January 26, 2020 Stroyexpert Home page » Foundation » By construction project

Cinder block garage foundation

A cinder block garage foundation provides sufficient strength at a reasonable cost. These indicators, combined with ease of installation, determine the popularity of this type of construction at household facilities.

Construction technology is a complex of activities that are closely interrelated. Therefore, when choosing a specific building material, you should study possible designs and solutions for it. Some materials have restrictions on the construction of structural elements.

A cinder block garage foundation looks like a good alternative to other materials. The blocks are lightweight but strong enough to withstand the load of a garage. In this case, the arrangement of the foundation is significantly simplified and it is enough to get by with a shallow-depth strip option.

Garage base

Such a foundation, the depth of which also depends on the owner’s desire to have a basement, will last the entire period of operation of the building without problems or complaints.

Preparation for work

First, it should be noted that before moving on to the main work on laying the foundation, a number of preparatory measures need to be carried out. First of all, we are talking about the fact that the site that is planned for construction must be leveled as much as possible and cleared of construction and other debris. For these purposes, special equipment can be used, which will reduce the work time and make it easier to complete, but you can also do it yourself, doing everything manually. During work, special attention must be paid to ensure that there are no large tree roots remaining in the ground (especially under the foundation), which could subsequently grow and damage both the foundation and the walls of the building.

In addition to physical work, at the preparation stage it is also necessary to draw up a detailed drawing of both the entire future garage and the foundation in particular. Here it is necessary to add that these works require precision and knowledge of the drafting craft, and therefore, if the necessary abilities in this area are not available, then the work should be entrusted to specialists. This way you won’t have to worry that errors made during calculations will lead to errors during construction.

Features of the design and operation of the garage

When choosing a foundation for a garage made of cinder blocks on a suburban site or inside a garage cooperative, you need to take into account the nuances of operation:

Concrete screed:

Crushed stone or gravel surfaces are inconvenient for a vehicle. Floorboards have a low service life in the presence of oils, fuels and lubricants and other aggressive substances. Porcelain tiles are dangerous due to falls during the winter and off-season (slippery). Therefore, concrete screeds are used, which can be additionally covered with rubber coatings, linoleum, or polymer self-leveling flooring.

Inspection hole:

It is not named this way by chance - the car owner does not have to independently repair the vehicle, but before long trips it would be useful to make sure that the chassis is in good working order. In addition, the pit can significantly reduce the operating budget of the machine. For example, changing the oil will take a maximum of 20 minutes and will not cost the owner anything.

Shelves:

Unlike racks, they save the already small space of the garage. However, the corner is embedded into the masonry of expanded clay concrete blocks in a cantilever manner, the loads from the weight of spare parts and tools stored on the shelves are transferred to the foundation.

Cellar:

More often it is included in projects of garages located in common cooperative rows. It is more convenient to organize the entrance to the basement along concrete steps from the pit. This is much more convenient than entering through a hatch using a ladder.

Important! It should be noted that in 85% of cases the garage is made one-story, which reduces the requirements for the bearing capacity of the foundation and the base (soil) underneath it.

Garages usually do not have heating, so freezing and swelling of clay soils can only be prevented by insulating the entire perimeter of the room and the blind area. Expanded polystyrene is able to retain the geothermal heat of the subsoil under the building.

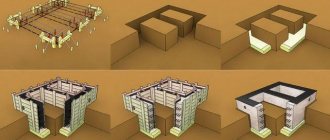

Site marking

Marking

Once the selected site for construction has been prepared, you can proceed to marking. By and large, we are talking about transferring the calculations obtained when drawing up the drawing to the terrain. For these purposes, it is convenient to use scraps of metal reinforcement and some kind of cord of sufficient length.

First, in accordance with the dimensions obtained earlier, two pieces of reinforcement are driven into the ground, and a cord is pulled between them. Then, at the required distance from these two stakes, two more are driven in, and the whole thing is connected with a cord. As a result of these actions, you will get a clearly marked external contour of the future foundation. After it is completed, you need to mark the inner side at a distance corresponding to the thickness of the foundation, by analogy with the previous steps.

Note! To check the correctness of the markings, you need to pull the cords diagonally. If all the work is done correctly, the length of the cords should match.

Carrying out excavation work

Digging a trench

When the site is marked, you can begin excavation work, or rather, digging trenches for the foundation. The work can be carried out either manually or using special equipment, depending on the availability of it or other circumstances. The depth of the trench should be below the freezing depth of the soil, but in most cases one and a half meters will be enough. (There are technologies that allow the foundation to be laid above the freezing level of the soil, but they are not discussed in this article).

Note! The depth of soil freezing may vary depending on the region.

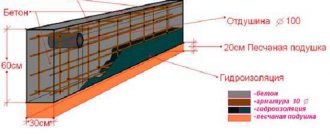

After this, it is necessary to make a shock-absorbing and waterproofing cushion. To do this, it is necessary to sequentially pour two layers of sand and crushed stone of the middle fraction onto the bottom of the pit, each of which should be about 30 cm thick and compacted over the entire area.

Recessed base

To construct a deep foundation, a concrete strip is usually poured. The foundation should be strip in an area where groundwater lies far from the soil surface. On water-saturated soils, such a foundation will require the construction of a drainage system, drainage of melt and groundwater, and installation of waterproofing, which will affect the cost of the entire construction.

The exact foundation level is calculated using the formula below. To avoid manual calculations, you can use tabular data or a map from SNiP 2.01.01-82. All calculations of foundation parameters are carried out using soil properties X, which are calculated using the formula:

X = Xn / γg, where:

- Xn is a standard parameter of soil properties,

- γg—soil reliability coefficient.

The reliability coefficient can be found out by calculating the strength characteristics U, Ci and Cu of moisture-saturated soils and the resistance Rc of rocky soils, as well as the density coefficient ρ, which depend on changes in these and other parameters described in GOST 20522. For other soil parameters, the value γg can be equal to 1. The table below shows soil properties for some cities of the Russian Federation.

Most often, these parameters are taken into account in clayey, loamy and sandy loam soils. The soil is rocky, coarse and sand, allowing water to pass through, and it does not affect the base of the garage. You can avoid the negative influence of frost heaving forces by leveling any of the factors that provide it. In order not to spend money on geological surveys, you can find out what kind of soil is on the site yourself. To do this, you dig a hole or drill a well, and you can find out its composition by the layers of the soil. GOST 25100.2011 will help you not to make mistakes in determining the soil.

It is recommended to erect a deeply buried monolithic strip foundation if there is a basement or underground in the project.

Installation of formwork

Manufacturing of formwork

When the previous work is completed, it is necessary to install the formwork. To do this, you need to knock down wide panels from edged boards or thick plywood, which should be installed inside the pit along its entire perimeter. It is also worth adding that the panels that make up the formwork above the trench must be fixed both inside and outside. This is necessary so that the cement solution does not push through the formwork, and it does not collapse inward or, conversely, outward. Inside the formwork you also need to lay a layer of waterproofing, which can be thick polyethylene; its sheets should be laid with an overlap of at least 25 cm.

Installation of reinforcing strapping

Next, two layers of reinforcing strapping must be installed inside the formwork. For its manufacture, steel reinforcement rods Ø 12–14 mm are usually used, which are secured with tying wire or using spot welding. The general idea is that the bottom layer should be located a few centimeters above the level of the bottom of the pit, and the top layer a few centimeters below its upper edge, respectively. The reinforcing sheathing will give the foundation the necessary strength and resistance to deformation that may occur during soil movements.

Laying method

There are the following methods for laying cinder block walls that are suitable for building a garage:

- Half a block. It is used for the construction of partitions between rooms and other structures that are not subject to excessive loads. Suitable for building garage walls, but the structure may be flimsy.

- Masonry 1 block thick. It is used for the construction of utility rooms, including garages. The best choice in terms of price/strength ratio.

- The masonry is one and a half blocks thick. Suitable for the construction of load-bearing walls subject to additional load. Suitable for a garage, but will be more expensive.

- In two blocks. This is an inappropriate method of laying the block, since a similar method is used for 2-3-story buildings. A simple garage built in this way will cost a decent amount of money.

Pouring the foundation

Pouring concrete

The final stage of making a foundation is its pouring. Here it is necessary to especially note the fact that the work must be carried out without interruptions. That is, you need to immediately prepare (or purchase) a sufficient amount of concrete and pour it in one day. We offer two options.

- You can purchase ready-made concrete, which will be delivered to the site by a special vehicle (mixer). This will cost money, but it will eliminate the need for calculations and greatly speed up the entire process.

- If you want to save money and be confident in the quality of concrete, then you can prepare the solution yourself.

To do this, you need to mix M400 cement and sifted sand in a 1×3 ratio. The mixture is diluted with water and crushed stone is added to it to strengthen the composition. The ratio 1x3x5 (water, sand, crushed stone) is quite enough for the foundation of a garage. The resulting mixture is poured into the pit and evenly distributed over the entire area and compacted. After pouring, the mixture must be left until it hardens. It should be taken into account that the surface must be slightly moistened in case of too hot weather and covered with a film from rain. At this point, the foundation for the garage can be considered complete.

In conclusion, we can add that the above is only one of the options for making a foundation, but it is the most acceptable in most cases.

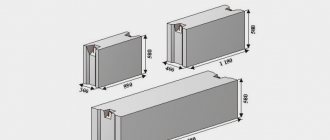

Calculation of the number of cinder blocks

Calculating the number of cinder blocks for a garage will not be a problem if you have ready-made drawings. To do this, we follow the following algorithm:

- As a basis, we take the thickness of the garage wall as half a block.

- We calculate the area of the outer side of the building material. For standard blocks measuring 39 centimeters by 19, it is 741 square centimeters.

- Accordingly, 1 square meter of garage wall will require 13.5 blocks. We round to 14 and make further calculations based on this figure.

- To find out the total number of cinder blocks needed to build a garage, we calculate the perimeter of the building, multiply it by the height of the walls being built and subtract the area of the garage door from the resulting value.

- Then we multiply the resulting figure by 14 and get the total number of cinder blocks that will need to be purchased.

You can use a calculator to calculate the number of cinder blocks.