10/31/2018 Category: Foundation

Underground structures of buildings and structures are divided into groups according to different criteria. They can be strip and columnar, slab and pile, monolithic and prefabricated, concrete, wood, stone and metal. But in construction practice, a combined foundation is often used as the foundation of a house, which is a combination of different types of structures, materials and shapes. Such schemes are used in various situations, for example, for the purpose of economy or due to strengthening the bearing capacity of the foundation.

What kind of foundation should I make for the extension?

Part of the Lesser Poland Voivodeship, on the border of Beskid Makowski and Pogórze Wieliczka, among sparsely scattered houses and chessboards, surrounded by centuries-old trees and bushes. Add to this the roaming deer and it's busy. They resigned when it became clear that the cost of adapting the building to modern requirements would be comparable to the money that would have to be spent on building a new house. Moreover, restructuring does not guarantee that they will be able to achieve the standard they dreamed of. Decorative walls.

Features of connecting foundations

The most important thing that is important for the homeowner to take into account is that the foundation of the attached structure must correspond to the foundation of the main building. Savings are not appropriate here. It is not recommended to place an extension on poles if the house itself is on a reinforced concrete strip. In addition, when designing a new foundation, it is important to respect the width of the strip base or the dimensions and depth of the pillars in the ranges of the previously built house.

The reason that the foundations of buildings should be the same is their different interaction with soils and, accordingly, differences in shrinkage. To avoid the occurrence of cracks and other violations of the integrity of the structure, do not neglect this rule. Maintaining identical foundation depths will help avoid distortions of buildings.

Methods and steps for connecting bases

There are various ways to connect the old and new foundations of a house. First, you need to decide whether the extension will have an autonomous base or whether the buildings will be connected by a single base.

The following methods of connecting foundations exist:

Rigid base connection

One of the most reliable. The most commonly chosen method by homeowners. And, although it is quite difficult to make such a connection, the resulting result will justify the invested effort and finances. The method is especially suitable for tying to the foundation of a house located on difficult soil, as well as for high-rise buildings. Knowing the technology and the order of the stages of work, using high-quality materials, the homeowner can carry out a rigid connection independently. At the same time, the connection of strip bases and slab bases has differences.

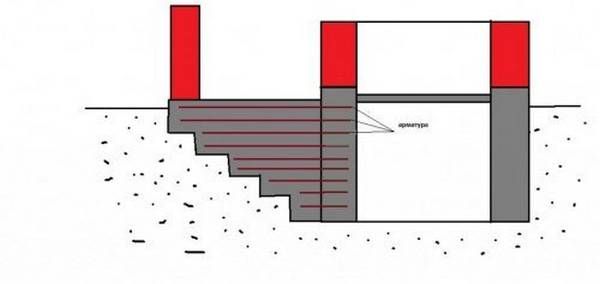

The connection of strip foundations is carried out in a number of the following stages:

- First, it is necessary to dig out the foundation of the constructed object along the side on which it is planned to make the connection. It is necessary to dig to the very beginning to a depth of 2 meters until a trench is formed. Next, at the very bottom, a sand cushion is formed, which is compacted and watered.

- The next stage involves creating holes in the standing base for reinforcement, for which appropriate ranges of diameter and depth are provided. For the middle of the strip base, holes are drilled to a depth of ¾ of its width, for the base in the corners - to half a meter. A staggered pattern of holes is recommended.

- Next, reinforcement is driven into the holes, which are drilled 3/4 deep from the width of the strip foundation, having a slot into which a propping wood element is inserted. 14mm reinforcement with a periodic profile is driven into other holes.

- The last stage involves the manufacture of a frame structure for the future foundation. For this purpose, reinforcement parts driven into the foundation of the built house are used. To connect different parts of the bases, it is necessary to provide special outlets, which are subsequently welded together.

Slab foundations can be rigidly tied only if they are thick enough - 40 cm or more, or if they have slab protrusions from the base part.

As a rule, they are left in cases of planning the construction of aerated concrete buildings. The size of the protrusion must be at least 30 cm so that it is possible to expose the reinforcement in order to weld a new base in the future.

As a result of the rigid bonding method, foundations are securely fastened together, forming an integral structure. However, it is necessary to take into account that this connection method is only suitable for those buildings that are approximately equal in weight to each other. In the case of an extension of a lighter structure, for example, a wooden veranda, the connection of the foundation to the existing foundation will be different.

Creating an expansion joint

Another way to connect the old and new foundations of a house is the expansion joint method. In this case, two bases are created separately from one another, without forming an integral structural structure. This method involves erecting a reinforced concrete grillage near the wall to which the extension is planned, and laying waterproofing or thermal insulation materials between the two bases. The main point is to create a layer of deformation between the buildings, minimizing the possibility of destruction during the period of natural shrinkage.

When planning to make a connection by creating a deformation seam, it is necessary to focus on the main soil indicators, as well as on the possible loads of the object being attached to the site. When designing the foundation, it is necessary to take into account an allowance for potential shrinkage. Therefore, the future foundation should be laid at a slightly higher height than the old one, since the constructed structure, after a certain period of time, will shrink to the depth of the foundation of a residential building. As a rule, due to the light weight of the extension, using this type of connection, a foundation is created from pillars.

Also, as an option, the extension can be placed on a pad made of concrete. It is cast right on the job site. To do this, the finished piles must be pre-impregnated. Mastic, waterproofing materials or other protective impregnations can be used as impregnation. Next, the piles are installed directly into the mold and concreted.

The distance from one pillar to another varies from 1 to 1.5 meters and depends on the dimensions and weight of the future structure, and their height depends on the level at which the extension floor is intended to be located.

The pillars are cut to this level. Then the structure's frame is attached to them. After about two to three days, you can begin the construction itself, which significantly reduces the work time.

Introduction

Connection device:

In order to ensure spatial rigidity and stability of the building, a system of connections is provided between the main load-bearing structures of the covering and along the columns.

Seam arrangement:

Temperature seam

SNiP “Steel Structures” provides for a temperature block length of 160 m for heated buildings with a metal frame. This building, 180 m long, requires an expansion joint that divides the building into 2 compartments of 90 m each.

Anti-seismic seam

From the manual for SNiP II-7-81 on the design of frame industrial buildings for construction in seismic areas, the installation of an anti-seismic seam is necessary, because the length of the building in the longitudinal direction is more than 150 m. The anti-seismic joint coincides with the temperature one.

Expansion joint

The building has no height differences and is rectangular in plan, so an expansion joint is not necessary.

Foundation materials

Having understood the features, as well as methods of how to attach to the old foundation, it is necessary to study the question of what materials will be needed for its manufacture.

- Cement. Concrete is one of the strongest materials used for building foundations. It contains cement and various fillers. The quality of the latter determines the properties of concrete that it may possess. Any cement on the market is marked in a special way. Strength is indicated by the letter “M” and a three-digit code, reflecting the maximum weight that can withstand 1 cm3 of material mixed with sand and hardened. The presence of additives is indicated by the letter “D”. Most often, cement marked M400-D20 is used for the construction of residential buildings, the additives of which make it possible to create foundations that are most resistant to groundwater and weather changes

- Sand. This material is also included in the concrete mixture. Among other things, sand pillows are made from it. For mixtures, quartz fine sand is used. To have an idea of how much sand is required for concrete, you need to make the following calculations - multiply the amount of cement by 3, and the resulting number by 1.2 to create a reserve.

- Crushed stone. It is used during the construction of a building on wet soils, when there is a need for additional separation of the base from the soil. A crushed stone cushion protects the foundation from the effects of low temperatures and moisture. In some cases, a concrete base is made from crushed stone. When mixed with M100-150 cement, a light, quickly hardening concrete is obtained,

- Fittings. Although concrete can withstand high pressure, it is weak in bending, which leads to a violation of its integrity under external influences. To prevent this from happening, steel reinforcement is installed in the foundation, which holds the structure in one position, preventing subsidence, stretching or cracks. Reinforced concrete is stronger than concrete, which is why it is popular for use in the construction industry. To avoid corrosion, the reinforcement must be covered with at least a 6cm layer of concrete. The reinforcement bars are connected with wire into a mesh or by welding into a monolith. More often than others, rods with a diameter of 10 mm are used, as well as notches that increase adhesion to cement. The diameter of the rods used for reinforcement depends entirely on the weight of the building: the heavier it is, the larger the diameter. For large buildings, 16 mm rods are suitable.

- Insulating materials. Insulation from external influences is required for all types of foundations. The strength, durability and need for foundation repair work directly depend on this. To know how to create thermal insulation, you need to have an idea of the requirements for it. The main characteristics of thermal insulation include: resistance to humidity, the ability to withstand high pressure, low heat transfer, the ability to install it yourself, protection for waterproofing, and an affordable price. Despite the wide range of thermal insulation materials, only two of them meet all requirements: extruded polystyrene foam (EPS) and expanded clay gravel. EPS is made from the same mass as polystyrene foam. Thanks to a different processing method, the resulting material is homogeneous in structure, which does not crumble or be compressed. Gravel is made from baked clay, has an oval shape, and does not damage waterproofing.

1.2.2. Snow load

The full standard value of the snow load on the horizontal projection of the coating qсн. should be determined by the formula:

Concentrated load on the truss nodes: = 3.54 t where S0 is the standard value of the weight of snow cover per 1 m2 of horizontal surface of the earth, accepted in accordance with SNiP 2.01.07 - 85 for a given snow area S0 = 0.07;

B – frame pitch, m;

gf – load reliability factor.

m=1 – coefficient of transition from the weight of the snow cover of the ground to the snow load on the cover, adopted in accordance with SNiP 2.01.07 – 85.

How to connect two foundations with your own hands?

What is important to know?

Owners of country houses are often faced with the issue of expanding their living space. If the initial budget did not allow for the construction of a large house with sufficient space, then it is possible to build an extension to the house.

Scheme of the foundation for the extension.

At the very beginning of construction work, the new foundation of the extension should be connected to the old one.

Before connecting two foundations with your own hands, you must keep in mind that a new foundation, even one made identical to the old one, will give rise to sediment. To prevent the formation of cracks on the walls, a sedimentary joint should be left between the walls. Attaching a new foundation to a house is possible in the shape of the letter P. If you drive piles into the old foundation to connect it to the new one, the latter will still be subject to settlement. If the procedure is carried out incorrectly, the facade will be torn. In this case, the assistance of a designer who can cope with this task professionally plays a special role.

Construction of a foundation for an extension to a house (scheme of connecting two foundations).

To properly build a foundation with your own hands, you should know the type and method of constructing it under the house. With the tape type, you need to know the size of the width of the base. If the old foundation is columnar, then construction is based on knowledge of the overall dimensions of the pillars and the depth of the foundation. According to experts, you should not combine the old with another type of new foundation of the house; they should be the same. You should not save on construction by choosing a cheaper type than the old one, since the shrinkage of different foundations is different. To measure the width, take a metal rod and bend it at a right angle; measuring the depth is easy.

In the process of connecting the foundations of buildings, it is important to take into account that in spring there is a process of decreasing the bearing capacity of the soil, which entails an increase in its humidity and additional shrinkage. The weight of the old and new buildings is different, so a technological gap is provided between them to connect the foundations. It is a gap ranging in size from 20 to 40 cm. Sections of protruding reinforcing bars are placed in it.

It is necessary to understand what type of foundation is best to pour in order to build an extension module to the house. During the connection process, the following tools and materials may be needed:

What methods of connecting foundations are best to use?

Tape-to-tape connection

To connect strip foundations with each other with your own hands, use the “tape-tape” method. The connection is made in the following order:

Scheme of connecting foundations using the “tape-tape” method.

Connection using the slab-to-slab method

If there is a large thickness (more than 400 mm) of the slab foundation of a residential building and the new foundation, you can use their connection using the “slab-to-slab” method. This method is used when there is a basement at the base of the building. In the process of using this method, the foundation is built up, leaving protrusions equal to about 30 cm, allowing the slab reinforcement to be exposed and welded to the frame of the new slab foundation.

Large differences in the weight of the old and new structures suggest building up the foundations not by rigid tying, but by constructing a separate one. For example, in the case of constructing a light gazebo or veranda as an extension. Here you need a separate foundation for the extension.

How to connect foundations by constructing a separate foundation using an expansion joint?

The simplest and most common option for constructing a foundation is the construction of a separate foundation placed directly near the base of the house. The method is associated with the construction of a full-fledged reinforced concrete grillage. Two foundations are laid using a layer of waterproofing using roofing material, special thermal insulation material or tow.

The essence of this method is to create a new foundation, the settlement of which will not damage the old foundation. The presence of an expansion joint is associated with a focus on soil quality indicators and the potential load on the extension site with the foundation.

Combination options

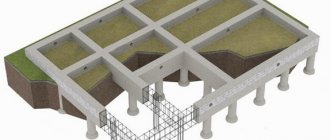

In the process of designing, constructing or operating a house, circumstances arise that require the installation of different types of foundations in one building. In this case, the combination is carried out according to one of the following schemes:

- the piles are tied not with a grillage, but with a high concrete strip;

- Brick or concrete blocks are laid between monolithic pillars;

- the slab is supported not on a sand cushion, but on piles;

- the house is built on a strip foundation, and the extension is built on brick pillars;

- Prefabricated blocks are installed on monolithic pillows.

There are quite a lot of options for combined foundations. One of the most common options is the installation of a monolithic reinforced concrete belt around the entire perimeter of foundation walls made of piece materials. This combination increases the reliability of the underground structure, providing the opportunity to combine different sections into a common system.

A brick wall is easiest in townhouses or lofts, where simply scraping the plaster wall is often sufficient. And while this original, covered surface patio has the most charm, a similar decoration can also be used in the interior of new construction.

There are two main pairing methods

This often happens with old rubber gaskets, which after a few years lose their elasticity, are often shredded, and sometimes become porous and hard. Use the worn gasket to simply replace it with a new one of the same cross-section.

In this case, the strapping is the same grillage, but with increased dimensions in height. On the other hand, recessed pillars for a strip foundation provide additional support if it is erected on a weak-bearing foundation or on heaving soils. Ribbon-column structures have a number of advantages, namely:

The appearance of the facade greatly influences the aesthetics of the entire house. When it is old it may be grey, the green one will be destroyed. But for the convenience of residents, more important than the appearance of the wall is information about whether it is exhausted. Walls in an old house without insulation. Thermal insulation.

Old house for renovation or demolition? The architect is Pave, Litvinovich, who, together with his wife Alexander, is also the author of the project for the building. Although his condition seemed very alarming at first glance, constructive analysis showed that the elements. Also prone to wrapping. By giving them a solid rope or stand, we will protect the old wall and give the plant a chance to climb onto the smooth wall. We get up as we go.

- the permissibility of erecting massive structures in difficult geological conditions, even on horizontally moving soils;

- the ability to increase the strength and stability of pillars;

- the likelihood of a more even distribution of loads;

- the feasibility of building houses on areas with difficult terrain, including on slopes.

It should be noted that the combined strip-column type foundation has the positive properties of both types of structures - strip and column. During its construction, the volume of excavation work and the consumption of materials are reduced, since pouring a concrete strip to a great depth is not required. But the combined version of the foundation causes problems with the construction of basements or ground floors.

New house in the style of an old mansion

Adapt to your family's needs. The development of the expansion project was entrusted to the architects Andrzej Marczak.

Interiors with sapphire walls

Production is past, but don't announce any surprises in the middle. The appearance looks pretty and standard - a well-groomed lawn and a fence in a box.

Vinegar - planting a homemade vineyard

Several weeks in containers, even when they have fruit. Many winegrowers grow new varieties in old meadows that have been exposed to frost, disease and pests for many years, and, as a result, are the best local varietal beds.

Reinforced concrete pillars are placed in the corners of the building, at the junction of load-bearing walls and evenly around the perimeter of the house. The reinforcement, placed in wells or pits, runs along the entire height of the tape and is connected to its frame. Thus, the foundation becomes a single structure.

House in the old chapel on the hill

Pomai is collapsing - the walls are covered with moss, there is hula in the hollow winds. The chapel would probably disappear from the surface if the destroying building was not of interest. Type of Plaster Once a protective barrier has been made on the wall, the associated plaster needs to be repaired. Traditional cement, lime, lime or gypsum plasters are not suitable for use on damp and salty walls. Although a preventive barrier was made.

What can you do in a brick garden?

The old brick wall is the ornament itself. Added stylish details. The cost of grilling bricks can be easily reduced by using brick bricks, but only the last layer of briquette of all the elements.

New heating in an old house

The old, flammable system is up to the wall and attached to its new, completely non-flammable one. Choose the right heating system for your home. Only systems approved by Technical Approval can be used to insulate an older home.

Work on the construction of combined foundations is carried out in several stages.

First, a trench is dug according to the design documentation, and the installation locations for the pillars are outlined. As a rule, the width of the recess is 300-400mm, and the depth is 600mm. They dig holes under the pillars or drill wells below the freezing depth of the soil. A carefully compacted sand cushion 150-200 mm thick is placed along the bottom, the formwork is mounted just above the top mark of the tape or plinth and the reinforcement cages are laid according to the drawings. Often the structure being built is reinforced with metal profile beams.

It's hard to believe how much he's changed

We will preserve the unique character of this place and show all its beauty,” emphasizes the architect. The most important problem, however, was the insulation of the building's foundations and its walls. Replacing the old roof was also a big task. The roof is made of the best materials, namely boards, sheets and the popular square asbestos tiles, completely replaced with new ones.

Reconstruction of an old limestone house

Only houses with beautiful, white, local stone remained. Among them was an old photograph. It is small, located next to similar buildings, next to cobbled streets. One of the walls is based on the slope of the Three Crosses of Kazimierz. As in the previous two cases. This old, unused barn was to become a residential building - that was the plan when the future owner of the house bought the building together. Unfortunately, the building was in poor technical condition, and, in addition, investors.

The combined foundation is poured with concrete in a certain sequence. First, the wells or pits intended for the pillars are filled, and then the tape formwork is filled, but without significant interruptions in work. Otherwise, the required structural strength will not be achieved.

Important points before docking

Before you begin work on increasing the area of your home with extensions, you need to obtain the appropriate permits. All distances from nearby buildings and neighboring properties must be taken into account and maintained.

The extension can be built as an independent building or integrated into an existing one. It is important to note that the building already in use must be older than 1 year. During this period of time, it will give the necessary shrinkage and will not carry away the new foundation built nearby.

The old and newly constructed foundations must be of the same type. If a residential building is installed on a strip foundation, the extension must be built on the same one. This will significantly reduce the risk of deformation of the combined, docked base.

Tools and materials for work

To build the foundation, a significant amount of excavation work will be required, as well as reinforcement and concreting.

Materials you will need:

- Reinforcement bars with a cross section of 8-10 mm;

- Knitting wire;

- Cement grade not lower than M400;

- Sand and crushed stone of the middle fraction for preparing cement-sand mortar and forming a shock-absorbing “cushion”;

- Metal studs (you can use reinforcement with a cross-section of 12 mm) to connect the new foundation to the old one.

Connection steps

In order to properly combine the two foundations, you need to think through in advance all the nuances of each stage of work. It is necessary to choose a method for “ligating” the bases. Several options are possible.

Method number 1: “tape-tape”. Used to build a foundation of similar width and depth. It is carried out in several stages.

They are marking the site for the construction of an extension.

A ditch is dug around the perimeter of such a width that it can accommodate the formwork for pouring the tape of the required parameters. Level the bottom and walls of the dug trench using shovels.

A sand-crushed stone fill is made, consisting of 5-7 cm of compacted sand and 10-15 cm of crushed stone, which is also compacted.

Tamping is done with a vibrating plate and available materials. For example, a barrel half filled with stones, a piece of timber.

Formwork is assembled in a trench from any suitable lumber.

A reinforcing belt is made, consisting of two tiers of mesh with a mesh size of 15x15 or 20x20 cm, connected to each other by vertical metal rods.

A gap of 1.5-2.5 cm wide is left between the foundations, which is filled with mineral wool. The formwork is limited at the junction of the bases with a wooden or metal shield.

Using a concrete mixer, a cement-sand solution is prepared in a 1:3 ratio (1 part cement and 3 parts sand, water and filler in the form of crushed stone or gravel).

Concrete is poured into the formwork in layers. They pierce it repeatedly with a rod of reinforcement so that all the air comes out of the solution. After the concrete has set, the formwork is dismantled.

The damper joint of the foundations is closed with a rubber band or waterproofed in another way.

This method of tying the bases allows you to be sure that the new one will shrink and carry the old one with it. After the strip foundation shrinks, it is increased in height so that it is in the same plane as the base of the residential building.

Method number 2: “plate-tape”. It is carried out similarly to the previous one, with the only difference that the damper seam is made longer: along the entire slab.

Builders do not recommend rigidly tying both foundations to each other.

This joining method is optimal only for stable soils, when there is confidence that there will be no significant subsidence of the extension after its construction.

1.2.3. Wind load

The standard value of the average component of the wind load is qwind. It should be determined by the formula: qwind.=w0×V×H×gf ×k×c, where w0 is the standard value of wind pressure, adopted in accordance with SNiP 2.01.07 – 85, for wind region III w0=0.06;

В and Н – frame pitch and floor height, respectively;

gf=1.4 – load reliability factor;

k – coefficient taking into account the change in wind pressure along the height, is conventionally assumed to be equal to 1;

с – aerodynamic coefficient, we accept according to SNiP 2.01.07 – 85.

qwind.=0.06×6×0.8×1×1.4=0.4 t/m;

qreflection=0.06×6×0.6×1×1.4=0.3 t/m;

Wa=3.1 t;

Wots=2.2 t.