A large number of people who want to build a private house with their own hands are complicated by the choice of material for constructing the foundation for a residential building.

Nowadays, there are many options for raw materials, the use of each of which is relevant in one case or another and is therefore suitable depending on the specific situation, the amount of money allocated for the purchase, and individual characteristics. One of these exceptions is foundation brick, since it has a large number of advantages, and its price is not too high. It is important to make the right choice at the time of purchase. So which brick is better for the foundation? Experts believe that the only correct option is a red burnt block.

Factors affecting a brick foundation

A brick foundation is being erected on an area where there is no groundwater

The choice and operation of a brick foundation is influenced by soil resistance and the degree of pressure of the building on it. In addition, soil swelling forces are of great importance.

Additional factors:

- Groundwater level. It can be determined by drilling wells at different points on the site. Depending on what material the house will be built from, their depth ranges from 5-10 m.

- Soil freezing level.

- The purpose of the structure, its design features. This takes into account the thickness of the walls, the presence of a basement, garage, and outbuildings.

Don’t forget about the characteristics of the material chosen for the foundation.

Is it possible to use brick for the base of the structure?

A brick foundation has certain limitations:

- The maximum load level on a brick foundation with a width of 30 cm should be no more than 14 tons per square meter.

- Bricks are porous and absorb liquid well. As snow and ice melt, water will destroy the material. Therefore, it is important to consider the pumping system and waterproofing layer.

- If your site is located on marshy soils that are regularly subject to flooding, and there are also sources of groundwater nearby, using such a foundation is prohibited.

- The structure can be damaged by tree roots. Therefore, uprooting may be necessary.

- This kind of installation takes a lot of time. Laying will require much more time than pouring or installing piles.

The advantages include:

- Fast shrinkage compared to other foundation options.

- If you comply with all the requirements during the installation process, the service life of such a foundation will pleasantly surprise you.

- Brick is capable of allowing air to pass through.

- To install such a foundation, you do not need to use special equipment, such as for concrete, and qualifications are not so important.

- Relatively small mass.

- The material is completely natural.

- Does not contain substances that could become a substrate for mold and mildew.

- If there is no surface water, installing such a foundation will not be an obstacle to building a basement.

- Easy to restore. Repairs can be carried out piecemeal, without the need to renew the masonry and the risk of collapse.

Existing design bases

The foundation for a brick house comes in different types. The choice of a specific base depends on the type of construction and soil characteristics.

Columnar

Columnar brick foundation supports small buildings

The columnar base is suitable for structures with a small mass: summer houses, bathhouses, open verandas and terraces. Install supports in the corners of the structure, as well as at the intersections of walls. Additional posts are installed around the entire perimeter of the building. The step between them is 2 m.

This type of foundation is laid in square pits, the size of which is 1x1 m. Before installing the brick, a sand cushion is laid at the bottom, which is compacted.

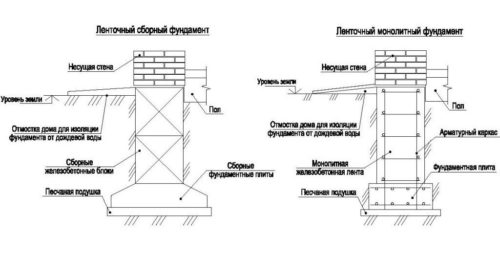

Tape

If the structure will have a lot of weight, it is better to use a strip version of the brick base. It is suitable for covered terraces, houses with extensions. To install a brick strip foundation, prepare a trench whose width is 1 m.

To make the base strong and geometrically correct, the construction of formwork is required. The work uses not only bricks, but also concrete mortar. Your mortar must be uniform along the entire length of the foundation. Bricks must be laid with bandaged seams. Reinforcement is laid between every two rows of material. Steel rods or mesh are used. These elements will make the foundation more durable and resistant to external negative influences.

A slab foundation involves the use of a monolithic element under the entire building. In this case, the base base is made of brick. The concrete slab can be buried in the ground or lie on its surface.

Which brick is better to choose

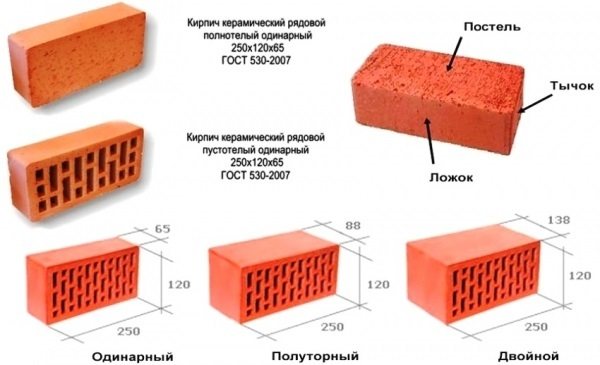

Which brick to choose from this variety? First of all, you need to proceed from the area of application: the products are construction and cladding. The first option is chosen for arranging foundations, walls, and partitions. Such materials are silicate and ceramic. Facing brick blocks have a more precise geometry and aesthetic appearance. As the name implies, the materials are intended for cladding facades and plinths, and are often used for interior decoration. Almost all of the listed types of materials can be used for cladding, so you should purchase those that best meet the requirements of the future project and personal tastes.

Bricks for cladding can be textured and shaped. The textured look of the product is distinguished by its decorative surface and standard shape, while the shaped (also called figured) has a non-standard configuration and allows you to implement any exterior element with a different design. Its use requires the highest qualifications from masons. After determining the type of material, you may wonder what size is needed. The most versatile is considered to be a single brick, which is suitable not only for masonry, but also for cladding. When constructing massive structures, a one-and-a-half block is often used; its use saves time.

| Product type | Type designation | Nominal sizes | Size designation | ||

| Length | Width | Thickness | |||

| Normal format brick (single) | KO | 250 | 120 | 65 | 1 SF |

| Euro Brick | KE | 250 | 85 | 65 | 0.7 NF |

| Thickened brick | KU | 250 | 120 | 88 | 1.4 NF |

| Single modular brick | KM | 280 | 138 | 65 | 1.3 NF |

| Thickened brick with horizontal voids | KUG | 250 | 120 | 88 | 1.4 NF |

When choosing a brick, the fullness of the material matters. Solid blocks do not have any chambers or holes and are mainly used for laying walls, foundations and other serious structures. A hollow block, on the contrary, has chambers or holes of different shapes, thanks to which significant savings in raw materials are achieved. This type of building material weighs less and, accordingly, is cheaper. And due to the presence of air in the voids, the products have thermal insulation properties. Typically, facades are finished with a hollow block and used for the construction of interior partitions. To work with it, you need a fairly thick solution that will not flow into the voids.

| Name | Brand | Compressive strength | Manufacturing strength |

| Solid brick | M100 | 100 kg/cm3 | 22 kg/cm3 |

| Solid brick | M125 | 125 kg/cm3 | 25 kg/cm3 |

| Solid brick | M150 | 150 kg/cm3 | 28 kg/cm3 |

| Solid brick | M200 | 200 kg/cm3 | 34 kg/cm3 |

| Solid brick | M250 | 250 kg/cm3 | 39 kg/cm3 |

| Solid brick | M300 | 300 kg/cm3 | 44 kg/cm3 |

Choosing a brick for the foundation

Red solid brick is the strongest, so you can make a foundation from it

The strength of the base depends on the quality of the material. There are these types of products:

- Silicate (white). Such a brick is acceptable for the construction of the above-ground part - the base. The limitation for use is the shallow depth of groundwater.

- Made of clay (red). The material has high strength. You can choose to construct the underground part of the structure. This is dictated by good resistance to the influence of soil moisture and compression.

The choice of product is influenced by the possible load per 1 cm² of area. Material grade 150 and higher has good properties. You also need to take into account the frost resistance level of the brick. This figure should not be less than F-35. The moisture absorption coefficient is important. The optimal level is from 6 to 16%. The size of the elements can be standard, modular or thickened.

When choosing a foundation brick, you need to pay attention to its quality, which is determined by visual inspection of each product:

- uneven coloring indicates a violation of the material production technology;

- if the edges are uneven and the element itself crumbles easily, it has already been used;

- bricks should not quickly absorb moisture, as this will destroy them faster.

A more durable structure can be obtained from products with grooved sides. They have better adhesion to concrete mortar.

Selection of base material

The foundation is considered the most important element of a residential building. For this reason, the base must have a reliable and durable structure.

A structure that uses brick as a base, according to experts, is considered reliable and durable. Before installing the base, you should select the block very carefully:

- The main part of the foundation of the building is considered to be foundation bricks, which in turn must be of high quality. It should be remembered that only ceramic bricks can be used to construct such a structure. The silicate white type of material cannot be used, since it has no protection from moisture, and under prolonged exposure it is destroyed. The required volume of foundation bricks will directly depend on the size of the structure, as well as its depth level. This level often develops differently in each region. In order to determine the required amount of immersion of the foundation brick into the soil structure, you can use a special table in which all the data is clearly described.

Multiply the size of the base by the number of elements in 1 m3 - this will be the number of bricks per foundation - In order to simplify the calculations of the number of foundation bricks, it is necessary to multiply the total volume of the base by the number of elements in one cubic meter. As a result, taking into account the size of each joint, approximately 400 blocks are obtained. It is important to use solid brick, because it is considered more reliable in long-term use. Hollow red brick has increased moisture resistance, but can withstand light loads compared to solid ceramic bricks. This material is best used for the construction of walls of a residential building.

- The standard dimensions for red brick foundations are 250-125-88 mm. Most often during construction work we use cement grades M250, 300, 200. When purchasing the material, you must remember that only 360 pieces can be placed on one pallet.

It is important to remember at the moment when a brick foundation is being made that the resistance to frost on the base should not exceed 45 cycles. For this reason, it is prohibited to use materials with inappropriate frost resistance for the foundation.

Necessary tools for work

To strengthen the structure you will need reinforcing mesh

To make a red brick foundation, in addition to the base material, you need concrete mortar and reinforcing mesh to strengthen the structure. Separately, you need sand and crushed stone to install the cushion at the bottom of the trench. Masonry tools you will need:

- Master OK;

- cord, jointing;

- hammer-pick;

- shovel;

- construction and hydraulic level, plumb line;

- pegs for marking the territory;

- steel reinforcement.

You can prepare the cement mortar manually, but it is better to use a concrete mixer.

Main varieties

Each type of brick is created to carry out certain construction activities.

- Red brick of ordinary type is classified into hollow and solid varieties. If you are laying out a brick foundation, it is better to use a solid version. As for hollow bricks, they have found their application in the construction of partitions and walls.

- As for the facing red brick, it can also serve as a decorative material. It is characterized by its lightness, as well as its ability to retain heat. This product is used primarily during facing work.

- For a variety of special bricks, we provide for the addition of fireclay during the production process. Its purpose is to install fireplaces, stoves and other similar structures. This also includes chimneys.

Stages of building a brick foundation

A sand cushion is poured under the base of the brick pillar

To build a brick foundation with your own hands, no special knowledge is required. It is necessary to follow the technology of work and correctly calculate the amount of building material.

Sequencing:

- Site marking. It is carried out according to plan. Pegs and cord are used.

- Preparing the trench. If the foundation is strip, the pit should be slightly wider than the expected thickness of the structure for ease of work and waterproofing.

- Making a sand cushion. After excavating the earth, sand is poured into the bottom of the trench, which is moistened and compacted. The pillow layer is 15 cm. It must be even, which is checked using a building level.

- Installation of waterproofing. It is better to use several layers of roofing felt. It is laid on the bottom and walls of the trench.

- Installation of formwork. After installation, a cushion is made from concrete mortar, the height of which is 10 cm. It will improve the load-bearing capacity of the base.

- Bricklaying. First, the corners are mounted, and then the rows with the seams bandaged. After which they take a break for 2-3 weeks. This is necessary for the solution to gain strength.

- Backfill. After the concrete has hardened, the formwork is removed, the remaining cavities are filled with construction waste, crushed stone, gravel or broken bricks.

To prevent precipitation from harming the foundation, beating is required along the entire perimeter of the structure. Before erecting the frame of the house, a layer of waterproofing is laid on the upper part of the plinth.

Brick is suitable for the construction of structures of small number of floors and mass: garages, outbuildings, baths. It should be taken into account that the pressure of the box on the ground should be minimal. The design is used on stable, dry soils.

Masonry technology

To create the foundation you will need the following materials:

- Estimated quantity of bricks.

- Material for waterproofing.

- Mortar parts (sand and cement).

- Crushed stone for forming a pillow.

The following tools may be required:

- Shovel.

- Container for solution.

- Drill for mixing.

- Level and roulette.

- Master OK.

Strip foundation

- Dig a ditch around the perimeter.

- Place a cushion of gravel and sand up to 10cm deep on the bottom.

- Lay a waterproofing layer.

- Fill the bottom with concrete and wait until it hardens completely.

- Lay the brick with joints spaced apart/

- Strengthen the masonry with a special mesh.

- After the cement has hardened, it is important to lay waterproofing material.

- Fill the ditch around the walls with soil.

Columnar foundation

Such a design requires accurate calculation of the load. Such a base is suitable only for light structures: gazebos, bathhouses and summer kitchens. During the calculation process, it is important to select the load-bearing capacity and dimensions of the future masonry.

For installation, a brick with a strength of at least M150 is used. In this case, the foundation can be with a recess from 0.7 to 2 m. The distance between pillars is up to 2 meters. The installation method is similar to the standard tape one. However, there are a number of characteristic differences. It is important to choose the right waterproofing.

Features of base protection

It is necessary to perform certain work that will significantly extend the life of your building.

An example of arranging the foundation of a small house

We do waterproofing

The best option is to use traditional roofing felt. To improve its properties, the material can be folded in half. This is necessary in order to protect this part of the building from the negative effects of moisture and prevent its further spread to the walls of the house.

Advice. The waterproofing layer should be below the future floor. Take this into account. This way, you will further prevent moisture from spreading and entering your home.

In general, at the moment on the building materials market you can find various means by which it is easy to waterproof the foundation plinth. Among them, roofing felt is the most optimal in terms of price-quality ratio, but if your budget allows, you can use more expensive products.

Protection of the base when construction stops

Unfortunately, it is not always possible to complete construction in one warm season and it is quite likely that the construction site will have to be mothballed. In such a situation, it is also important to take care of the safety of the base.

Laying a brick plinth

You can prevent the negative destructive effects of adverse weather conditions by doing the following:

- cover the entire surface with thick film;

- press it down with heavy objects along the entire perimeter so that moisture and snow do not get under it.