Choosing formwork for the foundation for a fence

If the fence is made of stone and reinforced concrete, no formwork is installed, but when pouring monolithic concrete, the construction of formwork is a prerequisite. Before installing future formwork, you need to decide on its type.

There are several types of formwork:

- horizontal;

- vertical;

- inclined.

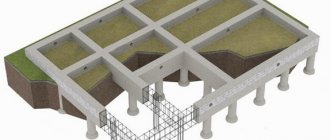

For a massive foundation, a horizontal type of formwork is used, which can be removable or permanent:

- Removable formwork is installed temporarily and is used more than once. It consists of individual elements, which are often homemade and made from available materials.

- Fixed formwork has the form of blocks and is made of polystyrene foam or fiberboard. They are connected to each other by jumpers and are not removed after pouring the concrete solution. Such formwork requires less time and serves as protection of concrete from corrosion.

Regardless of the type, any formwork must be installed correctly, since the strength of the future fence depends on its design

Advantages and disadvantages of concrete fence posts

You can make concrete fence posts yourself

Concrete is a durable, reliable and affordable material. You can buy ready-made concrete mix or make it yourself. In a semi-liquid form, the mass has the highest plasticity and, when solidified, takes on any shape.

Concrete supports have many advantages:

- high load-bearing load – fencing sections can consist of any material;

- the stone is resistant to rain, snow, wind and sun, which ensures the durability of the fence;

- concrete is not subject to corrosion and other damage;

- supports of any size and shape are cast from the material, this allows you to equip fences in a variety of styles;

- concrete is not afraid of temperature changes, so it is used in both southern and northern regions;

- the supports do not require special maintenance: they do not need to be painted, primed, or treated with impregnations;

- The cost of the material is extremely low.

Minuses:

- The main disadvantage is the heavy weight. You can make and install one pole with two people, but to install an entire section you will need the help of a team.

- The appearance of concrete is unattractive.

For fencing made of lightweight materials, only support posts are required. If the fence is being built heavy - stone, brick, for example, it is necessary to erect the fence on a foundation, with a basement section. This option is much stronger, but also more massive. It will take a lot more time and effort.

Materials for formwork assembly

During the installation of formwork, different materials are used, the main thing is that they can withstand the load that the concrete solution will create during pouring. Depending on the thickness of the foundation, suitable available materials are selected.

In independent work they often use:

- Chipboards. They are able to make the concrete surface as smooth as possible. Chipboards are easy to install, but they cannot be used for the following work due to their low resistance to moisture. They will cost more than wood boards, but will save time on installing formwork and dismantling it.

- Wood boards. This material is used more than others in the installation of formwork. The boards form not only the formwork, but also the fixing supports; they are economical and easy to use.

- Sheets of plywood. They are not used as often as boards due to their cost. This material is very convenient when installing large foundations. It creates a smooth surface on concrete mortar and can be used several times.

- Styrofoam. Often used on permanent structures and low foundations. Ready-made blocks are sold from polystyrene foam; they are connected with special jumpers. They save time on assembly, are light in weight and moisture resistant.

Reinforced concrete formwork saves the amount of concrete and increases the strength of the foundation structure

Installation of formwork for the foundation under a fence with your own hands

The construction of formwork does not require additional equipment. Before installing it, you need to decide on all the aspects of the work. Make your own design and sketch of the future fence.

Write down in the project:

- stages of work;

- select the type of formwork materials;

- accurately determine the length and height of the fence.

The size will help determine the depth of the foundation, and its length will determine the amount of material.

Necessary materials and tools during formwork installation:

- wooden boards;

- wooden blocks of 50-70 cm;

- nails, screws;

- hammer, screwdriver;

- polyethylene film.

Each stage of construction work is thought out to the smallest detail, since the final result and durability of the fence depend on their implementation. Installation of strip foundation formwork is carried out in several stages.

Stage 1. Investigation of the construction site and marking of the territory

Many inexperienced builders underestimate the importance of this preparatory stage.

Studying the site, making calculations and marking the territory will help determine some of the nuances and think through solutions to emerging problems in advance:

- During the exploration of the area, the fenced area is inspected. On the way there may be various holes, extra bushes, trees and their stumps, laid communications and debris. Studying the site helps determine what needs to be removed and what will have to be bypassed when marking the area.

- Markings are made along the perimeter of the future fence. It is carried out using pegs and a cord. Before marking, the place where the strip foundation will be located is removed and cleared of unnecessary vegetation.

During marking, the possible difference in soil height is determined, which affects the amount of concrete solution when pouring

Stage 2. Excavation

After marking the territory, excavation work begins. A trench is dug along the perimeter of the future fence.

At this stage, the master must accurately determine the depth and width of the trench:

- Depth. One of the important indicators, since the distribution of the load on the entire fence structure will depend on it. If the future fence is lightweight, then the standard trench depth reaches 50-60 cm, but with a massive fence, for example made of brickwork, it is necessary to lay the foundation below the freezing level of the ground.

- Width. The width of the trench should not be less than the width of the fence itself; it is also necessary to take into account the thickness of the formwork material, since on loose soils it is installed at the bottom of the trench. If it is not possible to make the trench walls vertical, they are dug at an angle.

Before excavation begins, additional pegs are installed and a second cord is pulled to the width of the future trench. After digging a trench, the soil is thoroughly compacted and covered with a 15-20 cm layer of crushed stone and sand and compacted securely again. The thickness of the sand and crushed stone cushion is taken into account when digging the depth of the trench.

The width and depth of the trench are very important indicators on which the load of the fence on the base of the foundation will depend

Stage 3. Installation of bars for fastening panels

Inside the trench, wooden blocks are placed vertically at a distance of 100 cm from each other on each side. Long bars are used so that they protrude 25 cm from the poured foundation. The bars must be driven in strictly vertically, and the work done is checked with a building level. The formwork panels will be attached to the bars; without them, the panels will be loose, and it will not be possible to pour concrete correctly.

Stage 4. Assembly and installation of panels

The production of formwork panels occurs by knocking down the boards into one sheet, and if the panel is made from chipboard sheets, then they are sawn into strips. The formwork can be erected immediately along the entire perimeter of the trench and poured in one stage. Some builders prefer to do the pouring in stages, and install the formwork in sections 5-10 meters long.

The shields are a monolithic wall made of boards and are located along the perimeter of the trench on both sides. They are installed on previously driven bars. The shield is positioned strictly vertically; if necessary, the previously driven beam is adjusted. The lower part of the wooden panels should be placed as tightly as possible on the bed of sand and crushed stone. The panels are attached to the bars using nails and self-tapping screws, preferably on the outside of the formwork.

After formwork, they begin to install reinforcement elements, which increases the strength and durability of the foundation

In addition to fastening to vertical bars, the shields are additionally secured:

- spacers;

- struts;

- various supporting elements.

If there is free space outside the trench, the shields are secured with supporting parts made of timber. They are placed 50-60 cm outside the formwork. The panels are fastened together parallel to each other by horizontal strips, which during the installation process help to adjust and check the equal distance between the panels along the perimeter of the formwork.

Pouring the base

The construction of a formative foundation begins with digging a hole. If the product involves brickwork, the parameters of the ditch must correspond to the dimensions of the fence. For other structures, you can limit yourself to bases for fixing concrete pillars, the depth of which reaches one meter. Using sand, we fill the pits, periodically compacting the layers, until we get a solid, dense ceiling.

Materials required for the base

For kneading you will need:

- capacity;

- drill;

- water;

- cement;

- sand;

- crushed stone;

- plasticizer no more than 1% of the total volume.

We combine the above building materials and mix using a special drill attachment until smooth.

How to properly prepare a concrete composition?

Having compiled a list of the above materials, select from it fine sand, crushed stone with medium fractions, water and M300 cement. Concrete is prepared in a ratio of 1 part cement to 3 parts sand and 4 parts crushed stone. Water is added until it becomes sour cream. The plasticizer must be added according to the manufacturer's requirements. Builders advise replacing synthetic compounds with liquid soap - this way the mixture will spread evenly over the formwork and prevent its shrinkage.

Preparation of the reinforcing frame

Formwork for the fence in accordance with the diagram is a guarantee of the reliability of the foundation and the quality of work. Formation is necessary to strengthen the strength of the foundation, especially if groundwater is close to the soil or on loams. It is performed in several technological steps:

- We take reinforcement bars with a cross-sectional diameter of 10 mm and fix them 5 cm above the level of the bottom of the pit.

- We mount a support under each pin.

- We make a retreat from the trench by 10 cm, and begin to fix the reinforcing sticks, alternating horizontal pins with vertical ones every 40 cm.

- Using a welding machine, we connect lines in different directions to obtain a single, reliable frame.

When the work of installing the reinforcement is completed, we begin preparing the cement mortar.

Subtleties of working with concrete mortar

It is not recommended to fill the fence base with cement mortar in one go. The mold must be filled gradually, making holes with an iron rod in each layer. This will help prevent the appearance of swelling and surface relief. We cover the concreted surface with a film to protect it from the effects of natural phenomena and other debris. Spray the surface with water every three days. After a two-week period, we dismantle the fence formwork in the following order:

- remove the clamps between the beams;

- We begin to disassemble the load-bearing elements towards the edge of the trench;

- Lastly, we dismantle the form-building chipboard sheets.

It will take a month for the cement to completely harden, but in hot conditions it is recommended to remove the frame after 15 days. The foundation requires periodic moistening with water.

Dismantling the formwork system

After pouring the foundation and its complete drying, they proceed to stripping. Removal of formwork elements must be done with care so as not to deform the concrete structure. After proper dismantling, the removed formwork materials are used for possible subsequent work.

It is better to calculate the stages of formwork dismantling from the very beginning of the work, before installing the formwork. The most unloaded elements begin to be dismantled and the shields are removed last. The process begins at the top of the structure, and the spacers, struts and possible fastening elements are slowly removed. Removal of elements is carried out over several days. It is important to take care of the quality of dismantling, which can directly affect the reliability and strength of the concrete foundation.

The stages of formwork dismantling are carried out in the opposite direction to how it was built

Formwork on a slope: features

A fence on a sloping piece of land has a decorative and protective function; it strengthens the soil from crumbling. There are three types of slopes:

- short;

- average;

- high.

If there is a high slope on the construction site, a stepped foundation is used. A fence that follows the curves of the terrain will not be suitable for such a site, which looks aesthetically pleasing on plots of land with a low and medium slope. If the master wants to create a level fence, then he should choose a leveling concrete structure.

The manufacture of a strip stepped foundation requires some specific features of the work:

- When studying the terrain and marking the territory, it is necessary to determine the height differences between the corners of the fence.

- Excavation work starts from the highest point, and the depth of the trench and foundation will vary.

- Each section of the stepped foundation is dug out separately.

- In the lower section of construction, a cushion of crushed stone and sand is poured flush with the ground, and the foundation will be built on the surface of the earth.

- The formwork of a stepped foundation will consist of sections of equal length in the form of steps.

- Pouring the concrete solution begins from the top of the ground.

A sloping area needs reliable drainage and a strong foundation.

Recommendations

After installing the formwork, inexperienced specialists are concerned with the question: “How to make a foundation for a fence?” The durability and strength of the future structure will depend on the quality of the concrete solution. It is necessary to use only high-quality components. The most optimal option is crushed stone with a fraction of 1-2 cm, it is better to use river sand, and grade 500 cement. On average, one bucket of cement will take 4 buckets of sand and 6 buckets of crushed stone.

The formwork for concrete stairs must be strong, since a monolithic concrete staircase is very heavy. It is installed using wooden boards or metal. The most suitable angle of inclination of the stairs is 30˚. Before installation, the boards are treated with waterproofing materials.

It is better to use smooth plywood and sanded boards on the inside of the formwork so that you do not have to finish the concrete surface in the future. When attaching formwork elements, use self-tapping screws rather than nails.

Plastic formwork for monolithic construction is a modern, convenient, reusable material. A qualitative advantage of such formwork is its low cost. It is used on removable and permanent formwork. The details of such formwork have special holes that allow you to quickly and reliably assemble the formwork, as well as model it in different ways. The advantage of plastic formwork over wooden formwork is that it does not absorb water and does not take excess moisture from the concrete.

Tips from builders

- Mikhail is 32 years old. I used the simplest scheme. I dug holes, inserted pipes with a diameter of 80 millimeters into them and filled everything with concrete. This scheme is very economical, and has the advantage that the formwork is the soil walls themselves. It turned out quite tough and fast, I recommend it to everyone.

- Alexander 56 years old. When constructing the fence, I used a used profiled sheet as a formwork base. This sheet was cut into the required sizes, and the holes from the screws did not interfere at all. Concrete is quite viscous and cannot seep into such small holes.

- Peter is 50 years old. I have been involved in construction for over 35 years. I always use OSB boards as fence panels. This material has a reasonable price and is easy to cut. OSB sheets also have good flexibility and decent strength characteristics.

- Alexander 29 years old. I built a very original crushed stone fence. As a formwork structure I used a rowan mesh with a mesh size of 25 millimeters. This mesh is stretched and secured onto pre-installed metal posts on both sides. After this, crushed stone or gravel is poured there in layers of 200 millimeters, and each layer is spilled with cement water. The result is a very strong and original wall.

Fence formwork, when using concrete mortar, is a very important part of the structure. For its construction, you can use various structural materials, use removable and non-removable frame options.

With non-removable technology, care should be taken about the aesthetics of the coating. After installing the fence, such a structure is treated with various compounds to give it a beautiful appearance. You can also cover it with tiles or natural stone.