connected, and after cooling the seam is examined for quality. The appearance of cracks, the state of the resulting slag, and the depth of penetration of the reinforcement body are monitored. If at least one of the parameters does not seem to meet the standards and conditions, the current strength in the welding machine is adjusted or the electrodes are changed.

How to weld reinforcement

Security measures

Welding reinforcement, like other products and structures, requires compliance with safety rules. This is a guarantee of high-quality work and ensures the desired result. The preparation stage includes fitting, cleaning and turning the ends of metal products.

The performer must use protective equipment: mask, overalls and leggings.

The equipment must be in good working order and grounded. It is unacceptable to carry out welding in conditions of high relative humidity.

Special mention must be made of safety measures when carrying out welding work at height.

How to exercise at altitude

Welding work at height should be carried out in accordance with safety regulations. Several important points should be emphasized:

- welding of reinforcement at height must be carried out from scaffolding, scaffolding, hanging cradles or ladders that have platforms with fences and flooring made of fireproof materials;

- if it is impossible to install the above means, work can be carried out from previously installed structures with fences to which safety belts can be attached (they are used when working at a height of over 1.5 meters);

- When performing work in several tiers, the presence of fencing devices is necessary. Shields and flooring prevent metal splashes and sparks from reaching those working at lower levels;

- the welder must use special devices for carrying tools and electrodes, as well as for collecting cinders;

- welding equipment must be splash-, dust- and precipitation-proof; if it is not there, you should build a canopy from fireproof materials;

- if there is no protection, then welding work is not carried out during rain and snow;

Possible welding problems

These types of problems occur most often.

- Electrode sticking. The current is insufficient, it should be increased.

- Burning a surface without sticking to it. The current is too high and needs to be reduced.

- Difficulties with “catching” the arc, the rod is burned through. An electrode with a smaller cross-section is required.

- Foaming of slag, burning of the electrode with a “visor”. The electrode is defective or on the verge of wear. To be replaced.

The welding technology itself is not too complicated; if necessary, work on constructing a frame for the supporting structure can be carried out directly on the construction site. If the construction volumes are small, often the workers constructing the foundation do just that.

Welding for stable soils

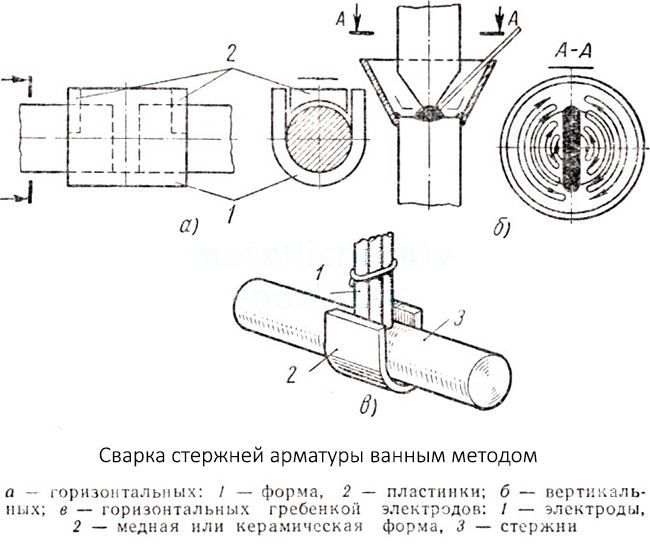

Features of bath welding

The essence of this technology is the melting of steel rods, which are immersed in a special form made of low-carbon steel material - a bath (you can make it yourself or buy a ready-made matrix). After this, the ends of the reinforcement bars are melted with electrodes (with a cross-section of 5-6 mm) at a fairly strong current of the order of 450-550 A. When the melted liquid metal fills the bath, the reinforcing bars are connected, which turn into a single rod, the cross-section of which will depend on the dimensions of the mold .

Healthy! If welding of reinforcement using the hot tub method is performed at low temperatures, then the current power must be increased by 15%.

This type of welding is suitable for columns, foundations and other structures that will bear heavy loads. In addition, this method is used for:

- large reinforcement products (bar diameter 2-10 cm);

- reinforcement in the form of a lattice (when the frame is laid in several rows);

- joining flanges made of steel strips of the largest cross-section;

- connections of complex frames.

Using a bath for welding reinforcement allows you to join rods both horizontally and vertically. Thanks to this, the procedure for creating seams is greatly simplified; edging of the structure is not required.

What this type of welding process looks like is clearly shown in the video:

Let us consider in more detail this method of connecting reinforcing elements.

Minimizing negative impacts

It is clear that natural factors cannot be overcome (at least in most cases). However, it is considered quite possible to reduce the negative impact of welding on metal in construction work. Experts have developed a whole range of measures aimed at minimizing losses during welding operations.

- Selection of reinforcement for the frame. It is strongly recommended to use rods classified as A400C or A500C. Their diameter and carbon content in the metal are optimal for equipping the supporting structure by welding.

- Selection of electrodes. They must correspond to the diameter of the elements assembled into the frame. If relatively thin rods are to be used, most commercially available electrodes will suffice. If the reinforcement frame is constructed from elements with a diameter greater than 14 mm, you will have to stock up on specialized electrodes for these cases. Moreover, it is advisable to purchase those that are designed to work with low-carbon steel. Such electrodes have a less intense impact on the metal during welding and will provide a structure with greater strength.

- Welding machine. For welding reinforcement for the foundation, when connecting reinforcing elements, it is recommended to use equipment with continuously variable control of the supplied current. Insufficient current will not make it possible to achieve a reliable, durable and high-quality seam, which can subsequently lead to subsidence of the foundation, or even to the destruction of the building as a whole. An excessively intense current will overheat the metal, and the reinforcing element will become brittle after cooling.

Need a welding machine

- In order for the welded joint to be as strong as possible, it is necessary to press the welded elements together as tightly as possible. However, this is quite difficult to do. Some craftsmen advise using a grinding tool. The rods are cleaned to relative smoothness, and the connection area of the reinforcement increases.

And finally, there are recommendations in construction work for treating seams with anti-corrosion compounds. At the point of welding, the metal becomes more vulnerable to moisture, and the solution from which the foundation is poured contains plenty of it and takes a long time to dry.

Subtleties of welding work

To completely dispel the myth of why you can’t weld reinforcement in the foundation, you need to know the specifics of performing all the actions.

Initially, reinforcement of the required diameter and length is prepared, corresponding to the design specifications for the arrangement of the foundation frame. After this, the following algorithm of actions follows:

- purchased material is checked for quality;

- Rejection is carried out, during which metal blanks are identified whose characteristics do not meet the requirements of regulatory documents;

- steel rods are cleaned of corrosion, straightened, coated with an abrasive compound, and cut into blanks of the required sizes;

- all elements of the future frame structure are connected in a common plane using light tack welding units, final fixation is carried out later;

- blanks for the future frame part are fixed with special jigs at distances determined by the design drawings;

- the structures are tacked by welding, the compliance of the frame parameters with the data in the design documentation is specified;

- The final working stage is the final welding of the frame.

When following the technological stages of welding reinforcing bars at a construction site, remember that it is better to use a special unit for inverter welding.

The main indicators of the modes during operation of the welding machine are:

- electrode cross section;

- the magnitude of the type and polarity of the electric current;

- electric arc voltage indicator;

- speed of welding work;

- number of approaches.

When using the contact welding method and determining its operating parameter, the main indicator is the strength of the current used, on which the quality characteristics of the resulting weld and the work productivity indicator completely depend.

The choice of electrode diameter is made taking into account the thickness of the metal being connected. It must be remembered that the operating mode is based on the level of electrical current. When the electrode used is thicker than four millimeters, it is recommended to reduce the standard current by ten to fifteen percent. When deciding on the polarity mode, give preference to reverse. Due to the fact that when working on a constant electric current, thermal energy is actively generated, the likelihood that burns will appear in the metal material increases.

The latest welding units can convert alternating electric current, and after switching on the appropriate mode, the electric current supplied to the electrode rod turns into direct current.

When choosing a speed mode, make sure that the bath filled with hot steel is located above the surface of the edges. It is best to select a mode in which the width of the welding seam is one and a half to two times the diameter of the electrode rod.

Having assembled the reinforcement structure intended for the foundation, it is necessary to carry out a simple test. A board is laid on the surface of the frame, on which a person begins to walk. If the frame system is assembled according to the design drawings, it will not bend due to weight.

Before starting to supply the concrete mixture, the reinforcement system is further strengthened in order to be securely fixed in the foundation body.

Knitting method

Knitting is carried out using a specialized wire that connects the reinforcement bars to each other in the corners of the foundation structures. Knitting is quite easy to do if you know the basic principles of the work.

Knitting method

When the foundation has already been built, it may still sag in the ground for some time. This is due to the large mass of the entire structure. In this case, the knitting will give the foundation reinforcement being connected some freedom, the connections will remain in their proper places (they will not break, as is the case with welding, if the level of soil subsidence in the place chosen for construction is high enough). We can safely talk about using this method of knitting reinforcement even on the most difficult soils. The welding will not withstand the loads and will crack. This will not happen during mating. All connections in the foundation remain more or less movable. And this nuance does not entail the appearance of additional stress in the foundation structure.

Knitting is used on difficult ground

The simplicity and convenience of the knitting process is that everything is done directly on site (for large structures, sometimes in a workshop). Simple tools are used, which (unlike welding) can be handled even by a less experienced builder. Most often, this is a special kind of hook; it allows you to connect several parts of the reinforcement to each other. The operation of the connection will require minimal costs - the effort of one worker is enough. When using this method, the strength of the entire structure will not decrease, and the structure of the metal will be preserved. Rigidity with reinforcement strength is at the proper level.

By the way, you can also acquire special tools for the job. Today, tying guns are widely available. The design is quite simple, and the cost is not too high, so you can afford it. In addition, the cost of work is reduced as a result. But you can also use an ordinary crochet hook.

Knitting technologies

Technology of joining and joining by manual arc welding

When welding reinforcing bars, it is important to choose the right equipment and consumables, carefully check and control their quality.

The features of the work listed earlier should be taken into account. When increased demands are placed on the finished product, each welded connection must be performed with high quality. Because even one unreliable seam can lead to uneven load distribution and damage to the entire metal structure.

In some cases, to increase the rigidity of the structure, it is necessary to weld additional ribs. They will affect the strength for the better.

Useful video

We invite you to watch the video, but we definitely ask you to take into account what was said above about welding critical structures and design documentation.

Mechanical method of connecting reinforcement

Compared to other technologies, mechanical joining has a number of advantages.

- No overlap is required, which saves metal. The overlap increases the consumption of reinforcement by a quarter.

- Compared to welding, firstly, it is a more productive process, and secondly, it does not require highly qualified workers.

Additional advantages of mechanical butt joints are the strength of the resulting structure and the ability to implement this technology in all weather conditions.

To carry out mechanical joining, a hydraulic press is used as equipment, and steel couplings are used as consumables. You can speed up the mechanical connection of reinforcement bars using couplings with a central partition. The rods are inserted into the coupling, which is compressed using a press. The presence of replaceable dies in the press makes it possible to work with reinforcement of different diameters. The process is carried out by two people.

Basic techniques for tying reinforcement

You can knit reinforcing bars in different ways. But basically the reinforcement is knitted in accordance with the following principles:

- To perform the work, wire cutters must have blunt ends (so that the wire does not break during the bending process);

- You can connect the rods by pulling them one to the other;

- The easiest way to connect reinforcement cages is with the help of special racks;

- if a special hook is used to knit rods, the number of turns must be at least three;

- if it is inconvenient to knit the reinforcement, use a sectional connection.

Experienced specialists prefer to knit rather than weld foundation reinforcement for the following reasons:

- the strength of the reinforcement is maintained at the original level;

- the structure of the metal is preserved;

- the strength properties of metals are preserved;

- The stiffness parameters of the material are saved.

Today, in the relevant sector of the market, you can purchase special guns that are used to knit reinforcing bars.

In some cases, reinforcement bars are knitted using reinforcing couplings. But in the modern domestic market it is not used very often, although foreign builders use couplings quite actively.

Knots and materials used for tying reinforcement

The rods can be connected in various ways. Most often, when performing this type of work, the following types of ligaments are used:

- dead;

- double row;

- corner;

- cross;

- double;

- simple.

It is recommended to use annealed wire with a diameter of 0.8 to 4 mm. The specific choice of section should be made taking into account the characteristics of the structure being built. As for the frequency of fastening and the pitch of laying reinforcing bars, these indicators are calculated in advance at the stage of creating the project and must be indicated in the working documentation.

You can knit reinforcement for the foundation directly at the construction site or in a specially equipped workshop. You can use the simplest tool for the job. Most often we are talking about a hook made of a special wire, which allows you to reliably connect several reinforcement rods together. You can also use reinforcement cutters.

If you plan to do a large amount of work, you can purchase a rebar gun, which is quite simple in Japan. In addition, its use allows you to significantly increase the knitting speed.

A pistol is a professional tool, the cost of which is quite high. Therefore, if we are talking about a single case of connecting a reinforcement frame, it will be unprofitable to buy it.

To make the work easier, the wire with which specialists will knit the frame must be cut into separate pieces before work, the length of which can vary from 80 to 100 mm and tied into bundles. It will not be superfluous to mark the prepared wire by length and diameter. The easiest way to mark is by dipping the ends of the rods into a container of appropriate oil paint.